Abstract

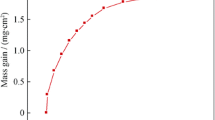

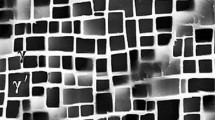

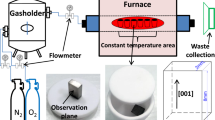

The oxidation behavior of a nickel-based superalloy at 1000°C in air was investigated through X-ray diffraction, scanning electron microscopy, and energy-dispersive spectroscopy analysis. A series of oxides, including external oxide scales (Cr2O3, (TiO2 + MnCr2O4)) and internal oxides (Al2O3,TiN), were formed on the surface or sub-surface of the substrate at 1000°C in experimental still air. The oxidation resistance of the alloy was dependent on the stability of the surface oxide layer. The continuity and density of the protective Cr2O3 scale were affected by minor alloying elements such as Ti and Mn. The outermost oxide scale was composed of TiO2 rutile and MnCr2O4 spinel, and the growth of TiO2 particles was controlled by the outer diffusion of Ti ions through the pre-existing oxide layer. Severe internal oxidation occurred beneath the external oxide scale, consuming Al and Ti of the strength phase γ′ (Ni3(Al,Ti)) and thereby severely deteriorating the surface mechanical properties. The depth of the internal oxidation region was approximately 35 μm after exposure to experimental air at 1000°C for 80 h.

Similar content being viewed by others

References

H. Naffakh-Moosavy, Microstructural evolution and castability prediction in newly designed modern third-generation nickel-based superalloys, Int. J. Miner. Metall. Mater., 23(2016), No. 5, p. 548.

J.H. Chen, P.M. Rogers, and J.A. Little, Oxidation behavior of several chromia-forming commercial nickel-base superalloys, Oxid. Met., 47(1997), No. 5, p. 381.

S. Huang, L. Wang, X.T Lian, G.P. Zhao, F.F. Li, and X.M. Zhang, Hot deformation map and its application of GH4706 alloy, Int. J. Miner. Metall. Mater., 21(2014), No. 5, p. 462.

X.F. Liang, Y.T. Zhao, Z.H. Jia, and C. Zhang, Preparation and tensile properties of DD5 single crystal castings, Int. J. Miner. Metall. Mater., 23(2016), No. 6, p. 683.

S. Cruchley, H.E. Evans, M.P. Taylor, M.C. Hardy, and S. Stekovic, Chromia layer growth on a Ni-based superalloy: Sub-parabolic kinetics and the role of titanium, Corros. Sci., 75(2013), No. 7, p. 58.

Y.L. Xu, C.X. Yang, Q.X. Ran, P.F. Hu, X.S. Xiao, X.L. Cao, and G.Q. Jia, Microstructure evolution and stress-rupture properties of Nimonic 80A after various heat treatments, Mater. Des., 47(2013), No. 9, p. 218.

I.M. Edmonds, H.E. Evans, and C.N. Jones, The role of the γ' precipitate dispersion in forming a protective scale on Ni-based superalloys at 750°C, Oxid. Met., 73(2010), No. 1, p. 193.

D. Kim, C. Jang, and W.S. Ryu, Oxidation characteristics and oxide layer evolution of alloy 617 and Haynes 230 at 900°C and 1100°C, Oxid. Met., 71(2009), No. 5-6, p. 271.

H. Singh, D. Puri, S. Prakash, and R. Maiti, Characterization of oxide scales to evaluate high temperature oxidation behavior of Ni–20Cr coated superalloys, Mater. Sci. Eng. A, 464(2007), No. 1-2, p. 110.

S.Q. Zhao, X.S. Xie, and G.D. Smith, The oxidation behavior of the new nickel-based superalloy Inconel 740 with and without Na2SO4 deposit, Surf. Coat. Technol., 185(2004), No. 2-3, p. 178.

A. Jalowicka, W. Nowak, D.J. Young, V. Nischwitz, D. Naumenko, and W.J. Quadakkers, Boron depletion in a nickel base superalloy induced by high temperature oxidation, Oxid. Met., 83(2015), No. 3, p. 393.

F. Abe, H. Araki, H. Yoshida, and M. Okada, The role of aluminum and titanium on the oxidation process of a nickel-base superalloy in steam at 800°C, Oxid. Met., 27(1987), No. 1, p. 21.

W.F. Gale and T.C. Totemeier, Smithells Metals Reference Book, Elsevier Butterworth- Heinemann, Burlington, 2003, p. 13.

C. Wagner, Oxidation of alloys involving noble metals, J. Electrochem. Soc., 103(1956), No. 10, p. 571.

J. Issartel, S. Martoia, F. Charlot, V. Parry, G. Parry, R. Estevez, and Y. Wouters, High temperature behavior of the metal/oxide interface of ferritic stainless steels, Corros. Sci., 59(2012), p. 148.

A.N. Blacklocks, A. Atkinson, R.J. Packer, S.L.P. Savin, and A.V. Chadwick, An XAS study of the defect structure of Ti-doped α-Cr2O3, Solid State Ionics, 177(2006), No. 33-34, p. 2939.

A. Atkinson, M.R. Levy, S. Roche, and R.A. Rudkin, Defect properties of Ti-doped Cr2O3, Solid State Ionics, 177(2006), No. 19-25, p. 1767.

A. Naoumidis, H.A. Schulze, W. Jungen, and P. Lersch, Phase studies in the chromium-manganese-titanium oxide system at different oxygen partial pressures, J. Eur. Ceram. Soc., 7(1991), No. 1, p. 55.

D.R. Sigler, The oxidation behavior of Fe-20Cr alloy foils in a synthetic exhaust-gas atmosphere, Oxid. Met., 46(1996), No. 5, p. 335.

S.H. Song, Z.X. Yuan, and P. Xiao, Electrical properties of MnCr2O4 spinel, J. Mater. Sci. Lett., 22(2003), No. 10, p. 755.

G.R. Holcomb and D.E. Alman, The effect of manganese additions on the reactive evaporation of chromium in Ni–Cr alloys, Scripta Mater., 54(2006), No. 10, p. 1821.

Acknowledgments

The authors gratefully appreciate the financial support of Science and Technology Program of Jiangsu Province (Nos. BE2015144 and BE2015145) and the partner company, Jiangsu Shenyuan Special Steel Company.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Zy., Cai, Yf., Gong, Yj. et al. Isothermal oxidation behavior and mechanism of a nickel-based superalloy at 1000°C. Int J Miner Metall Mater 24, 776–783 (2017). https://doi.org/10.1007/s12613-017-1461-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1461-y