Abstract

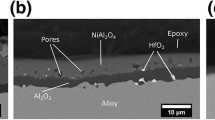

The oxidation behavior of mechanically alloyed(MA) Al-Ti alloys containing 5 and 10 at.% Ti wereinvestigated at 500-600°C under 1 atm of oxygen. Ateach temperature, alloys oxidized linearly during the initial stage and later followed the parabolicrate law. During the initial stage, the oxidation ratesof nanocrystalline (≤50 nm) Al-Ti alloys were fasterthan those of conventional (≤200 nm) alloys. It is suggested that more grain boundaries innanocrystalline alloys provide more nucleation sites foroxides, so that the oxide scales grew faster as denseprotective layers. During the parabolic stage, the nanocrystalline alloys had greater oxidationresistance than conventional alloys because of the denseprotective layer. Oxide scales on both alloys consistedof a mixture of γ-Al2O3 andTiO2 in the outer layer andγ-Al2O3 near the alloy as aprotective layer.

Similar content being viewed by others

REFERENCES

F. H. Froes, Met. Powder Rep. 44, 59 (1989).

D. J. Skinner, R. L. Bye, D. Raybould, and A. M. Brown, Scripta Metall. 20, 867 (1986).

R. Sundarensan and F. H. Froes, Met. Powder Rep. 44, 195 (1989).

W. L. Johnson, Prog. Mat. Sci. 30, 81 (1986).

R. B. Schwarz and C. C. Koch, Appl. Phys. Lett. 49, 146 (1986).

C. C. Koch, Nanostruct. Mat. 2, 109 (1993).

C. P. Dogan, J. C. Rawers, R. D. Govier, and G. Korth, Nanostruct. Mat. 4, 631 (1994).

J. S. C. Jang, S. G. Donnelly, P. Godavarti, and C. C. Koch, Int. J. Power. Metall. 24, 315 (1988).

R. Lerf and D. G. Morris, Mat. Sci. Eng. A128, 119 (1990).

K. Schubert, in Intermetallic Compounds, H. Westbrook, ed. (Krieger, New York, 1977), pp. 118, 159.

R. C. Benn, P. K. Mirchandanie, and A. S. Watwe, in Modern Developments in P/M, Vol. 21 (Metal Power Industries Federation, Princeton, NJ, 1988), p. 479.

K.-M. Lee and I.-H. Moon, Mat. Sci. Eng. A185, 165 (1994).

K. Y. Wany, J. G. Wang, and G. L. Chen, J. Mat. Res. 10, 1247 (1995).

B. Mei, R. Yuan, and X. Duan, J. Mat. Res. 8, 2830 (1993).

J. G. Goedjen and D. A. Shores, Oxid. Met. 37, 125 (1992).

S. N. Basu and G. J. Yurek, Oxid. Met. 36, 281 (1991).

M. K. Hossian, Corros. Sci. 19, 1031 (1979).

H.-J. Lim, S.-W. Park, and S.-G. Kang, Oxid. Met. 48, 391 (1997).

W. W. Smeltzer, J. Electrochem. Soc. 103, 209 (1956).

M. J. Dignam and W. R. Fawcett, J. Electrochem. Soc. 113, 663 (1966).

K. Shimizu, R. C. Furneaux, G. E. Thompson, G. C. Wood, A. Gotch, and K. Kobayashi, Oxid. Met. 35, 427 (1991).

G.-H. Kim, Master Thesis, Han Yang University, Seoul, Korea, 1991.

Y. Umakoshi, M. Yamaguchi, T. Sakagami, and T. Yamane, J. Mat. Sci. 25, 1599 (1989).

C. Lang and M. Schütze, Oxid. Met. 46, 255 (1996).

S. Becker, A. Rahmel, M. Schorr, and M. Schütze, Oxid. Met. 38, 425 (1992).

Y. Shida and H. Anada, Corros. Sci. 35, 945 (1993).

P. Kofstad, Oxid. Met. 24, 265 (1985).

Rights and permissions

About this article

Cite this article

Myung, JS., Lim, HJ. & Kang, SG. Oxidation Behavior of Nanocrystalline Al Alloys Containing 5 and 10 at.% Ti. Oxidation of Metals 51, 79–95 (1999). https://doi.org/10.1023/A:1018802218912

Issue Date:

DOI: https://doi.org/10.1023/A:1018802218912