Abstract

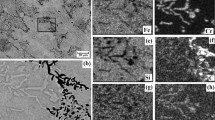

Metal dusting is the disintegration of alloys into carbon and metal particles during high-temperature exposure to carbon-bearing gases. Model Fe–Cr and Fe–Ni–Cr alloys were studied to test the hypothesis that M3C formation is necessary for metal dusting to occur. The alloys were exposed to a 68% CO–26% H2–6% H2O gas mixture at 680°C (ac=2.9) under thermal cycling conditions. Equilibrium calculations predicted the formation of M3C at the surface of Fe–25Cr, but not Fe–60Cr. All compositions were expressed in w/o, weight percent. Alloys of Fe–25Cr with 2.5, 5, 10, and 25 w/o nickel additions were also exposed to the same conditions to study the role of nickel in destabilizing the precipitation of M3C and, hence, altering the resistance to metal dusting. Metal dusting was observed on all the alloys except Fe–60Cr. For Fe–25Cr, Fe–25Cr–2.5Ni, and Fe–25Cr–5Ni, the carbonization and dusting process was localized, and its incidence decreased in Fe–25Cr–2.5Ni, consistent with the increased destabilization of M3C precipitation. However, Fe–25Cr–10Ni and Fe–25Cr–25Ni both underwent extensive dusting in the absence of protective Cr2O3 formation. The carbon deposits formed consisted of carbon filaments, which contained particles at their tips. These were shown by electron diffraction to be exclusively Fe3C in Fe–25Cr, Fe–25Cr–2.5Ni, and Fe–25Cr–5Ni, and a mixture of austenite and (Fe,Ni)3C in Fe–25Cr–10Ni and Fe–25Cr–25Ni.

Similar content being viewed by others

REFERENCES

R. F. Hochman, Proceedings of the 4th International Congress on Metal Corrosion, N. E. Hammer, ed. (NACE, Houston, TX, 1972), p. 258.

R. F. Hochman, Proceedings of the Symposium on Properties of High Temperature Alloys with Emphasis on Environmental Effects, Z. A. Foroulis and F. S. Pettit, eds. (The Electrochemical Society, Pennington, NJ, 1972), p. 715.

H. J. Grabke, R. Krajak, and E. M. Müller-Lorenz, Werkst. Korros. 44, 89 (1993).

H. J. Grabke, R. Krajak, E. M. Müller-Lorenz, and S. Strauß, Werkst. Korros. 47, 495 (1996).

H. J. Grabke, E. M. Müller-Lorenz, J. Klöwer, and D. C. Agarwal, Mater. Performance 37, 58 (1998).

R. Schneider, E. Pippel, J. Wolftersdolf, S. Strauß, and H. J. Grabke, Steel Res. 68, 326 (1997).

R. T. K. Baker, M. A. Barber, P. S. Harris, F. S. Feates, and R. J. Waite, J. Catal. 26, 51 (1972).

J. L. Figueiredo, C. A. Bernardo, J. J. Chludzinski, Jr., and R. T. K. Baker, J. Catal. 110, 127 (1988).

Y. Nishiyama and Y. Tamai, J. Catal. 33, 98 (1974).

J. Rostrup-Nielsen and D. L. Trimm, J. Catal. 48, 155 (1977).

M. Audier and M. Coulon, Carbon 23, 317 (1985).

R. T. K. Baker, M. A. Barber, P. S. Harris, F. S. Feates, and R. J. Waite, J. Catal. 26, 51 (1972).

W. L. Holstein and M. Boudart, Latin Amer. J. Chem. Eng. Appl. Chem. 62, 107 (1983).

M. Audier, P. Bowen, and W. Jones, J. Crystallogr. 24, 291 (1983).

A. Sacco, P. Thacker, T. N. Chang, and A. T. S. Chiang, J. Catal. 85, 224 (1984).

R. T. K. Baker, J. R. Alonzo, J. A. Dumesic, and D. J. C. Yates, J. Catal. 77, 74 (1982).

A. J. H. Kock, P. K. de Bokx, E. Boellard, and J. W. Geus, J. Catal. 96, 468 (1985).

I. Stewart, M. J. Tricker, and J. A. Cairns, J. Catal. 94, 360 (1985).

I. A. Alstrup, J. Catal. 109, 241 (1988).

E. C. Bianchini and C. R. F. Lund, J. Catal. 117, 455 (1989).

B. Sundman, B. Jansson, and J.-O. Andersson, CALPHAD 9, 135 (1985).

C. S. Giggins and F. S. Pettit, Oxid. Met. 14, 363 (1980).

R. A. Perkins, R. A. Padgett, and N. K. Tunali, Metall. Trans. 4, 2535 (1973).

A. F. Smith, Metal Sci. 8, 407 (1974).

A. Schnaas and H. J. Grabke, Oxid. Met. 12, 387 (1978).

H. J. Grabke, Corrosion 51, 711 (1995).

C. A. Barrett and C. E. Lowell, Oxid. Met. 9, 307 (1975).

D. J. Young and O. Ahmed, Mater. Sci. Forum 369-372, 93 (2001).

S. I. Ford, P. R. Munroe, and D. J. Young, Mater. High Temp. 17, 279 (2000).

R. T. K. Baker, D. J. C. Yates, and J. A. Dumesie, Coke Formation on Metal Surfaces, L. F. Albright and R. T. K. Baker, eds. (ACS Symp. Ser. 220 (1982), p. 1.

E. Pippel, J. Woltersdolf, H. J. Grabke, and S. Strauß, Steel Res. 66, 217 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Toh, C., Munroe, P. & Young, D. Metal Dusting of Fe–Cr and Fe–Ni–Cr Alloys Under Cyclic Conditions. Oxidation of Metals 58, 1–21 (2002). https://doi.org/10.1023/A:1016032722703

Issue Date:

DOI: https://doi.org/10.1023/A:1016032722703