Abstract

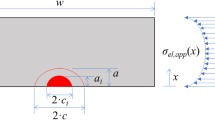

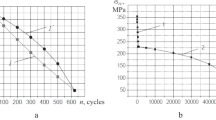

This is Part II of a series of two papers that describe the development and evaluation of a fracture-mechanics based life-prediction methodology for treating fretting fatigue in structural alloys. In Part I, the development of a life-prediction methodology based on the worst case fret (WCF) concept is presented with parametric calculations to illustrate the capability of the method. In this paper, the results of an experimental program designed to evaluate the applicability of the WCF model to treating high-cycle fretting fatigue in Ti-6Al-4V are described. High-cycle fretting fatigue tests were performed on Ti-6Al-4V at ambient temperature and at 2100 Hz. A flat pad with rounded edges or a cylindrical pad on rectangular specimens was fretted using either single or multiple cyclic load steps. Each load step was conducted for 107cycles before the cyclic load range was increased. This process repeated until fretting fatigue specimen failed. The existence of nonpropagating cracks was identified using metallography and fractography. The experimental results were used to assess the accuracy of the WCF methodology.

Similar content being viewed by others

REFERENCES

Adibnazari, S. and Hoeppner, D.W. (1992). Wear 159, 43–46.

Alic, J.A. and Hawley, A.L. (1979). Wear 56, 377–389.

Antoniou, R.A. and Radtke, T.C. (1997). Materials Science and Engineering A237, 229–240.

Chan, K.S., Davidson, D.L., Lee, Y-D. and Hudak, Jr., S.J. (2001). International Journal of Fracture, 000, 000–000 (this issue).

Cowles, B.A. (1996). International Journal of Fracture 80, 147–163.

Davidson, D.L., Nagy, A. and Owen, T.E. (1997). High Cycle Fatigue of Structural Materials(Edited by Soboyejo, W.O. and Srivatsan, T.S.), TMS, Warrendale, PA 263–258.

Endo, K. and Goto, H. (1975). Wear 38, 311–324.

Endo, K. (1981). Fretting Fatigue(edited by Waterhouse R.B.), Applied Science Publishers, London 127–141.

Faanes, S. and Fernando, U.S. (1994). Fretting Fatigue, ESIS 18(edited by Waterhouse, R.B. and Lindley, T.C.), Mechanical Engineering Publications, London, 149–159.

Gallagher, J.P. (1999). Improved High Cycle Fatigue (HCF) Life Prediction, Final Report, Contract No. F33615-96-5269, UDRI Report No. UDR-TR-1999-00079, University of Dayton, Dayton, OH.

Goss, G.L. and Hoeppner, D.W. (1973). Wear 24, 77–95.

Hattori, T., Nakamura, M., Sakata, H. and Watanabe, T. (1988). JSME International Journal 31, 1–107.

Hoeppner, D.W. and Goss, G.L. (1974). Wear 27, 61–70.

Hudak, Jr., S.J., McClung, R.C., Chan, K.S., Chell, G.G. and Davidson, D.L. (1998). High Cycle Fatigue of Turbine Engine Materials, SwRI's Annual Interim Technical Report to UDRI under PRDA 95.

Kitagawa, H. and Takahashi, S. (1967). Proceedings of the 2nd International Conference on Mechanical Behavior of Materials, Boston, MA, 627–631.

Lindley, T.C. (1997). International Journal of Fatigue 19, 539–549.

Liu, H.W., Corten, H.T. and Sinclair, C.M. (1957). American Society Testing of Materials Proceedings 57, 623.

Mutoh, Y. (1995). JSME International Journal A38, 405–415.

Nakazawa, K., Sumita, M. and Maruyama, N. (1992). Standardization of Fretting Fatigue Test Methods and Equipment, ASTMSTP 1159, (Edited by Helini Attia, M. and Waterhouse, R.B.), American Society for Testing and Materials, Philadelphia, PA, 115–125.

Nicholas, T. and Ziuker, J.R. (1996). International Journal of Fracture 80, 219–235.

Nishioka, K. and Hirakawa, K. (1969). Bulletin of JSME 12, 180–187.

Nix, K.J. and Lindley, T.C. (1988). Wear 125, 147–162.

Nowell, D. and Araujo, J.A. (1999). Small Fatigue Cracks: Mechanics, Mechanisms, and Applications(edited by Ravichandran, K.S., Ritchie, R.O. and Murakami, Y.), Elsevier Science, Oxford, UK, 361–372.

Sato, K., Fujii, H. and Kodama, S. (1986). Wear 107, 245–262.

Waterhouse, R.B. (1992). International Materials Reviews 37, 77–97.

Wharton, M.H., Taylor, D.E. and Waterhouse, R.B. (1973). Wear 23, 251–260.

Williams, D.R., Davidson, D.L. and Lankford, J. (1980) Experimental Mechanics 20, 134–139.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chan, K.S., Davidson, D.L., Owen, T.E. et al. A fracture mechanics approach to high cycle fretting fatigue based on the worst case fret concept – II. Experimental evaluation. International Journal of Fracture 112, 331–353 (2001). https://doi.org/10.1023/A:1013519825958

Issue Date:

DOI: https://doi.org/10.1023/A:1013519825958