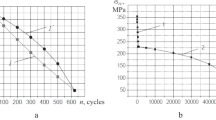

The literature survey reveals the importance of determining the durability of materials before fatigue crack initiation. For this purpose, various criteria are used, including the most popular ones, featuring the microstructural characteristics of metal materials. However, incorporating these characteristics in the defining dependencies leads to complications associated with using specific values that are difficult to determine or find in the reference literature. In this regard, it is proposed to use the French line (FL) and the calculation-experimental method for its construction, considering the polycrystal's characteristic microstructural unit. The author has previously proposed such a method, substantiated by the experimental literature data on the FL accelerated construction. When applying this method to the new data on the experimental determination of the FL performed by the conventional, deviations in the calculated and experimental durabilities were obtained. The regularities of these deviations were established, their cause was identified, and a method for their elimination was proposed in this study. For this purpose, the concept of a variable endurance limit in the cyclic loading process was substantiated and accepted. The obtained dependencies were subdivided into two stages of a smooth specimen's fatigue damage: (i) from the beginning of loading to FL, and (ii) from FL to complete failure.

Similar content being viewed by others

References

D. L. McDowell, K. Gall, M. Horstemeyer, and J. Fan, “Microstructure-based fatigue modeling of cast A356- T6 alloy,” Eng Fract Mech, 70, 49–80 (2003).

Y. Xue, C. L. Burton, M. F. Horstemeyer, et al., “Multistage fatigue modeling of cast A356-T6 and A380-F aluminum alloys,” Metall Mater Trans B, 38, 601–606 (2007).

K. J. Miller, “The behaviour of short fatigue cracks and their initiation. Part II – a general summary,” Fatigue Fract Eng Mater Struct, 10, 93–113 (1987).

S. Suresh and R. O. Ritchie, “Propagation of short fatigue cracks,” Int Met Rev, 29, 445–475 (1984).

L. Zhu, Z. R. Wu, X. T. Hu, et al., “Investigation of small fatigue crack initiation and growth behaviour of nickel base superalloy GH4169,” Fatigue Fract Eng Mater Struct, 39, 1150–1160 (2016).

E. Santecchia, A. M. S. Hamouda, F. Musharavati, et al., “A review on fatigue life prediction methods for metals,” Adv Mater Sci Eng, 9573524 (2016).

O. H. Basquin, “The exponential law of endurance tests,” Proc Am. Soc Test Mater, 10, 625–630 (1910).

European Committee for Standardization (CEN). EN 1993-1-9: Eurocode 3: Design of Steel Structures, Part 1–9: Fatigue, Brussels (2004).

L. F. Coffin, Jr., “A study of the effects of cyclic thermal stresses on a ductile metal,” Trans Am Soc Mech Eng, 76 (6), 931–949 (1954).

S. S. Manson, “Behaviour of materials under conditions of thermal stress,” in: Heat Transfer Symposium, University of Michigan Engineering Research Institute, Ann Arbor, MI (1953), pp. 9–75.

J. Morrow, “Cyclic plastic strain energy and fatigue of metals,” in: ASTM STP 378 (1965), pp. 45–87.

K. N. Smith, P. Watson, and T. H. Topper, “A stress-strain function for the fatigue of metals,” J Mater, 5, 767–776 (1970).

V. T. Troshchenko and L. A. Khamaza, Mechanics of Scattered Fatigue Damage [in Russian], Pisarenko Institute of Problems of Strength of the National Academy of Sciences of Ukraine, Kyiv (2016).

K. C. Liu, “A method based on virtual strain-energy parameters for multiaxial fatigue life prediction,” in: ASTM STP 1191 (1993), pp. 67–84.

Bai-Mao Lei, Van-Xuan Tran, Saïd Taheri, et al., “Toward consistent fatigue crack initiation criteria for 304L austenitic stainless steel under multi-axial loads,” Int J Fatigue, 75, 57–68 (2015).

M. Meshii (Ed.), M. E. Fine, and R. O. Ritchie, Fatigue and Microstructure, American Society for Metals, Metals Park, Ohio, USA (1979), pp. 245–255.

P. Lukaš and L. Kunz, “Small cracks–nucleation, growth and implication to fatigue life,” Int J Fatigue, 25, 855–862 (2003).

M. Marx, W. Schaef, and M. T. Welsch, “The microstructure as crack initiation point and barrier against fatigue damaging,” Int J Fatigue, 41, 57–63 (2012).

T. H. Lin and Y. M. Ito, “Mechanics of a fatigue crack nucleation mechanism,” J Mech Phys Solids, 17 (6), 511–523 (1969).

K. Tanaka and T. Mura, “A dislocation model for fatigue crack initiation,” J Appl Mech, 48 (1), 97–103 (1981).

K. Tanaka and T. Mura, “A theory of fatigue crack initiation at inclusions,” Metall Trans A, 13 (1), 117–123 (1982).

K. S. Chan, “A microstructure-based fatigue-crack-initiation model,” Metall Mater Trans A, 34, 43–58 (2003).

K. S. Chan, “Variability of large-crack fatigue-crack-growth thresholds in structural alloys,” Metall Mater Trans A, 35, 3721–3735 (2004).

K. S. Chan, “Roles of microstructure in fatigue crack initiation,” Int J Fatigue, 32, 1428–1447 (2010).

T. Mura and Y. Nakasone, “Theory of fatigue crack initiation in solids,” J Appl Mech, 57 (1), 1–6 (1990).

G. Venkataraman, Y.-W. Chung, Y. Nakasone, and T. Mura, “Free energy formulation of fatigue crack initiation along persistent slip bands: calculation of S-N curves and crack depths,” Acta Metall Mater, 38 (1), 31–40 (1990).

O. M. Herasymchuk and O. V. Kononuchenko, “Model for fatigue life prediction of titanium alloys. Part 1. Elaboration of a model of fatigue life prior to initiation of microstructurally short crack and a propagation model for physically short and long cracks,” Strength Mater, 45, No. 1, 44–55 (2013). https://doi.org/https://doi.org/10.1007/s11223-013-9431-8

O. M. Herasymchuk and O. V. Kononuchenko, “Model for fatigue life prediction of titanium alloys. Part 2. Model testing and analysis of obtained results,” Strength Mater, 45, No. 2, 163–170 (2013). https://doi.org/https://doi.org/10.1007/s11223-013-9443-4

O. M. Herasymchuk, Microstructure-Dependent Model of Fatigue Life of Two-Phase Titanium Alloys [in Ukrainian], Ph.D. Thesis, Pisarenko Institute of Problems of Strength, National Academy of Sciences of Ukraine, Kyiv (2016).

X. Wu, “On Tanaka–Mura’s fatigue crack nucleation model and validation,” Fatigue Fract Eng Mater Struct, 41 (4), 894–899 (2018).

M. D. Sangid, “The physics of fatigue crack initiation,” Int J Fatigue, 57, 58–72 (2013).

H. French, “Fatigue and hardening of steel,” Trans Am Soc Steel Treat, 21, 899–946 (1933).

G. V. Tsybanev, “An energy approach to fatigue tests and crack initiation stage determination,” Strength Mater, 26, No. 2, 103–109 (1994). https://doi.org/https://doi.org/10.1007/BF02209324

M. Klesnil, “The degree of damage at the French curve and of the fatigue limit during oscilating bend loading,” Metal Treatment Drop Forging, No. 32, 55–63 (1965).

D. Radaj, C. M. Sonsino, and W. Fricke, Fatigue Assessment of Welded Joints by Local Approaches, Woodhead Publishing, Cambridge, UK (2006).

M. D. Chapetti, “Fatigue propagation threshold of short cracks under constant amplitude loading,” Int J Fatigue, 25, 1319–1326 (2003).

C. He, Y. Wu, L. Peng, et al., “Effect of microstructure on small fatigue crack initiation and early propagation behavior in Mg-10Gd-3Y-0.3Zr alloy,” Int J Fatigue, 119, 311–319 (2019).

D. Jíša, P. Liškutín, T. Kruml, and J. Polák, “Small fatigue crack growth in aluminium alloy EN-AW 6082/T6,” Int J Fatigue, 32, 1913–1920 (2010).

S. Syngellakis, M. S. Ali, and P. A. S. Reed, “Microstructural modelling of fatigue initiation in aluminiumbearing alloys,” Int J Comp Meth Exp Meas, 1, No. 3, 249–264 (2013).

A. Khayatzadeh, S. Guth, and M. Heilmaier, “Comparison of the internal fatigue crack initiation and propagation behavior of a quenched and tempered steel with and without a thermomechanical treatment,” Metals, 12, 995 (2022).

W. Chen, Y. Wang, L. Wang, and J. Zhou, “Effect of lamellar microstructure on fatigue crack initiation and propagation in AlCoCrFeNi2.1 eutectic high-entropy alloy,” Eng Fract Mech, 246 (2021). https://doi.org/10.1016/j.engfracmech.2021.107615

T. Yuri, Y. Ono, T. Ogata, et al., “Effect of microstructure on high-cycle fatigue properties of Ti-6Al-4V alloy forging at cryogenic temperatures,” AIP Conf Proc, 1574, 27, 27–33 (2014).

V. S. Ivanova, T. S. Maryanovskaya, and V. F. Terentyev, “Accelerated method for constructing a French line with the use of energy fatigue criteria,” Zavod. Lab., No. 2, 225–228 (1966).

M. Klesnil and P. Lukaš, Fatigue of Metallic Materials, Academia, Prague (1981).

M. Hempel, “Die Entstehung von Mikrorissen in metallischen Werkstoffen unter Wechselbeanspruchung,” Arch Eisenhuttenwes, 38, No. 6, 446–456 (1967).

V. S. Ivanova and V. F. Terentyev, Nature of Metal Fatigue [in Russian], Nauka, Moscow (1965).

G. V. Tsybanev, Prediction of Cyclic Durability of Structural Elements by the Limit State of Material in Concentration and Fretting Zones [in Russian], Ph.D. Thesis, Pisarenko Institute of Problems of Strength, National Academy of Sciences of Ukraine, Kiev (1996).

K. J. Miller, “The two thresholds of the fatigue behaviour,” Fatigue Fract Eng Mater Struct, 16, No. 9, 931–939 (1993).

M. H. El Haddad, T. H. Topper, and K. N. Smith, "Prediction of nonpropagating cracks,” Eng Fract Mech, 11 (3), 573–584 (1979).

GOST 25.502-79. Methods of Mechanical Testing of Metals. Methods of Fatigue Testing [in Russian], Standards Publishing House, Moscow, Introduced on July 1, 1986.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, pp. 48 – 59, May – June, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tsybanyov, G.V. French Line Prediction for Steels Using Experimental Data to Construct a Fatigue Curve. Part 1. Literature Survey and Development of the Computational Method for Constructing the French Line. Strength Mater 55, 493–502 (2023). https://doi.org/10.1007/s11223-023-00542-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00542-3