Abstract

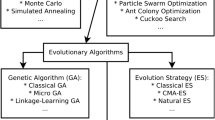

This paper describes a methodology for the choice of a pull production-control strategy. The methodology is based on optimization, using an Evolutionary Algorithm and discrete-event simulation, of a generic system that can model Kanban, Conwip, and Hybrid. This approach is illustrated through the examples of production lines with six, eight, and ten stages. The optimization procedure leads to a simplified Hybrid system.

Similar content being viewed by others

References

Amin, M. and Altiok, T. (1997) Control policies for multiproduct multi-stage manufacturing systems: an experimental approach. International Journal of Production Research, 35(1), 201–223.

Berkley, B. J. (1992) A review of the Kanban production control research literature. Production and Operations Management, 1(4), 393–411.

Bertrand, J. W. M. (1983) The use of workload information to control job lateness in controlled and uncontrolled release production systems. Journal of Operations Management, 3(2), 79–92.

Bonvik, A. M., Couch, C. E. and Gershwin, S. B. (1997) A comparison of production-line control mechanisms, International Journal of Production Research, 35(3), 789–804.

Bonvik, A. M. (1996) Performance analysis of manufacturing systems under hybrid control policies. Ph.D. Dissertation, Massachusetts Institute of Technology.

Buzacott, J. A. (1989) Queuing models of Kanban and MRP controlled production systems. Engineering Cost and Production Economics, 17, 3–20.

Chu, C.-H. and Shih,W.-L. (1992) Simulation studies in JIT production. International Journal of Production Research, 30(11), 2573–2586.

Dallery, Y. and Liberopoulos, G. (1995) A new Kanban-type pull control mechanism for multi-stage manufacturing systems, Proceedings of the 3rd European Control Conference, Rome, September 5–8, 4(2), 3543–3548.

Davis, W. J. and Stubitz, S. J. (1987) Configuring a Kanban system using a discrete optimization of multiple stochastic responses, International Journal of Production Research, 25(5), 721–740.

De Koster, R. and Wijngaard, J. (1989) Local and integral control of workload, International Journal of Production Research, 27(1), 43–52.

Duri, C. (1997) Etude comparative des gestions à flux tiré. Thèse de doctorat de l'Institut National Polytechnique de Grenoble, Laboratoire d'Automatique de Grenoble, Janvier.

Gaury, E. G. A., Pierreval, H. and Kleijnen, J. P. C. (1997) Modélisation et simulation dans l'étude de systèmes de production gérés en Juste-A-Temps, Proceedings of the First French-speaking AFCET/FRANCOSIM/SCS conference on modeling and simulation (MOSIM'97), Rouen, France, 5–6.

Goldberg, D. (1989) Genetic Algorithms in Search Optimization and Machine Learning, Addison-Wesley Publishing Company, Reading, MA.

Goldratt, E. M. and Fox, R. E. (1986) The race, North River Press, N.Y.

Golhar, D. Y. and Stamm, C. L. (1991) The just-in-time philosophy: A literature review. International Journal of Production Research, 29(4), 657–676.

Gupta, P. Y. and Gupta, C. M. (1989) A system dynamic model for multi-stage multi-line dual-card JIT-Kanban system. International Journal of Production Research, 27, 309–352.

Huang, C.-C. and Kusiak, A. (1996) Overview of Kanban systems. International Journal of Computer Integrated Manufacturing, 9(3), 169–189.

Huang, P. Y., Rees, L. P. and Taylor, B. W. (1983) A simulation analysis of the Japanese Just-In-Time technique (with Kanbans) for a multiline, multistage production system. Decision Sciences, 14(3), 326–344.

Kimura, O. and Terada, H. (1981) Design and analysis of pull system, a method of multi-stage production control. International Journal of Production Research, 19(3), 241–253.

Michalewicz, Z. (1992) Genetic algorithms + data structures = evolution programs. Springer-Verlag.

Monden, Y. (1981) How Toyota shortened lot production time, waiting time and conveyance time. Industrial Engineer, 13, 22–30.

Paris, J. L. and Pierreval, H. (1997) Configuration of a multiproduct Kanban system using a distributed evolutionary algorithm. Proceedings of the IFAC/IFIP Conference on Management and Control of Production and Logistics (MCPL'97), Las Campinas, Brazil, 31 Aug.-3 Sept. 97.

Paris, J. L., Pierreval, H. and Tautou, L. (1996) Une méthode d'optimisation-simulation par algorithme évolutionniste en gestion de production juste-à-temps. Journal Européen des Systèmes Automatisés (JESA), 30(7), 929–944.

Pierreval, H. and Tautou, L. (1997) Using evolutionary algorithms and simulation for the optimization of manufacturing systems. IIE Transactions, 29(3), 181–189.

Price, W., Gravel, M. and Nsakanda, A. L. (1994) A review of optimization models of Kanban-based production systems. European Journal of Operational Research, 75, 1–12.

Roderick, L. M., Phillips, D. T. and Hogg, G. L. (1992) A comparison of order release strategies in production control systems. International Journal of Production Research, 30(3), 611–626.

Roderick, L. M., Toland, J. and Rodriguez, F. (1994) A simulation study of Conwip versus MRP at Westinghouse. Computers and Industrial Engineering, 26(2), 137–142.

Schonberger, R. J. (1982) Japanese Manufacturing Technique, The Free Press, New York.

Schroer, B. J., Black, J. T. and Zhang, S. X. (1985) Just-In-Time (JIT), with Kanban, manufacturing system simulation on a microcomputer. Simulation, 45(2), 62–70.

Sing, N. and Brar, J. K. (1992) Modeling and analysis of Just-In-Time manufacturing systems: A review. International Journal of Operations & Production Management, 12(2), 3–14.

Spearman, M. L. and Hogg, G. L. (1986) Production rates, flow times and work in process levels in a generalized pull production system. Manuscript, Department of Industrial Engineering and Management Sciences, Northwestern University, Evanstin IL, Department of Industrial Engineering, Texas A&M University, College Station, TX.

Spearman, M. L., Woodruff and Hopp, W. J. (1990) CONWIP: a pull alternative to Kanban. International Journal of Production Research, 28(5), 879–894.

Spears, W. M., Dejong, K. A., Bäck, T., Fogel, D. and Degaris, H. (1993) An overview of evolutionary computation. Proceedings of the European Conference on Machine Learning, Springer, New York, 442–459.

Sugimori, Y., Kusunoki, K., Cho, F. and Uchikawa, S. (1977) Toyota production system and Kanban system materialization of just-in-time and respect-for-human system. International Journal of Production Research, 15(6), 553–564.

Villeda, R., Dudek, R. and Smith, M. L. (1988) Increasing the production rate of a just-in-time production system with variable operation times. International Journal of Production Research, 26, 1749–1768.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gaury, E.G.A., Pierreval, H. & Kleijnen, J.P.C. An evolutionary approach to select a pull system among Kanban, Conwip and Hybrid. Journal of Intelligent Manufacturing 11, 157–167 (2000). https://doi.org/10.1023/A:1008938816257

Issue Date:

DOI: https://doi.org/10.1023/A:1008938816257