Abstract

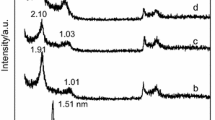

Cationic clays and Layered Double Hydroxides (LDHs) are both layeredion exchangers, in which a stable (micro)porosity can be induced via apillaring process. For the cationic clays, the [Zr]-pillaring of hectoritecreates a broad micropore distribution with the maximum at 1.42–2.12nm. The [Al]-equivalent exhibits a narrower distribution, with pores between0.71 and 1.06 nm being dominant. In case of the [Zr]-pillared form a surfacearea of 294 m2/g and a micropore volume of 0.118cm3/g have been obtained. The same reaction on the syntheticlaponite clay reveals a much higher surface area (606 m2/g)and porosity (µPV = 0.336 cm3/g). Forlaponite, extra pores are created in the supermicropore-small mesoporeregion due to the preferential edge-to-face and edge-to-edge stacking of itssmaller sized clay layers.

For the pillaring of MgAl- and ZnAl-LDHs with polyoxometalates (POMs),using large organic anions for pre-swelling purposes forms the mostpromising method for the creation of stable pores. It avoids the formationof sidephases, and gives rise to medium(-high) µPVs. Charge density onthe layers forms the key factor, lowering it improves the porositycharacteristics significantly. [Fe(CN)6]-MgAl-LDHs exhibitmore spectacular properties, with surface areas and µPVs exceedingthose of pillared hectorite. A variation in the charge density via theM II/M III ratio optimizes theporosity properties. A M II/M IIIratio of 3.33 results in a SA of 499 m2/g and a µPV of0.177 cc/g. For LDHs, both types of pillars create mainly small micropores,with a diameter smaller than 0.71 nm.

Similar content being viewed by others

References

T.J. Pinnavaia, Science 220, 365 (1983).

J. Shabtai, United States Patent 4, 188 (1980).

R.M. Barrer, Zeolites and Clay Minerals as Sorbents and Molecular Sieves(Academic Press, London, 1978), p. 407.

L. Van Leemput, M.S. Stul, A. Maes, J.B. Uytterhoeven, and A. Cremers, Clays and Clay Minerals 31, 261 (1983).

R.H. Loeppert, M.M. Mortland, and T.J. Pinnavaia, Clays and Clay Minerals 27, 201 (1979).

T. Endo, M.M. Mortland, and T.J. Pinnavaia, Clays and Clay Minerals 28, 105 (1980).

R. Burch, Catalysis Today 2, 297 (1988).

M.P. Atkins, in Pillared Layered Structures: Current Trends and Applications, edited by IV Mitchell (Elsevier, Essex, 1990), p. 159.

R.A. Schoonheydt, J. Van Den Eynde, H. Tubbax, H. Leeman, M. Stuyckens, I. Lenotte, and W.E.E. Stone, Clays and Clay Minerals 41, 598 (1993).

K. Ohtsuka, Y. Hayashi, and M. Suda, Chemistry of Materials 5, 1823 (1993).

J. Sterte, Clays and Clau Minerals 34, 658 (1986).

S. Yamanaka and G.W. Brindley, Clays and Clay Minerals 26, 21 (1978).

T.J. Pinnavaia, M.S. Zhou, and S.D. Landau, Journal of the American Chemical Society 107, 4783 (1985).

E.G. Rightor, M.S. Zhou, and T.J. Pinnavaia, Journal of Catalysis 130, 29 (1991).

N. Maes, H.-Y. Zhu, and E.F. Vansant, Journal of Porous Materials 2, 97 (1995).

H.-Y. Zhu, N. Maes, and E.F. Vansant, in Surface Science and Catalysis, edited by J. Rouquerol, F. Rodriguez-Reinoso, K.S.W. Sing, and K.K. Unger (Elsevier, Amsterdam, 1994), Vol. 87, p. 457.

R.A. Schoonheydt, H. Leeman, A. Scorpion, I. Lenotte, and P. Grobet, Clays and Clay Minerals 42, 518 (1994).

T.J. Pinnavaia, M.S. Tzou, S.D. Landau, and R.H. Raythatha, Journal of Molecular Catalysis 27, 195 (1984).

M.A. Drezdon, Inorganic Chemistry 27, 4628–4632 (1988).

T. Sato, H. Fujita, T. Endo, and M. Shimada, React. of Solids 5, 219 (1988).

T. Kwon and T. Pinnavaia, Chemistry of Materials 1(4), 381–383 (1989).

J. Wang, Y. Tian, R.-C. Wang, and A. Clearfield, Chem. Mater. 4, 1276–1282 (1992).

M.-A. Ulibarri, F.M. Labajos, V. Rives, R. Trujillano, W. Kagunya, and W. Jones, Inorganic Chemistry 33(12) 2592–2599 (1994).

T. Kwon and T. Pinnavaia, Journal of Molecular Catalysis 74, 23–33 (1992).

T. Kwon, G.A. Tsigdinos, and T. Pinnavaia, J. Am. Chem. Soc. 110, 3653–3654 (1988).

E.D. Dimotakis and T.J. Pinnavaia, Inorganic Chemistry 29(13), 2393–2394 (1990).

E. Narita, P. Kaviratna, and T. Pinnavaia, Chemistry Letters 805–808 (1991).

F. Trifiro and A. Vaccari, in Comprehensive Supramolecular Chemistry, edited by J.L. Atwood, D.D. MacNicol, J.E.D. Davies, and F. Vögtle (Pergamon Press, Oxford, 1995), Vol. 7, Chapter 10.

F.A.P. Cavalcanti, A. Schutz, and P. Biloen, in Preparation of Catalysts IV, edited by B. Delmon, P. Grange, P.A. Jacobs, and G. Poncelet (Elsevier, Amsterdam, 1987).

H.C.B. Hansen and C.B. Koch, Clays and Clay Minerals 42(2), 170–179 (1994).

S. Kikkawa and M. Koizumi, Mat. Res Bull. 17, 191 (1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nijs, H., Cool, P. & Vansant, E. Cationic versus Anionic Pillared Layered Substrates: Comparison of the Pillaring Reactions and the Resulting Porosities. Interface Science 5, 83–94 (1997). https://doi.org/10.1023/A:1008659822144

Issue Date:

DOI: https://doi.org/10.1023/A:1008659822144