Abstract

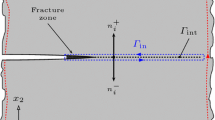

During steady state crack growth by diffusive cavitation at grain boundaries, crack tip fields are relaxed due to the presence of a cavitation zone. In the present analysis, analytic solutions for the actual crack tip stress fields and the crack velocity in the presence of cavitation zone consisting of continuously distributed cavities ahead of the crack tip are derived using the smeared volume concept. Results indicate that the r −1/2 singularity is now attenuated to r −1/2 + θ(0<θ<1/2) singularity. The singularity attenuation parameter θ is a function of the crack velocity and material parameters. The crack growth rate υ is related to the mode I stress intensity factor K by υ∝K 2 at relatively high load, υ∝K n at intermediate load, and approaches zero at small load near K th. Meanwhile, the cavitation zone extends further into the material due to the stress relaxation at the crack tip and the subsequent stress redistribution. Such relaxation effects become very distinct at low crack velocity and low applied load.

Key words: Creep crack growth, brittle material, diffusive cavity growth, sintering stress, crack tip stress field.

Similar content being viewed by others

References

Bilby, B.A. and Eshelby, J.D. (1969). Fracture; An Advanced Treatise, vol. 1 (Edited by H. Liebowitz) Academic Press, New York, 99–182.

Diboine, A. and Pineau, A. (1987). Creep crack initiation and growth in inconel 718 alloy at 650°C. Fatigue Fracture of Engineering Materials and Structure 10, 141–151.

Dyson, D.F. (1976). Constraints on diffusional cavity growth rates. Metal Science349–353.

Frost, H.J. and Ashby, M.F. (1982). Deformation Mechanism Maps, Pergamon Press, New York.

Hasegawa, T., Yakou, T. and Ishii, K. (1987). Experimental estimation of crack tip stresses during high temperature straining of type 316 stainless steel. Scripta Metallurgica 21, 913–918.

Hong, S.H. and Yu, J. (1989). The crack tip cavitation damage in a NiCr steel. Scripta Metallurgica 23, 1481–1486.

Hull, D. and Rimmer, D.E. (1959). The growth of grain boundary voids under stress. Philosophical Magazine 4, 673–687.

Hutchinson, J.W. (1983). Constitutive behavior and crack tip fields for materials undergoing creep-constrained grain boundary cavitation. Acta Metallurgica 31, 1079–1088.

Jeon, J.Y. (1994) Ph.D. Thesis, KAIST, Seoul.

Jeon, J.Y. and Yu, J. (1994). Relaxation of crack tip stresses by diffusive growth of grain boundary cavity. Strength of Materials(Edited by H. Oikawa, et al.) The Japan Institute of Metals, Sendai, 611–614.

Landes, J.D. and Begley, J.A. (1976). A Fracture Mechanics Approach to Creep Crack Growth, Mechanics of Crack Growth, ASTM STP 590, ASTM (1976) 128–148.

Raj, R. and Baik, S. (1980). Creep crack progagation by cavitation near crack tips. Metal Science 14, 385–394.

Riedel, H. (1976). Plastic yielding on inclined slip-planes at a crack tip. Journal of the Mechanics and Physics of Solids 24, 277–289.

Riedel, H. (1977). A Dugdale model for crack opening and crack growth under creep conditions. Materials Science and Engineering 30, 187–196.

Sadananda, K. and Shahinian, P. (1977). Creep crack growth in alloy 718. Metallurgical Transactions A 8A, 439–449.

Staley Jr, J.T. and Saxena, A. (1990). Mechanisms of creep crack growth in 1wt% antimony-copper; Implications for fracture parameter. Acta Metallurgica et Materialia 38, 897–908.

Trinkaus, H. and Ullmaier, H. (1979). A model for the high-temperature embrittlement of metals containing helium. Philosophical Magazine A 39, 563–580.

Vitek, V. (1976). Yielding on inclined planes at the tip of a crack loaded in uniform tension. Journal of the Mechanics and Physics of Solids 24, 263–275.

Williams, M.L. (1957).On the stress distribution at the base of a stationary crack. Journal of Applied Mechanics 24, 109–114.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jeon, J., Lee, Y. & Yu, J. Creep crack growth in brittle materials. International Journal of Fracture 101, 203–214 (2000). https://doi.org/10.1023/A:1007685831651

Issue Date:

DOI: https://doi.org/10.1023/A:1007685831651