Abstract

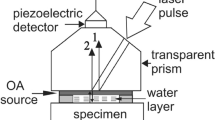

A laser ultrasonic method for nondestructive evaluation of the structure of composite materials is proposed. Specimens of graphite-epoxy composites with compaction-type defects and air cavities are investigated. The method is based on the laser thermooptical generation of wide-band acoustic pulses - optoacoustic (OA) signals - in the material investigated. The acoustic pulses backscattered by structural ingomogeneities and defects are registered by a wide-band piezotransducer, which makes it possible to detect acoustic pulses in the frequency range from 0.1 to 30 MHz. Since the generation and detection of acoustic pulses takes place on the front surface of the specimen, this method allows us to carry out nondestructive evaluation with one-sided access to the object under study. The spectral and correlation analyses of backscattered OA signals are used for mathematical processing of the experimental data. The method developed makes it possible to determine the type of defects and the depth of their location.

Similar content being viewed by others

REFERENCES

D. W. Fitting and L. Adler, Ultrasonic Spectral Analysis for Nondestructive Evaluation, Plenum Press, New York (1981).

A. Vary, “Ultrasonic measurements of material properties,” Res. Techn. Nondestr. Eval., 4, No. 5, 160–204 (1980).

W. R. Scott and P. F. Gordon, “Ultrasonic spectral analysis for nondestructive evaluation of layered composite materials,” J. Acoust. Soc. Am., 62, No. 1, 108–116 (1984).

D. K. Hsu and S. M. Nair, “Evaluation of porosity in graphite-epoxy composite by frequency dependence of ultrasonic attenuation,” Rev. Progr. Quantit. Nondestr. Eval., 6b, 1185–1193 (1987).

A. Rogerson and R. A. Murgatroyd, “Defect characterization using ultrasonic techniques,” Res. Techn. Nondestr. Eval., 5, No. 12, 451–507 (1982).

V. E. Gusev and A. A. Karabutov, Laser Optoacoustics [in Russian], Nauka, Moscow (1991).

A. A. Karabutov and N. B. Podymova, “Nondestructive evaluation of fatigue-induced changes in the structure of composites by an ultrasonic method using a laser,” Mech. Compos. Mater., 31, No. 3, 301–304 (1995).

A. A. Karabutov, M. P. Matrosov, N. B. Podymova, and V. A. Pyzh, “Pulsed acoustic spectroscopy with a laser sound source,” Akust. Zh. 37, No. 2, 311–323 (1991).

A. A. Karabutov, V. V. Murashov, and N. B. Podymova, “Evaluation of layered composites by laser optoacoustic transducers,” Mech. Compos. Mater., 35, No. 1, 89–94 (1999).

A. A. Karabutov, I. M. Kershtein, I. M. Pelivanov, and N. B. Podymova, “Laser ultrasonic investigation of the elastic properties of unidirectional graphite-epoxy composites,” Mech. Compos. Mater., 34, No. 6, 575–582 (1998).

A. A. Karabutov, I. M. Kershtein, I. M. Pelivanov, and N. B. Podymova, “Distribution of longitudinal and shear acoustic video pulses in graphite-epoxy composites,” Akust. Zh., 45, No. 1, 86–91 (1999).

O. Svelto, Principles of Lasers, Plenum, New York-London.

J. Max, Methodes et Techniques de Traitement du Signal et Applications aux Mesures Physiques. Vol. 1, Paris (1981).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Karabutov, A.A., Pelivanov, I.M. & Podymova, N.B. Nondestructive Evaluation of Graphite-Epoxy Composites by the Laser Ultrasonic Method. Mechanics of Composite Materials 36, 497–500 (2000). https://doi.org/10.1023/A:1006714818203

Issue Date:

DOI: https://doi.org/10.1023/A:1006714818203