Abstract

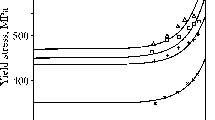

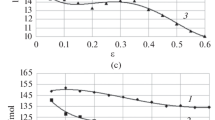

Under hot-forming conditions characterized by high homologous temperatures and strain-rates, metals usually exhibit rate-dependent inelastic behavior. An elastic-viscoplastic constitutive model is presented here to describe metal behavior during hot-forming. The model uses an isotropic internal variable to represent the resistance offered to plastic deformation by the microstructure. Evolution equations are developed for the inelastic strain and the deformation resistance based on experimental results. A methodology is presented for extracting model parameters from constant true strain-rate compression tests performed at different temperatures. Model parameters are determined for an Al-1Mn alloy and an Al-Mg-Si alloy, and the predictions of the model are shown to be in good agreement with the experimental data.

Similar content being viewed by others

References

C. Bertrand-Rossini et al., “Modeling of Metal-Forming Processes” (Kluwer Academic Publishers, Dordrecht, The Netherlands, 1988) p. 271.

J. M. Rigaut, D. Lochegnies, J. Oudin, J. C. Gelin and Y. Ravalard, “Modeling of Metal-Forming Processes” (Kluwer Academic Publishers, Dordrecht, The Netherlands, 1988) p. 261.

C. R. Boer, N. Rebelo, H. Rydstad and G. Schroder, “Process Modeling of Metal-Forming and Thermomechanical Treatment” (Springer-Verlag Berlin, Heidelberg, 1986).

D. Iddan and J. R. Tirosh, Journal of Applied Mechanics 63 (1996) 27.

O. C. Zienkiewicz and P. N. Godbole, International Journal for Numerical Methods in Engineering 8 (1974) 3.

H. Shi, A. J. Mclaren, C. M. Sellars, R. Shahani and R. Bolingbroke, Materials Science and Technology 13 (1997) 210.

T. Sheppard and A. Jackson, ibid. 13 (1997) 203.

J. M. Cabrera, J. J. Jonas and J. M. Prado, ibid. 12 (1996) 579.

S. R. Bodner, in “Unified Constitutive Equations for Creep and Plasticity,” edited by A. K. Miller (Elsevier Applied Science, New York, 1987) p. 273.

A. K. Miller, in “Unified Constitutive Equations for Creep and Plasticity,” edited by A. K. Miller (Elsevier Applied Science, New York, 1987) p. 139.

M. A. Rowley and E. A. Thornton, Journal of Engineering Materials and Technology 118 (1996) 19.

A. F. Skipor, S. V. Harren and J. Botsis, ibid. 118 (1996) 1.

L. Anand, ibid. 104 (1982) 12.

S. B. Brown, K. H. Kim and L. Anand, International Journal of Plasticity 5 (1989) 95.

V. M. Sample, L. A. Lalli and O. Richmond, “Modeling the Deformation of Crystalline Solids” (TMS, Warrendale, PA, 1991) p. 327.

D. C. Stouffer and L. T. Dame, “Inelastic Deformation of Metals: Models, Mechanical Properties, and Metallurgy” (John Wiley and Sons, New York, 1996).

S. R. Bodner and Y. Partom, Journal of Applied Mechanics 42 (1975) 385.

F. Garofalo, Transactions AIME 227 (1963) 351.

J. J. Jonas, C. M. Sellars and W. J. MCG. Tegart, Metallurgical Reviews 14 (1969) 1.

J. Sarkar, Y. V. R. K. Prasad and M. K. Surappa, Journal of Materials Science 30 (1995) 2843.

W. H. Press, S. A. Teukolsky, W. T. Vetterling and B. P. Flannery, “Numerical Recipes in FORTRAN: The Art of Scientific Computing,” 2nd ed. (Cambridge University Press, 1992).

C. S. Barrett and T. B. Massalski, “Structure of Metals,” 3rd ed. (McGraw Hill, 1966).

Z. Jin, G. T. Gray and Y. W. Kim, Materials Science and Engineering A 239 (1997) 729.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Santhanam, S. An elastic-viscoplastic constitutive model for the hot-forming of aluminum alloys. Journal of Materials Science 35, 3647–3654 (2000). https://doi.org/10.1023/A:1004882001651

Issue Date:

DOI: https://doi.org/10.1023/A:1004882001651