Abstract

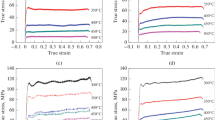

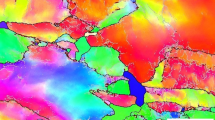

The hot deformation behavior of spray-formed 7055 aluminum alloy was investigated using a thermo-mechanical simulator by a series of isothermal and constant strain-rate compression tests. These tests were at deformation temperatures ranging from 653 to 713 K and strain rates ranging from 0.1 to 15s−1. The microstructure characteristics of these deformed samples were examined by optical microscope (OM) and electron back-scattered diffraction (EBSD) techniques. The material flow patterns and relevant microstructural analyses indicated that specific thermo-mechanical conditions including the Zener-Hollomon parameter, temperature, and strain, determined the onset and degree of obvious dynamic recrystallization (DRX) behavior. A partially recrystallized grain microstructure was observed and enhanced the flow softening especially at low Zener-Hollomon values. The influence of different hot deformation conditions on the material flow behavior and the evolution of microstructure was confirmed. A new three-stage constitutive equation, accompanied by a microstructure evolution model, was developed to predict the flow stress of sprayed-formed 7055 aluminum alloy and the corresponding characteristics of DRX transformation during the hot deformation process. The predicted performance was evaluated by experimental data and showed good accuracy.

Similar content being viewed by others

References

H.-Y. Yang, Z. Wang, L.-Y. Chen, S.-L. Shu, F. Qiu, and L.-C. Zhang, Interface Formation and Bonding Control in High-Volume-Fraction (TiC+ TiB2)/Al Composites and Their Roles in Enhancing Properties, Compos. Part B Eng., 2021, 209, p 108605.

B.-X. Dong, Q. Li, Z.-F. Wang, T.-S. Liu, H.-Y. Yang, S.-L. Shu, L.-Y. Chen, F. Qiu, Q.-C. Jiang, and L.-C. Zhang, Enhancing Strength-Ductility Synergy and Mechanisms of Al-Based Composites by Size-Tunable In-Situ TiB2 Particles with Specific Spatial Distribution, Compos. Part B Eng., 2021, 217, p 1089.

H.-Y. Yang, Z.-J. Cai, Q. Zhang, Y. Shao, B.-X. Dong, Q.-Q. Xuan, and F. Qiu, Comparison of the Effects of Mg and Zn on the Interface Mismatch and Compression Properties of 50 vol% TiB2/Al Composites, Ceram. Int., 2021, 47, p 22121–22129.

H. Yang, X. Yue, Z. Wang, Y. Shao, and S. Shu, Strengthening Mechanism of TiC/Al Composites Using Al-Ti-C/CNTs with Doping Alloying Elements (Mg, Zn and Cu), J. Market. Res., 2020, 9, p 6475–6487.

P.Y. Guo, H. Sun, Y. Shao, J.T. Ding, J.C. Li, M.R. Huang, S.Y. Mao, Y.X. Wang, J.F. Zhang, R.C. Long, and X.H. Hou, The Evolution of Microstructure and Electrical Performance in Doped Mn-Co and Cu-Mn Oxide Layers with the Extended Oxidation Time, Corros. Sci., 2020, 172, p 108738.

K.K. Sankaran, and R.S. Mishra, Metallurgy and Design of Alloys with Hierarchical Microstructures, Elsevier Science, 2017.

P.Y. Guo, B. Lu, and Y. Shao, Optimal Design for Preform of Blade Forging by Topological Algorithm Combined with Numerical Simulation and Physical Experiment, Rare Metal Mat. Eng., 2017, 46, p 461–467.

J. Li, D. Feng, W. Xia, W. Guo, and G. Wang, The Non-Isothermal Double Ageing Behaviour of 7055 Aluminum Alloy, Acta Metall. Sin., 2020, 56(11), p 1495–1506.

Y. Shao, J.T. Ding, P.Y. Guo, W.X. Ou, S.Y. Mao, M.R. Huang, Z. He, D.P. Wang, L.L. Yang, P.J. Zhou, and S.J. Chen, High Temperature Characteristics and Phase Compositions of Cu/Mn Multilayers with the Different Average Thickness Prepared by Electrodeposition, J. Alloys Compd., 2021, 871, p 1594.

A. Rollett, G.S. Rohrer, J. Humphreys, Recrystallization and Related Annealing Phenomena, Newnes, 2017.

Y. Lin, and X.-M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759.

J. Ren, R. Wang, Y. Feng, C. Peng, and Z. Cai, Hot Deformation Behavior and Microstructural Evolution of as-Quenched 7055 Al Alloy Fabricated by Powder Hot Extrusion, Mater. Charact., 2019, 156, p 109833.

Y. Lin, Y.-J. Liang, M.-S. Chen, and X.-M. Chen, A Comparative Study on Phenomenon and Deep Belief Network Models for Hot Deformation Behavior of an Al–Zn–Mg–Cu Alloy, Appl. Phys. A, 2017, 123, p 1–11.

X. Wang, Q. Pan, S. Xiong, and L. Liu, Prediction on Hot Deformation Behavior of Spray Formed Ultra-High Strength aluminum Alloy—A Comparative Study Using Constitutive Models, J. Alloy. Compd., 2018, 735, p 1931–1942.

D.-N. Zhang, Q.-Q. Shangguan, C.-J. Xie, and F. Liu, A Modified Johnson-Cook Model of Dynamic Tensile Behaviors for 7075–T6 Aluminum Alloy, J. Alloy. Compd., 2015, 619, p 186–194.

R. Bobbili, V. Madhu, and A.K. Gogia, Tensile Behaviour of Aluminium 7017 Alloy at Various Temperatures and Strain Rates, J. Market. Res., 2016, 5, p 190–197.

D. Feng, X.M. Zhang, S.D. Liu, and Y.L. Deng, Constitutive Equation and Hot Deformation Behavior of Homogenized Al–768Zn–212Mg–198Cu–012Zr Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2014, 608, p 63–72.

C.-Q. Huang, J. Deng, S.-X. Wang, and L.-L. Liu, A Physical-Based Constitutive Model to Describe the Strain-Hardening and Dynamic Recovery Behaviors of 5754 Aluminum Alloy, Mater. Sci. Eng., A, 2017, 699, p 106–113.

H. Hallberg, M. Wallin, and M. Ristinmaa, Modeling of Continuous Dynamic Recrystallization in Commercial-Purity Aluminum, Mater. Sci. Eng. A, 2010, 527, p 1126–1134.

M. Bacca, and R.M. McMeeking, Latent Heat Saturation in Microstructural Evolution by Severe Plastic Deformation, Int. J. Plast, 2016, 83, p 74–89.

Z. Sun, H. Wu, J. Cao, and Z. Yin, Modeling of Continuous Dynamic Recrystallization of Al-Zn-Cu-Mg Alloy During Hot Deformation Based on the Internal-State-Variable (ISV) Method, Int. J. Plast, 2018, 106, p 73–87.

S. Gourdet, and F. Montheillet, A Model of Continuous Dynamic Recrystallization, Acta Mater., 2003, 51, p 2685–2699.

J. Zhang, Z. Li, K. Wen, S. Huang, X. Li, H. Yan, L. Yan, H. Liu, Y. Zhang, and B. Xiong, Simulation of Dynamic Recrystallization for an Al-Zn-Mg-Cu Alloy Using Cellular Automaton, Progr. Nat. Sci. Mater. Int., 2019, 29, p 477–484.

A. Eivani, H. Vafaeenezhad, O. Nikan, and J. Zhou, Modeling High Temperature Deformation Characteristics of AA7020 Aluminum Alloy Using Substructure-Based Constitutive Equations and Mesh-Free Approximation Method, Mech. Mater., 2019, 129, p 104–112.

S. Ding, S.A. Khan, and J. Yanagimoto, Flow Behavior and Dynamic Recrystallization Mechanism of A5083 Aluminum Alloys with Different Initial Microstructures During Hot Compression, Mater. Sci. Eng. A, 2020, 787, p 13952.

Q. Yang, Z. Deng, Z. Zhang, Q. Liu, Z. Jia, and G. Huang, Effects of Strain Rate on Flow Stress Behavior and Dynamic Recrystallization Mechanism of Al-Zn-Mg-Cu Aluminum Alloy during Hot Deformation, Mater. Sci. Eng. A, 2016, 662, p 204–213.

M. Rokni, A. Zarei-Hanzaki, A.A. Roostaei, and H. Abedi, An Investigation into the Hot Deformation Characteristics of 7075 Aluminum Alloy, Mater. Des., 2011, 32, p 2339–2344.

R. Doherty, D. Hughes, F. Humphreys, J.J. Jonas, D.J. Jensen, M. Kassner, W. King, T. McNelley, H. McQueen and A. Rollett, Current Issues in Recrystallization: A Review, Mater. Sci. Eng. A, 1997, 238, p 219–274.

S. Ding, S.A. Khan, and J. Yanagimoto, Constitutive Descriptions and Microstructure Evolution of Extruded A5083 Aluminum Alloy During Hot Compression, Mater. Sci. Eng., A, 2018, 728, p 133–143.

S. Yong, Z. Pengfei, L. Qihang, G. Pingyi, S. Fengjian, Y. Hongyu, Y. Lin, and Y. Na, Microstructure and Tensile Property Inhomogeneity of Commercial 7055–T7951 Aluminum Alloy Thick Plate by Hot Rolling, Rare Metal Mat. Eng., 2020, 49, p 4199–4206.

H. Yu, M. Wang, X. Sheng, Z. Li, L. Chen, Q. Lei, C. Chen, Y. Jia, Z. Xiao, W. Chen, H. Wei, H. Zhang, X. Fan, and Y. Wang, Microstructure and Tensile Properties of Large-Size 7055 Aluminum Billets Fabricated by Spray Forming Rapid Solidification Technology, J. Alloy. Compd., 2013, 578, p 208–214.

A. Chamanfar, M.T. Alamoudi, N.E. Nanninga, and W.Z. Misiolek, Analysis of Flow Stress and Microstructure During Hot Compression of 6099 Aluminum Alloy (AA6099), Mater. Sci. Eng. A, 2019, 743, p 684–696.

J. Castellanos, I. Rieiro, M. Carsí, J. Muñoz, M. El Mehtedi, and O.A. Ruano, Analysis of Adiabatic Heating and its Influence on the Garofalo Equation Parameters of a High Nitrogen Steel, Mater. Sci. Eng. A, 2009, 517, p 191–196.

U. Kocks, and H. Mecking, Physics and Phenomenology of Strain Hardening: The FCC Case, Prog. Mater Sci., 2003, 48, p 171–273.

A. Laasraoui, and J. Jonas, Recrystallization of Austenite After Deformation at High Temperatures and Strain Rates—Analysis and Modeling, Metall. Trans. A, 1991, 22, p 151–160.

H.J. McQueen, S. Spigarelli, M.E. Kassner, and E. Evangelista, Hot Deformation and Processing of Aluminum Alloys, CRC Press, London, 2011.

Y. Deng, Z. Yin, and J. Huang, Hot Deformation Behavior and Microstructural Evolution of Homogenized 7050 Aluminum alloy During Compression at Elevated Temperature, Mater. Sci. Eng., A, 2011, 528, p 1780–1786.

A. Najafizadeh, and J.J. Jonas, Predicting the Critical Stress for Initiation of Dynamic Recrystallization, ISIJ Int., 2006, 46, p 1679–1684.

H. Mirzadeh, and A. Najafizadeh, Prediction of the Critical Conditions for Initiation of Dynamic Recrystallization, Mater. Des., 2010, 31, p 1174–1179.

A. Momeni, G. Ebrahimi, M. Jahazi, and P. Bocher, Microstructure Evolution at the Onset of Discontinuous Dynamic Recrystallization: A Physics-Based Model of Subgrain Critical Size, J. Alloy. Compd., 2014, 587, p 199–210.

S.W. Cheong, and H. Weiland, Understanding a Microstructure Using GOS (Grain Orientation Spread) and its Application to Recrystallization Study of Hot Deformed Al-Cu-Mg Alloys, Mater. Sci. Forum, 2007, 558, p 153–158.

G. Meng, B. Li, H. Li, H. Huang, and Z. Nie, Hot Deformation and Processing Maps of an Al–57 wt% Mg Alloy with Erbium, Mater. Sci. Eng. A, 2009, 517, p 132–137.

Y.C. Lin, X.-Y. Wu, X.-M. Chen, J. Chen, D.-X. Wen, J.-L. Zhang, and L.-T. Li, EBSD study of a Hot Deformed Nickel-Based Superalloy, J. Alloy. Compd., 2015, 640, p 101–113.

X.-M. Chen, Y.C. Lin, D.-X. Wen, J.-L. Zhang, and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2014, 57, p 568–577.

T.J. Ballard, J.G. Speer, K.O. Findley, and E. De Moor, Double Twist Torsion Testing to Determine the Non Recrystallization Temperature, Sci. Rep., 2021, 11, p 1–19.

A. Hadadzadeh, F. Mokdad, M. Wells, and D. Chen, A New Grain Orientation Spread Approach to Analyze the Dynamic Recrystallization Behavior of a Cast-Homogenized Mg-Zn-Zr Alloy Using Electron Backscattered Diffraction, Mater. Sci. Eng., A, 2018, 709, p 285–289.

B. Aashranth, D. Samantaray, M.A. Davinci, S. Murugesan, U. Borah, S.K. Albert, and A. Bhaduri, A Micro-Mechanism to Explain the Post-DRX Grain Growth at Temperatures> 0.8 Tm, Mater. Charact., 2018, 136, p 100–110.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shao, Y., Liu, Q., Yan, L. et al. A New Constitutive Model for 7055 Aluminum Alloy. J. of Materi Eng and Perform 31, 8183–8198 (2022). https://doi.org/10.1007/s11665-022-06869-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06869-3