Abstract

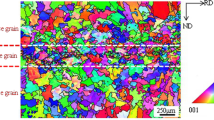

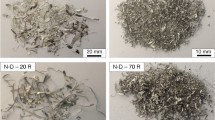

The effect of thermomechanical treatments (TMT) on the microstructuresand properties of Cu-1.5Ni-0.3Si-0.03P-0.05Mg leadframe alloy wasinvestigated. The Cu-base leadframe alloy was received as hot rolledplates with 8 mm thickness. The hot rolled plates were solutiontreated at 700°C or 800°C for 1 hour, and coldrolled with 40–85% reduction, then followed by aging treatment at450°C. The leadframe alloy solution treated at 800°Cshowed larger grain size of 15 μm comparing with the grain size of10 μm in leadframe alloy solution treated at 700°C. Theleadframe alloy with smaller grain size of 10 μm showed highertensile strength and lower electrical resistivity than that withlarger grain size of 15 μm. The dislocation density increased withincreasing reduction ratio of cold rolling from 40% to 85% andresulted in finer Ni2Si precipitates. Tensile strength increasedand electrical resistivity decreased with increasing reduction ratioof cold rolling due to the formation of finer Ni2Si precipitates.Two types of thermomechanical treatments were performed to enhance theproperties of leadframe alloy. One type of thermomechanical treatmentis to refine the grain size through the overaging, cold rollingfollowed by recrystallization. The recrystallization process improvedthe tensile strength to 540 MPa and elongation to 15% by reducing thegrain size to 5 μm. The other type of thermomechanical treatmentis to refine the precipitate size by two-step aging process. Thetwo-step aging process increased the tensile strength to 640 MPa andreduced the electrical resistivity to1.475 × 10−8 Ωm by reducing the size of Ni2Si precipitates to 4 nm.

Similar content being viewed by others

References

J. Crane and J. F. Breedis, Packages 33 (1985) 483.

D. J. Lee, Semiconductor 10 (1987) 204.

M. L. Mings, “Electronic Materials Handbook,” No. 1 (ASM international, Ohio, 1992) p. 483.

H. Koeppen and L. Muller, IEEE Trans. on Components Hybrids and Manufacturing Tech. 9 (1986) 1.

J. Kobelco, Tech. Rev. 2 (1989) 1.

H. Koeppen, J. Mater. Sci. 20 (1986) 1192.

M. K. Bharagava and S. Shan, Z. Metallkd. 63 (1972) 155.

M. D. Teplitskiy and A. K. Nikolayev, Fiz. Met. Metalloved 40 (1975) 1240.

D. Tunbill, Acta Metall. 8 (1960) 277.

T. C. Tisone, G. Y. Chin and B. W. Wonsiewiez, Metall. Trans. 1 (1970) 2010.

D. B. Roach, R. B. Fisher and J. H. Jackson, Trans. of ASM 46 (1953) 329.

Z. Rdzawski and J. Stobrawa, Mater. Sci. Tech. 9 (1993) 142.

J. C. M. Li, Trans. ASM. 227 (1963) 239.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ryu, H.J., Baik, H.K. & Hong, S.H. Effect of thermomechanical treatments on microstructure and properties of Cu-base leadframe alloy. Journal of Materials Science 35, 3641–3646 (2000). https://doi.org/10.1023/A:1004830000742

Issue Date:

DOI: https://doi.org/10.1023/A:1004830000742