Abstract

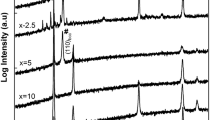

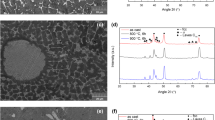

Alloys from the CoCrFeMnNi family remain the most studied austenitic high-entropy alloys. In this study, four alloys, i.e., Cantor alloy, A3S (modified nonequiatomic Cantor composition), both “pure” or doped with carbon (200 wt. ppm) and niobium (1.3 wt.%), were investigated. Firstly, alloys were induction cast using a cold-crucible method. The obtained ingots were molten, and rapidly solidified by melt-spinning at two cooling rates to obtain “ribbons”, typical of such processing. The effects of the solidification rate and the presence of carbon and niobium on the microstructure and hardness were studied. All the studied alloys show an fcc structure. The lattice parameter of the fcc phase increases with the increasing cooling rate, and with the addition of niobium and carbon, which confirms at least a partial presence of these elements in solid solution. Yet, TEM observations revealed the formation of nanometric NbC precipitates. The microstructure of melt-spun ribbons consists of equiaxed grains of a few micrometers in size. The higher cooling rate led to a small decrease in the grain size and a slight increase in hardness. Moreover, the hardness of doped alloys can be further improved by annealing (500°C for 24 h) through NbC precipitation.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.-W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006).

D.B. Miracle, and O.N. Senkov, Acta Mater. 122, 448 (2017).

J. Dąbrowa, M. Zajusz, W. Kucza, G. Cieślak, K. Berent, T. Czeppe, T. Kulik, and M. Danielewski, J. Alloys Compd. 783, 193 (2019).

K. Biswas, J.W. Yeh, P.P. Bhattacharjee, and J.T.M. DeHosson, Scr. Mater. 188, 54 (2020).

B. Gludovatz, D. Catoor, E.H. Chang, A. Hohenwarter, E.P. George, and R.O. Ritchie, Science (80-) 345, 1153 (2014).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

T.K. Tsao, A.C. Yeh, C.M. Kuo, K. Kakehi, H. Murakami, J.W. Yeh, and S.R. Jian, Sci. Rep. 7, 1 (2017).

S.S. Nene, K. Liu, M. Frank, R.S. Mishra, R.E. Brennan, K.C. Cho, Z. Li, and D. Raabe, Sci. Rep. 7, 16167 (2017).

O. El-Atwani, N. Li, M. Li, A. Devaraj, J.K.S. Baldwin, M.M. Schneider, D. Sobieraj, J.S. Wróbel, D. Nguyen-Manh, S.A. Maloy, and E. Martinez, Sci. Adv. 5, eaav2002 (2019).

H. Luo, W. Lu, X. Fang, D. Ponge, Z. Li, and D. Raabe, Mater. Today 21, 1003 (2018).

Y. Shi, B. Yang, X. Xie, J. Brechtl, K.A. Dahmen, and P.K. Liaw, Corros. Sci. 119, 33 (2017).

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, and E.P. George, Acta Mater. 112, 40 (2016).

E.J. Pickering, R. Muñoz-Moreno, H.J. Stone, and N.G. Jones, Scr. Mater. 113, 106 (2016).

B. Cantor, Prog. Mater. Sci. 120, 100754 (2020).

J.B. Seol, J.W. Bae, Z. Li, J. Chan Han, J.G. Kim, D. Raabe, and H.S. Kim, Acta Mater. 151, 366 (2018).

N.D. Stepanov, N.Y. Yurchenko, M.A. Tikhonovsky, and G.A. Salishchev, J. Alloys Compd. 687, 59 (2016).

J. Li, B. Gao, Y. Wang, X. Chen, Y. Xin, S. Tang, B. Liu, Y. Liu, and M. Song, J. Alloys Compd. 792, 170 (2019).

K.S. Chung, P.M. Yiu, T.F. Hung, and C.H. Shek, J. Alloys Compd. 871, 159587 (2021).

J.Y. Ko, and S.I. Hong, J. Alloys Compd. 743, 115 (2018).

H. Cheng, H.Y. Wang, Y.C. Xie, Q.H. Tang, and P.Q. Dai, Mater. Sci. Technol. 33, 2032 (2017).

C. Scott, B. Remy, J.L. Collet, A. Cael, C. Bao, F. Danoixd, B. Malardc, and C. Curfse, Int. J. Mater. Res. 102, 538 (2011).

N. Gao, D.H. Lu, Y.Y. Zhao, X.W. Liu, G.H. Liu, Y. Wu, G. Liu, Z.T. Fan, Z.P. Lu, and E.P. George, J. Alloys Compd. 792, 1028 (2019).

E. Abbasi, and K. Dehghani, Mater. Sci. Eng. A 753, 224 (2019).

E. Abbasi, and K. Dehghani, J. Alloys Compd. 783, 292 (2019).

E. Abbasi, and K. Dehghani, Mater. Sci. Eng. A 772, 138812 (2020). https://doi.org/10.1016/j.msea.2019.138812

E. Abbasi, and K. Dehghani, Mater. Sci. Eng. A 772, 138771 (2020). https://doi.org/10.1016/j.msea.2019.138771

G. Bracq, M. Laurent-Brocq, C. Varvenne, L. Perrière, W.A. Curtin, J.M. Joubert, and I. Guillot, Acta Mater. 177, 266 (2019).

S.F. Liu, Y. Wu, H.T. Wang, J.Y. He, J.B. Liu, C.X. Chen, X.J. Liu, H. Wang, and Z.P. Lu, Intermetallics 93, 269 (2018).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Acta Mater. 62, 105 (2014).

G. Qin, R. Chen, H. Zheng, H. Fang, L. Wang, Y. Su, J. Guo, and H. Fu, J. Mater. Sci. Technol. 35, 578 (2019).

A. Fraczkiewicz, French Patent, FR-1459567 (2014).

M. Mroz, Design and Structural Optimization of a High Entropy Alloy (HEA) of the CoCrFeMnNi Family with High Mechanical Resistance, Ph.D. thesis, Ecole des Mines de Saint Etienne, France (2018).

E.J. Lavernia, and T.S. Srivatsan, J. Mater. Sci. 45, 287 (2010).

A.G. Gillen, and B. Cantor, Acta Metall. 33, 1813 (1985).

J. Rogal, F. Morgiel, B.B. Stein, and J. Dutkiewicz, Mater. Charact. 148, 134 (2019).

C. Chen, H. Zhang, Y. Fan, W. Zhang, R. Wei, T. Wang, T. Zhang, and F. Li, J. Magn. Magn. Mater. 502, 166513 (2020).

T.P. Yadav, S. Mukhopadhyay, S.S. Mishra, N.K. Mukhopadhyay, and O.N. Srivastava, Philos. Mag. Lett. 97, 494 (2017).

C. Chen, H. Zhang, Y. Fan, R. Wei, W. Zhang, T. Wang, T. Zhang, K. Wu, F. Li, S. Guan, and J. Jiang, Intermetallics 122, 106778 (2020).

Q. Hu, S. Guo, J.M. Wang, Y.H. Yan, S.S. Chen, D.P. Lu, K.M. Liu, J.Z. Zou, and X.R. Zeng, Sci. Rep. 7, 1 (2017).

B. Sarac, V. Zadorozhnyy, E. Berdonosova, Y.P. Ivanov, S. Klyamkin, S. Gumrukcu, A.S. Sarac, A. Korol, D. Semenov, M. Zadorozhnyy, A. Sharma, A.L. Greer, and J. Eckert, RSC Adv. 10, 24613 (2020).

V.I. Tkatch, A.I. Limanovskii, S.N. Denisenko, and S.G. Rassolov, Mater. Sci. Eng. A 323, 91 (2002).

T. Gheiratmand, H.R.M. Hosseini, P. Davami, F. Ostadhossein, M. Song, and M. Gjoka, Nanoscale 5, 7520 (2013).

A. Druker, P. La Roca, P. Vermaut, P. Ochin, and J. Malarría, Mater. Sci. Eng. A 556, 936 (2012).

C. Chattopadhyay, A. Prasad, and B.S. Murty, Acta Mater. 153, 214 (2018).

M. Laurent-Brocq, L. Perrière, R. Pirès, F. Prima, P. Vermaut, and Y. Champion, Mater. Sci. Eng. A 696, 228 (2017).

F. Otto, N.L. Hanold, and E.P. George, Intermetallics 54, 39 (2014).

Y. Lin, B. Wu, S. Li, S. Mao, X. Liu, Y. Zhang, and L. Wang, Mater. Sci. Eng. A 621, 212 (2015).

Y. Lin, S. Mao, Z. Yan, Y. Zhang, and L. Wang, J. Alloys Compd. 651, 699 (2015).

D.J. Powell, R. Pilkington, and D.A. Miller, Acta Metall. 36, 713 (1988).

E. Ma, JOM 58, 49 (2006).

Acknowledgements

The authors would like to acknowledge the late Dr. Jerzy Latuch (WUT) for the preparation of alloys by melt-spinning. The authors gratefully thank the staff from the MINES lab: Olivier Valfort (XRD analyses), Claude Varillon (alloys elaboration), Gilles Blanc (metallographic preparation of samples), and Delphine Juhem (samples preparation for TEM analyses).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Stasiak, T., Oleszak, D. & Fraczkiewicz, A. Effects of Solidification Conditions on Microstructure and Properties of High-Entropy Alloys from the CoCrFeMnNi Family. JOM 74, 4842–4852 (2022). https://doi.org/10.1007/s11837-022-05543-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05543-2