Abstract

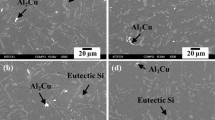

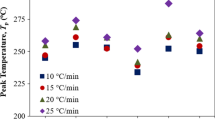

The solidification behaviour of an Al–7% Si–0.3% Mg alloy during rotary spray forming was studied. The ability to form a coating was insensitive to the thermal processing parameters, yielding material exchangess greater than 90%. The level of porosity varied typically between 1.5 and 4.75%. The dendrite arm spacing was evaluated and used to estimate the cooling rates. Typical dendrite secondary arm spacings were of the order of 3 μm, 12 μm and 25 μm, corresponding to cooling rates of 4630 K s−1, 72 K s−1 and 8 K s−1, respectively. The fraction primary precipitation was experimentally determined and the partition coefficient calculated indirectly using the Scheil equation. The partition coefficient is increased during rotary spray forming. This is explained by the presence of trapped vacancies at the solidification front. The vacancies change the solid's free energy and thus change the phase diagram and the partition coefficient. A simplistic analysis of entrapment and condensation of vacancies and their influence on the partition coefficient is made.

Similar content being viewed by others

References

A. R. E. Singer, J. Inst. Metals 100 (1972) 185.

Idem., Mater. Sci. Engng A135 (1991) 185.

E. J. Lavernia, E. M. Guiterrez-miravete, J. Szekely and N. J. Grant, Int. J. Rapid Solidification 4 (1988) 89.

E. M. Guiterrez-miravete, E. J. Lavernia, G. M. Trapaga and J. Szekely, ibid. 4 (1988) 125.

E. M. Guiterrez-miravete, E. J. Lavernia, G. M. Trapaga, J. Szekely and N. J. Grant, Metall. Trans. A 2 0 (1989) 71.

X. Zeng, H. Liu, M. G. Chu and E. J. Lavernia, ibid. 23 (1992) 3394.

X. Zeng, H. Liu and E. J. Lavernia, in “Metal matrix composites”, Vol. 1, Proceedings of Ninth International Conference on Composite Materials, edited byA. Miravete, University of Zaragosa, Zaragosa, Spain (1993).

A. E. W. Jarfors, in “Spray processing”, Proceedings of the Sefström Symposium, Royal Institute of Technology, Department of Metallurgy 1994, pp. 305–324.

A. E. W. Jarfors, Journal of Materials Processing 71 (1997) pp. 440–455.

German Patent 116, 698–1899 (1899).

German Patent 24, 460–1882 (1882).

E. J. Lavernia and Y. Wu, “Spray atomization and deposition” (Wiley, Chichester, West Sussex 1996).

S. Su, X. Liang, A. Moran and E. J. Lavernia, Int. J. Rapid Solidification 8 (1994) 161.

“Metals handbook”, Volume 8, “Metallography, structures and phase diagrams” (8th Edn 1973) pp. 396–397.

N. El-mahallawy, M. Taha and H. Fredriksson, Mater. Sci. Engng A179–A180 (1994) 587.

M. Haddad-sabzevar and H. Fredriksson, Metall. Trans. (1998) in press.

S. Berg, J. DahlstrÖm and H. Fredriksson, Iron Steel Inst. Jpn. Int. 35 (1995) 876.

T. Imura, H. Saka, T. Kobayashi, N. Kawabe, A. Sakai and H. Suga, Mem. Facul. Engng, Nagoya Univ. 39 (1987) 195.

H. Fredriksson and U. Åkerlind, Unpublished work (1996).

T. Gorecki, Ber. Bunsenges. Phys. Chem. 87 (1983) 801.

W. M. Lomer, “Vacancies and other point defects in metals and alloys” (Institute of Metals, London 1958) p. 79.

F. W. Schapink, Phil. Mag. 12 (1965) 1055.

D. Altenpohl, “Aluminium viewed from within” (Aluminium-Verlag, Düsseldorf 1982) p. 74.

C. De W. Van siclen and W. G. Wolfer, Acta Metall. Mater. 49 (1992).

G. F. Bolling and D. Fainstein, Phil. Mag. 25 (1972) 45.

E. A. Brandes and G. B. Brook (eds), “Smithell's metals reference book”, Butterworth—Heinemann, Oxford, 7th Edn, (1992).

E. Ozawa and H. Kimura, Acta Metall. 18 (1970) 995.

V. Heine and Hafner, in “Proceedings of the Conference on Many-Atom Interactions in Solids”, edited byR. M. Nieminen, M. J. Puska and M. J. Manninen, Pajulahti, 5–9 June (1989) pp. 12–31.

M. J. Aziz, Metall. Trans. A 27 (1996) 671.

M. J. Aziz and T. Kaplan, Acta Metall. 36 (1988) 2335.

K. A. Jackson, G. H. Gilmer and D. E. Temkin, Phys. Rev. Lett. 75 (1995) 2530.

W. J. Boettinger and M. J. Aziz, Acta Metall. 37 (1989) 3379.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jarfors, A.E.W. Solidification behaviour of Al–7% Si–0.3% Mg during rotary spray forming. Journal of Materials Science 33, 3907–3918 (1998). https://doi.org/10.1023/A:1004632326038

Issue Date:

DOI: https://doi.org/10.1023/A:1004632326038