Abstract

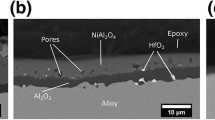

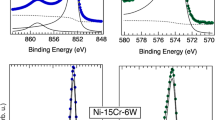

The sulfidation mechanism of Ni–20Cr and Ni–13.5Co–20Cralloys was investigated at 873 K under low sulfur pressures (10−4.0,10−5.5, and 10−7.0 Pa) inH2–H2S gas mixtures by marker measurements ofdiffusion in the scales, the composition profiles in the scale and alloy,and a determination of the structure and composition of the equilibratedsulfide phases. A Pt marker experiment on the Ni–20Cr alloy indicatedchanges in the marker morphology, with marker fragments in the inner Cr3S4layer and a swelled marker section in the outer Ni3S2layer where the composition ranged from pure Pt to a Pt-(76–80) at.%Nialloy. The changes in morphology and composition of the Pt markers wereexplained by the phase constitution of the Pt–Ni–S andPt–Cr–S systems. The growth of the multilayer sulfide structureson both alloys at sulfur pressures above 10−5.5 Pa wascontrolled by the outward diffusion of cations through the inner Cr3S4layer. While, the inward sulfur and outward-chromium diffusion in the alloysubstrate played an important role in the internal sulfidation and in theexternal scale growth at 10−7.0 Pa. The concentration profiles of eachelement were measured by EPMA and the corresponding diffusion paths areplotted in a phase diagram of the Ni–Cr–S system at 873 K.

Similar content being viewed by others

REFERENCES

P. Dowson, D. M. Rishel and N. S. Bournstein, Proc. 24th Turbomachinery Symp. (Turbomachinery Laboratory, Texas A&M University, College Station, Texas, 1995), p. 11.

H. Yakuwa, T. Narita, M. Kawasaki, M. Miyasaka, C. Fang, T. Go, and S. Nakahama, Proc. 27th Turbomachinery Symp. (Turbomachinery Laboratory, Texas A&M University, College Station, Texas, 1998), p. 49.

S. Mrowec, T. Werber, and M. Zastawnik, Corros. Sci. 6, 47 (1966).

G. Romeo, W. W. Smeltzer, and J. S. Kirkaldy, J. Electrochem. Soc. 118, 740 (1971).

J. A. Chitty and W. W. Smeltzer, J. Electrochem. Soc. 120, 1362 (1973).

G. Romeo, W. W. Smeltzer, and J. S. Kirkaldy, J. Electrochem. Soc. 118, 1336 (1971).

H. Yakuwa, M. Miyasaka, and T. Narita, Proc. 30th Intern. Congr. (Melbourne, Australia, 1996), Paper No. 288.

H. Yakuwa, M. Miyasaka, and T. Narita, Proc. 14th Intern. Congr. (Cape Town, South Africa, 1999), Paper No. 56.

C. Fang, H. Yakuwa, M. Miyasaka, and T. Narita, Oxid. Met. in press.

JCPDS, Powder Diffraction File, No. 21-255.

F. Jellinek, Acta Crystallogr. 10, 620 (1957).

C. Fang, H. Yakuwa, M. Miyasaka, and T. Narita, Oxid. Met. in press.

T. Narita and T. Ishikawa, Mater. Sci. Eng. A120, 31 (1989).

Thermodynamic Data Base MALT, Version 2 for PC-9801, The Japan Society of Calorimetry and Thermal Analysis.

H. Rau, J. Less. Common Met. 55, 205 (1977).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fang, C., Yakuwa, H., Miyasaka, M. et al. Sulfidation Mechanism of Ni–20Cr and Ni–13.5Co–20Cr Alloys at 873 K under Low Sulfur Pressures in H2S–H2 Atmospheres. Oxidation of Metals 54, 163–171 (2000). https://doi.org/10.1023/A:1004615032355

Issue Date:

DOI: https://doi.org/10.1023/A:1004615032355