Abstract

Further detailed analysis of the indentation size effect exhibited by some single-phase metals leads to a new, very accurate, descriptive equation. This affords consistent and realistically low evaluation of macrohardness from micro-indentation test data.

The indentation size effect exhibited by fused silica is also matched precisely by the new description, demonstrating a common phenomenology regardless of the different micro-mechanisms sustaining indentation.

Comparison of data from standard and low-load Vicker's tests with data from ultra-micro-indentation with a Berkovich indenter establishes continuity of a monotonic size effect throughout the entire range of indent size.

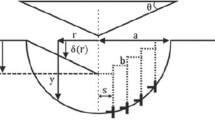

The observed size effects are consistent with the projected refinement of a previously proposed model of indentation that attributed the effect to varying importance of the constrained flexing at the perimeter of the indent.

The magnitude of the size effect appears to be a measure of the resistance to strain concentration in the perimeter flexure zone. The large size effect for eminently plastic metals indicates that restricted micro-deformation capability is not the major cause. © 1998 Kluwer Academic Publishers

Similar content being viewed by others

References

R. SMITH and G. SANDLAND, Proc. Inst. Mech. Engng. 1 (1922) 623.

L. E. SAMUELS, in “Microindentation techniques in materials science and engineering”, edited by Blau and Lawn (ASTM STP 889, 1986) p. 5.

D. TABOR, ibid p. 129

E. MEYER, Zeit. Ver. Deutsch. Ing. 52 (1908) 645.

D. TATE, Trans. Amer. Soc. Metall. 35 (1945) 374.

B. W. MOTT, “Micro-indentation hardness testing” (Butterworths, London, 1956).

H. BUCKLE, Metall. Rev. 4 (1959) 49.

M. ATKINSON, Mater. Sci. Engng. A197 (1995) 165.

Idem., J. Mater. Res. 10 (1995) 2908.

Idem., J. Mater. Sci. 30 (1995) 1728.

P. M. SARGENT, in “Microindentation techniques in materials science and engineering”, edited by Blau and Lawn (ASTM STP 889, 1986) p. 160.

M. ATKINSON and H. SHI, Mater. Sci. Technol. 5 (1989) 613.

H. SHI and M. ATKINSON, J. Mater. Sci. 25 (1990) 2111.

M. ATKINSON, J. Testing and Evaluation 19 (1991) 368.

J. BYSTRZYCKI and R. A. VARIN, Scripta Metall. Mater. 29 (1993) 605.

M. ATKINSON, Int. J. Mech. Sci. 33 (1991) 843.

R. HILL, R. H. LEE and S. J. TUPPER, Proc. Roy. Soc. A188 (1947) 273.

N. ALAM, University of Wollongong, Australia, private communication.

D. DENGEL and E. KROESKE, Materpruf. 18 (1976) 161.

F. FRÖHLICH, P. GRAU and W. GRELLMANN, Phys. Status Solidi (a) 42 (1977) 79.

D. NEWEY, M. A. WILKINS and H. M. POLLOCK, J. Phys. E 15 (1982) 119.

M. F. DOERNER and W. D. NIX, J. Mater. Res. 1 (1986) 601.

T. J. BELL, A. BENDELI, J. S. FIELD, M. V. SWAIN and E. G. THWAITE, Metrologia 28 (1991/2) 463.

M. V. SWAIN, C.S.I.R.O., Sydney, Private communication.

W. C. OLIVER and G. M. PHARR, J. Mater. Res. 7 (1992) 1564.

M. C. SHAW and G. J. DASALVA, J. Engng. Industry 92 (1970) 480.

D. S. DUGDALE, J. Mech. Phys. Solids 3 (1955) 206.

S. J. BULL, T. F. PAGE and E. H. YOFFE, Phil. Mag. Lett. 59 (1989) 281.

T. F. PAGE, W. C. OLIVER and C. J. MCHARGUE, J. Mater. Res. 7 (1992) 450.

S. S. CHIANG, D. B. MARSHALL and A. G. EVANS, J. Appl. Phys. 53 (1982) 298.

A. K. BATTACHARYA and W. D. NIX, Int. J. Sol. Struct. 24 (1988) 881.

R. HILL, B. STORÅKERS and A. B. ZDUNEK, Proc. Roy. Soc. A423 (1989) 301.

W. G. CROUCH, ME (hons) thesis, University of Wollongong, Australia, 1993.

H. LI, A. GHOSH, Y. H. HAN, and R. C. BRADT, J. Mater. Res. 8 (1993) 1028.

H. LI and R. C. BRADT, J. Mater. Sci. 28 (1993) 917.

D. G. HOLLOWAY; “Strength of inorganic glasses”, (Plenum Press, New York 1986) p. 1.

N. GANE and J. M. COX, Phil. Mag. 19 (1970) 881.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Atkinson, M. Phenomenology of the size effect in hardness tests with a blunt pyramidal indenter. Journal of Materials Science 33, 2937–2947 (1998). https://doi.org/10.1023/A:1004350512987

Issue Date:

DOI: https://doi.org/10.1023/A:1004350512987