Abstract

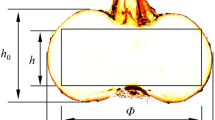

Bamboo weevil larva has excellent performance on cutting plant fiber. From quantitative analysis of the mandible incisor profile of bamboo weevil larva, it was found that the primary cutting edge of incisor is close to a standard circular arc, which is helpful for improving the cutting efficiency of mandible incisor. Inspired from the geometrical characteristics of the bamboo weevil larva’s incisor, a new bionic mincing blade was designed and manufactured. The experimental results of chopping equal Chinese cabbages showed that, when the rotational speed was 1400 rpm, the mincing energy consumption of bionic blade was 12.8% lower than conventional blade and the chopping efficiency of bionic blade was 12.5% higher. Meanwhile, the mincing capacity of bionic blade was 36 kg·h−1, which was 1.5 times of that of the conventional blade, 24 kg·h−1. The material weight loss rate was 11.2 % lower than that of conventional blade. The qualification rate of the minced cabbage chopped by bionic blade was 93.3%, which was higher than the 85.7% of conventional blade. Therefore, the bionic blade could obviously promote the quality of product and the working efficiency of mincing machine. These results would provide guidance for designing cutting component of vegetable choppers, succulence cutter and other food processing machines.

Similar content being viewed by others

References

Krickmeier J, Schnaeckel W, Pongjanyanukul W, Schnaeckel D, Micklisch I. Analysis for optimization of the mincing process Part 2: Distribution of necessary cutting works in dependence of machinery and raw material influences. Fleischwirtschaft, 2012, 92, 88–92.

Valentas K J, Clark J P, Levin L. Food Processing Operations and Scale-up, Marcel Dekker, New York, USA, 1991.

Lehto M, Kuisma R, Määttä J, Kymäläinen H R, Mäki M. Hygienic level and surface contamination in fresh-cut vegetable production plants. Food Control, 2011, 22, 469–475.

Jongen W M F. Fruits and Vegetables Processing: Improving Quality, Woodhead Publisher, Cambridge, UK, 2002.

Thompson A K. Postharvest Technology of Fruits and Vegetables, Blackwell Publishing Limited, UK, 2003.

Irmscher S B, Gibis M, Herrmann K, Kohlusb R, Weiss J. Manufacturing costs of fermented sausages with new technologies noticeable reducible: Energy-saving potential during the processing of fermented sausages with the grinder-fillers by higher raw material temperature. Fleischwirtschaft, 2011, 91, 115–121.

Dowgiallo A. Cutting force of fibrous materials. Journal of Food Engineering, 2005, 66, 57–61.

Irmscher S B, Böjthe Z, Herrmann K, Gibis M, Kohlus R, Weiss J. Influence of filling conditions on product quality and machine parameters in fermented coarse meat emulsions produced by high shear grinding and vacuum filling. Journal of Food Engineering, 2013, 117, 316–325.

Krzywdzińska-Bartkowiak M, Piątek M, Dolata W. A comparative quality appraisal of finely comminuted batters produced using three types of knives. Meat Science, 2014, 96, 429–435.

McCarthy C T, Annaidh A N, Gilchrist M D. On the sharpness of straight edge blades in cutting soft solids: Part II-Analysis of blade geometry. Engineering Fracture Mechanics, 2010, 77, 437–451.

Tong J, Moayad B Z, Ma Y H, Sun J Y, Chen D H, Jia H L, Ren L Q. Effects of biomimetic surface designs on furrow opener performance. Journal of Bionic Engineering, 2009, 6, 280–289.

Han Z, Zhang J, Ge C, Lü Y, Jiang J, Liu Q, Ren L. Anti-erosion function in animals and its biomimetic application. Journal of Bionic Engineering, 2010, 7, S50–S58.

Zhu W, Zhao X, Gong B. Left-handed metamaterials based on a leaf-shaped configuration. Journal of Applied Physics, 2011, 109, 093504.

Jia H, Li C, Zhang Z, Wang G. Design of bionic saw blade for corn stalk cutting. Journal of Bionic Engineering, 2013, 10, 497–505.

Li M, Chen D, Zhang S, Tong J. Biomimetic design of a stubble-cutting disc using finite element analysis. Journal of Bionic Engineering, 2013, 10, 118–127.

Meyers M A, Lin A Y M, Lin Y S, Olevsky E A, Georgalis S. The cutting edge: Sharp biological materials. JOM, 2008, 60, 19–24.

Kuřavová K, Hajduková L, Kočárek P. Age-related mandible abrasion in the groundhopper Tetrix tenuicornis (Tetrigidae, Orthoptera). Arthropod Structure & Development, 2014, 43, 187–192.

Ball G E, Acorn J H, Shpeley D. Mandibles and labrum-epipharynx of tiger beetles: Basic structure and evolution (Coleoptera, Carabidae, Cicindelitae). ZooKeys, 2011, 147, 39–83.

Angelini D R, Smith F W, Aspiras A C, Kikuchi M, Jockusch E L. Patterning of the adult mandibulate mouth-parts in the red flour beetle, Tribolium castaneum. Genetics, 2012, 190, 639–654.

Yang Y J, Wang S F, Mu C. A Preliminary report on investigation of bamboo diseases and pests in Leshan city, Sichuan Province. World Bamboo and Rattan, 2008, 6, 39–43. (in Chinese)

Hartley R, Zisserman A. Multiple View Geometry in Computer Vision, Cambridge university press, Cambridge, UK 2003.

Winston P H, Horn B. The Psychology of Computer Vision, McGraw-Hill, New York, USA, 1975.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tong, J., Xu, S., Chen, D. et al. Design of a Bionic Blade for Vegetable Chopper. J Bionic Eng 14, 163–171 (2017). https://doi.org/10.1016/S1672-6529(16)60387-6

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(16)60387-6