Abstract

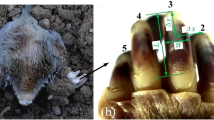

The fore claws of the nymph of Cryptotympana atrata have excellent ability to cut and dig soil. Inspired by this, we designed a biomimetic stubble cutter to reduce the cutting resistance. Reverse engineering and 3D print technology were applied to design the biomimetic stubble cutter. Two types of biomimetic corn stubble cutters with different tooth heights (5 mm and 2.5 mm) were designed. The cutting ability of biomimetic corn stubble cutters was compared to the conventional design by the quadratic regression orthogonal test. Tooth height, dip angle of cutting edge, and cutting velocity were chosen as orthogonal test factors. The biomimetic stubble cutters show lower cutting resistance than the conventional one. Cutting velocity exerts the least effect on cutting resistance, followed by tooth height and dip angle of cutting edge. Optimal combination with the least cutting resistance is tooth height of 2.5 mm and dip angle of cutting edge of 40° while the cutting resistance does not vary remarkably with cutting velocity. Test results indicate the serrated structure design as a principal factor for cutting resistance reduction. The biomimetic stubble cutter design, inspired by the soil-cutting mechanism of Cryptotympana atrata nymph, remarkably improves the performance of stubble cutter.

Similar content being viewed by others

References

Sang Z T. Agricultural Machinery, China Machine Press, Beijing, China, 1988. (in Chinese)

Wu T, Ma X, Chen J W, Wei K X. Present state and development trends on technology of corn stubble mechanical processing. Journal of Agricultural Mechanization Research, 2014, 36, 238–242. (in Chinese)

Tagar A A, Ji C, Ding Q, Adamowski J, Chandio F A, Mari I A. Soil failure patterns and draft as influenced by consistency limits: An evaluation of the remolded soil cutting test. Soil and Tillage Research, 2014, 137, 58–66.

Maciejewski J, Mróz Z. Analysis of deformation and damage processes in soil-tool interaction problems. Bifurcations, Instabilities and Degradations in Geomaterials, Springer Berlin Heidelberg, 2011, 325–345.

Ma X, Chen X S, Qi L, Chen G R, Lai Y Z. Design and experiment of root stubble harvester for corn. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42, 21–25.

Quan L Z, Tong J, Zeng B G, Chen D H. Optimization design of sliding cutting edge curve of corn rootstalk cutting tool. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27, 13–17. (in Chinese)

Lu Y X. Significance and progress of bionics. Journal of Bionics Engineering, 2004, 1, 1–3.

Vincent J F V, Mann D L. Systematic technology transfer from biology to engineering. Philosophical Transactions of the Royal Society A, 2002, 360, 159–173.

Cui X X, Zhang N, Wang Y M, Ren L Q, Xu X B, Chen B C, Li A Q. Constitution of pangolin scales and mechanism of reducing adhesion of soil to their cuticle. Transactions of the Chinese Society of Agricultural Engineering, 1990, 6, 15–22. (in Chinese)

Ren L Q. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines. Science in China Series E: Technological Sciences, 2009, 52, 273–284.

Ji W F, Chen D H, Jia H L, Tong Jin. Experimental investigation into soil-cutting performance of the claws of mole rat (Scaptochirus moschatus). Journal of Bionic Engineering, 2010, 7, S166–S171.

Tong J, Moayad B Z, Ma Y H, Sun J Y, Chen D H, Jia H L, Ren L Q. Effects of biomimetic surface designs on furrow opener performance. Journal of Bionic Engineering, 2009, 6, 280–289.

Jia H L, Li C Y, Zhang Z H, Wang G. Design of bionic saw blade for corn stalk cutting. Journal of Bionic Engineering, 2013, 10, 497–505.

Li M, Chen D H, Zhang S J, Tong J. Biomimetic design of a stubble-cutting disc using finite element analysis. Journal of Bionic Engineering, 2013, 10, 118–127.

Li M. Design of Bionic Stubble-Cutting Blade Based on the Structure Characteristic of Praying Mantis (Mantis religiosa Linnaeus)’s Foreleg, doctoral dissertation, Jilin University, China, 2013. (in Chinese)

Bouwer N, Midgley J M, Timm A E, Villet M H. Successful identification of the final instar nymph of Quintilia carinata (Thunberg) (Hemiptera: Cicadidae) by DNA extraction from the exuvium. Journal of Natural History, 2014, 48, 937–943.

Clay K, Shelton A L, Winkle C. Differential susceptibility of tree species to oviposition by periodical cicadas. Ecological Entomology, 2009, 34, 277–286.

Xu L, Lin M X, Li J Q, Wang Z L, Chirende B. Three-dimensional geometrical modelling of wild boar head by reverse engineering technology. Journal of Bionic Engineering, 2008, 5, 85–90.

Wang J, Gu D X, Yu Z Y, Tan, C B, Zhou L S. A framework for 3D model reconstruction in reverse engineering. Computers & Industrial Engineering, 2012, 63, 1189–1200.

Weir D J, Milroy M J, Bradley C, Vickers G W. Reverse engineering physical models employing wrap-around B-spline surfaces and quadrics. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 1996, 210, 147–157.

Seo J, Lee H C, Park S. Reconstruction of a composite surface by reverse engineering techniques. The International Journal of Advanced Manufacturing Technology, 2001, 17, 639–643.

Li S W, Tong J, Zhang S J, Chen B C. Reverse engineering and engineering bionics. Transactions of the Chinese Society of Agricultural Engineering Machinery, 2004, 35, 109–112. (in Chinese)

Baxter I D, Mehlich M. Reverse engineering is reverse forward engineering. Science of Computer Programming, 2000, 36, 131–147.

Lee I K. Curve reconstruction from unorganized points. Computer Aided Geometric Design, 2000, 17, 104–112.

Díaz-Vilarino L, Khoshelham K, Martínez-Sanchez J, Arias P. 3D modeling of building indoor spaces and closed doors from imagery and point clouds. Sensors, 2015, 15, 3491–3512.

Smith J J, Hasiotis S T. Traces and burrowing behaviors of the cicada nymph Cicadetta calliope: Neoichnology and paleoecological significance of extant soil-dwelling insects. Palaios, 2008, 23, 503–513.

Box G E P, Behnken D W. Some new three level designs for the study of quantitative variables. Technometrics, 1960, 2, 455–475.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, Z., Liu, W., Tong, J. et al. Design and experiments of biomimetic stubble cutter. J Bionic Eng 13, 335–343 (2016). https://doi.org/10.1016/S1672-6529(16)60306-2

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(16)60306-2