Abstract

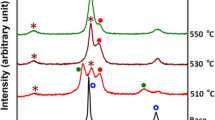

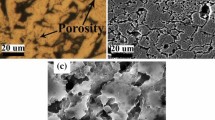

In this study, the applicability of plasma nitriding treatment in the production of non-magnetic and corrosion resistant layer on 316L stainless steel implant material was investigated. 316L stainless steel substrates were plasma nitrided at temperatures of 350 °C, 375 °C, 400 °C, 425 °C and 450 °C for 2 h in a gas mixture of 50% N2–50% H2, respectively. It was determined that the treatment temperature is the most important factor on the properties of the corrosion resistant layer of 316L stainless steel. The results show that s-phase formed at the temperatures under 400 °C, and at the temperatures above 400 °C, instead of s-phase, CrN and γ′-Fe4N phases were observed in the modified layer. The electrical resistivity and surface roughness of the modified layer increase with treatment temperature. Under 400 °C the corrosion resistance increased with the temperature, above 400 °C it decreased with the increase in treatment temperature. It was analyzed that the electrical resistivity and the soft (ideal) ferromagnetic properties of 316L stainless steel increased with treatment temperature during nitriding treatment. Also, plasma nitriding at low temperatures provided magnetic behavior close to the ideal untreated 316L stainless steel.

Similar content being viewed by others

References

Nosei L, Avalos M, Gómez B, Nachez L, Feugeas J. Stability under temperature of expanded austenite developed on stainless steel AISI 316L by ion nitriding. Thin Solid Films, 2004, 468, 134–141.

Wang J, Xiong J, Peng Q, Fan H, Wang Y, Li G, Shen B. Effect of DC plasma nitriding parameters on microstructure and properties of 304L stainless steel. Materials Characterization, 2009, 60, 197–203.

Wang Q, Zhang L, Dong J. Effects of plasma nitriding on microstructure and tribological properties of CoCrMo alloy implant materials. Journal of Bionic Engineering, 2010, 7, 337–344.

Yetim A F, Alsaran A, Çelik A. Investigation of tribological and electrochemical properties of dual layer after low temperature plasma carbo-nitriding. Surface Engineering, 2010, 26, 178–184.

Yetim A F, Alsaran A, Çelik A, Efeoglu I. Corrosion behaviour of Ti-DLC deposition on prenitrided 316L stainless steel and Ti-6Al-4V alloy. Corrosion Engineering Science and Technology, 2011, 46, 439–444.

Yıldız F, Yetim A, Alsaran A, Çelik A, Kaymaz İ. Fretting fatigue properties of plasma nitrided AISI 316L stainless steel: Experiments and finite element analysis. Tribology International, 2011, 44, 1979–1986.

Puchi-Cabrera E, Staia M, Ochoa-Pérez E, Teer D, Santana-Méndez Y, La Barbera-Sosa J, Chicot D, Lesage J. Fatigue behavior of a 316L stainless steel coated with a DLC film deposited by PVD magnetron sputter ion plating. Materials Science and Engineering: A, 2010, 527, 498–508.

Arslan E, İǧdil M C, Trabzon L, Kazmanli K, Gulmez T. The corrosion behaviour of austenitic 316L stainless steel after low-T plasma nitridation in the physiological solutions. Plasma Processes and Polymers, 2007, 4, S717–S720.

Luo Y, Yang L, Tian M. Influence of bio-lubricants on the tribological properties of Ti6Al4V alloy. Journal of Bionic Engineering, 2013, 10, 84–89.

Nosei L, Farina S, Ávalos M, Náchez L, Gómez B, Feugeas J. Corrosion behavior of ion nitrided AISI 316L stainless steel. Thin Solid Films, 2008, 516, 1044–1050.

Menthe E, Bulak A, Olfe J, Zimmermann A, Rie K-T. Improvement of the mechanical properties of austenitic stainless steel after plasma nitriding. Surface and Coatings Technology, 2000, 133–134, 259–263.

Ichii K, Fujimura K, Takase T. Structure of the ion-nitrided layer of 18-8 stainless steel. Technical Report of Kansai University, 1986, 135–144.

Singh V, Marchev K, Cooper C, Meletis E. Intensified plasma-assisted nitriding of AISI 316L stainless steel. Surface and Coatings Technology, 2002, 160, 249–258.

Gontijo L C, Machado R, Casteletti L C, Kuri S E, Nascente P A P. Study of the s phases formed on plasma-nitrided austenitic and ferritic stainless steels. In Chandra T, Wanderka N, Reimers W, Ionescu M (eds.), Thermec 2009, Trans Tech Publications Ltd, Stafa-Zurich, Switzerland, 2010, 775–780.

Williamson D L, Davis J A, Wilbur P J, Vajo J J, Wei R, Matossian J N. Relative roles of ion energy, ion flux, and sample temperature in low-energy nitrogen ion implantation of Fe-Cr-Ni stainless steel. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 1997, 127, 930–934.

Blawert C, Mordike B, Jirásková Y, Schneeweiss O. Structure and composition of expanded austenite produced by nitrogen plasma immersion ion implantation of stainless steels X6CrNiTi1810 and X2CrNiMoN2253. Surface and Coatings Technology, 1999, 116, 189–198.

Omari M A, Sevostianov I. Evaluation of the growth of dislocations density in fatigue loading process via electrical resistivity measurements. International Journal of Fracture, 2013, 179, 229–235.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials, 2006, 27, 2907–2915.

Yetim A F, Yildiz F, Alsaran A, Çelik A. Surface modification of 316L stainless steel with plasma nitriding. Kovove Materialy-Metallic Materials, 2008, 46, 105–116.

Rohde U L, Poddar A K, Patel P, Badea D, Schoepf K J. Low Thermal Drift, Tunable Frequency Voltage Controlled Oscillator, Google Patents, No:US7262670 B2-2007.

Fossati A, Borgioli F, Galvanetto E, Bacci T. Glow-discharge nitriding of AISI 316L austenitic stainless steel: Influence of treatment time. Surface and Coatings Technology, 2006, 200, 3511–3517.

Sun Y, Li X, Bell T. X-ray diffraction characterisation of low temperature plasma nitrided austenitic stainless steels. Journal of Materials Science, 1999, 34, 4793–4802.

Borgioli F, Fossati A, Galvanetto E, Bacci T, Pradelli G. Glow discharge nitriding of AISI 316L austenitic stainless steel: Influence of treatment pressure. Surface and Coatings Technology, 2006, 200, 5505–5513.

Smith A. The friction and sliding wear of unlubricated 316 stainless steel at room temperature in air. Wear, 1984, 96, 301–318.

Sun Y, Bell T. Silinding wear characteristics of low temperarure plasma nitrided 316 austenitic stainless steel. Wear, 1998, 218, 34–42.

Borgioli F, Fossati A, Galvanetto E, Bacci T. Glow-discharge nitriding of AISI 316L austenitic stainless steel: influence of treatment temperature. Surface and Coatings Technology, 2005, 200, 2474–80.

Wei B, Shima M, Pati R, Nayak S K, Singh D J, Ma R, Li Y, Bando Y, Nasu S, Ajayan P M. Room-temperature ferromagnetism in doped face-centered cubic Fe nanoparticles. Small, 2006, 2, 804–809.

Hannula S-P, Nenonen P, Hirvonen J-P. Surface structure and properties of ion-nitrided austenitic stainless steels. Thin Solid Films, 1989, 181, 343–350.

Öztürk O, Okur S, Riviere J. Structural and magnetic characterization of plasma ion nitrided layer on 316L stainless steel alloy. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2009, 267, 1540–1545.

Akamatsu K. Stainless steel 2000. Proceedings of an International Current Status Seminar on Thermochemical Surface Engineering of Stainless Steel, Maney Publ., London, 2000.

Abedi H, Salehi M, Yazdkhasti M, Hemmasian-E A. Effect of high temperature post-oxidizing on tribological and corrosion behavior of plasma nitrided AISI 316 austenitic stainless steel. Vacuum, 2010, 85, 443–447.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yetim, A.F., Yazıcı, M. Wear Resistance and Non-Magnetic Layer Formation on 316L Implant Material with Plasma Nitriding. J Bionic Eng 11, 620–629 (2014). https://doi.org/10.1016/S1672-6529(14)60073-1

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(14)60073-1