Abstract

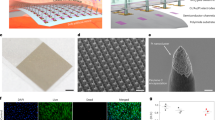

Ionic Polymer Metal Composite (IPMC) can be used as an electrically activated actuator, which has been widely used in artificial muscles, bionic robotic actuators, and dynamic sensors since it has the advantages of large deformation, light weight, flexibility, and low driving voltage, etc. To further improve the mechanical properties of IPMC, this paper reports a new method for preparing organic-inorganic hybrid Nafion/SiO2 membranes. Beginning from cast Nafion membranes, IPMCs with various tetraethyl orthosilicate (TEOS) contents were fabricated by electroless plating. The elastic moduli of cast Nafion membranes were measured with nano indenters, the water contents were calculated, and the cross sections of Nafion membranes were observed by scanning electron microscopy. The blocking force, the displacement, and the electric current of IPMCs were then measured on a test apparatus. The results show that the blocking force increases as the TEOS content gradually increases, and that both the displacement and the electric current initially decrease, then increase. When the TEOS content is 1.5%, the IPMC shows the best improved mechanical properties. Finally, the IPMC with the best improved performance was used to successfully actuate the artificial eye and tested.

Similar content being viewed by others

References

Oguro K, Kawami Y, Takenaka H. Bending of an ion-conducting polymer film-electrode composite by an electric stimulus at low voltage. Journal of Micromachine Society, 1992, 5, 27–30.

Shahinpoor M, Kim K J. Ionic polymer-metal composites: I. Fundamentals. Smart Materials and Structures, 2001, 10, 819–833.

Shahinpoor M, Kim K J. Mass transfer induced hydraulic actuation in ionic polymer-metal composites. Journal of Intelligent Material Systems and Structures, 2002, 13, 369–376.

Shahinpoor M, Kim K J. The effect of surface electrode resistance on the performance of ionic polymer-metal composite (IPMC) artificial muscles. Smart Materials and Structures, 2000, 9, 543–551.

Mosdale R, Gebel G, Pineri M. Water profile determination in a running proton exchange fuel cell using small-angle Newtron scattering. Journal of Membrane Science, 1996, 118, 269–277.

Nemat-Nasser S, Li J Y. Electromechanical response of ionic polymer-metal composites. Journal of Applied Physics, 2000, 87, 3321–3331.

Onishi K, Sewa S, Asaka K, Fujiwara N, Oguro K. The effects of counter ions on characterization and performance of a solid polymer electrolyte actuator. Electrochimica Acta, 2001, 46, 1233–1241.

Yeom S W, Oh I K. A biomimetic jellyfish robot based in ionic polymer metal composite actuators. Smart Materials and Structures, 2009, 18, 085002.

Tiwari R, Kim K J. Disc-shaped ionic polymer metal composites for use in mechano-electrical applications. Smart Materials and Structures, 2010, 19, 065016.

Yu M, Shen H, Dai Z D. Manufacture and performance of Ionic polymer-metal composites. Journal of Bionic Engineering, 2007, 4, 143–149.

Kim K J, Shahinpoor M. A novel method manufacturing three-dimensional ionic polymer-metal composites (IPMC) biomimetic sensors, actuators and artificial muscles. Polymer, 2002, 43, 797–802.

Lee J W, Kim J H, Chun Y S, Yoo Y T, Hong S M. The performance of Nafion-based IPMC actuators containing polypyrrole/alumina composite fillers. Macromolecular Research, 2009, 17 1032–1038.

Paquette J W, Kim K J, Kim D. Low temperature characteristics of ionic polymer-metal composite actuators. Sensors and Actuators A, 2005, 118, 135–143.

Asaka K, Fujiwara N, Oguro K, Onishi K, Sewa S. State of water and ionic conductivity of solid polymer electrolyte membranes in relation to polymer actuators. Journal of Electroanalytical Chemistry, 2001, 505, 24–32.

Kim S J, Lee I T, Kim Y H. Performance enhancement of IPMC actuator by plasma surface treatment. Smart Materials and Structures, 2007, 16, N6–N11.

Guo D J, Ding H T, Wei H J, He Q S, Yu M, Dai Z D. Hybrids perfluorosulfonic acid ionomer and silicon oxide membrane for application in ion-exchange polymer-metal composite actuators. Science in China Series E: Technological Sciences, 2009, 52, 3061–3070.

Liu X, Peng Y, Ji S. A new method to prepare organic- inorganic hybrid membranes. Desalination, 2008, 221, 376–382.

Tang H, Wan Z, Pan M, Jiang S P. Self-assembled Nafion-silica nanoparticles elevated-high temperature polymer electrolyte membrane fuel cells. Electrochemistry Communications, 2007, 9, 2003–2008.

He Q S, Yu M, Song L L, Ding H T, Zhang X Q, Dai Z D. Experimental study and model analysis of the performance of IPMC membranes with various thickness. Journal of Bionic Engineering, 2011, 8, 77–85.

Choi N J, Lee H K, Jung S, Lee S, Park K H. Electroactive polymer actuator with high response speed through anisotropic surface roughening by plasma etching. Journal of Nanoscience and Nanotechnology, 2008, 8, 5385–5388.

Choi N J, Lee H K, Jung S, Lee S, Park K H. Optimum condition of anisotropic plasma etching for improving bending properties of ionic polymer-metal composites. Journal of Nanoscience and Nanotechnology, 2010, 10, 3299–3303.

He Q S, Yu M, Ding H T, Guo D J, Dai Z D. Effects of anisotropic surface texture on the performance of ionic polymer-metal composite (IPMC). Proceedings of SPIE, Smart Structures/NDE Symposium, EAPAD Conference, San Diego, CA, USA, 2010, 7642, 76420Y.

Lee S G, Pandita S D, Park H C, Yoo Y T. Performance improvement of IPMC (ionic polymer metal composites) for a flapping actuator. International Journal of Control, Automation, and Systems, 2006, 4, 748–755.

Dai Z D, Yu M, Li Y X, He Q S. The One and Two Dimensional Bionic Eyes Actuated by IPMCs. CN Patent, 201110009203.3. (in Chinese)

Ke L Q. The Structure of the Rotatable Eyes of a Doll. CN Patent, 2464398Y. (in Chinese)

Zou X Z. A Flickering Eyeball Structure of a Toy. CN Patent, 2379181Y. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Q., Yu, M., Li, Y. et al. Investigation of Ionic Polymer Metal Composite Actuators Loaded with Various Tetraethyl Orthosilicate Contents. J Bionic Eng 9, 75–83 (2012). https://doi.org/10.1016/S1672-6529(11)60099-1

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(11)60099-1