Abstract

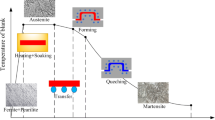

Hot stamping has been widely used in car industry to produce safety components. Most existing researches focused on the stamping and quenching process, but less on the mechanical properties of stamped parts. The fracture behaviors of hot stamped boron steel B1500HS have been studied, and other four commonly used sheet metals with different strengths, including Q235, TRIP780, QP980 and MS1300, were also introduced for comparison. Both uniaxial tests and mechanical trimming tests were performed, and the fracture surfaces under different stress states were observed and discussed. The SEM observations showed that the fracture models are closely related to the stress states, i. e., the tensile surfaces have ductile rupture characters while the trimming surfaces have brittle rupture characters. Compared with other steels, the quenched boron steel has smaller dimple size accompanied by shear planes in the tensile surface, and has smaller burnish zone in the trimming surface, and its cutting surface with ‘S’ like shape is also very different with others. Furthermore, two fitted empirical models were derived to describe the quantitative correlations between the average dimple diameter and the steel strength and between the percentage of burnish zone and the steel strength.

Similar content being viewed by others

References

G. Jha, S. Das, S. Sinha, A. Lodh, A. Haldar, Mater. Sci. Eng. A 561 (2013) 394–402.

H. Karbasian, A. E. Tekkaya, J. Mater. Process. Technol. 210 (2010) 2103–2118.

J. H. Kim, D. Kim, H. Han, F. Barlat, M. G. Lee, Mater. Sci. Eng. A 559 (2013) 222–231.

V. Uthaisangsuk, U. Prahl, W. Bleck, Eng. Fract. Mech. 78 (2011) 469–486.

X. Sun, K. S. Choi, A. Soulami, W. N. Liu, M. A. Khaleel, Mater. Sci. Eng. A 526 (2009) 140–149.

I. Barsoum, J. Faleskog, Int. J. Solids Struct. 44 (2007) 1768–1786.

C. C. Tasan, M. Diehl, D. Yan, F. Roters, Int. J. Plast. 63 (2014) 198–210.

H. So, H. Hoffmann, in: S. D. Yoo (Eds.), Proceedings of the Eu-Korea Conference on Science and Technology, Ekc, Korea, 2008, pp. 315–325.

K. Mori, T. Maeno, S. Fuzisaka, J. Mater. Process. Technol. 212 (2012) 534–540.

V. Savic, L. Hector, K. Snavely, J. Coryell, SAE Int. J. Mater. Manuf. 3 (2010) 246–254.

X. H. Han, K. Yang, S. S. Chen, J. Chen, J. Mater. Eng. Perform. 24 (2015) 3845–3851.

X. H. Han, K. Yang, Y. N. Ding, S. L. Tan, J. Chen, J. Mater. Process. Technol. 234 (2016) 158–168.

M. Rossini, P. R. Spena, L. Cortese, P. Matteis, D. Firrao, Mater. Sci. Eng. A 628 (2015) 288–296.

P. X. Liu, Y. S. Zhang, H. Q. Liu, Z. X. Gui, Int. J. Adv. Manuf. Technol. 70 (2014) 1421–1426.

A. Lara, I. Picas, D. Casellas, J. Mater. Process. Technol. 213 (2013) 1908–1919.

K. Mori, T. Maeno, Y. Maruo, CIRP Ann. 61 (2012) 255–258.

H. S. Choi, B. M. Kim, D. H. Kim, D. C. Ko, Int. J. Precis. Eng. Manuf. 15 (2014) 1087–1093.

H. So, D. Fassmann, H. Hoffmann, R. Golle, M. Schaper, J. Mater. Process. Technol. 212 (2012) 437–449.

A. Ghiotti, S. Bruschi, D. Pellegrini, Key Eng. Mater. 473 (2011) 201–208.

H. P. Li, G. Q. Zhao, L. F. He, L. Zhang, J. Mech. Eng. 48 (2012) 21–27.

P. Yang, Y. Y. Fu, F. G. Cui, Z. Q. Sun, Acta Metall. Sin. 37 (2001) 592–600 (in Chinese).

H. Y. Li, Y. J. Zhang, W. J. Zhao, Z. F. Gu, X. C. Li, J. Iron Steel Res. Int. 22 (2015) 256–263.

K. S. Diao, H. M. Jiang, X. P. Chen, Forg. Stamping Technol. 37 (2012) 113–115, 121.

D. C. Wen, Wear 268 (2010) 629–636.

X. G. Liang, T. Jia, J. Z. Jiao, G. D. Wang, X. H. Liu, J. Iron Steel Res. 20 (2008) No. 10, 59–62 (in Chinese).

X. L. Zhao, W. Bayanheshig, W. H. Li, Y. X. Jiang, Y. Song, X. T. Li, S. Jiang, N. Wu, Applied Optics. 55 (2016) 8683–8689.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, Sl., Yang, K., Ding, Yn. et al. Fracture morphologies of a hot stamped steel and comparisons with several sheet metals. J. Iron Steel Res. Int. 24, 634–640 (2017). https://doi.org/10.1016/S1006-706X(17)30095-X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(17)30095-X