Abstract

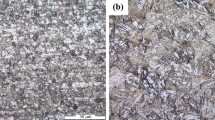

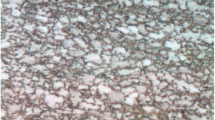

The wide application of high-strength low-alloy (HSLA) steels in the automobile industry makes the metallurgical properties and mechanical attributes of spot welds essential. The relationships among macrostructure, microstructure, mechanical properties, and failure modes of welded joints of HSLA 420 steel were studied. An optical microscope was employed to describe the microstructure, macrostructure, and geometry of the welds, while their mechanical properties and failure modes were characterized via tensile shear tests. It turns out to be that the weld nugget mainly contains lath martensite. The results of the microhardness test show that the microhardness of the fusion zone (FZ) is superior to those of the heat-affected zone (HAZ) and base metal (BM). The increase in heat input brings about a decrease in FZ martensite hardness, but the hardness distribution is more uniform. The grain size of the FZ is 38 µm, 51 µm, and 62 µm when the welding time is at the levels of 11 cycles, 15 cycles, and 19 cycles, while its values increased by about 58% as the welding current increases from 7.2 to 9.6 kA. As the welding time increases, the differences between the maximum hardness and minimum hardness decrease from 74 to 54 HV. In the tensile shear test, interfacial fracture and pullout fracture were observed, followed by BM sheet tearing. Evidently, the weld nugget with the size of 4t0.5 (t = sheet thickness) will not bring about pullout fracture. Furthermore, existing standards for determining the acceptable load capacity of welded joints cannot guarantee good welding quality. Finally, moderate welding current (from 8.4 to 9 kA) and long welding time (above 15 cycles) should be used to obtain the welded joints with sufficiently large FZs which present good mechanical properties in the tensile shear test.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Omiya M, Arakawa S, Yao Z, Muramatsu M, Nishi S, Takada K, Murata M, Okato K, Ogawa K, Oide K, Kobayashi T (2022) Influence of strength and notch shape on crack initiation and propagation behavior of advanced high strength steel sheets. Eng Fract Mech 9:108573

Ribeiro HV, Baptista CA, Lima MS, Torres MA, Marcomini JB (2021) Effect of laser welding heat input on fatigue crack growth and CTOD fracture toughness of HSLA steel joints. J Market Res 11:801–810

Zhao D, Wang Y, Zhang P, Liang D (2019) Modeling and experimental research on resistance spot welded joints for dual-phase steel. Materials 12:1108

Jafari Vardanjani M (2022) A comparative study of technical aspects of resistance spot brazed and resistance spot welded joints. Weld Int 36:208–219

Butsykin S, Gordynets A, Kiselev A, Slobodyan M (2022) Evaluation of the reliability of resistance spot welding control via on-line monitoring of dynamic resistance. J Intell Manuf. https://doi.org/10.1007/s10845-022-01987-0

Özen F, Aslanlar S (2021) Mechanical and microstructural evaluation of resistance spot welded dissimilar TWIP/martensitic steel joints. Int J Adv Manuf Technol 113:3473–3489

Viňáš J, Kaščák Ľ, Greš M (2016) Optimization of resistance spot welding parameters for microalloyed steel sheets. Open Eng 6:504–510

Kaščák Ľ, Spišák E, Gajdoš I (2013) Joining the combination of AHSS steel and HSLA steel by resistance spot welding. Acta Mech Autom 7:75–78

Pouranvari M (2012) Failure mode transition in similar and dissimilar resistance spot welds of HSLA and low carbon steels. Can Metall Q 51:67–74

Mi K, Ml K, Biro E, Zhou Y (2008) Microstructure and mechanical properties of resistance spot welded advanced high strength steels. Mater Trans 49:1629–1637

Habib L, Abdelkader Z, Habib B, Benallel BF (2016) Experimental study of tensile test in resistance spot welding process. Lat Am J Solids Struct 13:1228–1235

Pouranvari M (2013) On the failure mode of resistance spot welded HSLA 420 steel. Arch Metall Mater 58:67–72

Ignasiak A, Korzeniowski M, Ambroziak A (2012) Investigations of microstructure of resistance spot-welded joints made of HSLA340 and DP600 steels. Arch Metall Mater 57:1081–1086

Delgado-Pamanes MF, Maldonado-Ruiz SI, Guerrero-Mata MP, Olvera-Vázquez ZL (2018) Evaluating the deterioration of electrodes when increasing the number of pulses in the welding time using galvanised IF and HSLA steels and assigning mechanical properties in the spot welds. Weld Int 32:629–639

Janardhan G, Mukhopadhyay G, Kishore K, Dutta K (2020) Resistance spot welding of dissimilar interstitial-free and high-strength low-alloy steels. J Mater Eng Perform 29:3383–3394

Janardhan G, Kishore K, Dutta K, Mukhopadhyay G (2020) Tensile and fatigue behavior of resistance spot-welded HSLA steel sheets: effect of pre-strain in association with dislocation density. Mater Sci Eng A 793:139796

Zhao D, Osipov A, Bezmelnitsyn A, Vdonin N, Liang D (2021) Statistical modeling and optimization of the resistance welding process with simultaneous expulsion magnitude consideration for high-strength low alloy steel. Int J Adv Manuf Technol 113:1173–1189

Shi L, Xue J, Kang J, Haselhuhn AS, Carlson BE (2022) Effect of specimen configuration and notch root angle on fatigue behavior of novel dissimilar resistance spot welds of AA5754 to HSLA steel. Procedia Struct Integr 37:351–358

Soomro IA, Pedapati SR, Awang M (2022) A review of advances in resistance spot welding of automotive sheet steels: emerging methods to improve joint mechanical performance. Int J Adv Manuf Technol 118:1335–1366

Vijayan V, Murugan SP, Ji C, Son SG, Park YD (2021) Factors affecting shrinkage voids in advanced high strength steel (AHSS) resistance spot welds. J Mech Sci Technol 35:5137–5142

Feujofack Kemda BV, Barka N, Jahazi M, Osmani D (2020) Optimization of resistance spot welding process applied to A36 mild steel and hot dipped galvanized steel based on hardness and nugget geometry. Int J Adv Manuf Technol 106:2477–2491

Valencia TE, del Carmen Téllez Anguiano A, Caballero LE, Hernández HJ, Calderón FR (2021) Statistical analysis related to the quantification of microhardness and the percentage of martensite after the application of welding. Int J Adv Manuf Technol 116:3687–3698

Cho H, Nam S, Hwang I, Oh JH, Kang M, Kim YM (2019) Fatigue behaviors of resistance spot welds for 980 MPa grade TRIP steel. Metals 9:1086

Cunha CF, de Oliveira GJ, de Carvalho HM (2022) A new approach to reduce the carbon footprint in resistance spot welding by energy efficiency evaluation. Int J Adv Manuf Technol 119:6503–6520

Tamizi M, Pouranvari M, Movahedi M (2021) The role of HAZ softening on cross-tension mechanical performance of martensitic advanced high strength steel resistance spot welds. Metall and Mater Trans A 52:655–667

American National Standard Weld Button Criteria, Recommended practices for test methods for evaluating the resistance spot welding behavior of automotive sheet steel materials. ANSI/AWS/SAE/D8.9–97 (1997) (Section 5.7)

Chao YJ (2003) Failure mode of spot welds: interfacial versus pullout. Sci Technol Weld Joining 8:133–137

Vandenbossche DJ (1977) Ultimate strength and failure mode of spot welds in high strength steels. SAE Trans. https://doi.org/10.4271/770214

Chen F, Sun S, Ma Z, Tong GQ, Huang X (2018) Effect of weld nugget size on failure mode and mechanical properties of microscale resistance spot welds on Ti–1Al–1Mn ultrathin foils. Adv Mech Eng 10:1–10

Zhao D, Wang Y, Liang D, Ivanov M (2020) Performances of regression model and artificial neural network in monitoring welding quality based on power signal. J Market Res 9:1231–1240

Májlinger K, Katula LT, Varbai B (2022) Prediction of the shear tension strength of resistance spot welded thin steel sheets from high-to ultrahigh strength range. Period Polytech Mech Eng 66:67–82

Tutar M, Aydin H, Bayram A (2017) Effect of weld current on the microstructure and mechanical properties of a resistance spot-welded TWIP steel sheet. Metals 7:519

Owsiński R, Lachowicz DS, Lachowicz CT, Gil R, Niesłony A (2021) Characterisation of joint properties through spatial mapping of cracks in fatigue specimens, extracted from the linearly friction welded steel coupon. Precis Eng 71:78–89

Salimi Beni S, Atapour M, Salmani MR, Ashiri R (2019) Resistance spot welding metallurgy of thin sheets of zinc-coated interstitial-free steel. Metall Mater Trans A 50:2218–2234

Zhao D, Bezgans Y, Vdonin N, Radionova L, Bykov V (2021) Modeling and optimization of weld bead profile with varied welding stages for weathering steel A606. Int J Adv Manuf Technol 116:3179–3192

Valizadeh B, Mansouri M (2021) Dissimilar DP780/DP980 resistance spot welded joints: microstructure, mechanical properties and critical diameter. J Adv Mater Process 9:3–10

Feujofack Kemda BV, Barka N, Jahazi M, Osmani D (2021) Modeling of phase transformation kinetics in resistance spot welding and investigation of effect of post weld heat treatment on weld microstructure. Met Mater Int 27:1205–1223

Bagheri B, Abbasi M, Abdollahzadeh A, Moghaddam AO (2021) Numerical modeling and experimental analysis of water jet spot welding and friction stir spot welding: a comparative study. J Mater Eng Perform 30:1454–1471

Bagheri B, Abbasi M, Hamzeloo R (2020) The investigation into vibration effect on microstructure and mechanical characteristics of friction stir spot vibration welded aluminum: simulation and experiment. Proc Inst Mech Eng C J Mech Eng Sci 234:1809–1822

Bagheri B, Abbasi M, Givi M (2019) Effects of vibration on microstructure and thermal properties of friction stir spot welded (FSSW) aluminum alloy (Al5083). Int J Precis Eng Manuf 20:1219–1227

Bagheri B, Abbasi M, Abdollahzadeh A, Omidvar H (2020) Advanced approach to modify friction stir spot welding process. Met Mater Int 26:1562–1573

Bagheri B, Mahdian Rizi AA, Abbasi M, Givi M (2019) Friction stir spot vibration welding: improving the microstructure and mechanical properties of Al5083 joint. Metallogr Microstruct Anal 8:713–725

Zhao D, Bezgans Y, Vdonin N, Kvashnin V (2022) Mechanical performance and microstructural characteristic of gas metal arc welded A606 weathering steel joints. Int J Adv Manuf Technol 119:1921–1932

Funding

The authors are thankful for the financial support offered by the Russian Science Foundation (22–29-20095).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Since the tests and experiments in this study are not performed on humans or animals, ethical approval is unnecessary.

Consent to participate

All the authors agree to participate.

Consent for publication

All the authors agree to publish this article.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, D., Vdonin, N., Bezgans, Y. et al. Mechanical attributes and microstructural characteristics of resistance spot-welded HSLA 420 steel joints. Int J Adv Manuf Technol 124, 3505–3518 (2023). https://doi.org/10.1007/s00170-022-10798-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10798-9