Abstract

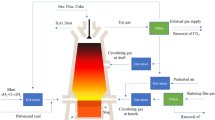

Aiming at the current characteristics of blast furnace (BF) process, carbon saving potential of blast furnace was investigated from the perspective of the relationship between degree of direct reduction and carbon consumption. A new relationship chart between carbon consumption and degree of direct reduction, which can reflect more real situation of blast furnace operation, was established. Furthermore, the carbon saving potential of hydrogen-rich oxygen blast furnace (OBF) process was analyzed. Then, the policy implications based on this relationship chart established were suggested. On this basis, the method of improving the carbon saving potential of blast furnace was recycling the top gas with removal of CO2 and H2O or increasing hydrogen in BF gas and full oxygen blast. The results show that the carbon saving potential in traditional blast furnace (TBF) is only 38–56 kg · t−1 while that in OBF is 138 kg · t−1. Theoretically, the lowest carbon consumption of OBF is 261 kg · t−1 and the corresponding degree of direct reduction is 0.04. In addition, the theoretical lowest carbon consumption of hydrogen-rich OBF is 257 kg · t−1. The modeling analysis can be used to estimate the carbon savings potential in new ironmaking process and its related CO2 emissions.

Similar content being viewed by others

References

C. B. Xu, D. Q. Gang, J. Iron Steel Res. Int. 17 (2010) No. 3, 1–7.

Y. P. Shen, H. Cao, Anhui Metallurgy (2015) No. 4, 57–59 (in Chinese).

A. H. Pamm, Calculation and Analysis of Modern Blast Furnace Process, Metallurgical Industry Press, Beijing, 1987.

Y. Jianwei, S. Guolong, K. Cunjiang, Y. Tianjun, Energy 28 (2003) 825–835.

Y. Ohno, M. Matsuura, H. Mitsufuji, Tetsu-to-Hagané 32 (1992) 838–847.

M. S. Chu, H. Nogami, J. Yagi, ISIJ Int. 44 (2004) 2159–2167.

Y. H. Han, J. S. Wang, R. Z. Lan, X. F. She, Q. G. Xue, Ironmak. Steelmak. 39 (2012) 313–317.

R. Z. Lan, J. S. Wang, Y. H. Han, X. F. She, L. T. Wang, Q. G. Xue, J. Iron Steel Res. Int. 19 (2012) No. 9, 13–19.

Y. Ohno, M. Matsuura, Tetsu-to-Hagané 76 (1990) 1262–1269.

J. A. de Castro, H. Nogami, J. Yagi, ISIJ Int. 42 (2002) 1203–1211.

M. Matsuura, T. Furukawa, Y. Ohno, Rev. Metall. 88 (1991) 453–459.

S. Natusui, S. Ueda, H. Nogami, J. Kano, R. Inoue, T. Ariyama, ISIJ Int. 51 (2011) 1410–1417.

S. Natusui, S. Ueda, H. Nogami, J. Kano, R. Inoue, T. Ariyama, ISIJ Int. 51 (2011) 51–58.

Z. L. Liu, Ironmaking Theory and Technology, Chemical Industry Press, Beijing, 2000 (in Chinese).

Y. J. Liang, Y. C. Che, Handbook of Thermodynamic Data for Inorganic Material, Northeastern University Press, Shenyang, 1993 (in Chinese).

D. M. Kundrat, Mater. Trans. B 18 (1986) 705–724.

D. M. Kundrat, Mater. Trans. B 20 (1989) 205–218.

A. Ziebik, K. Lampert, M. Szega, Energy 33 (2008) 199–205.

S. Paul, S. K. Roya, P. K. Sen, Mater. Trans. B 44 (2013) 20–27.

T. Ariyama, M. Sato, ISIJ Int. 46 (2006) 1736–1744.

D. Gielend, Y. Moriguchi, Energy Policy 30 (2002) 849–863.

M. T. Johansson, M. Söderström, Energy 36 (2011) 191–198.

G. Q. Zuo, A. Hirsch, Rev. Metall. 106 (2009) 387–392.

G. Danloy, A. Berthelemot, M. Grant, Rev. Metall. 106 (2009) 1–8.

J. O. Choi, J. G. Kim, in: Proceedings of 7th the International Conference on Carbon Dioxide Utilization, Seoul, Korea, 2004, pp. 153–157.

P. L. Hooey, A. Boden, C. Wang, C. E. Grip, B. Jansson, ISIJ Int. 50 (2010) 924–930.

J. van der Stel, T. Bell, M. Hattink, J. Stuurwold, M. G. Tonks, D. Jameson, in: Proc. of 4th Int. Cong, on the Science and Technology of Ironmaking, ISIJ, Tokyo, 2006, pp. 564–569.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

She, Xf., An, Xw., Wang, Js. et al. Numerical analysis of carbon saving potential in a top gas recycling oxygen blast furnace. J. Iron Steel Res. Int. 24, 608–616 (2017). https://doi.org/10.1016/S1006-706X(17)30092-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(17)30092-4