Abstract

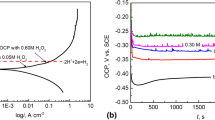

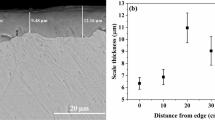

To shorten the time required for the pickling process and to enhance the quality of ferritic stainless steel plates, the effects of oxidants including hydrogen peroxide (H2O2), potassium permanganate (KMnO4), and potassium chlorate (KClO3) on the pickling behavior in HCl-based electrolyte as well as the surface quality of hot-rolled and blasted 430 stainless steel (430-SS) were studied. Experiments were conducted using mass-loss tests, micro-structure analyses, potentiodynamic polarization curves, and electrochemical impedance spectroscopy measurements. The results showed that the addition of oxidants substantially accelerated the pickling process of 430-SS by enhancing the cathodic reaction rate and reducing the charge transfer resistance. In electrolytes comprising 5 – 8 mass% HCl at a temperature of 40 – 60 °C and at the same concentration within the range from 0 to 2 mass%, H2O2 was demonstrated to be superior to KMnO4 and KClO3 in accelerating the pickling process. The surface quality of 430-SS pickled in the presence of H2O2 was better than those of specimens pickled in the presence of KMnO4 and KClO3 when the removal of the oxide layer, intergranular corrosion, and surface roughness were collectively considered. When 1 mass% H2O2 was added, the mass loss rate of 430-SS was increased by 629% and no residual oxide layer or intergranular corrosion was observed on the surface of the steel; in addition, the roughness was only 1. 7 µm. H2O2 was determined to be a better oxidant than KMnO4 and KClO3 when the pickling process, surface quality, solution recycling, and environment protection were considered as a whole.

Similar content being viewed by others

References

W. G. Imhoff, Pickling of Iron and Steel, The Penton Publishing Co., Cleveland, 1929.

B. S. Covino, J. V. Scalera, P. M. Fabis, Pickling of Stainless Steels: A Review, Bureau of Mines Information Circular, USA, 1984.

L. F. Li, P. Caenen, M. F. Jiang, Corros. Sci. 50 (2008) 2824–2830.

L. F. Li, P. Caenen, J. P. Celis, J. Electrochem. Soc. 152 (2005) B352–B357.

C. Bitondo, A. Bossio, T. Monetta, M. Curioni, F. Bellucci, Corros. Sci. 87 (2014) 6–10.

A. Turnbull, K. Mingard, J. D. Lord, B. Roebuck, D. R. Tice, K. J. Mottershead, N. D. Fairweather, A. K. Bradbury, Corros. Sci. 53 (2011) 3398–3415.

W. F. Kladnig, J. Iron Steel Res. Int. 15 (2008) No. 4, 1–6.

N. J. Sanders, Anti-Corros. Method M 44 (1997) 20–25.

D. Lindell, R. Pettersson, Steel Res. Int. 81 (2010) 542–551.

M. F. Jiang, X. L. Li, Y. Y. Yue, P. Y. Shi, C. J. Liu, Mater. Res. Innovations 18 (2014) Suppl. 5, 62–65.

X. L. Li, P. Y. Shi, Y. Y. Yue, M. F. Jiang, J. Northeast. Univ. 35 (2014) 1548–1551.

W. Brigitta, B. Edgar, M. Geral, Process of Pickling Stainless Steel, US, 6250314B1, 2001.

C. J. Peterson, Rinse Aid and Process for Stainless Steel, US, 5821212A, 1998.

G. D. Sala, A. Artillo, S. Ricart, A. Spinella, J. Organomet. Chem. 692 (2007) 1623–1627.

E. Rodríguez, A. Sordo, J. S. Metcalf, J. L. Acero, Water Res. 41 (2007) 2048–2056.

S. Shabnam, A. Raheleh, Carbohydr. Polym. 95 (2013) 348–359.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Liaoning Province Programs for Science and Technology Development of China (2012221013)

Rights and permissions

About this article

Cite this article

Xie, Q., Shi, Py., Liu, Cj. et al. Effects of Different Oxidants on HCl-based Pickling Process of 430 Stainless Steel. J. Iron Steel Res. Int. 23, 778–783 (2016). https://doi.org/10.1016/S1006-706X(16)30120-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(16)30120-0