Abstract

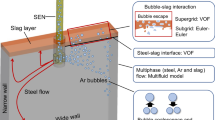

The bubble-liquid flow, especially the aggregation and breakage behavior, plays a significant role in the slab continuous casting process. A 1/4th water model was employed to investigate the two-phase flow characteristics and the bubble size distribution. A mathematical model based on the Euler-Euler approach was developed to analyze the bubble aggregation and breakage in the bubbly flow. The population balance model (PBM) was applied to calculate bubble size distribution, and the simulation was implemented through the MUSIG (multiple size group) model. The numerical predictions were verified by the water model experiment. The results show that the PBM is a useful approach for analyzing bubble size distribution and can be taken into industrial applications of gas-liquid two phase flow inside the continuous casting mold. The ratio of big bubbles and bubble mean diameter in the upper recirculation zone are found to decrease with the increment of water flow rate and increase with the increment of gas flow rate. The bubble aggregation and breakage behavior, bubble size distribution and the effect of gas bubbles on flow field in the continuous casting mold are revealed. The numerical results are compared with the experiment and they show good agreement.

Similar content being viewed by others

References

G. Abbel, W. Damen, G. de Gendt, W. Tiekink, ISIJ Int. 36 (1996) S219–S222.

N. Kasai, Y. Watanabe, K. Kajiwara, M. Toyoda, Tetsu-to-Hagané 83 (1997) 24–29.

Z. Q. Liu, L. M. Li, F. S. Qi, B. K. Li, M. F. Jiang, F. Tsukihashi, Metall. Mater. Trans. B 46 (2015) 406–420.

G. G. Lee, B. G. Thomas, S. H. Kim, Met. Mater. Int. 16 (2010) 501–506.

H. Bai, B. G. Thomas, Metall. Mater. Trans. B 32 (2001) 1143–1159.

Y. J. Kwon, J. Zhang, H. G. Lee, ISIJ Int. 46 (2006) 257–266.

B. G. Thomas, X. Huang, R. C. Suaaman, Metall. Mater. Trans. B 25 (1994) 527–547.

R. Sanchez-Perez, R. D. Morales, L. Garcia-Demedices, J. Palafox Ramos, M. Diaz-Cruz, Metall. Mater. Trans. B 35 (2004) 85–99.

Z. Q. Liu, B. K. Li, M. F. Jiang, F. Tsukihashi, ISIJ Int. 53 (2013) 484–492.

B. K. Li, F. Tsukihashi, ISIJ Int. 45 (2005) 30–36.

Y. Miki, H. Ohno, Y. Kishimoto, S. Tanaka, Tetsu-to-Hagané 97 (2011) 423–432.

N. G. Deen, T. Solberg, B. H. Hjertager, Chem. Eng. Sci. 56 (2001) 6341–6349.

D. Ramkrishna, A. W. Mahoney, Chem. Eng. Sci. 57 (2002) 595–606.

T. Wang, J. Wang, Y. Jin, Ind. Eng. Chem. Res. 44 (2005) 7540–7549.

Y. Sato, K. Sekoguchi, Int. J. Multiphase Flow 2 (1979) 79–85.

X. Li, H. Zhang, R. Wang, J. Wang, Aerosp. Sci. Technol. 14 (2010) 203–212.

Y. Liao, D. Lucas, E. Krepper, M. Schmidtke, Nucl. Eng. Des. 241 (2011) 1024–1033.

M. J. Prince, H. W. Blanch, AIChE Journal 36 (1990) 1485–1499.

H. Luo, H. F. Svendsen, AIChE Journal 42 (1996) 1225–1233.

L. M. Li, Z. Q. Liu, B. K. Li, H. Matsuura, F. Tsukihashi, ISIJ Int. 55 (2015) 1337–1346.

L. Schiller, Z. Naumann, Z. Ver. Deutsch. Ing. 77 (1935) 318–320.

S. Kumar, D. Ramkrishna, Chem. Eng. Sci. 51 (1996) 1311–1332.

S. C. P. Cheung, G. H. Yeoh, J. Y. Tu, Chem. Eng. Sci. 62 (2007) 4659–4674.

Z. Q. Liu, F. S. Qi, B. K. Li, M. F. Jiang, J. Iron Steel Res. Int. 21 (2014) No. 12, 1081–1089.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51574068)

Rights and permissions

About this article

Cite this article

Li, Lm., Liu, Zq. & Li, Bk. Modelling of bubble aggregation, breakage and transport in slab continuous casting mold. J. Iron Steel Res. Int. 22 (Suppl 1), 30–35 (2015). https://doi.org/10.1016/S1006-706X(15)30134-5

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30134-5