Abstract

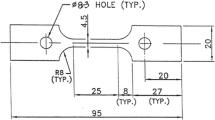

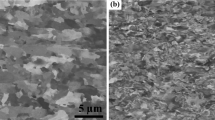

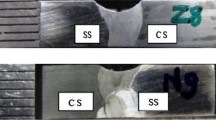

The influence of Ti on weld microstructure and mechanical properties in large heat input welding of high strength low alloy steels is investigated. The results indicate that a moderate amount of Ti is still effective for grain refinement even under larger heat input and a large amount of acicular ferrite (AF) is formed in the weld metal when Ti content is within 0.028%–0.038%. With increasing Ti content, proeutectoid ferrite in the weld metal decreases, whereas bainite and M-A constituent increase. The type of inclusion in the welds varies from Mn-Si-Al-O to Ti-Mn-Al-O and finally to Ti-Al-O as Ti content increases from 0 up to 0.064 %. As for adding 0.028%–0.038% Ti, high weld toughness could be attained since most inclusions less than 2 µm which contain Ti2O3 provide the effective nuclei for acicular ferrite formation. However, the toughness of the weld metals severely reduces when Ti content is over the optimum range of 0.028%–0.038%.

Similar content being viewed by others

References

J. S. Byun, J. H. Shim, Y. W. Cho, D. N. Lee, Acta Mater. 51 (2003) No. 6, 1593–1606.

W. W. Bosefilho, A. L. M. Carvalho, M. Strangwood, Mater. Charact. 58 (2007) 29–39.

A. M. Paniagua-Mercado, V. M. Loprz-Hirata, H. J. Dorantes-Rosales, P. Estrada Diaz, E. Diaz Valdez, Mater. Charact. 60 (2009) 36–39.

T. Wegrzyn, P. Szopa, M. Miros, Welding Int. 23 (2009) 54–59.

F. Chai, H. Su, C. F. Yang, D. M. Xue, J. Iron Steel Res. Int. 21 (2014) 369–374.

A. G. Fox, D. G. Brothers, Scripta Metall. Mater. 32 (1995) No. 7, 1061–1066.

C. Zhang, Z. X. Xia, Z. G. Yang, Z. H. Liu, J. Iron Steel Res. Int. 17 (2010) No. 6, 36–42.

F. Chai, C. F. Yang, H. Su, Y. Q. Zhang, Z. Xu, J. Iron Steel Res. Int. 16 (2009) No. 1, 69–74.

T. Ryousuke, J. Yang, K. Mamoru, ISIJ Int. 47 (2007) 1379–1386.

X. L. Wan, R. Wei, K. M. Wu, Mater. Charact. 61 (2010) 726–731.

K. Yamamoto, T. Hasegawa, J. I. Takamura, ISIJ Int. 36 (1996) 80–86.

S. S. Bahu, Current Opinion in Solid State and Materials Science 8 (2008) 267–278.

J. L. Lee, Acta Metall. Mater. 42 (1994) 3291–3298.

Y. T. Pan, J. L. Lee, Mater. Des. 15 (1994) 331–338.

S. A. Court, G. Pollard, Metallography 22 (1989) 219–243.

S. St-Laurent, G. L. Espérance, Mater. Sci. Eng. A 149 (1992) 203–216.

B. Beidokhti, A. H. Koukabi, A. Dolati, Mater. Charact. 60 (2009) 225–233.

S. Moeinifar, A. H. Kokabi, H. R. M. Hosseini, Mater. Des. 31 (2010) 2984–2955.

Y. W. Shi, Z. X. Han, J. Mater. Process. Technol. 207 (2008) 30–39.

B. Beidokhti, A. H. Koukabi, A. Dolati, J. Mater. Process. Technol. 209 (2009) 4027–4035.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High Technology Research and Development Project of China (2009AA03Z530)

Rights and permissions

About this article

Cite this article

A-rong, Zhao, L., Pan, C. et al. Influence of Ti on weld microstructure and mechanical properties in large heat input welding of high strength low alloy steels. J. Iron Steel Res. Int. 22, 431–437 (2015). https://doi.org/10.1016/S1006-706X(15)30023-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30023-6