Abstract

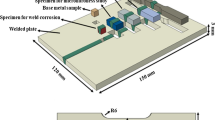

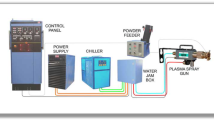

The effects of shielding gas and post weld heat treatment on the pitting resistance, stress corrosion cracking and hydrogen embrittlement of supermartensitic stainless steel deposits were studied. Two all-weld-metal test coupons were prepared using a metal-cored wire under Ar+5% He and Ar+18% CO2 gas shielding mixtures. Solubilizing and solubilizing plus double tempering heat treatments were done with the objective of achieving different microstructural results. The samples welded under Ar+5% He showed higher pitting corrosion resistance, for all post weld heat treatments, than those welded under Ar+18% CO2. The different post weld heat treatments generated higher susceptibility to this corrosion mechanism. None of the samples presented signs of stress corrosion cracking, but in those subjected to the heat treatment, grain boundary selective attack was observed, on the surfaces of all the samples studied. The samples with highest hardness were more susceptible to hydrogen damage, thereby leading to reduced tensile strength on this condition.

Similar content being viewed by others

References

Amaya H, Kondo K, Taniyama A, et al. Stress Corrosion Cracking Sensitivity of Super Martensitic Stainless Steel in High Chloride Concentration Environment [C] // Corrosion 2004. Houston: NACE International, 2004: 04124.

Van der Winden H, Toussaint P, Coudreuse L. Past, Present and Future of Weldable Supermartensitic Alloys [C] // Supermartensitic 2002. Brussels: Stainless Steel Word, 2002: 9.

Bilmes P, Llorente C, Solari M. Role of the Retained Austenite on the Mechanical Properties of 13Cr-4NiMo Weld Metals [C] // The 20th ASM Heat Treating Society. Missouri: ASM, 2000: 556.

Karlsson L, Rigdal S, Bruins W, et al. Efficient Welding of Supermartensitic Stainless Steels With Matching Composition Consumables [C] // Stainless Steel Word. The Hague: Stainless Steel Word, 1999: 341.

Srinivasan P, Sharkawy S, Dietzel W. Hydrogen Assisted Stress-Cracking Behavior of Electron Beam Welded Supermartensitic Stainless Steel Weldments [J]. Materials Science and Engineering, 2004, 385A(1/2): 6.

Zappa S, Svoboda H, Ramini M, et al. Improving Supermartensitic Stainless Steel Weld Metal Toughness [J]. Welding Journal, 2012, 91(3): 83s.

Bilmes P, Solari M, Llorente C. Characteristics and Effect of Austenite Resulting From Tempering of 13 Cr-NiMo Martensitic Steel Weld Metals [J]. Materials Characterization, 2001, 46(4): 285.

Bilmes P. Role of the Austenite on the Mechanical Properties of Soft Martensitic Stainless Steels Weld Metals [D]. La Plata: Universidad Nacional de La Plata, 2000.

Aquino J, Rovere C, Kuri S. Localized Corrosion Susceptibility of Supermartensitic Stainless Steel in Welded Joints [J]. Corrosion Science, 2007, 51(10): 2323.

Amaya H, Taniyama A, Ogawa K. Intergranular Stress Corrosion Cracking Susceptibility and Precipitation Behaviour on Grain Boundary by Post Weld Heat Treatment of Super Martensitic Stainless Steels [C] // Corrosion 2008. Houston: NACE International, 2008: 08100.

Hashizume S, Nakayama T, Sakairi M, et al. Electrochemical Behavior of Low C-13% Cr Weld Joints by Using Solution Flow Type Micro-droplet Cell [C] // Corrosion 2008. Houston: NACE International, 2008: 08102.

Miyata Y, Kimura M. Effects of Thermal Cycle Conditions on Intergranular Stress Corrosion Cracking in Sweet Environment for Supermartensitic Stainless Steel [C] // Corrosion 2005. Houston: NACE International, 2005: 05095.

Zappa S, Svoboda H, Ramini M, et al. Effect of Shielding Gas on the Properties of Supermartensitic Stainless Steel All Weld Metal [C] // CONAMET-SAM 2006. Santiago de Chile: CONAMET-SAM, 2006.

Lippold J, Kotecki D. Welding Metallurgy and Weldability of Stainless Steels [M]. New Jersey: John Wiley and Sons, 2005.

Kimura M, Miyata Y, Toyooka T, et al. Effect of Test Method on SSC Performance of Modified 13Cr Steel [C] // Corrosion 1998. Houston: NACE International, 1998: 98114.

Hara T, Asahi H. Conditions Under Which Cracks Occur in Modified 13% Chromium Steel in Wet Hydrogen Sulfide Environments [C] // Corrosion 2000. Houston: NACE International, 2000: 00050533.

ANSI/AWS A5.22—95, Specification for Stainless Steel Electrodes for Flux Cored Arc Welding and Stainless Steel Flux Cored Rods for Gas Tungsten Arc Welding [S]. Miami: American Welding Society, 1995.

ANSIB31. 3—96, Chemical Plant and Petroleum Refinery Piping [S]. Miami: American National Standards Institute, 1996.

ASTM E562—99, Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count [S]. Miami, ASTM International, 1999.

Cullity B, Stock S. Elements of X Ray Diffraction [M]. 3rd ed. New Jersey: Prentice Hall, 2001.

Bilmes P, Llorente C, Desimone J, et al. Microstructures and Properties of Martensitic Stainless Steels of 13% Cr-4% NiMo Weld Metals FCAW [C] // II Encuentro de Ingeniería de Materiales. La Habana: 1998: 252.

Zappa S, Svoboda H, Ramini M, et al. Effect of Post Weld Heat Treatment on the Properties of a Supermartensitic Stainless Steel Welded With a Tubular Metal-Cored Wire [J]. Soldagem e Inspecão, 2007, 12(2): 115.

Baroux B, Marcus P. Corrosion Mechanism in Theory and Practice [M]. 2nd ed. New York: [s. n.], 2002.

Shibata T, Takeyama T. Stochastic Theory of Pitting Corrosion [J]. Corrosion, 1977, 33(7): 243.

Bilmes P, Llorente C, Huamán L, et al. Microstructure and Pitting Corrosion of 13CrNiMo Weld Metals [J]. Corrosion Science, 2006, 48(10): 3261.

Shibata T. Uhlig’s Corrosion Handbook [M]. 2nd ed. New York: [s. n.], 2000.

NACE TM0177—05. Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments [S]. Miami: NACE International, 2005.

EFC 17. Corrosion Resistant Alloys for Oil and Gas Production Guidance on General Requirements and Test Methods for H2S Service [M]. 2nd ed. London: Maney Publishing, 1996.

Srinivasan P, Sharkawy S, Dietzel W. Environmental Cracking Behavior of Submerged Arc-Welded Supermartensitic Stainless Steel Weldments [J]. Journal of Materials Engineering and Performance, 2004, 13(2): 232.

Hazarabedian A, Bilmes P, Llorente C, et al. Effect of Post Weld Heat Treatments on the Damage Hydrogen Resistance of “Soft Martensitic” Stainless Steels Weld Metals [C] // SAM-CONAMET 2003. San Carlos de Bariloche: SAM-CONAMET, 2003: 242.

Bohni H. Uhlig’s Corrosion Handbook [M]. 2nd ed. Zurich: [s. n.], 2000.

Kimura M, Miyata Y, Toyooka T. Effect of Retained Austenite on Corrosion Performance for Modified 13% Cr Steel Pipe [J]. Corrosion, 2000, 57(5): 01050433.

Hara T, Asahi H. Effect of Delta-Ferrite on Sulfide Stress Cracking in a Low Carbon 13 mass% Chromium Steel [J]. ISIJ International, 2000, 40(11): 1134.

Woollin P. Post Weld Heat Treatment to Avoid Intergranular Stress Corrosion Cracking of Supermartensitic Stainless Steels [J]. Welding in the Word, 2005, 51(9/10): 31.

Beghini M, Benamati G, Bertini L, et al. Effect of Hydrogen on Tensile Properties of Martensitic Steel for Fusion Application [J]. Journal of Nuclear Materials, 1998, 258–263: 1295.

Gesnouin C, Hazarabedian A, Bruzzoni P, et al. Effect of Post-Weld Heat Treatment on the Microstructure and Hydrogen Permeation of 13CrNiMo Steels [J]. Corrosion Science, 2004, 46(7): 1633.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sebastián, Z., Estela, S. & Hernán, S. Effects of Welding Procedure on Corrosion Resistance and Hydrogen Embrittlement of Supermartensitic Stainless Steel Deposits. J. Iron Steel Res. Int. 20, 124–132 (2013). https://doi.org/10.1016/S1006-706X(13)60225-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60225-3