Abstract

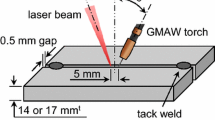

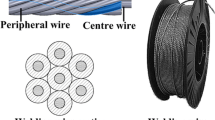

Cable welding wire (CWW) CO2 gas shielded welding is an innovative process arc welding with high efficiency, high quality and low consumption, in which cable wire is used as consumable electrode. CWW CO2 gas shielded welding and submerged arc welding (SAW) are used for contrast studies on processing property of high strength steel A36 used in ship structure. The results show that the shapes of weld seam, using CWW CO2 gas shielded welding and SAW, are good and no weld defect such as air hole, flaw, slag inclusion, incomplete fusion, lack of penetration and so on are found in the weld seam. Because the rotating of arc during CWW CO2 gas shielded welding process has a strong stirring effect on molten pool, the grain in the heat affected zone (HAZ) of the joints, using CWW CO2 gas shielded welding, is small. Tensile failure positions of joints by CWW CO2 gas shielded welding and SAW are all in the base metal, but tensile strength of CWW CO2 gas shielded welding joint is higher than that of SAW joint by an average of 2. 3%. The average impact energy of HAZ, using CWW CO2 gas shielded welding and SAW, is almost equal, but the average impact energy of the weld seam using CWW CO2 gas shielded welding is increased by 6%, and the average impact energy of the fusion line is increased by 7%. The 180° bending tests for the joints of CWW CO2 gas shielded welding and SAW are all qualified, and the joints hardness is all less than HV 355, but hardness of CWW CO2 gas shielded welding wire welding joint near the fusion line is obviously lower. It can be concluded that the properties of CWW CO2 gas shielded welding are better than those of the SAW joint, and CWW CO2 gas shielded welding is suitable for welding high strength steel A36 used in ship structure.

Similar content being viewed by others

References

PAN Ji-luan. Prospects for Welding Research in 21-st Century [J]. China Mechanical Engineering, 2000, 11(1): 21 (in Chinese).

FANG Chen-fu, HUANG Guo-jian, JIANG Chen-yu, et al. Inverter Arc Welding Machine—Inevitable Choice of Ship Building Welding [J]. Electric Welding Machine, 2000, 30(8): 7 (in Chinese).

YIN Shu-yan. Research Advance of High Effective Arc Welding Technique [J]. Welding and Joining, 2006(10): 7 (in Chinese).

Knapp I, Bartosik M. An Investigation of the TIME Welding Method [J]. Welding International, 1998, 12(1): 25.

Kim I S, Basu A. A Mathematical Model of Heat Transfer and Fluid Flow in the Gas Metal Arc Welding Process [J]. Journal of Materials Processing Technology, 1998, 77(1/2/3): 17.

ZHANG Ming-xian, WU Chuan-song, LI Ke-hai, et al. FEA Based Prediction of Weld Dimension in New DE-GMAW Process [J]. Trans China Weld Inst, 2007, 28(2): 33 (in Chinese).

XU Lu-ning, YIN Shu-yan, LU Zhen-yang. et al. Process and Development of High Efficiency MAG Process [J]. Electric Welding Machine, 2000, 30(5): 3 (in Chinese).

HU Xiao-guang. The Research on the Deposition Characteristics and the Joint Performance of the CWW CO2 Gas Shielded Welding [D]. Zhenjiang: Jiangsu University of Science and Technology, 2012 (in Chinese).

ZHOU Hang-yu. Study on CWW CO2 Gas Shielded Welding Multiple Rotating Coupled Arc and the Temperature Field [D]. Zhenjiang: Jiangsu University of Science and Technology, 2012 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item:Item Sponsored by National Natural Science Foundation of China (51275224, 51005106); Prospective Joint Research Project of Jiangsu Province of China (BY2012184)

Rights and permissions

About this article

Cite this article

Fang, Cf., He, B., Zhao, Zc. et al. Comparative Study on Processing Property Between CWW CO2 Gas Shielded Welding and SAW. J. Iron Steel Res. Int. 20, 81–86 (2013). https://doi.org/10.1016/S1006-706X(13)60087-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60087-4