Abstract

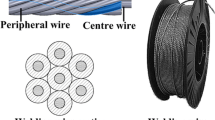

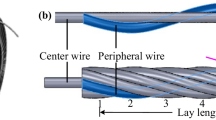

The cable-type welding wire (CWW) submerged arc surfacing (SAS) is an innovative welding process with the advantages of high efficiency, energy saving, and good welding quality. At present, this welding process has been applied to repair the large structure. This study investigate the arc heat efficiency and arc heat distribution of CWW SAS using the mathematical calculation method. The deposition rate and the surfacing layer area of CWW SAS increases with the increasing welding current. The deposition rate and the surfacing layer area of CWW SAS are larger than those in single-wire SAS. The ratio of the surfacing layer area between CWW SAS and single-wire SAS is similar to the ratio of the surfacing deposition rates between CWW SAS and single-wire SAS. The efficiency of the arc heat on melting wire in CWW SAS is larger than that in single-wire SAS. The arc heat working on base metal in CWW SAS is lower than that in single-wire SAS, leading to a smaller molten base metal area. The arc heat working on droplet transfer in CWW SAS is greater than that in single-wire SAS, leading to a larger surfacing area.

Similar content being viewed by others

REFERENCES

A. Joseph, D. Harwig, D. F. Farson, and R. Richardson, “Measurement and calculation of arc power and heat transfer efficiency in pulsed gas metal arc welding,” Sci. Technol. Weld. Joining 8, 400–406 (2003). https://doi.org/10.1179/136217103225005642

G. M. D. Cantin and J. A. Francis, “Arc power and efficiency in gas tungsten arc welding of aluminium,” Sci. Technol. Weld. Joining 10, 200–210 (2005). https://doi.org/10.1179/174329305x37033

N. Pépe, S. Egerland, P. A. Colegrove, D. Yapp, A. Leonhartsberger, and A. Scotti, “Measuring the process efficiency of controlled gas metal arc welding processes,” Sci. Technol. Weld. Joining 16, 412–417 (2011). https://doi.org/10.1179/1362171810Y.0000000029

M. B. Nasiri, M. Behzadinejad, H. Latifi, and J. Martikainen, “Investigation on the influence of various welding parameters on the arc thermal efficiency of the GTAW process by calorimetric method,” J. Mech. Sci. Technol. 28, 3255–3261 (2014). https://doi.org/10.1007/s12206-014-0736-8

A. Haelsig, M. Kusch, and P. Mayer, “New findings on the efficiency of gas shielded arc welding,” Weld. World 56 (11–12), 98–104 (2012). https://doi.org/10.1007/bf03321400

A. Haelsig and P. Mayr, “Energy balance study of gas-shielded arc welding processes,” Weld. World 57, 727–734 (2013). https://doi.org/10.1007/s40194-013-0073-z

A. Haelsig, M. Kusch, and P. Mayr, “Calorimetric analyses of the comprehensive heat flow for gas metal arc welding,” Weld. World 59, 191–199 (2015). https://doi.org/10.1007/s40194-014-0193-0

A. Haelsig, P. Mayr, and M. Kusch, “Determination of energy flows for welding processes,” Weld. World 60, 259–266 (2016). https://doi.org/10.1007/s40194-016-0297-9

J. N. Dupont and A. R. Marder, “Thermal efficiency of arc welding processes,” Weld. J. 74, 406–416 (1995).

C. Fang, Z. Chen, G. Xu, Q. Hu, H. Zhou, and Z. Shi, “Study on the process of CTWW CO2 gas shielded welding,” Acta Metall. Sin. 48, 1299–1305 (2012). https://doi.org/10.3724/sp.j.1037.2012.00296

C. Fang, Yo. Chen, Z. Yang, J. Wang, M. Wu, and K. Qi, “Cable-type welding wire submerged arc surfacing,” J. Mater. Process. Technol. 249, 25–31 (2017). https://doi.org/10.1016/j.jmatprotec.2017.05.020

C. Y. Liu and S. S. Huang, “Electrode arc equation and thermodynamic analysis of submerged arc welding with constant current power supply,” Trans. China Weld. Inst. 28, 22–24 (2007).

D. Radaj, Heat Effects of Welding (China Machine Press, 1997).

Yo. Chen, C. Fang, T. Zhang, Q. Li, Q. Hong, and L. Hua, “The decoupling behavior of arc coupling and rotating in seven-wire rotating arc EGW,” J. Manuf. Processes 55, 96–102 (2020). https://doi.org/10.1016/j.jmapro.2020.03.062

Yo. Chen, X. Sun, T. Zhang, Q. Li, S. Ni, and C. Fang, “Arc rotating behavior of SRA EGW in AH36 steel,” Mater. Manuf. Processes 35, 556–563 (2020). https://doi.org/10.1080/10426914.2020.1729987

J. S. Zou, Materials Joining Theories and Process (Harbin Institute of Technology Press, 2008).

Funding

This work was supported by the National Science Foundation of the Jiangsu Higher Education Institutions of China (Grant no. 20KJB460015); Start-up Fund for New Talented Researchers of Nanjing Vocational University of Industry Technology (Grant no. YK19-01-04), and the National Natural Science Foundation of China (Grant no. 51575250).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yong Chen, Xianrui Zhao, Tao Zhang et al. Arc Heat Distribution in Cable-Type Welding Wire Submerged Arc Surfacing. Phys. Metals Metallogr. 124, 1826–1836 (2023). https://doi.org/10.1134/S0031918X22601500

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22601500