Abstract

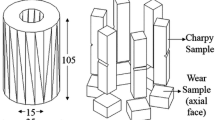

Dry sliding wear tests of a Cr-Mo-V cast hot-forging die steel was carried out within a load range of 50–300 N at 400 °C by a pin-on-disc high-temperature wear machine. The effect of heat treatment process on wear resistance was systematically studied in order to select heat treatment processes of the steel with high wear resistance. The morphology, structure and composition were analyzed using scanning electron microscopy (SEM), X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS); wear mechanism was also discussed. Tribo-oxide layer was found to form on worn surfaces to reduce wear under low loads, but appear inside the matrix to increase wear under high loads. The tribo-oxides were mainly consisted of Fe3O4 and Fe2O3, FeO only appeared under a high load. Oxidative mild wear, transition of mild-severe wear in oxidative wear and extrusive wear took turns to operate with increasing the load. The wear resistance strongly depended on the selection of heat treatment processes or microstructures. It was found that bainite presented a better wear resistance than martensite plus bainite duplex structure, martensite structure was of the poorest wear resistance. The wear resistance increased with increasing austenizing temperature in the range of 920 to 1120 °C, then decreased at up to 1 220 °C. As for tempering temperature and microstructure, the wear resistance increased in following order: 700 °C (tempered sorbite), 200 °C (tempered martensite), 440 to 650 °C (tempered troostite). An appropriate combination of hardness, toughness, microstructural thermal stability was required for a good wear resistance in high-temperature wear. The optimized heat treatment process was suggested for the cast hot-forging steel to be austenized at 1020 to 1120 °C, quenched in oil, then tempered at 440 to 650 °C for 2 h.

Similar content being viewed by others

References

Castro G, Fernandez-Vicente A, Cid J. Influence of the Nitriding Time in the Wear Behaviou of an AISI HI3 Steel During a Crankshaft Forging Process [J]. Wear, 2007, 263: 1375.

Beeley P R, Blackmore A. Production and Evaluation of Cast-to-Form Forging Dies in a Special Cast Steel [J]. Met Technol, 1981, 17–18: 268.

Beeley P R. Cast Steels for Tools and Dies: a Review [J]. The British Foundryman, 1986, 79: 441.

Jiang Q C, Fang J R, Wang S Q, et al. Selection of Tempering Technology of New Cast Die Steel for Hot Forging [J]. Metal Heat Treatment, 2000, 25: 34.

Barrau O, Boher C, Gras R, et al. Analysis of the Friction and Wear Behaviour of Hot Work Tool Steel for Forging [J]. Wear, 2003, 255: 1444.

Luong L H S, Heijkoop T. The Influence of Scale on Friction in Hot Metal Working [J]. Wear, 1981, 71: 93.

Zhu Z Y. Data of Hot Working Die Steels [J]. Mechanical Engineering Materials, 2001, 25: 40.

CUI Xiang-hong. High-Temperature Wear of a New-Developed Hot-Forging Cast Die Steel [D]. Changchun: Jilin University, 2006 (in Chinese).

CUI Xiang-hong, SHAN Jun, YANG Zi-run, et al. Alloying Design for High Wear-Resistant Cast Hot-Forging Die Steels [J]. Journal of Iron and Steel Research, International, 2008, 15(4): 67.

Cui X H, Wang S Q, Jiang Q C, et al. Research on Thermal Wear of Cast Hot Forging Die Steel Modified by Rare Earths [J]. Journal of Rare Earths, 2007, 25: 88.

Wei M X, Wang F, Wang S Q, et al. Comparative Research on the Elevated-Temperature Wear Resistance of a Cast Hot-Working Die Steel [J]. Materials and Design, 2009, 30: 3608.

Quinn T F J, Sullivan J L, Rowson D M. Developments in the Oxidational Theory of Mild Wear [J]. Tribology International, 1980, 13: 153.

So H, Yu DS, Chuang C Y. Formation and Wear Mechanism of Tribo-Oxides and the Regime of Oxidational Wear of Steel [J]. Wear, 2002, 253: 1004.

Wilson J E, Stott F H, Wood G C. The Development of Wear Protective Oxides and Their Influence on Sliding Friction [J]. Proc R Soc, 1980, 369A: 557.

Quinn T F J. Oxidational Wear Modelling Part III: the Effects of Speed and Elevated Temperatures [J]. Wear, 1998, 216: 262.

Suh N P. The Delamination Theory of Wear [J]. Wear, 1973, 25: 111.

Wang S Q, Wei M X, Wang F, et al. Transition of Elevated-Temperature Wear Mechanisms and the Oxidative Delamination Wear in Hot-Working Die Steels [J]. Tribology International, 2010, 43: 577.

Wang S Q, Wei M X, Zhao Y T. Effects of the Tribo-Oxide and Matrix on Dry Sliding Wear Characteristics and Mechanisms of a Cast Steel [J]. Wear, 2010, 269: 424.

QI Zheng-feng. Metal Heat-Treatment Principles [M]. Beijing: Machinery Industry Press of China, 1987: 159 (in Chinese).

Jahanmir S, Suh N P. Mechanics of Subsurface Void Nucleation in Delamination Wear [J]. Wear, 1977, 44, 17.

Wang S Q, Wei M X, Wang F, et al. Transition of Mild Wear to Severe Wear in Oxidative Wear of H21 Steel [J]. Tribology Letter, 2008, 32: 67.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Nature Science Foundation of China (51071078)

Rights and permissions

About this article

Cite this article

Wei, Mx., Wang, Sq., Wang, L. et al. Selection of Heat Treatment Process and Wear Mechanism of High Wear Resistant Cast Hot-Forging Die Steel. J. Iron Steel Res. Int. 19, 50–57 (2012). https://doi.org/10.1016/S1006-706X(12)60099-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60099-5