Abstract

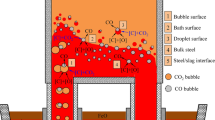

A mathematical model in present study has been established to investigate the effect of Rheinstahl Heraeus (RH) blow argon mode on the decarburization rate in ultra-low carbon steel refining based on the RH equipment of Shougang Qian’an Iron and Steel Co Ltd (SQISCO). The calculated results show that the increase of argon flowrate promotes the carbon elimination from argon gas bubble surface, molten steel free surface in vacuum as well as splash droplet surface, while reduces that from the interior of liquid steel. It has been found the critical turning point of flowrate ascension is at the 5th minute and the optimum blow argon flowrate in later stage is 2 100 L/min in accordance with the 2 stages argon blow mode, which have been confirmed in the commercial production in SQISCO.

Similar content being viewed by others

References

Masamitsu T, Hiroshi M, Tadashi S. Mechanism of Decar-burization in RH Degasser [J]. ISU International, 1995, 35 (12): 1452 (in Japanese).

YU Neng-wen. Mathematical and Physical Modeling of Multifunction RH Refining Process [D]. Shanghai: Shanghai University, 2001 (in Chinese).

The Japan Society for the Promotion of Science. Steelmaking Data Sourcebook [M]. New York: GBSP Publishers, 1984.

LI Chong-wei, CHENG Guo-guang, WANG Xin-hua, et al. The Establishment of RH Natural Decarburization Mathematical Model and the Study of Mechanism of Decarburization [J]. Journal of the Chinese Rare Earth Society, 2010(3): 112 (in Chinese).

Levich V G. Physicochemical Hydrodynamics [M]. Engle-wood Cliffs: Prentice-Hall Inc, 1962.

Harashima K, Mizoguchi S, Kajioka H. Kinetics of Decaburization of Low Carbon Liquid Iron under Reduced Pressures [J]. Tetsu-to-Hagane, 1988, 74: 449.

Park Y G, Doo W C, Yi K W, et al. Numerical Calculation of Circulation Flow Rate in the Degassing Rheinstahl-Heraeus Process [J]. ISIJ International, 2000, 40: 749.

Wallis G B, Mcgraw-Hill. One-Dimensional Two-phase Flow [M]. New York: [s. n. ], 1969.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Key Technology Research and Development Program in 11th Five-Year Plan of China (2006BAE03A13)

Rights and permissions

About this article

Cite this article

Li, Cw., Cheng, Gg., Wang, Xh. et al. Mathematical Model of RH Blow Argon Mode Affecting: Decarburization Rate in Ultra-Low Carbon Steel Refining. J. Iron Steel Res. Int. 19, 23–28 (2012). https://doi.org/10.1016/S1006-706X(12)60095-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60095-8