Abstract

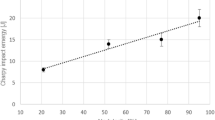

Complete experimental investigation on the instantaneous strain hardening behaviour of powder metallurgy (P/M) preforms of pure iron, Fe-0. 35%C, Fe-0. 75%C and Fe-1. 1%C was carried out. The strain hardening behaviour of the above-mentioned P/M sintered steel preforms with aspect ratio of 0. 4 under triaxial stress state condition was determined by cold upsetting under nil/no and graphite lubricant conditions. The instantaneous strain hardening value (ni), strength coefficient (Ki), and the stress as a function of strain and densification were obtained and analyzed. Furthermore, a relation was obtained from a semi-log plot of stress against relative density and analyzed to study the hardening behaviour owing to densification as stress was a function of induced strain as well as densification in the P/M materials.

Similar content being viewed by others

References

Agarwal M, Kumar S, Sutradhar G. Deformation of Solid Powder Discs and Strips Under Lubricated Condition [J]. J Mater Process Technol, 2002, 123(3): 440.

Hua L, Qin X, Mao H, et al. Plastic Deformation and Yield Criterion for Compressible Sintered Powder Materials [J]. J Mater Process Technol, 2006, 180(1/2/3): 174.

Kandavel T K, Chandramouli R, Ravichandran M. Experimental Study on the Plastic Deformation and Densification Characteristics of Some Sintered and Heat Treated Low Alloy Powder Metallurgy Steels [J]. Mater Des, 2010, 31(1): 485.

Wang B, Zhang E. On the Compressive Behavior of Sintered Porous Coppers With Low-to-Medium Porosities—Part II: Preparation and Microstructure [J]. Int J Mech Sci, 2008, 50 (3): 550.

Lindskog P. Economy in Car-Making—Powder Metallurgy [R]. London: Global Automotive Manufacturing and Technology, 2003.

Narayanasamy R, Anandakrishnan V, Pandey K S. Effect of Carbon Content on Workability of Powder Metallurgy Steels [J]. Mater Sci Eng, 2008, 494A(1/2): 337.

Narayanasamy R, Anandakrishnan V, Pandey K S. Effect of Molybdenum Addition on Workability of Powder Metallurgy Steels During Cold Upsetting [J]. Mater Sci Eng, 2009, 517A (1/2): 30.

Rajeshkannan A, Narayan S. Strain Hardening Behaviour in Sintered Fe-0. 8%C-l. 0%Si-0. 8%Cu Powder Metallurgy Preform During Cold Upsetting [J]. J Eng Manufacture, 2009, 223(12): 1567.

Selvakumar N, Ganesan P, Radha P, et al. Modelling the Effect of Particle Size and Iron Content on Forming of Al-Fe Composite Preforms Using Neural Network [J]. Mater Des, 2007, 28(1): 119.

Narayanasamy R, Pandey K S. Some Aspects of Work Hardening in Sintered Aluminium—Iron Composite Preforms During Cold Axial Forming [J], J Mater Process Technol, 1998, 84(1/2/3): 136.

Kahlow K J. Void Behaviour as Influenced by Pressure and Plastic Deformation [R]. Bethlehem: Institute for Metal Forming Report, Lehigh University, 1971.

Taha M A, El-Mahallawy N A, El-Sabbagh A M. Some Experimental Data on Workability of Aluminium-Particulate-Reinforced Metal Matrix Composites [J]. J Mater Process Technol, 2008, 202(1/2/3): 380.

Zhang X Q, Peng Y H, Ruan X Y, et al. Study of Workability Limits of Porous Materials Under Different Upsetting Conditions by Compressible Rigid Plastic Finite Element Method [J]. J Mater Eng Perform, 2000, 9(2): 164.

Narayanasamy R, Ramesh T, Pandey K S. An Investigation on Instantaneous Strain Hardening Behaviour in Three Dimensions of Aluminium-Iron Composites During Cold Upsetting [J]. Mater Sci Eng, 2005, 391A(1/2): 149.

Ebrahimi R, Pardis N. Determination of Strain-Hardening Exponent Using Double Compression Test [J]. Mater Sci Eng, 2009, 497A(1/2): 56.

Pandey K S. Some Investigations on the Cold Deformation Behaviour of Sintered Aluminium-4 % Copper Alloy Powder Preforms [J]. Int J Powder Met Sci Technol, 1991, 2(4): 45.

Kandavel T K, Chandramouli R, Shanmugasundaram D. Experimental Study of the Plastic Deformation and Densification Behaviour of Some Sintered Low Alloy P/M Steels [J]. Mater Des, 2009, 30(5): 1768.

DONG Xian-feng, HU Jian-dong, WANG Hong-ying, et al. A Study on Carbon Concentration Distribution and Microstructure of P/M Materials Prepared by Carbusintering [J]. J Mater Process Technol, 2009, 209(8): 3776.

Fillabi M G, Simchi A, Kokabi A H. Effect of Iron Particle Size on the Diffusion Bonding of Fe-5%Cu Powder Compact to Wrought Carbon Steels [J]. Mater Des, 2008, 29(2): 411.

Doraivelu S M, Gegel H L, Gunasekera J S, et al. A New Yield Function for Compressible P/M Materials [J]. Int J Mech Sci, 1984, 26(9/10), 527.

Narayanasamy R, Anandakrishnan V, Pandey K S. Effect of Geometric Work-Hardening and Matrix Work-Hardening on Workability and Densification of Aluminium-3. 5% Alumina Composite During Cold Upsetting [J]. Mater Des, 2008, 29 (8): 1582.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narayan, S., Rajeshkannan, A. Influence of Carbon Content on Strain Hardening Behaviour of Sintered Plain Carbon Steel Preforms. J. Iron Steel Res. Int. 18, 33–40 (2011). https://doi.org/10.1016/S1006-706X(12)60031-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60031-4