Abstract

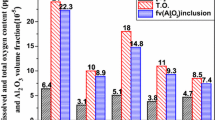

Alloying structural steel used for mechanical structures has a high requirement for cleanliness because its failures are greatly affected by non-metallic inclusions and total oxygen content in steel. It has been reported by some steelmaking plants to have some problems in controlling total oxygen content and inclusions during alloying structural steel production. For this purpose, cleanliness control in 0. 2C-0. 3Si-O. 6Mn-1Cr-0. 2Mo steel was investigated. Firstly, low melting temperature zone (⩽ 873 K) of CaO-Al2O3-MgO system and formation condition of low melting temperature inclusions were investigated through thermodynamic equilibrium calculation. On this basis, industrial tests were carried out. Through sampling at different stages, transformation of oxide inclusions and change of total oxygen content in steel were studied. The results show that: in order to form CaO-Al2O3-MgO system inclusions with low melting temperature, mass percent of A12O3, MgO and CaO in inclusions should be controlled from 37. 6% to 70. 8%, 0 to 17. 4% and 25. 5% to 60. 6%; For the condition of 1 873 K and 0. 05% (mass percent) dissolved aluminum in steel, the activities of dissolved oxygen, magnesium and calcium should be controlled as 0. 298 × 10−4 — 2 × 10−4, 0. 1 × 10−5 — 40 × 10−5 and 0. 8 × 10−8—180 × 10−8 respectively. With secondary refining proceeding, average total oxygen content and inclusion amount decrease, the type of most inclusions changes from Al2O3 after tapping to Al2O3-MgO after top slag is formed during ladle furnace refining and finally to CaO-Al2O3-MgO after RH treatment. In the final products, average total oxygen content was 12. 7 × 10−6 and most inclusions were in spherical shape with size less than 5 μm.

Similar content being viewed by others

References

WANG Xin-hua, CHEN Bin. Formation of Non-Metallic Inclusions With Lower Melting Temperatures by Slag-Metal Reaction for High Strength Alloying Steels [C]//The 4th International Congress on the Science and Technology of Steelmaking. Gifu; The Iron and Steel Institute of Japan, 2008: 21.

Abe Takayukil, Furuya Yoshiyukil, Matsuoka Saburo. Significance of Size and Type of Inclusions on Giga-Cycle Fatigue in High-Strength Steels [J]. Journal of the Iron and Steel Institute of Japan, 2003, 89(6): 711 (in Japanese).

JIANG Min, WANG Xin-hua. Formation of MgO · A12O3 Inclusions in High Strength Alloyed Structural Steel Refined by CaO-Si2-Al2O3-MgO Slag [J]. ISIJ International, 2008, 48(7):885.

Murakami Y, Kodama S, Konuma S. Quantitative Evaluation of Effects of Non-Metallic Inclusions on Fatigue Strength of High Strength Steels, I. Basic Fatigue Mechanism and Evaluation of Correlation Between the Fatigue Fracture Stress and the Size and Location of Non-Metallic Inclusions [J]. International Journal of Fatigue, 1989, 11. 291.

Wang Q Y, Bathias C, Kawagoishi N, et al. Effect of Inclusion on Subsurface Crack Initiation and Giga-Cycle Fatigue Strength [J]. International Journal of Fatigue, 2002, 24: 1269.

ZHANG Li-feng. Clean Steel and Inclusions [C]// 13th National Steelmaking Conference. Kunming: Metallurgical Industry Press, 2004: 36 (in Chinese).

Tardy P, Karoly Gy. Development of Clean Steel From 1970 to 2002 [C]// Proceedings of the 6th international Conference on Clean Steel. Balatonfured: [s. n.], 2002: 49.

Bertrand C, Molinero J, Landa S, et al. Metallurgy of Plastic Inclusions to Improve Fatigue Life of Engineering Steels [J]. Ironmaking and Steelmaking, 2003, 30(2): 165.

MIAO Xin-de, YU Chun-mei, SHI Chao-min. Formation and Controlling of Calcium-Aluminates Inclusions in Bearing Steel [J]. Journal of University of Science and Technology Beijing, 2007, 29(8): 771 (in Chinese).

JIN Li-ling, WANG Hai-tao, XU Zhong-bo. Composition Control of a CaO-SiO2-Al2O3-MnO System in Tire Cord Steel [J]. Journal of University of Science and Technology Beijing, 2007, 29(4): 377 (in Chinese).

Choudhary S K, Chandra S, Ghosh A. Prediction of Deoxidation and Inclusion Precipitation in Semi-Killed Steel [J]. Metallurgical and Materials Transactions, 2005, 36B: 59.

Suito H, Ryo Inoue. Thermodynamics on Control of Inclusions Composition in Ultra Clean Steels [J]. ISIJ International, 1996, 36(5): 528.

Ohta H, Suito H. Activities in CaO-MgO-Al2 O3 Slags and Deoxidation Equilibria of Al, Mg and Ca [J]. ISIJ International, 1996, 36(8): 983.

Sakai H, Suito H. Liquid Phase Boundaries at 1873 K in the Ternary CaO-Al2O3-MOx,(MOx MgO, ZrO2) and CaO-SiO2-MOx(MOx: TiO2, MgO, A12O3) Systems [J]. ISIJ International, 1996, 36(2): 138.

YE Guo-zhu, JONSS Par. Thermodynamics and Kinetics of the Modification of Al2O3 Inclusions [J]. ISIJ International, 1996, 36(Supplement): 105.

Korousic B. Fundamental Thermodynamic Aspects of the CaO-Al2O3-SiO2 System [J]. Steel Research, 1991, 62(7): 285.

Joo Hyun PARK. Formation Mechanism of Spinel-Type Inclusions in High-Alloyed Stainless Steel Melts [J]. Metallurgical and Materials Transactions, 2007, 38B: 657.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Basic Research Program of China (2010CB630806)

Rights and permissions

About this article

Cite this article

Yu, Hx., Wang, Xh., Zhang, J. et al. Cleanliness of Alloying Structural Steel. J. Iron Steel Res. Int. 18, 6–11 (2011). https://doi.org/10.1016/S1006-706X(12)60002-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60002-8