Abstract

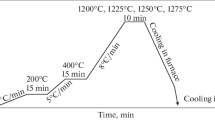

The Microstructure and room temperature abrasive wear resistance of chromium carbide reinforced Ni3Al matrix composite cladding at different depth on nickel base alloy were investigated. The results showed that there is a great difference in microstructure and wear resistance of the Ni3Al matrix composite at different depth. Three kinds of tests, designed for different load and abrasive size, were used to understand the wear behaviour of this material. Under all three wear conditions, the abrasion resistance of the composite cladding at the depth of 6 mm, namely NC-M2, was much higher than that of the composite cladding at the depth of 2 mm, namely NC-M1. In addition, the wear-resistant advantage of NC-M2 was more obvious when the size of the abrasive was small. The relative wear resistance of NC-M2 increased from 1.63 times to 2.05 times when the size of the abrasive decreased from 180 μm to 50 μm. The microstructure of the composite cladding showed that the size of chromium carbide particles, which was mainly influenced by cooling rate of melting pool, was a function of distance from the interface between the coating and substrate varied gradually. The chromium carbide particles near the interface were finer than that far from interface, which was the main reason for the different wear resistance of the composite cladding at different depth.

Similar content being viewed by others

References

Hans Berns, Stefan Koach. High Temperature Sliding Abrasion of a Nickel-Base Alloy and Composite [J]. Wear, 1999, (225–229): 154.

Dogan Ö N, Hawk J A, Tylczak J H, et al. Wear of Titanium Carbide Reinforced Metal Matrix Composite [J]. Wear, 1999, (225–229): 758.

Colaco R, Vilar R. Abrasive Wear of Metallic Matrix Reinforced Materials [J]. Wear, 2003, (255): 643.

Sikka V K, Deevi S C, Viswanathan S, et al. Advances in Processing of Ni3Al-Matrixd Intermetallics and Applications [J]. Intermetallics, 2000, (8): 1329.

Blau P J, Devore C E. Sliding Behavior of Alumina/Nickel and Alumina/Nickel Aluminide Couples at Room and Elevated Temperature [J]. Journal of Tribology, 1988, (110): 646.

Peter J Blau, Charles E Devore. Sliding Friction and Wear Behavior of Several Nickel Aluminide Alloys Under Dry and Lubricated Conditions [J]. Tribology International, 1990, 23(4): 226.

Fuchs G E. Development of Ni-Aluminide Based Composites for Elevated Temperature Applications [A]. Bhagat R B, Clauer A H, Kumar P, eds. Metal and Ceramic Matrix Composites: Processing, Modeling and Mechanical Behavior [C]. Anaheim; The Minerals, Metals and Materials Society, 1990. 391.

Compilatory Group of Machine-Producing Technology and Material. Handbook of Machine-Producing Technology and Material [M]. Beijing: Machine Industry Press, 1993.

LI Shang-ping, FENG Di, LUO He-li, et al. Development of New Wear-Resistant Surface Coating at Elevated Temperature [J]. Journal of Iron and Steel Research, International, 2006, 13(5): 37.

LI Shang-ping, FENG Di, LUO He-li. Microstructure and Abrasive Wear Performance of Chromium Carbide Reinforced Ni3Al Matrix Composite Coating [J]. Surface and Coating Technology, 2007, 201: 4542.

Hu J, Li D Y, Llewellyn R. Computational Investigation of Microstructural Effects on Abrasive Wear of Composite Materials [J]. Wear, 2005, 259: 6.

YIN Ruo-cai. Principle of Molten Welding and Metal Welding [M]. Beijing: Machine Industry Press, 2000 (in Chinese).

Deevi S C, Sikka V K. Exo-MeltTM Process for Melting and Casting Intermetallics [J]. Intermetallics, 1997, 5: 17.

Zhang Z F, Zhang L C, Mai Y W. Wear of Ceramic Particle Reinforced Metal-Matrix Composites [J]. J Mater Sci, 1995, 30: 1961.

Yilmaz O, Buytoz S. Abrasive Wear of Al2O3-Reinforced Aluminium-Based MMCs [J]. Compos Sci Technol, 2001, 61: 2381.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High Technical Research and Development Program of China (2002AA3310700)

Rights and permissions

About this article

Cite this article

Li, Sp., Luo, Hl., Feng, D. et al. Abrasive performance of chromium carbide reinforced Ni3Al matrix composite cladding. J. Iron Steel Res. Int. 16, 87–91 (2009). https://doi.org/10.1016/S1006-706X(10)60016-7

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(10)60016-7