Abstract

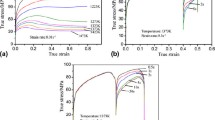

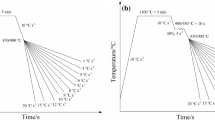

According to thermodynamics and kinetics of phase transformation, a mathematical model of phase transformation was proposed, and the microstructure evolution of an 82B rod at different cooling rates was simulated by using the FEM software Marc/Mentat, based on the measurement of time-temperature transformation (TTT) curves of the 82B rod. The simulated results were in good agreement with the actual measurements. From the results of computer simulation it was found that the cooling rate of the 82B rod, after laying, should be controlled within 5–8 °C/s. In the microstructure of rod there were over 95% of pearlite volume fraction and a small quantity of dispersive martensite (less than 5 %).

Similar content being viewed by others

References

Agrawal K, Brimacombe J K. Mathematical Model of Heat Flow and Austenite-Pearlite Transformation in Euteetoid Car bon Steel Rods for Wire [J]. Metallurgical Transactions, 1981, 12B: 121.

YE J S, CHANG H B, XU Z Y. Modeling for Formation of Proeutectoid Ferrite in Steel During Continuous Cooling [J]. Journal of Iron and Steel Research, International, 2004, 11(6); 33.

Homberg D. A Numerical Simulation of the Jominy End-Quench Test [J]. Acta Materialia. 1996, 44: 4375.

Serajzadeh S. Modeling of Temperature History and Phase Transformations During Cooling of Steels [J]. Journal of Materials Processing Technology, 2004, 146: 311.

CHENG H M, HUANG X Q, WANG H G. Calculation of the Residual of a 45 Steel Cylinder With a Non-Linear Surface Heat-Transfer Coefficient Including Phase Transformation During Quenching [J]. Journal of Materials Processing Technology, 1999, 89-90: 339.

PAN J S, LI Y J, LI D Q. The Application of Computer Simulation in the Heat-Treatment Process of a Large-Scale Bearing Roller [J]. Journal of Materials Processing Technology, 2002, 122: 241.

Koistinen D P, Marburger R E. A General Equation Describing the Extent of the Austenite-Martensite Transformation in Pure Iron-Carbon Alloys and Plain Carbon Steels [J]. Acta Metallurgica, 1959, 7(1), 59.

PAN J S, HU M J, TIAN D, et al. Computer Simulation of 3-D Temperature Fields and Phase Transformation in the Quenching Process of 45 Steel [J]. Hot Working Technology, 1998, (1): 9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by the National Doctorate Fund by the Ministry of Education of China (20020008011)

Rights and permissions

About this article

Cite this article

Xu, Jq., Liu, Yz. & Zhou, Sm. Computer Simulation of Microstructure Evolution of 82B Rod at Different Cooling Rates. J. Iron Steel Res. Int. 15, 56–59 (2008). https://doi.org/10.1016/S1006-706X(08)60032-1

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60032-1