Abstract

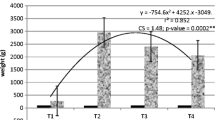

This study evaluated the impact of incorporating Zootech feed fortifier mix into a graded ration of sawdust and palm kernel cake (PKC); a high fibre diet, on the growth performance, carcass, organoleptic, and bio-economics of turkey birds. This eight-week feeding trial involved 320 unsexed indigenous strains of turkey poults brooded in deep litter and assigned to four dietary treatments (T1, T2, T3, and T4). The experimental design involved four treatments with four replicates, with a total of twenty birds per replicate. The treatment diets/groups were as follows: T1 (farmer’s practice turkey diet/standard turkey feed), T2 (5% sawdust/18% PKC), T3 (10% sawdust/13% PKC), and T4 (15% sawdust/8% PKC). It was revealed from this study that turkeys fed T4 diets exhibited significantly higher differences (p < 0.01) in final weight gain and average daily weight gain compared to other treatments. At the same time, T1 (control) had the lowest weight gain. Average daily feed intake had a significantly higher difference (p < 0.01) in turkeys fed T4 diets, with the lowest intake in the control group. Turkeys fed T4 and control diets achieved the best feed conversion ratio, while T2 and T3 groups were less efficient. Carcass traits and internal organ proportions were significantly higher (p < 0.05) in turkeys fed T4 diets. The organoleptic assessment indicated superior meat quality (p < 0.05) in treatment four groups . Economic analysis revealed significantly lower costs per kilogram of feed and total feed consumed in T2, T3, and T4 groups compared to the control (p < 0.05) groups. In summary, incorporating a Zootech feed fortifier into a sawdust/palm kernel diet positively influenced turkey growth, feed efficiency, carcass traits, tastes, and economic viability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The production of turkey birds has demonstrated economic value and social significance in West African countries, particularly as gifts and during festivities. Despite the favourable attributes associated with turkey, its production remains notably low compared to other poultry species. In Nigeria, the commercial-scale production of turkeys faces challenges such as concerns about the availability of the birds, the high cost of feed materials, inadequate information on the nutrient requirements of turkeys [1] as well as the high prices of the poults: foreign and local. Numerous alternative feedstuffs, possessing substantial potential as poultry feed ingredients, are abundantly available in Nigeria. These feedstuffs, sourced as waste from agro-processing and allied industries, include palm kernel cake, sawdust, jackfruit seeds, rice husks, and cassava sieving/peels, among others, as reported by [2, 3]. Utilizing sawdust sourced from timber milling industries, which is abundantly available at minimal cost, presents an opportunity for its integration into livestock and poultry nutrition. This approach can serve as an incentive for increased engagement of farmers in poultry and livestock production while simultaneously mitigating environmental pollution associated with these wood materials. However, before utilization, pre-feeding treatment is imperative to mitigate anti-nutrient effects and break down the polysaccharide and lignin content of the sawdust into simpler carbohydrates, thereby enhancing its digestibility by livestock and poultry. Also, [4] proposed the use of Zootech feed fortifier mix, a life enzyme with a strong potential for breaking down the recalcitrance of lignin and the crystalline nature of cellulose present in sawdust. This approach not only holds promise for reducing the cost of turkey production but also addresses environmental concerns related to pollution, digestion of fiber, and waste recycling. A study [5] indicated that Nigeria generates approximately 1.8 million tonnes of sawdust annually, while [6] reported over five million tonnes of wood residue per year. Regrettably, the implementation of inadequate management strategies has resulted in detrimental environmental outcomes, as a significant portion of the residual wood stays untreated and underutilized. Common disposal methods, such as piling at industrial sites, dumping along roadsides and in drainages, water bodies, and open-air burning; contribute to the destruction of biodiversity and human health, emission of harmful gases and eutrophication of water bodies [7]. Two dietary fiber components: soluble and insoluble fiber are found in plant-based foods including legumes, whole grains, cereals, vegetables, fruits, nuts, and seeds. Consuming a diet rich in fiber is generally associated with promoting overall health and reducing the risk of various diseases [8, 9]. The influence of dietary fiber is manifested through alterations in the composition of the gastrointestinal tract contents and modifications in the absorption of other nutrients and chemicals [10]. Despite the prevailing belief among poultry producers and feed industries that the fiber content of standardized diets should not exceed 7%, recent advancements in nutritional research and biotechnological approaches to fiber utilization in poultry nutrition suggest a shift toward higher fiber levels. Poultry lack the digestive structure necessary to handle high-fiber diets, preventing extensive bacterial digestion and hindering the proper utilization of fibrous feeds [11] but fiber levels of 8–10% have been recommended for broiler finishers, challenging the notion that dietary fiber merely serves as a diet diluent in poultry feeding [12]. Studies have indicated that incorporating moderate percentages of various fiber sources in poultry diets enhances digestive organ development [13, 14] and increases the secretion of hydrochloric acid (HCL), bile acids, and enzymes [15]. This leads to improved nutrient digestibility [16,17,18], growth performance [19, 20], and gastrointestinal tract (GIT) health [21,22,23]. Therefore, this study explores the biotechnological implications of utilizing Anigbogu's innovative Zootech feed fortifier mix into a graded ration of sawdust and palm kernel cake (PKC) diet on growth performance, organoleptic assessment of turkey meat quality, and economic gains within the value chain of turkey production.

2 Materials and methods

2.1 Location of the experiment

The research was conducted at the poultry research unit within the teaching and research farm of Michael Okpara University of Agriculture, Umudike, Umuahia, Abia State, Nigeria.

2.2 Experimental birds and diets

A significant quantity of untreated sawdust, exceeding 200 kg, was acquired from a timber milling factory in Umuahia, Abia State, Nigeria, to meet the experimental requirements. The sawdust originated from an Iroko tree (Milicia excelsa). To reduce moisture content, the sawdust underwent sun-drying and was then sieved through a 1 mm mesh to eliminate foreign materials. Some samples of untreated sawdust and Zootech feed fortifier were collected and stored over a desiccant to prevent moisture absorption and humidity until they were used for proximate analysis. This precaution aimed to preserve the chemical composition of the sawdust and feed fortifier, ensuring precise analytical results. For the experiment, 320 unsexed turkey poults of local strain were acclimatized in deep litter for a week. Subsequently, they were randomly weighed and assigned to four treatment diets labelled T1, T2, T3, and T4, each replicated four times with 20 birds per replicate. T1 represented a standard turkey feed (farmer's practice) from a feed company, containing no experimental diet. The feeds used for the treatment groups were formulated as follows: T2 comprised 5% sawdust and 18% PKC (palm kernel cake), T3 included 10% sawdust and 13% PKC, and T4 consisted of 15% sawdust and 8% PKC per kg. The zootech feed fortifer was added to the treatment groups at 5% per kg. The proximate chemical composition of untreated sawdust is presented in Table 1, while Tables 2 and 3 show the proximate composition of the Zootech feed fortifier analyzed using the guidelines provided in the [24] AOAC methods. In addition, the nutrient/proximate compositions and quantities of feed ingredients required to meet the metabolisable energy, crude fiber, and crude protein requirements for turkey poultry were determined using the National Listing of Approved Feed Ingredients for Feedmills in Nigeria [25] and Pearson’s Square method of straight feed formulation [26], as presented in Table 3. Water and feed were provided ad libitum, with other management practices (vaccinations etc.) duly executed. The feeding trial lasted for eight weeks. It is pertinent to know that all the houses and equipment used for the experiment were disinfected and sterilized before brooding and experiment. These birds were slaughtered, and their carcasses were utilized for evaluating organoleptic and carcass characteristics.

2.3 Data collection

The study encompassed the evaluation of various parameters, including growth performance, carcass characteristics, economics, and organoleptic attributes. Voluntary daily feed intake for growth assessment was calculated by deducting leftovers from the total feed provided, and this measurement was initiated during the second-week post-brooding. The calculation of the average body weight gain (BW gain) involved dividing the difference between two consecutive weights by the total number of turkeys. The average daily gain (ADG) was determined by dividing the final change in body weight by the number of experimental days. The feed conversion ratio was determined as the ratio of average daily feed intake to average daily weight gain. The collective body weights of the birds were recorded at the commencement of the experiment and subsequently every week until the conclusion of the trial. This process was carried out using a precision platform scale with a sensitivity of 0.001 g. Upon completion of the feeding trial, a total of forty-eight turkeys with weights slightly above or equal to the mean weight of the group were selected, with three birds chosen from each replicate within all treatment groups for the assessment of carcass characteristics. To empty their gastrointestinal tracts (GITs) and reduce carcass contamination by GIT contents, a 15 h fasting period preceded slaughter, during which the birds had continuous access to water. The slaughtering process involved making a clean incision across the jugular vein of each bird, allowing them to bleed for at least 120 s [3]. Bird weights were recorded before and after slaughter, and scalding was performed for 45 s at 63 °C [27]. The determination of the cut of the eviscerated carcass and identification of non-edible offal were integral components of the procedure. Evaluation of carcass yield/weight involved the examination of specific components, including the breasts, wings, drumsticks, thighs, and back-cut. The organ yield evaluation involved the weighing and analysis of the kidney, liver, intestines, lungs etc. Carcass proportion was computed by dividing the various cut parts by the live weight, multiplied by 100. Organoleptic assessment of meat quality included a 30 min cooking session at 80 °C with salt as the sole ingredient. Thirty panelists trained in basic sensory evaluation procedures were randomly selected and their consents were sought. They assessed the texture, aroma (flavour), colour, and taste using a nine-point category rating scale according to methods outlined by [28, 29]. The lean meat-to-fat ratio was determined using a ruler back fat probe [30]. Feed cost analysis involves determining the cost per kilogram of feed, total cost of feed consumed, cost of production, profit, return on investment (%), and gross profit. The exchange rate used for currency conversion for economic gain was 1 USD to 1,258.61 Naira (flutterwave exchange).

2.4 Experimental design and statistical analysis

The experimental design employed in this study followed a completely randomized design, and the collected data were subjected to analysis of variance using IBM SPSS version 29.0. Significant differences were further evaluated through Duncan's multiple range tests. The determination of significance levels was based on p-values (p < 0.05 and p < 0.01).

3 Results and discussion

3.1 Results

As illustrated in Table 4, the final weight gain and average daily weight gain of turkeys subjected to T4 diets, exhibited a significantly higher difference (p < 0.01) compared to other treatment levels, with the lowest weight gain observed in poults fed the T1 (control) diet. The average daily feed intake demonstrated a significant increase (p < 0.01) among poults that received T4 diets, while the lowest daily feed intake was observed in birds fed the control diet. The most favourable feed conversion ratio was achieved (p < 0.01) in turkeys fed T4 and control diets, whereas T2 and T3 exhibited suboptimal utilization, albeit all the feed conversion ratios of the turkeys fall slightly above the standard approval range of 2.0: 2.00 (hens) and 2.6: 2.8 (toms) according to the [31], especially for treatment four with the lowest FCR.

In Table 5, the carcass traits and proportions of internal organs in turkeys fed a sawdust/PKC diet mixed with zootech feed fortifier (T4 diets) showed a significantly higher difference (p < 0.05) compared to other treatment groups. Table 6 presents organoleptic assessments indicating superior meat quality (p < 0.05) in turkeys fed the T4 diet. Furthermore, the economic evaluation in Table 7 revealed a significantly (p < 0.05) lower cost per kilogram of feed and a reduced overall cost of feed consumption for treatments 2, 3, and 4 diets when compared to the control diet.

3.2 Discussion

The superior performance observed in the birds could be attributed to the effective digestion of dietary fiber facilitated by the Zootech feed fortifier mix. Importantly, the fiber content was maintained within tolerable limits which did not impede growth. Poultry species consistently exhibit an inflexible response to dietary fiber, [32]. Recommended fiber levels for growing broilers range from as low as 1.0–3% [33] to as high as 9–15% [34, 35]. Both young and mature birds can effectively tolerate fiber levels ranging from 13 to 15%, depending on diet composition and the presence of microbial biotechnological substrates for fiber degradation, as elucidated in this study. Research on the utilization of sawdust as a dietary feed ingredient is notably scarce. However, [36] reported that incorporating sawdust into broiler chicken diets resulted in reduced feed intake, decreased final body weight, carcass percentage, and abdominal fat deposition, attributable to the high fiber content of sawdust. Nevertheless, the findings of the present study contradict this, as the inclusion of sawdust/palm kernel cake (PKC), constituting a high-fiber diet, led to an enhanced growth rate in turkeys. Also, [37] found that when sawdust is degraded with diastatic microbes, it can potentially serve as a beneficial feed for goats. This observation may offer insight into the improved outcomes of the present study, suggesting that before the nutritional value of sawdust can be effectively utilized by animals, it may undergo some transformation/treatment process: biologically or chemically. This enhancement of parameters measured in this study is attributed to the presence of enzyme activators, particularly proteolytic and fibrolytic enzymes, within the Zootech feed fortifier mix. These active microbial fiber-biodegradable organic enzymes likely contributed to the breakdown of the complex lignocellulosic structure of non-starch polysaccharides, along with unidentified growth factors from the degraded sawdust-palm kernel cake mix. In laying hens, the inclusion of fiber levels has been found to mitigate ammonia emissions by supplying energy to microbes (bacteria) in the lower gastrointestinal tract. In this context, bacteria utilize nitrogen that would otherwise be excreted as uric acid for bacterial protein synthesis [38]. The metabolic activity of bacteria results in the production of short-chain fatty acids, lowering the pH in the manure and thereby converting ammonia (NH3) to ammonium (NH4+), which is less volatile [38]. This not only helps reduce ammonia emissions but also alleviates various health issues commonly observed in chicken flocks, including ascites, gastrointestinal tract irritation, respiratory diseases, and foot pad dermatitis. The impact of incorporating dietary fiber is dependent on several elements, such as the origin and amount of dietary fiber, dietary features, and the physiological condition and well-being of the chicken species [34]. The impact on the existing microbiota in the distal GIT can be influenced by both the amount and type of dietary fiber, as well as the composition of the basal diet, as reported by [16, 39]. A study by [34] emphasized that the effects of dietary fiber on productivity vary based on the solubility of the fiber source and its other physicochemical properties. The term “dietary fiber” encompasses a wide array of polymers with significant differences in physicochemical properties. When integrated into the diet, these polymers contribute to variations in digestive viscosity, ion exchange capacity, fermentation capability, and bulking effects within the GIT. These differences in physicochemical properties have been associated with diverse impacts on bird behaviour, enzyme production, microbiota growth, organ size, voluntary feed intake, and GIT motility of nutrient passage, as indicated by [34]. Also, in practical feeding scenarios, the productivity of birds can be influenced by the particle size and solubility of fiber fractions within the digestive environment. This impact stems from their role in modulating the rate of feed passage in the upper gastrointestinal tract and the fermentative capabilities in the distal part [40]. Moreover, Kluth and Rodehutscord [41] reported that an increase in the level of cellulose contributes to an elevation in crude protein and amino acids flow at the terminal ileum in broilers. The incorporation of 6% wood shavings in a wheat-soybean-based diet resulted in a notable increase in ileal starch digestibility, rising from 98.5 to 99.4%, as demonstrated by [16]. Studies on broiler chickens have indicated that the inclusion of fiber in low-fiber diets can enhance fat digestibility [13, 22]. Conversely, when a pelleted corn-based diet with 30% high-fiber sunflower meal was fed to broilers, a linear increase in the apparent ileal digestibility (AID) of fat and crude protein was observed, while dry matter and energy digestibility decreased [22]. The positive effects of fiber inclusion in diets extend beyond nutrient digestibility to impact intestinal function and alter the composition and quality of gut microflora populations in both poultry and pigs, as evidenced by in vitro studies [42] and in vivo studies [17, 21, 39, 43]. Furthermore, [34] reported enhanced growth performance in broiler chickens when fed insoluble and coarse sources of low-fiber diets at levels ranging between 2 and 3%. Dietary fiber serves as a nutrient diluent, improving its retention, digestion, and absorption. Notably, the absence of fiber in pelleted diets for hens has been associated with higher incidences of feather pulling, pecking interactions, feather damage scores, and cannibalism [44, 45]. The observed variations in carcass traits and internal organs were attributed to the fiber degradation and metabolism facilitated by the inclusion of the Zootech fortifier mix in the diets. The augmentation of dietary fiber content correlated with an increase in carcass weight. [26] found that utilising cassava waste meal, a high-fiber diet, at 10–15% inclusion levels, improved weight gain. Interestingly, [46] concluded that the use of insoluble fiber in commercial broiler chicks enhances meat production by improving intestinal morphology, emphasizing that completing the digestion and absorption processes enables birds to fully exploit their growth potential. Increasing the insoluble fiber content in the diet has been associated with several structural changes in the poultry digestive system. This includes a reduction in the length of the small intestine [16, 20], a decrease in proventricular weight [47], and an increase in gizzard weight and gizzard contents [13, 16, 19, 48]. These changes are generally indicative of an improved functioning of the gastrointestinal tract (GIT) [48, 49]. The accumulation of dietary fiber in the gizzard can slow the feed passage rate, particularly in the proximal part of the GIT [17, 48], and reduce the passage time of fine particles [17, 48,49,50]. A key advantage of including dietary fiber is its positive impact on gizzard development and functionality, as highlighted by [34]. The gizzard plays a fundamental role in various physiological aspects of the gastrointestinal tract, including particle size reduction, regulation of motility, control of feed flow and gastroduodenal refluxes, enhancement of digestive secretions such as HCl, bile acid, and endogenous enzymes, and synchronization of digestion and absorption processes. These activities collectively influence the functioning of the GIT and modify microbial growth at specific digestive organ sites. The optimal level of dietary fiber required for maximizing organ development is contingent upon the type of fiber used and the age of the birds [34]. While dietary fiber may have an abrasive effect on the intestinal wall, potentially leading to an increase in endogenous cell losses and nutrient release into the lumen [51], its metabolic effects on turkey meat quality were demonstrated through organoleptic tests. The findings from the organoleptic revealed a progressive improvement in the quality of the desired meat parts, indicating that fiber metabolism resulted in modified textural properties and enhanced shelf-life. The appearance of meat significantly influences consumer acceptance, with colour being the primary factor consumers use to assess meat quality and acceptability [52, 53]. The mean panel rating for meat colour across all turkey samples indicated a consistent increase within treatment groups, with T4 showing the highest meat colour. This suggests that the turkey used in the experiment produced meat with satisfactory to very good colour characteristics. Meat colour is influenced by pigment changes during cooking [54], with higher myoglobin concentrations in the muscles of older or more active animals [55]. According to [56], consumers tend to reject products that deviate from the expected normal appearance. Therefore, turkey-fed experimental diets 2, 3, and particularly 4 was more appealing to the panelists in terms of colour compared to meat from the control group in this study. Tenderness, a key aspect of meat texture, is commonly regarded as paramount in assessing the organoleptic qualities of meat, particularly in fast-growing poultry strains [57, 58]. On the other hand, the flavour tends to mature with the ageing process [59]. Nonetheless, our study revealed that turkey meat fed experimental diets showed a stronger consumer preference for both flavour and texture compared to those fed on control diets. However, the overall taste satisfaction or preference favoured the fourth treatment group, closely followed by the third treatment group. It is plausible that cooking losses contributed to a diminished degree of taste satisfaction [60, 61]. The lowest mean texture rating observed in the control group may be attributed to increased locomotive activities facilitated by more available space for exercise, leading to tougher muscles [62], and the high energy content of the feed resulting in energy expenditure and subsequent muscle toughness. Ahmed et al [63] noted that the body lipid ratio is influenced by genetic factors and varies among poultry species, independent of feeding regimes. The relatively poor mean lean meat-to-fat ratio observed in our study could be attributed to the strain or breed of turkeys utilized, as local strains known for lesser fat/meat deposition and slower growth were employed. This outcome may differ when genetically improved turkey breeds are employed in similar experiments. In addition, the size of the gizzard in this research exhibited a statistically significant difference (p < 0.05) attributable to the incorporation of both Zootech and high-fiber diets across the various dietary treatments, with treatment group four registering the highest impact. This finding aligns with prior studies by [3, 64,65,66] all of which reported a positive correlation between gizzard size and dietary fiber content. The gizzard holds considerable culinary appeal in Nigeria [67], emphasising the significance of this study. The application of Zootech feed fortifier in a high-fiber poultry diets, particularly those incorporating sawdust and palm kernel cake as primary fiber sources, notably at proportions of 15% sawdust and 8% PKC (treatment four), demonstrated significant advantages. These include enhanced growth performance, enhanced digestibility of nutrients and fibers, improved animal welfare by reducing emissions, and favourable meat quality. These favourable outcomes stem from the proficient breakdown of dietary fibers and the activation of microbial enzymes. These findings demonstrates the potential efficiency of integrating fiber-enhancing supplements such as Zootech feed fortifier into poultry diets, presenting a promising avenue for optimizing production efficiency while upholding standards of animal welfare and product quality. Such an approach empowers farmers to achieve heightened profitability while effectively managing production expenditures. Further investigation may be required to delve into its broader applicability, particularly concerning other poultry birds and genetically enhanced strains of turkey and other prevalent fibrous feed sources employed in poultry production.

Data availability

All data used for this study is available and can be provided upon reasonable request. Contact nmanigbogu@gmail.com or agida.agboje@mouau.edu.ng or the corresponding author.

Abbreviations

- PKC:

-

Palm kernel cake

- GIT:

-

Gastrointestinal tract

- DF:

-

Dietary fiber

- HCl:

-

Hydrochloric

- AID:

-

Apparent ileal digestibility

References

N. Anigbogu, I. Onyejekwe, and C. Odukwe. Metabolism of Protein and Energy by Maradi Goats Fed Zymomonas mobilis Degraded Rice Hull Diets. In Proceedings of the 16th Annual Conference for the Animal Science Association of Nigeria, 2011, pp. 99–103.

Anigbogu NM, Ononuju AN, Agida CA. Yam (Dioscorea rotundata) tuber waste as feed for poultry production: an alternative kitchen garbage waste management. Aceh J Animal Sci. 2023;8(1):16–23. https://doi.org/10.1317/ajas.8.1.25822.

Aroh I, Odukwe C, Macartan B, Agida C, Ullah K, Archibong B. Raw jackfruit (Artocarpus heterophyllus) seedmeal: effect on growth performance, organ weight, carcass yield, and economic production of guinea fowl keets. J Appl Life Sci Int. 2023;26(4):31–41. https://doi.org/10.9734/jalsi/2023/v26i4612.

Anigbogu N, Ibe S, Anosike J, Assam E. The effect of life-enzyme (sawdust treated with Zymomonas mobilis) on the performance characteristics of Red Sokoto goats. J Sustain Agric Environ. 2009;11(1/2):12–8.

Sambo AS. Strategic developments in renewable energy in Nigeria. Int Assoc Energy Econ. 2009;16(3):15–9.

V. Francescato et al. Wood fuels handbook, AIEL-Italian Agriforestry Energy Association. Benefits of Rural. (Tazi Hnyine et al.), 2008.

Arimoro FO, Ikomi RB, Osalor EC. The impact of sawmill wood wastes on the water quality and fish communities of Benin River, Niger Delta Area, Nigeria. Int J Sci Technol. 2007;2(1):1–12.

USDA. Dietary reference intakes for energy, carbohydrate, fiber, fat, fatty acids, cholesterol, protein and amino acids. Washington, DC: National Academies Press; 2005.

Veronese N, et al. Dietary fiber and health outcomes: an umbrella review of systematic reviews and meta-analyses. Am J Clin Nutr. 2018;107(3):436–44. https://doi.org/10.1093/ajcn/nqx082.

Eastwood M, Kritchevsky D. Dietary fiber: how did we get where we are? Annu Rev Nutr. 2005;25:1–8. https://doi.org/10.1146/annurev.nutr.25.121304.131658.

Choct M, Annison G. The inhibition of nutrient digestion by wheat pentosans. Br J Nutr. 1992;67(1):123–32. https://doi.org/10.1079/bjn19920014.

Rougière N, Carré B. Comparison of gastrointestinal transit times between chickens from D+ and D− genetic lines selected for divergent digestion efficiency. Animal. 2010;4(11):1861–72. https://doi.org/10.1017/s1751731110001266.

González-Alvarado J, Jiménez-Moreno E, Lázaro R, Mateos G. Effect of type of cereal, heat processing of the cereal, and inclusion of fiber in the diet on productive performance and digestive traits of broilers. Poult Sci. 2007;86(8):1705–15. https://doi.org/10.1093/ps/86.8.1705.

Hetland H, Svihus B. Inclusion of dust bathing materials affects nutrient digestion and gut physiology of layers. J Appl Poultry Res. 2007;16(1):22–6. https://doi.org/10.1093/japr/16.1.22.

Hetland H, Svihus B, Krogdahl Å. Effects of oat hulls and wood shavings on digestion in broilers and layers fed diets based on whole or ground wheat. Br Poult Sci. 2003;44(2):275–82. https://doi.org/10.1080/00071660301954.

Amerah A, Ravindran V, Lentle R. Influence of insoluble fibre and whole wheat inclusion on the performance, digestive tract development and ileal microbiota profile of broiler chickens. Br Poult Sci. 2009;50(3):366–75. https://doi.org/10.1080/00071660902865901.

Jiménez Moreno E, Romero C, Berrocoso J, Frikha M, Gonzalez Mateos G. Effects of the inclusion of oat hulls or sugar beet pulp in the diet on gizzard characteristics, apparent ileal digestibility of nutrients, and microbial count in the ceca in 36 day old broilers reared on floor. Champaign: Poultry Science Association; 2011.

Rogel A, Balnave D, Bryden W, Annison E. Improvement of raw potato starch digestion in chickens by feeding oat hulls and other fibrous feedstuffs. Aust J Agric Res. 1987;38(3):629–37. https://doi.org/10.1071/ar9870629.

González-Alvarado J, Jiménez-Moreno E, González-Sánchez D, Lázaro R, Mateos G. Effect of inclusion of oat hulls and sugar beet pulp in the diet on productive performance and digestive traits of broilers from 1 to 42 days of age. Anim Feed Sci Technol. 2010;162(1–2):37–46. https://doi.org/10.1016/j.anifeedsci.2010.08.010.

Sklan D, Smirnov A, Plavnik I. The effect of dietary fibre on the small intestines and apparent digestion in the turkey. Br Poult Sci. 2003;44(5):735–40. https://doi.org/10.1080/00071660310001643750.

Correa-Matos NJ, Donovan SM, Isaacson RE, Gaskins HR, White BA, Tappenden KA. Fermentable fiber reduces recovery time and improves intestinal function in piglets following Salmonella typhimurium infection. J Nutr. 2003;133(6):1845–52. https://doi.org/10.1093/jn/133.6.1845.

Kalmendal R, Elwinger K, Holm L, Tauson R. High-fibre sunflower cake affects small intestinal digestion and health in broiler chickens. Br Poult Sci. 2011;52(1):86–96.

Perez V, et al. Effect of corn distillers dried grains with solubles and Eimeria acervulina infection on growth performance and the intestinal microbiota of young chicks. Poult Sci. 2011;90(5):958–64. https://doi.org/10.3382/ps.2010-01066.

W. Horwitz, Official methods of analysis of AOAC International. Volume I, agricultural chemicals, contaminants, drugs/edited by William Horwitz. Gaithersburg (Maryland): AOAC International, 1997. 2010.

NIAS. National listing of approved feed ingredients for feedmills in Nigeria. Nigerian Institute of Animal Science, vol. NIAS/RA/LAFI-2022, 2022. https://nias.gov.ng/wp-content/uploads/2022/07/PDF-2022-NATIONAL-LISTING-OF-APPROVED-FEED-INGREDIENTS-FOR-FEEDMILLS-IN-NIGERIA.pdf.

Aroh IM, Agboje AC, Ogbonna GN, Anyanka SO, Ohanehi HA, Anigbogu NM. Sustainable poultry farming in developing nations: exploring cassava waste utilization for enhanced poultry production and economic viability. Animal Res One Health. 2024. https://doi.org/10.1002/aro2.50.

Fletcher DL. Poultry meat: processing. In: Pond WG, editor. Encyclopedia of animal science. Boca Raton: CRC Press; 2004. p. 740–3.

AMSA. Guidelines for cookery and sensory evaluation of meat. Chicago: National Livestock and Meat Board; 1978. p. 24.

Colle M. AMSA. 2015. Research guidelines for cookery, sensory evaluation, and instrumental tenderness measurements of meat. American meat science association, Champaign, IL. Bekhit, AEDA, DL Hopkins, FT Fahri, and EN Ponnampalam. 2013. Oxidative processes in muscle systems and fresh meat: sources, markers, and remedies. Post-harvest Influ Beef Flavor Dev Tenderness. 2020;110:127.

NRC. Designing foods: animal product options in the marketplace. Washington, DC: National Academies Press; 1988.

F. PReP. Foreign Animal Disease Preparedness & Response Plan. 2011.

Sittiya J, Yamauchi K, Nimanong W, Thongwittaya N. Influence of levels of dietary fiber sources on the performance, carcass traits, gastrointestinal tract development, fecal ammonia nitrogen, and intestinal morphology of broilers. Braz J Poult Sci. 2020. https://doi.org/10.1590/1806-9061-2019-1151.

Dhingra D, Michael M, Rajput H, Patil R. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49:255–66. https://doi.org/10.1007/s13197-011-0365-5.

Mateos G, Jiménez-Moreno E, Serrano M, Lázaro R. Poultry response to high levels of dietary fiber sources varying in physical and chemical characteristics. J Appl Poultry Res. 2012;21(1):156–74. https://doi.org/10.3382/japr.2011-00477.

Walugembe M, Rothschild M, Persia M. Effects of high fiber ingredients on the performance, metabolizable energy and fiber digestibility of broiler and layer chicks. Anim Feed Sci Technol. 2014;188:46–52. https://doi.org/10.1016/j.anifeedsci.2013.09.012.

Mandey J, Kowel Y, Regar M, Leke J. Effect of different level of energy and crude fiber from sawdust in diets on carcass quality of broiler. J Indonesian Trop Anim Agric. 2017. https://doi.org/10.1471/jitaa.42.4.240-246.

Anigbogu N, Afam-Ibezim E, Ukweni I. Values of sawdust degraded diastic microbes of Achatina fulica fed goats as part of formulated diets: an alternative municipal organic waste management. Niger Agric J. 2018;49(2):218–27.

Alabi OO, Shoyombo AJ, Akpor OB, Oluba OM, Adeyonu AG. Exogenous enzymes and the digestibility of nutrients by broilers: a mini review. Int J Poultry Sci. 2019;18:404–9. https://doi.org/10.3923/ijps.2019.404.409.

Shakouri M, Kermanshahi H, Mohsenzadeh M. Effect of different non starch polysaccharides in semi purified diets on performance and intestinal microflora of young broiler chickens. Int J Poult Sci. 2006;5(6):557–61. https://doi.org/10.3923/ijps.2006.557.561.

Saki A, Matin HH, Zamani P, Tabatabai M, Vatanchian M. Various ratios of pectin to cellulose affect intestinal morphology, DNA quantitation, and performance of broiler chickens. Livest Sci. 2011;139(3):237–44. https://doi.org/10.1016/j.livsci.2011.01.014.

Kluth H, Rodehutscord M. Effect of inclusion of cellulose in the diet on the inevitable endogenous amino acid losses in the ileum of broiler chicken. Poult Sci. 2009;88(6):1199–205. https://doi.org/10.3382/ps.2008-00385.

Dunkley K, et al. Comparison of in vitro fermentation and molecular microbial profiles of high-fiber feed substrates incubated with chicken cecal inocula. Poult Sci. 2007;86(5):801–10. https://doi.org/10.1093/ps/86.5.801.

Van der Meulen J, Panneman H, Jansman A. Effect of pea, pea hulls, faba beans and faba bean hulls on the ileal microbial composition in weaned piglets. Livest Sci. 2010;133(1–3):135–7. https://doi.org/10.1016/j.livsci.2010.06.045.

Aerni V, El-Lethey H, Wechsler B. Effect of foraging material and food form on feather pecking in laying hens. Br Poult Sci. 2000;41(1):16–21. https://doi.org/10.1080/00071660086349.

Hartini S, Choct M, Hinch G, Kocher A, Nolan J. Effects of light intensity during rearing and beak trimming and dietary fiber sources on mortality, egg production, and performance of ISA brown laying hens. J Appl Poultry Res. 2002;11(1):104–10. https://doi.org/10.1093/japr/11.1.104.

Sarikhan M, Shahryar HA, Gholizadeh B, Hosseinzadeh M-H, Beheshti B, Mahmoodnejad A. Effects of insoluble fiber on growth performance, carcass traits and ileum morphological parameters on broiler chick males. Int J Agric Biol. 2010;12(4):531–6.

Jiménez-Moreno E, González-Alvarado J, González-Serrano A, Lázaro R, Mateos G. Effect of dietary fiber and fat on performance and digestive traits of broilers from one to twenty-one days of age. Poult Sci. 2009;88(12):2562–74. https://doi.org/10.3382/ps.2009-00179.

Svihus B. The gizzard: function, influence of diet structure and effects on nutrient availability. Worlds Poult Sci J. 2011;67(2):207–24.

Hetland H, Svihus B. Effect of oat hulls on performance, gut capacity and feed passage time in broiler chickens. Br Poult Sci. 2001;42(3):354–61. https://doi.org/10.1080/00071660120055331.

Svihus B, Hetland H, Choct M, Sundby F. Passage rate through the anterior digestive tract of broiler chickens fed on diets with ground and whole wheat. Br Poult Sci. 2002;43(5):662–8. https://doi.org/10.1080/0007166021000025037.

Leterme P, Froidmont E, Rossi F, Théwis A. The high water-holding capacity of pea inner fibers affects the ileal flow of endogenous amino acids in pigs. J Agric Food Chem. 1998;46(5):1927–34.

Conforth D. Colour; its basis and importance. Qual Attrib Meas Meat, Poult Fish Prod. 1994. https://doi.org/10.1007/978-1-4615-2167-9_2.

Liang Y, Yin J, Huang B, Wang S, Teng Y. Effect of supplemental canthaxanthin and apoester in diets on performance of laying hens and yolk colour. China Poultry. 2004;8:161–3.

J. F. Price and B. S. Schweigert. The science of meat and meat products. FNP publications in food science and technology (USA), 1987.

Jeremiah LE. A review of factors affecting meat quality. 1978.

Qiao M, Fletcher D, Smith D, Northcutt J. The effect of broiler breast meat color on pH, moisture, water-holding capacity, and emulsification capacity. Poult Sci. 2001;80(5):676–80. https://doi.org/10.1093/ps/80.5.676.

Fanatico A, Pillai P, Cavitt L, Owens C, Emmert J. Evaluation of slower-growing broiler genotypes grown with and without outdoor access: growth performance and carcass yield. Poult Sci. 2005;84(8):1321–7. https://doi.org/10.1093/ps/84.8.1321.

Seabra L, Zapata J, Fuentes M, Aguiar C, Freitas E, Rodrigues M. Effect of deboning time, muscle tensioning, and calcium chloride marination on texture characteristics of chicken breast meat. Poult Sci. 2001;80(1):109–12. https://doi.org/10.1093/ps/80.1.109.

Lawrie R. Chemical and biochemical constitution of muscle. In: Toldra F, editor. Lawrie’s meat science. Amsterdam: Elsevier; 2006. p. 75–127.

Dabes A. Propriedades da carne fresca. Rev Nac da Carne. 2001;25(288):32–40.

A. Ikeme. Meat science and technology. African-Fep Publishers Limited, Book Houde Trust, Onitcha, Nigeria, pp. 267-287, 1990.

Shields SJ, Garner JP, Mench JA. Dustbathing by broiler chickens: a comparison of preference for four different substrates. Appl Anim Behav Sci. 2004;87(1–2):69–82.

Ahmed I, Li Z, Duan X, Gu D, Dou T, Huang Y, Jia J. Correlative analysis of lipid contents and relative gene expression between chicken breeds. Pak J Agric Sci, 2019;56(4).

Deaton J, Kubena L, Reece F, Lott B. Effect of dietary fibre on the performance of laying hens. Br Poult Sci. 1977;18(6):711–4. https://doi.org/10.1080/00071667708416425.

Kubena L, Deaton J, May J, Reece F. A dietary method to correct a gizzard abnormality of broilers. Poult Sci. 1974;53(1):407–9. https://doi.org/10.3382/ps.0530407.

Onwudike O. Palm kernel meal as a feed for poultry. 3. Replacement of groundnut cake by palm kernel meal in broiler diets. Anim Feed Sci Technol. 1986;16(3):195–202. https://doi.org/10.1016/0377-8401(86)90110-0.

Okeudo N, Eboh K, Izugboekwe NV, Akanno E. Growth rate, carcass characteristics and organoleptic quality of broiler fed graded levels of palm kernel cake. Int J Poult Sci. 2005;4(5):330–3. https://doi.org/10.3923/ijps.2005.330.333.

Acknowledgement

The authors and researchers involved in the research and the production of this article express their gratitude to the staff, students, and technicians at Michael Okpara University of Agriculture, Nigeria, for their valuable assistance and the conducive work environment they provided. Also, we appreciate the anonymous reviewers for their invaluable comments. This research did not receive any external funding.

ARRIVE Statement

The study was carried out in compliance with the ARRIVE guidelines.

Author information

Authors and Affiliations

Contributions

This work was carried out in collaboration with all other authors. All authors read and approved the final manuscript for submission. Izuchukwu Martin Aroh: Writing: review & editing-Lead. Agida Christopher Agboje—Conceptualization-Equal, Investigation-Equal, Methodology-Lead, Project administration-Equal, Supervision-Equal, Validation-Equal, Writing: original draft-Equal. Godswill C. Okechukwu—Conceptualization-Equal, Data curation-Supporting, Funding acquisition-Supporting, Methodology-Supporting, Resources-Lead. Nnamdi M Anigbogu—Conceptualization-Lead, Formal analysis-Equal, Funding acquisition-Supporting, Data Curation: Lead, Data Analysis: Supporting, Investigation-Lead, Methodology-Lead, Project administration-Lead, Resources-Lead, Supervision-Lead, Validation-Lead, Writing: original draft-Lead Writing: review & editing-Supporting. Ihugba Uchechi E: Writing: review and editing - Supporting.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The Department of Animal Welfare and Nutrition Research Committee at Michael Okpara University of Agriculture, Umudike, Nigeria, reviewed and approved the feeding trial. All the researchers involved in this project ensured compliance with the committee's guidelines and this research article was not submitted elsewhere for consideration.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Anigbogu, N.M., Agida, C.A., Okechukwu, G.C. et al. Enhancing growth performance, feed efficiency, and economic feasibility of turkey production through the incorporation of zootech feed fortifier in a high-fiber turkey diet. Discov Anim 1, 8 (2024). https://doi.org/10.1007/s44338-024-00006-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44338-024-00006-1