Abstract

Delving into fault diagnosis techniques for electrical machines, this comprehensive review focuses on three-phase induction motors. It covers various fault types including eccentricity, broken rotor bars, and bearing faults, discussing techniques such as Motor Current Signature Analysis (MCSA), partial discharge testing, and AI-based approaches. Providing insights into fault detection mechanisms, it emphasizes early identification for optimal machine performance and reliability. With a detailed examination of both traditional and advanced methods, the review serves as a valuable resource for practitioners and researchers in the field, facilitating informed decision-making for maintenance strategies and enhancing machine efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The increasing complexity of electrical machines and their growing integration into critical infrastructure have heightened the demand for robust fault diagnosis techniques to ensure operational reliability, safety, and efficiency. While traditional safety measures such as overcurrent, overvoltage, and earth-fault protection have been employed for decades, the potential for undetected faults to disrupt operations, cause schedule delays, and incur substantial financial losses necessitates more proactive and accurate fault detection methods.

The significance of three-phase induction motors in various industries lies in their high motive power generation, durability, and low maintenance costs. These motors are utilized as the prime mover in approximately 90% of industrial equipment globally, underpinning their vital role in industrial operations [1]. They are known for their robust nature and reliable performance, making them indispensable for industrial processes. Additionally, these motors are favored for their ability to provide flexible production control and soft motor start-up, offering a versatile and efficient solution for a wide range of industrial applications.

Electrical machine faults can be broadly categorized into five main areas: stator defects, improper stator winding connections [2,3,4,5,6], dynamic or static anomalies in the air gap, shorted rotor field windings, and bearing and gearbox failures. These faults can manifest in various forms, including overheating, vibration, noise, and changes in motor current signatures. Early detection and accurate identification of these faults are crucial for implementing timely maintenance strategies, preventing catastrophic failures, and ensuring optimal machine performance.

Numerous diagnostic techniques have been developed to address the challenge of fault detection in electrical machines. These techniques can be broadly classified into two categories: non-invasive and semi-invasive methods. Non-invasive techniques do not require direct contact with the machine, relying instead on external measurements such as temperature, vibration, acoustic noise, and radio frequency (RF) emissions. Examples of non-invasive techniques include temperature measurement, infrared thermography, vibration analysis, acoustic noise analysis, and RF emission monitoring [3]. Semi-invasive techniques, on the other hand, require some level of physical access to the machine, such as partial disassembly or insertion of probes. Examples of semi-invasive techniques include Motor Current Signature Analysis (MCSA), Online partial discharge (PD) testing, and axial flux component analysis [6].

In recent years, advanced diagnostic approaches based on artificial intelligence (AI) and neural network techniques have emerged as promising tools for fault detection in electrical machines [7, 8]. These methods leverage machine learning algorithms to analyze complex patterns in motor data, enabling them to identify subtle anomalies indicative of faults with greater accuracy and sensitivity than conventional techniques. AI-based fault diagnosis techniques are particularly well-suited for large datasets of motor data, allowing them to continuously monitor machine health and detect trends that may lead to future faults.

This comprehensive review article provides a detailed overview of the diverse range of fault diagnosis techniques for electrical machines, examining their effectiveness in detecting and classifying various types of faults. We will delve into the principles, applications, and limitations of each technique, highlighting the advantages and disadvantages of each approach. Additionally, we will provide an in-depth exploration of the emerging role of AI and neural network techniques in modern fault diagnosis applications, examining their potential for enhancing fault detection accuracy, providing predictive insights into potential fault scenarios, and enabling the development of proactive maintenance strategies.

Through this comprehensive review, we aim to provide a valuable resource for engineers, researchers, and practitioners involved in the design, operation, and maintenance of electrical machines. By understanding the strengths and limitations of each fault diagnosis technique and the potential of AI-based approaches, we can make informed decisions about selecting the most appropriate methods for specific applications and achieving optimal machine reliability and performance.

The review article revolves around the comprehensive exploration of various fault types and the corresponding detection methods employed in three-phase induction motors. The article delves into the adverse impact of eccentricity faults on motor efficiency, with a focus on the utilization of MCSA for the detection of static and dynamic eccentricities. Furthermore, the article meticulously addresses stator or armature faults arising from insulation failure through a multifaceted approach, including techniques such as PD tests, axial flux component analysis, and statistical process control. Additionally, the intricate domain of bearing faults is explored, categorizing them into ball defects, train defects, outer bearing race defects, and inner bearing race defects, with a comprehensive overview of advanced fault detection methods for three-phase induction motors, incorporating artificial intelligence-based approaches.

The review article conducted a comprehensive exploration into various fault types and the corresponding detection methods employed in induction motors. Their focus encompassed the adverse impact of eccentricity faults on motor efficiency, the detection of broken rotor bars leveraging MCSA alongside sideband components analysis, and the multifaceted approach to stator or armature faults arising from insulation failure. Additionally, the contributors delved into the intricate domain of bearing faults, categorizing them into distinct categories such as ball defects, train defects, outer bearing race defects, and inner bearing race defects. They showcased a comprehensive overview of advanced fault detection methods for three-phase induction motors, incorporating artificial intelligence-based approaches. This collaborative effort consolidated a wealth of insights into fault types and their detection mechanisms, providing a valuable resource for practitioners, researchers, and enthusiasts in the realm of induction motors.

The review article conducted an in-depth exploration into various fault types and the corresponding detection methods employed in induction motors. Their findings encompassed a comprehensive understanding of fault types such as eccentricity faults, squirrel cage rotor faults (broken bars and end rings) and bearing faults. They delved into the causes, detection techniques, and effects of each fault type, providing valuable insights for practitioners, researchers, and enthusiasts in the realm of induction motors. Additionally, the contributors unveiled advanced fault detection techniques for three-phase induction motors, incorporating artificial intelligence-based approaches and modern diagnostic methodologies.

2 The comprehensive theoretical basis of IM faults

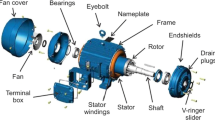

Figure 1(a, b) serves as a visual compass, offering a comprehensive overview of the myriad fault types and the diverse array of detection methods applied in the intricate realm of three-phase induction motors. The ramifications of these faults extend beyond mere operational glitches, potentially culminating in both reduced efficiency and the specter of catastrophic failure. This review endeavors to spotlight a specific facet of this complex landscape, centering its focus on internal mechanical faults and the cutting-edge realm of AI-based methods meticulously designed for fault detection.

Classification of the most frequent induction motor faults [9]

As we navigate through the intricacies of AI-infused fault detection, our journey will delve into not only the merits and advantages of these methodologies but also candidly address their limitations and the challenges that loom on the horizon. The following sections of this review article will serve as an exploratory voyage, shedding light on the nuanced landscape of internal mechanical fault detection, with a keen eye on AI-based techniques. Furthermore, we will cast our gaze toward the future, outlining potential directions for advancements and innovations in the realm of fault detection methods.

The expansive landscape of three-phase induction motors unfolds within the purview of this reviewed article, where a comprehensive exploration ensues into a spectrum of faults that can disrupt their seamless operation. These include the elusive eccentricity, intricacies within the squirrel cage rotor, potential stator or armature aberrations, and the critical domain of bearing faults. Table 1, a trove of insights, serves as a structured repository that meticulously dissects the causes, detection techniques, and the ripple effects each fault can induce.

The intricate dance of eccentricity, the subtleties within the squirrel cage rotor, and the vulnerabilities embedded in the stator or armature find their place under the scrutiny of this article's lens. Delving into the root causes, the article unravels the mechanisms and intricacies involved in the detection of these faults, ensuring a comprehensive understanding of their manifestations. Bearing faults, a linchpin in the operational integrity of induction motors, receive dedicated attention, with Table 1 serving as a roadmap elucidating the nuanced landscape of their causes, detection techniques, and the consequential effects on motor performance.

As we traverse the contents of Table 1, a mosaic of insights unfolds, offering not only a panoramic view of fault intricacies but also serving as a practical guide for engineers, researchers, and enthusiasts navigating the labyrinth of three-phase induction motor faults. This review article, through its meticulous exploration and presentation, endeavors to contribute to the collective knowledge base, fostering a deeper comprehension of the challenges and solutions within this dynamic realm.

2.1 Eccentricity faults

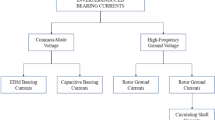

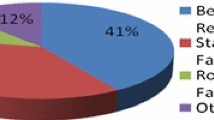

Diving into the wealth of insights provided by studies conducted by the IEEE-Industry Applications (IAS), the intricate landscape of failure mechanisms in induction machines comes to light. These studies reveal a breakdown of common failure types, with stator faults accounting for 38%, rotor defects at 10%, bearing defects taking a significant share of 40%, and the remaining 12% attributed to various other defects[6]. This comprehensive breakdown serves as a valuable benchmark, providing a nuanced understanding of the vulnerability points within these motors.

Among the myriad mechanical faults that can afflict induction motors, one that stands out prominently is eccentricity, a fault that can manifest in static, dynamic, or mixed forms, as the results are simulated using m-file in Fig. 2 [8, 10,11,12]. Static eccentricity, a notable subtype, finds its origins in the stator core's ovality or improper rotor and stator alignment during the commissioning phase. Conversely, dynamic eccentricity, another facet of this fault, is the result of bearing wear, mechanical resonance, or rotational misalignment arising from a bent rotor shaft. The interplay of these factors culminates in a nonuniform air gap, triggering instability in air-gap voltage and line current.

The consequences of eccentricity extend beyond the mechanical intricacies, directly impacting the motor's efficiency. As eccentricity intensifies, it gives rise to a discernible increase in average motor current and losses, unveiling a direct correlation between the fault's severity and its adverse effects on motor performance. This phenomenon underscores the importance of vigilance in monitoring and addressing eccentricity in induction motors, as it plays a pivotal role in maintaining operational stability and efficiency. The insights gleaned from these studies not only shed light on the prevalence of eccentricity but also emphasize its critical role in the broader landscape of induction motor performance [13].

Eccentricity emerges as a pivotal determinant in the manifestation of failures within the realm of three-phase induction motors, wielding substantial influence over their operational integrity. The repercussions of eccentricity extend beyond mere performance degradation, as it induces vibration and uneven magnetic forces (UMF), thereby curtailing the machine's lifespan. The deleterious effects of eccentricity are further compounded by the mechanical stress it imparts on various machine components, notably escalating bearing wear [14].

In the intricacies of real-world scenarios [15], a noteworthy observation surfaces—both static and dynamic eccentricities often coexist within induction machines. Even in the nascent stages of machine life, static eccentricity, an inherent byproduct of production and assembly processes, is prevalent. This results in a consistent unbalanced magnetic pull (UMP) in a specific direction, laying the groundwork for potential issues such as accelerated bearing wear or a misaligned rotor shaft. Concurrently, dynamic eccentricity may arise from these inherent factors, and if left unaddressed, these effects can accumulate, precipitating a severe machine breakdown, including stator-to-rotor hub failure. MCSA emerges as a key diagnostic tool adept at identifying both static and dynamic eccentricities. Equation (1) encapsulates the essence of MCSA, providing a framework for detecting relevant frequency components [16].

Here, fh denotes the frequency of the shaft's lateral vibration, fr represents the rotor frequency, fs stands for the frequency of stator vibration, nd signifies the frequency of the bearing's outer race defect, Z2 denotes the bearing's characteristic frequency, k serves as a variable multiplier contingent on the bearing type and operating conditions, and υ accounts for any misalignment between the shaft and bearing.

Various models, including the DFT and Modified Prony's Method, are instrumental in discerning eccentricity faults. While DFT is user-friendly, its drawback lies in being time-consuming and ill-suited for dynamic models. Conversely, the Modified Prony's Method emerges as a pragmatic alternative, demonstrating efficacy in accurately identifying fault characteristic frequencies based on the stator's power and current outcomes [17].

2.2 Squirrel cage rotor faults: broken bars and end rings

Furthermore, delving into the intricacies of rotor failures reveals a nuanced dichotomy between cast and fabricated rotors. Cast rotors, renowned for their enhanced durability [18,19,20], have witnessed an expanded domain of application, particularly in larger machines reaching power capacities up to 3000 kW, courtesy of innovations like cast ducted rotors. In contrast, fabricated rotors find their niche in larger or specialized application machines, delineating a tailored approach based on specific operational requirements.

The genesis of rotor malfunctions, notably the breakdown of rotor bars and end rings, unfolds as a multifaceted interplay of electromagnetic forces, residual tensions, thermal strains, mechanical strains, environmental stressors, and dynamic stresses. Cast rotors, while celebrated for their durability, pose a unique challenge when afflicted with faults such as cracked or fractured rotor bars, rendering them practically impossible to repair [21].

When analyzing squirrel cage rotor faults using the stator currents in the abc reference frame, it provides a clear view of the currents in their natural phase orientation. However, if the Instantaneous Space Phasor (ISP) technique is employed, the analysis focuses on a vector representation of the currents. This change in representation can significantly affect the frequency spectrum of the fault signature. The ISP method often highlights specific harmonics and space harmonics that are not as apparent in the abc frame, potentially providing a more sensitive detection mechanism for rotor faults[22].

Within the diagnostic realm, MCSA emerges as a key methodology for detecting broken rotor bars. This technique relies on identifying sideband components, denoted as 'fb,' around the fundamental frequency, as encapsulated in Eq. (2). The lower sideband signifies the presence of broken rotor bars, while the upper sideband is indicative of speed oscillations. The versatility of this approach is further underscored by Eq. (3), wherein multiple sidebands may occur due to broken bars, each corresponding to different values of 'k' (1, 2, 3, and so forth).

A noteworthy leap in this field involves the integration of a soft sensor [23,24,25,26] designed to identify broken rotor bars. This innovative solution harnesses an ensemble learning method based on Dynamic Weighted Majority (DWM) and incorporates drift detection with automatic structure evolution using the entropy criterion. The fuzzy classifier's membership degree assumes significance in calculating entropy for drift detection, presenting a sophisticated and adaptive approach to rotor fault identification [27]. It is pertinent to note that uninsulated rotor cages, featuring a robust contact between the rotor core and bars, may pose challenges in accurately pinpointing broken bars. To complement these advanced techniques, diagnostic tools such as the analysis of harmonics at stator terminal voltages after motor shutdown offer additional insights into the intricacies of rotor health [28]. This holistic exploration not only unveils the complexities of rotor failures but also underscores the imperative for sophisticated diagnostic approaches in ensuring the reliability and longevity of induction motors.

2.3 Stator or armature faults

Delving deeper into the intricate landscape of stator faults, it becomes evident that their prevalence, constituting a significant portion of induction motor failures [29], necessitates a thorough understanding and proactive diagnostic approaches. These faults, often stemming from insulation failure, unfold in the form of phase-to-ground or phase-to-phase faults, gradually evolving from minor aberrations to major disruptions. The multifaceted etiology of stator or armature insulation failure encompasses an array of contributing factors, including but not limited to short circuits during motor startup, environmental stressors, insufficient bracing of end windings, compromised lamination of the core, leaks in the cooling system, electrical arcing, and elevated temperatures within the stator core or winding [30].

Similar to rotor faults, using the ISP analysis for stator faults alters the frequency signature spectrum. ISP analysis can reveal specific fault-related harmonics in the stator currents that might be less detectable in the traditional abc frame. This can improve the accuracy and sensitivity of fault detection, particularly for identifying issues such as short circuits or winding degradations [31].

The diagnostic arsenal deployed to identify these insidious faults is as diverse as the faults themselves. While online PD test methods stand as stalwarts in reliability, especially for large generators and motors with stator windings rated at 4 kV and above, a conspicuous gap exists in standardized stator defect detection methods for low voltage motors. Bridging this gap, innovative techniques involve the analysis of the axial flux component of the machine through a strategically positioned large coil wound tightly around the shaft, exemplified by the work of [32]. Further refinement in pinpointing fault location is achieved through the installation of four coils symmetrically in each of the motor's quadrants, offering a diagnostic framework governed by Eq. (4).

Insightful research, as conducted by [7], has identified errors causing machine impedance asymmetry leading to unbalanced phase currents, while [33] attributed such imbalances to negative sequence currents. In a modeling endeavor, has intricately mapped these imbalances, uncovering a "bolted" flaw among 648 turns. Building on these foundations, [34] proposes a diagnostic index based on the ratio of faulty to healthy positive sequence current. Augmenting these methodologies, techniques such as SPC and signal processing [35] contribute to the robust identification of stator defects, underscoring the need for a multifaceted and adaptive approach to fault diagnosis in the dynamic landscape of induction motor operations. This comprehensive exploration not only sheds light on the complexities of stator faults but also emphasizes the crucial role of advanced diagnostic methodologies in ensuring the reliability and longevity of induction motors across diverse operating conditions.

2.4 Bearing faults

In the intricate realm of electrical machines, the ubiquitous use of ball or rolling element bearings with an inner and outer ring, housing a set of rolling components rotating within raceways, is a common design paradigm[36]. Despite efforts to maintain load balance and alignment, the specter of fatigue failures looms, potentially giving rise to heightened vibration and noise levels [37]. These failures, often insidious and multifaceted, can be precipitated by external factors such as improper lubrication leading to abrasion and heating, suboptimal bearing placement resulting in raceway indentations, and the insidious influence of contamination or corrosion by water and abrasive particles. The consequences of such failures extend beyond the mechanical intricacies of the bearings, as they have the potential to cause substantial damage to the overall motor system.

Bearing faults can manifest distinct vibration fault signature spectra depending on whether the fault is in the inner or outer bearing race. Inner race faults typically produce vibration frequencies related to the shaft rotation and harmonics of the shaft speed, while outer race faults produce frequencies that are linked to the ball pass frequency of the outer race. These differences in vibration signatures are critical for accurate fault diagnosis [38].

The detection of faults associated with bearings, a critical yet under-documented aspect, assumes paramount importance due to their significant contribution to motor failures, accounting for a staggering 40–50% of reported cases. The intricate landscape of bearing-related faults manifests as rotor asymmetry, often symptomatic of eccentricity, and can be systematically categorized into ball defects, train defects, outer bearing race defects, and inner bearing race defects.

Understanding the nuanced manifestations of these faults becomes imperative for maintaining the operational integrity of electrical machines. Ball defects, arising from anomalies within the rolling.

components, can introduce irregularities in the rotational motion, leading to a cascade of detrimental effects. Train defects, characterized by issues among the entire set of rolling components, present a broader challenge requiring comprehensive diagnostic strategies. Outer bearing race defects, occurring in the outer ring raceway, and inner bearing race defects, manifesting in the inner ring raceway, represent distinct fault categories, each with its unique set of challenges and diagnostic considerations.

As the need for more comprehensive diagnostic methodologies in bearing fault detection becomes evident, it underscores the urgency for further research and development in this domain. The intricate interplay between mechanical factors, external influences, and fault manifestations necessitates a holistic approach to ensure the reliable and efficient operation of electrical machines across diverse applications and operating conditions.

3 Methods for advanced fault detection

In this section, I introduce an M-file created with MATLAB for visualizing and comparing various fault detection methods for induction motors. This tool streamlines the analysis process, enabling researchers to assess the effectiveness of different techniques efficiently. By synthesizing findings from diverse studies, it offers valuable insights into the most suitable IM fault detection method for specific industrial applications.

In the realm of advanced fault detection techniques for 3-phase induction motors, a diverse array of methodologies emerges, each contributing to the evolving landscape of motor diagnostics. One such approach involves the application of Incremental Broad Learning and Non-Negative Matrix Factorization. This sophisticated technique seeks to enhance fault detection capabilities by harnessing the power of incremental broad learning, coupled with the insights derived from non-negative matrix factorization. The fusion of these methodologies aims to provide a comprehensive and nuanced understanding of motor faults, enabling more accurate and timely detection [39, 40].

Rectified Stator Current analysis stands as another noteworthy methodology in the arsenal of fault detection techniques. By scrutinizing the stator current in a rectified manner, this approach offers unique insights into the motor's health and performance. The rectification process allows for a more granular examination of the current waveform, facilitating the identification of subtle deviations that may indicate underlying faults. This method proves to be a valuable tool in the diagnostic toolkit for 3-phase induction motors [41, 42].

The measurement of Space and Time Dependencies of Air Gap Flux represents a cutting-edge approach in fault detection. By analyzing the intricate interplay of spatial and temporal variations in the air gap flux, this methodology unveils valuable information about the motor's condition. This holistic perspective allows for the identification of faults that may manifest in complex ways, contributing to a more comprehensive understanding of motor health [38, 43].

The computational cost of advanced fault detection techniques can be significant, particularly for methods that require real-time data processing. Techniques such as model-based fault detection, machine learning algorithms, and high-frequency spectral analysis can be computationally intensive, which might limit their practical real-time implementation. Ensuring sufficient computational resources and optimizing algorithms for efficiency are essential considerations [44].

Artificial Intelligence-Based Stator Winding Fault Estimation in Three-Phase Induction Motor takes advantage of the prowess of artificial intelligence to predict and estimate faults in the stator winding. Leveraging advanced algorithms and machine learning techniques, this approach offers a predictive framework for fault estimation, enabling proactive maintenance and minimizing downtime [45].

For asynchronous motors, fault detection is tackled using ANN and fuzzy logic methods. These intelligent systems are designed to learn and adapt, providing a dynamic approach to fault detection in asynchronous motors. The fusion of ANN and fuzzy logic methodologies equips the diagnostic system with the ability to navigate the complex and dynamic nature of asynchronous motor faults, enhancing overall reliability.

In a diagnostic methodology proposed for 3-phase induction motors (TPIM) faults [46], a comprehensive framework is outlined, encompassing feature extraction, broad learning, and incremental broad learning. The system is trained utilizing processed experimental data, and its adaptability is highlighted through retraining with incremental wide learning. The study underscores the effectiveness of incremental broad learning and advocates for future research to focus on improving feature extraction and developing automatic selection methods for incremental nodes. The versatility of this approach extends beyond TPIM faults, making it applicable to a spectrum of motor diagnostic issues, with the potential for increased accuracy through the augmentation of feature nodes or inputs. This emphasis on continuous improvement and adaptability positions these advanced fault detection techniques at the forefront of ensuring the reliability and efficiency of 3-phase induction motors in diverse operational scenarios.

3.1 Incremental broad learning and non-negative matrix factorization (NFM-IBL)

TPIMs stand as intricate machinery, subject to an array of potential faults arising from the dynamic interplay of stator and rotor conditions. The complexity inherent in these motors necessitates a diagnostic system that can swiftly and accurately respond to emerging issues [46, 47]. While machine learning-based diagnostic systems have been developed for induction motors, their intricate design often entails prolonged training times and necessitates complete retraining in the event of inaccuracies.

To address the nuanced challenges posed by TPIM faults, a novel approach is proposed, leveraging the adaptable Incremental Broad Learning (IBL) method. This method encompasses the integration of NMF-IBL, along with feature extraction techniques employing Empirical Mode Decomposition (EMD) and Sample Entropy (SampEn). The amalgamation of these methodologies forms the backbone of the proposed TPIM fault diagnostic framework, which comprises four essential sub-modules: data collection and processing, broad learning, incremental broad learning, and structure simplification by Non-Negative Matrix Factorization (NMF) [48].

The first sub-module, data collection and processing, serves as the foundation for the diagnostic framework, where relevant data pertaining to the TPIM's operational conditions and performance are systematically collected and processed. This crucial step lays the groundwork for subsequent analysis and fault detection.

Broad learning, the second sub-module, involves the application of advanced learning algorithms to glean insights from the processed data. This phase aims to build a foundational understanding of the motor's normal behavior and performance, serving as a reference point for anomaly detection.

The third sub-module, incremental broad learning, introduces adaptability into the diagnostic system. This incremental approach allows the system to learn and adjust over time, avoiding the need for extensive retraining in the face of inaccuracies or evolving motor conditions. This flexibility is particularly crucial in addressing the dynamic nature of TPIM faults.

The final sub-module, structure simplification by NMF, adds a layer of sophistication to the diagnostic framework. Non-Negative Matrix Factorization is employed to simplify the complex structure of the data, enabling a more streamlined and interpretable representation. This step enhances the diagnostic system's ability to identify and isolate faults accurately.

The proposed TPIM fault diagnostic framework,the results of simulating the findings in [49] using m-file illustrated in Fig. 3, embodies a holistic and adaptive approach to fault detection. By integrating innovative methodologies and leveraging adaptability through incremental learning, this framework aims to overcome the challenges associated with TPIM faults. As the diagnostic landscape continues to evolve, the emphasis on real-time responsiveness, accuracy, and adaptability positions this framework at the forefront of ensuring the reliable and efficient operation of three-phase induction motors in diverse operational scenarios [50].

3.1.1 Data acquisition

Within the intricate framework of the proposed TPIM fault diagnostic system, the data acquisition sub-module takes center stage, serving as the gateway to a nuanced understanding of the motor's operational dynamics. This sub-module is designed to detect and capture four crucial signals: sound waves and the currents in windings A, B, and C, denoted as × 1, × 2, × 3, and × 4, respectively. However, since TPIM operation inherently involves only two stator currents, a strategic selection is made, utilizing only three signals (× 1, × 2, and × 3). To further refine the data and mitigate interference, a band-limiting filter is judiciously applied, enhancing the accuracy and reliability of the subsequent diagnostic processes.

The sound signal, denoted as × 1, assumes a pivotal role in the diagnostic framework. In alignment with best practices gleaned from studies [52], this signal is meticulously divided into distinct training, validation, and test datasets. This segmentation is a critical step that facilitates the robust training and validation of the diagnostic system, ensuring its efficacy in accurately discerning the intricate nuances of TPIM faults.

In addition to acoustic signals and stator electrical signals, other important variables that should be acquired include vibration data, temperature readings, flux measurements, and mechanical position data. These additional data sources can provide a more comprehensive picture of the motor’s operating condition and help in diagnosing a wider range of faults [53].

The judicious selection and processing of signals within the data acquisition sub-module lay the groundwork for subsequent phases of the diagnostic framework. By focusing on essential signals and implementing measures to reduce interference, this sub-module enhances the precision and reliability of the overall TPIM fault diagnostic system. The meticulous attention to signal processing, guided by established studies, underscores the commitment to a scientifically grounded and empirically validated approach in unraveling the complexities of three-phase induction motor faults [50].

3.1.2 Data processing

The quantity of data acquired and the sampling frequency of the digital platform significantly impact data processing. High-resolution data and high sampling rates improve the accuracy of fault detection but also increase the computational load and data storage requirements. Balancing the trade-off between data resolution and processing capability is crucial for effective fault detection [53].

In the intricate landscape of TPIM fault diagnostics, the application of the (EMD technique emerges as a pivotal step in the analysis of raw signals [54]. This technique yields three distinct datasets: xk-EMD-Train, xk-EMD-Vali, and xk-EMD-Test. These datasets, each encapsulating unique insights derived from the raw signals, lay the foundation for a more nuanced and granular understanding of the motor's operational dynamics.

To distill pertinent information and eliminate redundancy within these datasets, the Sample Entropy (SampEn) statistical approach is enlisted. SampEn serves as a powerful tool in extracting relevant features, ensuring that the subsequent analysis is focused on the most discriminative and informative aspects of the signals. The resultant features are then subjected to normalization, a crucial step to ensure that each feature contributes equally to the diagnostic process. These normalized features are stored as xk-SE-Train, xk-SE-Vali, and xk-SE-Test, respectively, encapsulating the refined and normalized representations of the original signals.

Recognizing the value of domain knowledge (DK) in enhancing defect detection, attributes informed by domain knowledge are strategically added to the processed datasets. These DK attributes serve as additional layers of information, enriching the datasets with insights that complement the statistical features derived from EMD and SampEn.

In the final stages of preprocessing, the datasets undergo a renaming process, signifying the completion of the intricate signal processing journey. The preprocessed datasets are now denoted as xk-Proc-Train, xk-Proc-Vali, and xk-Proc-Test. This nomenclature reflects the comprehensive nature of the datasets, encompassing the insights derived from EMD, SampEn, and domain knowledge attributes. These preprocessed datasets are poised for further in-depth analysis, setting the stage for the subsequent phases of the TPIM fault diagnostic framework.

This meticulous and systematic preprocessing pipeline, informed by established techniques and statistical approaches, underscores the commitment to precision and accuracy in unraveling the complexities of TPIM faults. By harnessing the power of EMD, SampEn, and domain knowledge, the diagnostic framework ensures that the subsequent analysis is grounded in a robust and comprehensive understanding of the underlying signals.

3.1.3 Board learning [50]

The culmination of signal processing and preprocessing efforts leads to the pivotal stage of model training within the TPIM fault diagnostic framework. A wide learning model, trained using the meticulously prepared xk-Proc-Train dataset, serves as the initial foray into understanding and predicting the intricacies of motor faults. This model is subjected to rigorous evaluation, scrutinizing its accuracy to ascertain if it aligns with the predetermined goal percentage.

The evaluation of the wide learning model serves as a crucial checkpoint, ensuring that the initial training phase meets the desired level of accuracy. If, however, the model falls short of the predetermined goal percentage, a strategic pivot is initiated. The diagnostic system seamlessly transitions into the incremental broad learning phase, an adaptive approach designed to enhance the model's performance dynamically.

In the incremental broad learning phase, a pivotal adjustment is made by increasing the number of enhancement nodes. This augmentation is a strategic intervention aimed at refining the model's understanding and predictive capabilities. By introducing additional nodes, the model gains a more nuanced grasp of the underlying patterns within the data, enabling it to adapt and evolve in response to the dynamic nature of TPIM faults.

This iterative and adaptive process exemplifies the commitment to continuous improvement within the TPIM fault diagnostic framework. The seamless transition from wide learning to incremental broad learning underscores the flexibility inherent in the diagnostic system, ensuring that it can effectively navigate evolving motor conditions and fault manifestations. The goal-oriented approach, coupled with an adaptive learning strategy, positions the TPIM fault diagnostic framework as a robust and responsive tool in ensuring the reliability and efficiency of three-phase induction motors across diverse operational scenarios.

3.1.4 Incremental broad learning [50]

Within the TPIM fault diagnostic framework, the IBL submodule assumes a crucial role in refining the accuracy of the model. Leveraging the insights derived from the xk-Proc-Vali dataset, this submodule dynamically adjusts the number of enhancement nodes, a strategic intervention aimed at continually improving the model's predictive capabilities.

However, the adaptive nature of the IBL submodule brings forth a challenge—the potential for overfitting. If the number of nodes is excessively high, the model may start fitting the training data too closely, leading to a reduction in its generalization capabilities. To circumvent this issue, a meticulous trial-and-error process is instituted. This process is geared towards determining the optimal number of nodes, denoted as N, striking a delicate balance between enhancing accuracy and preventing overfitting.

The trial-and-error methodology is a nuanced approach that involves systematically experimenting with different node configurations until the desired validation accuracy is achieved. This iterative process is informed by insights presented in a comprehensive review article, providing a theoretical and empirical foundation for optimizing the IBL submodule.

The overarching goal is to ensure that the model's adaptability and dynamic learning capabilities are harnessed without compromising its ability to generalize to new data. By fine-tuning the number of enhancement nodes through a systematic trial-and-error approach, the IBL submodule aligns with the broader objective of the TPIM fault diagnostic framework— achieving a robust and accurate model that can effectively discern and predict motor faults.

This emphasis on preventing overfitting, coupled with the evidence-based approach outlined in the review article, underscores the commitment to precision and reliability in the TPIM fault diagnostic system. The iterative nature of the trial-and-error process encapsulates the adaptive spirit of the diagnostic framework, ensuring that it continually evolves to meet the complexities and challenges posed by the dynamic landscape of three-phase induction motor faults.

3.1.5 Structure simplification [49]

In the pursuit of optimizing the TPIM fault diagnostic system, a critical post-processing phase comes into play. The learning system, having undergone the adaptive and dynamic processes of wide learning and incremental broad learning, may inadvertently harbor redundant nodes. To streamline and refine the model, a systematic approach is employed to identify and eliminate these redundancies, ensuring the efficiency and interpretability of the diagnostic system.

The process of node reduction involves simplifying the learning system through low-rank approximations, a technique aimed at retaining the essential features while discarding unnecessary redundancies. This reduction not only enhances the computational efficiency of the model but also contributes to a more interpretable and streamlined representation.

To further optimize the IBL structure, Non-Negative Matrix Factorization (NMF) is introduced as a compression mechanism. NMF, a powerful mathematical tool, facilitates the extraction of meaningful patterns within the learning system, promoting a more concise representation without compromising diagnostic accuracy [55].

The compression of the IBL structure through NMF serves as a strategic step in minimizing system error and refining the diagnostic capabilities of the TPIM fault diagnostic system. However, the pursuit of optimal diagnostic accuracy remains paramount. If the diagnostic accuracy falls outside the predefined range, denoted as [TP 0.025], an additional layer of compression is initiated through the incremental broad learning submodule. This iterative compression process ensures that the TPIM fault diagnostic system continually adapts to achieve the delicate balance between model complexity and diagnostic precision.

By incorporating these compression techniques, informed by established mathematical methodologies, the TPIM fault diagnostic system aligns with the principles of efficiency, interpretability, and adaptability. The iterative nature of compression, coupled with the strategic incorporation of NMF and incremental broad learning, underscores the commitment to continuous improvement within the diagnostic framework. This meticulous post-processing phase is integral to ensuring that the TPIM fault diagnostic system stands as a robust, efficient, and accurate tool in unraveling the complexities of three-phase induction motor faults.

3.2 Rectified stator current

In the realm of fault detection for induction motors, stator current analysis[56] stands as a prominent and widely employed technique. Renowned for its simplicity and the minimal hardware and software prerequisites it demands, this non-invasive method has proven effective across various motor sizes and operational conditions. However, the practical application of stator current analysis encounters challenges, particularly when dealing with large induction motors operating at extremely low slip rates.

One of the primary challenges inherent in stator current analysis is the potential concealment of fault harmonics by the fundamental component, particularly in situations where the motor operates at extremely low slip. This concealment phenomenon poses a significant obstacle, often resulting in delayed fault detection until the damage reaches a severe stage. In response to this limitation, a novel approach based on rectified motor current analysis emerges as a pragmatic and effective solution.

The proposed rectified motor current analysis approach introduces a simple yet powerful strategy to overcome the challenges associated with fundamental component leakage. By rectifying the motor current, the fault harmonics are distinctly revealed at a lower frequency, untethered from the interference of the fundamental component. This innovative method not only circumvents the delayed detection issue but also offers a versatile solution that can be seamlessly implemented through both software and hardware.

The practical efficacy of the proposed approach is robustly demonstrated through experimental verification [57], wherein the method proves instrumental in detecting a broken bars defect in a large induction motor. This empirical validation underscores the real-world applicability and effectiveness of the rectified motor current analysis, positioning it as a valuable addition to the arsenal of fault detection techniques for large induction motors.

Stator current analysis remains a stalwart in fault detection, the proposed rectified motor current analysis emerges as a complementary and pragmatic approach tailored to address the nuances of large induction motors operating at extremely low slip rates. Its simplicity, effectiveness, and demonstrated success in real-world scenarios mark it as a noteworthy advancement in the pursuit of reliable and timely fault detection strategies for induction motors.

3.3 Measuring the variations of air gap flux with respect to both space and time

Ensuring the efficient and dependable operation of induction motors hinges on robust condition monitoring systems, a critical facet addressed in this section. Contemporary diagnostic systems predominantly rely on external measurements such as current, voltage, vibration, or flux to glean insights into the motor's health. However, this study advocates for a groundbreaking online fault diagnostic method, as proposed in [48, 58,59,60,61], which introduces a paradigm shift by utilizing an array of Hall effect flux sensors to measure the internal main air gap flux density of induction motors.

The crux of this method lies in its applicability to specialized motors with elevated reliability requirements. Unlike traditional diagnostic approaches, the proposed method offers a comprehensive solution for diagnosing induction motor failures by tapping into the internal dynamics of the motor's air gap flux density. This internal measurement not only provides a unique perspective but also allows for the detection of issues at an early stage, enabling timely intervention to prevent the escalation of faults.

To acquire data on air gap flux variations for fault diagnosis, specialized instrumentation such as flux sensors or search coils placed in strategic positions within the motor is necessary. These sensors must be capable of capturing high-resolution spatial and temporal variations in the flux to provide meaningful diagnostic information[62]

A distinctive feature of the proposed method is its capability to not only detect faults but also identify their precise location and gauge their severity [55]. This granular level of diagnostic information is instrumental in formulating targeted maintenance strategies, enhancing the overall reliability and lifespan of the induction motors.

To substantiate the efficacy of the proposed method, the study undertakes extensive simulations and develops a prototype online condition monitoring system based on the National Instruments real-time platform [63]. The results of these simulations and the functioning prototype serve as empirical evidence, confirming the effectiveness of the proposed method in real-world scenarios. This empirical validation reinforces the viability of integrating Hall effect flux sensors for online fault diagnosis, establishing it as a potent tool for ensuring the health and longevity of induction motors.

This section not only highlights the pivotal role of condition monitoring in induction motor operation but also introduces a pioneering online fault diagnostic method that leverages Hall effect flux sensors. The method's applicability to specialized motors, early fault detection capabilities, and the ability to pinpoint fault location and severity underscore its significance in advancing the field of induction motor diagnostics. The combination of theoretical proposals, simulations, and a functional prototype serves as a robust foundation for considering the proposedmethod as a valuable addition to the repertoire of condition monitoring techniques for induction motors.

3.3.1 Faulty stator winding

Stator winding shorts pose a severe threat, with the potential to rapidly escalate into catastrophic failures [53]. When a single turn of the stator winding becomes shorted, it becomes disconnected from other turns within the same phase coil. This disconnection induces a shift in the phase magnetomotive force (MMF), altering the magnetic field distribution. Simultaneously, the isolated turn carries a loop current, exceeding the rated current and resulting in excessive heating. The swift identification and localization of stator winding problems are imperative, underscored by an alarming experiment where the temperature of a shorted turn soared from 60 to 120 °C in just 6 s. This stark reality emphasizes the critical need for effective fault diagnosis methods.

For electric stator open circuit faults, specific techniques such as monitoring the unbalance in phase currents or utilizing the ISP method can be effective. These methods can detect anomalies that indicate an open circuit condition, which might not be apparent through traditional analysis [64].

A groundbreaking study [58] proposes an innovative fault diagnosis method capable of detecting and precisely locating stator winding problems. This method operates by quantifying the distortion caused by stator shorts directly within the main air gap flux. By doing so, it offers a direct and efficient means of identifying faults in the stator winding. Moreover, the proposed method excels in pinpointing the exact site of the fault through the analysis of the rise in primary wave magnitude during rotation. This strategic approach not only mitigates the uncertainties associated with time harmonic interpretation but also optimizes the use of extensive instrumentation deployed in investigative processes.

The experimental results, an m-file was written to simulate the results [65] in Fig. 4, showcase a substantial increase in the magnitude of the primary wave during the short rotation. This remarkable rise serves as a reliable indicator that can be leveraged to precisely locate the fault. The implications of this method extend beyond mere fault detection; it offers a comprehensive solution that addresses the urgency of timely identification and localization of stator winding problems, thereby averting potential catastrophic outcomes in induction motors.

3.3.2 Eccentricity, both static and dynamic

This groundbreaking article[66] introduces a pioneering approach aimed at enhancing the instrumentation crucial for the effective operation of induction motors. The key innovation lies in the utilization of a Hall effect sensor array strategically positioned around the stator circumference within the motor air gap. This strategic placement enables the sensor array to capture vital information about the motor's internal dynamics and performance. The study is dedicated to unraveling the fundamental theory underlying AC motor faults, with a specific emphasis on detecting critical issues such as stator winding defects, static and dynamic eccentricity, and rotor bar faults[66].

The proposed approach extends beyond theoretical considerations, providing concrete algorithms designed for the accurate detection of these various faults. Notably, the study employs a comprehensive condition monitoring system, leveraging the capabilities of the National Instruments Compact RIO real-time platform. This system has demonstrated exceptional fault sensitivity, noise immunity, and dynamic variation tolerance, making it a robust tool for diagnosing and monitoring the health of induction motors.

The empirical validation of this approach further solidifies its credibility. The study underscores that this innovative methodology is particularly well-suited for dynamic applications involving inverter-fed large induction motors with elevated reliability requirements. The systematic development and validation of this approach contribute significantly to the field of fault diagnosis in induction motors[7]. It not only enhances the understanding of motor faults but also presents a practical and effective solution for real-world applications, promising heightened reliability and performance in dynamic settings.

3.4 Estimation of stator winding fault in three-phase ınduction motors using artificial ıntelligence

The challenge of detecting faults in induction motors through multiple optimization techniques has spurred innovative research. In a noteworthy study[64], researchers have proposed an intelligent approach harnessing the power of fuzzy logic to detect short-circuit faults in the stator winding of a three-phase induction motor. This method stands out by employing a fuzzy logic controller, which carefully analyzes the stator current and provides indications regarding the type of motor failure based on a well-defined rule base and inference mechanism[67,68,69].

Artificial intelligence algorithms for fault detection are typically trained using a variety of data, including stator currents, vibration signals, acoustic signals, temperature data, and sometimes flux measurements. The diverse data sources allow the AI models to learn and recognize complex patterns associated with different types of faults, enhancing their diagnostic accuracy [20].

The implementation of this intelligent approach is facilitated through the use of MATLAB-SIMULINK software, enabling the simulation of both healthy and short-circuit fault conditions in a three-phase induction motor, as depicted in Fig. 5. The fuzzy logic-based approach offers a distinctive advantage by enabling fault detection based on available inputs, presenting itself as an intelligent and adaptable method for motor condition monitoring and fault analysis.

The significance of this approach goes beyond its technical prowess. By facilitating the detection of faults at an earlier stage, it contributes to the establishment of a safer working environment in industries. The proactive nature of fault detection aligns with the broader goal of ensuring the reliability and safety of induction motors in industrial settings. This study not only introduces an intelligent methodology for fault detection but also underscores its potential impact on industrial operations, emphasizing the importance of early fault detection in maintaining a secure and efficient working environment.

In [70] proposes artificial intelligence (AI) algorithms for detecting interturn short circuit (ITSC) faults in three-phase induction motor stators, with a focus on the use of ANN and fuzzy logic systems to reduce the impact of load changes on defect detection. The ANN algorithm is capable of detecting and locating ITSC faults, while the Fuzzy method can diagnose the severity of ITSC defects. The effectiveness of both techniques is validated through simulation and experimental results under ITSC fault and load change conditions.

In order to achieve reliable stator defect detection even under load changes, a combination of ANN and Fuzzy Logic System (FLS) is proposed. Specifically, this research [71] utilizes a feedforward multi-layer perceptron (MLP) Neural Network trained with the back propagation (BP) algorithm to automatically detect and locate ITSC faults. The suggested approach and neural network architecture are illustrated in Fig. 5, with the NN's output number set at three to correspond with the three phases of the induction motor where the ITSC fault could potentially occur.

The selection of fault indicators is a crucial step in developing a monitoring and diagnostic system. Interturn short-circuit (ITSC) faults in induction motors are often detected using the phase shifts between line current and phase voltage, which provide a wealth of information about the fault. In healthy motors, the phase voltage and line current have identical magnitudes and are displaced by 120 electrical degrees. However, faulty operation can lead to changes in the magnitudes and phase shifts. To investigate the behavior of three-phase shifts under various ITSC faults, the faulty stator model proposed in Section II was simulated under different load torques (T = 3 and 7 N·m) (Fig. 6) is the output of m-file written to simulate the results [72] of the three-phase shifts as a function of the number of short-circuited turns under load torque of 5 N·m. The results reveal the influence of load changes on the ITSC fault detection technique.

This study [73] presents two AI-based techniques for robust stator failure detection in the presence of load variations. Artificial Neural Networks and Fuzzy Logic are utilized to eliminate the need for an induction motor model during fault detection, resulting in adaptable and easily deployable systems. The ANN technique identifies the faulty phase, while the Fuzzy Logic-based detector determines the severity of the problem. These smart techniques have various applications, including alerting the workforce of a dangerous condition and facilitating the repair of a defective stator.

4 Modelling applications

As the popularity of artificial intelligence-based condition monitoring systems rises, fault detection systems[7, 25, 63, 71, 74, 75] utilizing Support Vector Machine (SVM), ANN, Nave Bayes classifier, Ensemble, and K-Nearest Neighbors (KNN) have become more prevalent. These systems can detect faults and determine their severity level, but they require extensive data to train and malfunctioning machines are scarce. Numerical methods can simulate faulty conditions that are difficult to test in the field or lab, providing fault data for machine learning algorithms. Accurate Induction Motor (IM) malfunctioning models can minimize harmful testing, lower costs, and validate new fault detection techniques[76, 77], making them beneficial for training and testing artificial intelligence-based condition monitoring systems. This section covers recent developments in IM models, which are categorized into electrical circuits, magnetic circuits, numerical approaches, and hybrid models, and provides an overview of various fault diagnosis methods[78] as shown in Fig. 7.

The coupling circuit models (MCC) model represent a wide variety of fault modes including stator open circuit, stator short circuit, broken rotor bar, broken end ring, static eccentricity, dynamic eccentricity, mixed eccentricity, and defective bearing. In contrast, the d-q model simplifies the representation of faults and reduces the number of equations required for simulation but does not provide specific information about individual rotor bars or end ring currents. Meanwhile, the Models based on magnetic circuits (MEC) model offers detailed magnetic modeling with reluctances and permeances to accurately simulate faults, and the models based on mathematical procedures (FEM) approach, while computationally intensive, enables comprehensive modeling of induction machine faults by considering the nonlinearities of magnetic materials and accurately reproducing the performance of the machine.

4.1 Models featuring coupled circuits

Dynamic models of three-phase induction motors use parameters that can change under fault conditions, such as resistance, inductance, and mutual inductance values. When a machine is under fault conditions, these parameter variations can impact the accuracy and reliability of the proposed modeling scheme. It is essential to account for these changes in the model to ensure it remains valid and effective in diagnosing faults. Techniques such as adaptive modeling or real-time parameter estimation can help mitigate these impacts [79].

The d-q model is a widely used coupling circuit model that assumes symmetrical motors, linear iron permeability, uniform air-gap, and no tangential induction. These simplifications allow for a fast and accurate mathematical model but are problematic when dealing with faulty equipment. This section discusses recent breakthroughs in MCC and d-q models illastrated on Table 2.

4.1.1 Multiple coupled circuit models

After determining model parameters, the expressions characterizing IM behavior (related to rotor conductors) and requiring stator solving are known as in Eqs. 5,6,7 and 8 [83].

The equations consist of various vectors and matrices, including [Us] for stator voltage, [Is] for stator currents, [Ir] for rotor loop current, [∅s] for stator flux linkage, [Rs] for stator phase resistances, [Lss] for stator windings inductance, and [Lsr] for stator to rotor mutual inductance. Additionally, [Ur] denotes the rotor voltages vector, [Ir] the rotor currents vector, [Ir] the rotor loop currents vector, [∅r] the rotor flux linkages vector, [Rr] the rotor resistance matrix, and [Lrr] the rotor inductance matrix.

4.1.2 d-q model

The implementation of the space vector transformation technique is beneficial for depicting an induction machine with structural symmetry in simulations. By utilizing this method, it is possible to represent such machines using only four differential equations that are linked together. This leads to a reduction in the overall number of equations that are required for simulation purposes. Consequently, the equations that define the stator voltage can be expressed as follows:

The variables in the aforementioned EqS. 9 and 10 can be defined as follows: wb refers to the base per-unit electrical speed, while Øds, Øqs, and Ø0s represent the d-axis, q-axis, and zero-sequence stator flux connections. The stator resistance is denoted by Rs, and the d-axis, q-axis, and zero-sequence stator currents are respectively represented by ids, iqs, and i0s. Additionally, vdr and vqr refer to the d-axis and q-axis rotor voltages, while φdr and φqr are the d-axis and q-axis rotor flux linkages. Furthermore, ω denotes the per-unit synchronous speed, and ωr refers to the per-unit mechanical or rotational speed.

4.2 Models based on magnetic circuits (MEC)

In this approach, discrete winding distributions, stator and rotor slotting, and magnetic material saturation-induced saliency effects related to space harmonics are taken into account [106]. The nodal magneto-motive forces [F] are connected to the reluctances [R] in Eq. 11, which represent the fluxes of the rotor and stator [Ø].

In conclusion, the MEC-based framework has demonstrated high precision in predicting machine performance across diverse operating points, load conditions, and even unbalanced excitation and faulty conditions. Its accuracy and computational efficiency make it an ideal alternative between the standard lumped parameter models and FEM-based approaches [107]. The MEC technique has also proven effective in modeling a range of induction motor faults.

4.3 Models based on mathematical procedures (FEM)

By utilizing the machine's actual magnetic and geometric properties, this technique calculates the distribution of the magnetic field [91, 107]. In general, faulty induction motor models are created in 2D, which offers excellent accuracy in terms of magnetic phenomena. However, these models do not consider the rotor's skewing behavior or the end rings, and the connection of the rotor bars is typically addressed through an ideal current source in the electrical circuit [88]. The magneto-dynamic field equation for a standard induction motor in 2D is defined as follows:

In the given Eq. 12, (A)⃗ represents the magnetization potential, Az is the z-component of the magnetic vector potential, J0 refers to the applied density current source, v⃗ represents velocity, σ is the electric conductivity, and v represents permeability.

4.4 Models with hybrid components

Recent research suggests that combining FEM and analytical methodologies can generate models with FEM level accuracy, which can be executed in real-time simulators [55]. A hybrid model based on the d-q method and finite element analysis has been proposed to model short circuit defects in IM drives. In this model, sparse identification is utilized to minimize the number of FEM simulations needed to compute the IM coupling parameters. FEM is used to solve the entire geometry of the IM, and the coupling parameters are then imported into the machine's analytical model [55]. The sparse identification method is effective in obtaining a defective IM model while minimizing the number of FEM simulations needed, thus reducing computing expenses by over 99.9%. However, the full FEM analysis is still required for each failure scenario, resulting in extensive simulation periods and expensive computational costs. TSFEM-based models require lengthy simulation times for small simulated spans, whereas hybrid models require approximately 25 min [101]. Even when the time to execute one simulation is factored in, the time savings exceed 98%.

5 Challenges and future directions

The existing challenges in fault detection for three-phase induction motors encompass a range of factors[115], including the limitations of current signature analysis (CSA), the need for specialized diagnostic methodologies, and the impact of variable frequency drives (VFDs). Furthermore, the reliance on Fourier analysis for signal interpretation and feature extraction presents certain drawbacks, such as the lack of transient information and the absence of spectrum content variations over time. These challenges have fostered the exploration of various data-driven prognostics and health management (PHM) methodologies driven by artificial intelligence, machine learning, and deep learning, aiming to leverage current, vibration, and thermal signals for effective fault detection and isolation.

The challenges in fault detection for three-phase induction motors can include issues with accurately identifying incipient faults, distinguishing between various fault types, and dealing with the effects of operating conditions and external disturbances. Additionally, extracting fault signatures from noisy measurements and developing reliable and automated fault detection methods also present significant challenges in this domain [25].

The existing challenges in fault detection for three-phase induction motors are multifaceted and encompass various aspects of signal analysis, system complexity, and operational conditions. Some of the prominent challenges include:

(a) Complex Operating Conditions: Induction motors operate in diverse industrial environments where operating conditions such as variable loads and speeds, temperature variations, and mechanical stresses can influence the manifestation of faults and complicate the diagnostic process [116]. (b) Incipient Fault Detection: Early detection of incipient faults, such as broken rotor bars, poses a significant challenge due to the limited availability of diagnostic techniques capable of identifying subtle changes in motor behavior at the initial stages of fault development [117]. (c) Signal Interpretation: The interpretation of motor current and vibration signals to differentiate between normal and faulty conditions requires accurate analytical models and sophisticated signal processing techniques to extract relevant fault signatures and mitigate false alarms [118]. (d) Transient Regimes: Fault detection during transient regimes, such as startup and shutdown, presents challenges due to signal variations and the need for suitable methods to differentiate between normal transient behavior and actual fault conditions [119]. (f) Noise and Interference: The presence of electrical and mechanical noise, as well as interference from external sources, can mask fault signatures in the acquired signals, making it challenging to extract relevant diagnostic information [99]. (g) Operational Dependence: The effectiveness of fault detection techniques can be influenced by the operational characteristics of induction motors, necessitating robust diagnostic methods capable of accommodating varying operating conditions and loads [26]. (h) Need for Expert Identification: Traditional fault detection in induction motors often relies on the expertise of skilled engineers to interpret diagnostic data, highlighting the need for automated and intelligent diagnostic systems to overcome human-related limitations [120]. (i) Inadequate Diagnostic Techniques: The limitations of conventional diagnostic methods in detecting specific fault types, such as broken rotor bars, and the lack of comprehensive fault detection solutions present challenges in ensuring reliable and accurate fault diagnosis in induction motors. (j) Varied Operating Conditions: The fault detection process can be complicated due to the diverse operating conditions experienced by induction motors, such as variable speeds, load variations, and environmental factors [84]. (k) Dynamic Stresses: Induction motors used in variable-speed applications undergo dynamic stresses at high power levels, leading to reduced lifetimes compared to constant-speed motors, adding complexity to fault detection [121]. (l) Non-Deterministic Fault Characteristics: Some faults, such as eccentricity and certain rotor faults, may manifest in non-stationary and intermittent characteristics, making them challenging to detect and diagnose accurately [84, 122]. (m) Reliability and Complexity of Parameters: Parameters such as induced rotor voltage exhibit non-reliability and complexity, posing challenges for their usage in condition monitoring and fault diagnosis [123].

To overcome these challenges, it is crucial to continue researching and developing advanced diagnostic techniques that leverage cutting-edge signal analysis, machine learning, and artificial intelligence to enhance the accuracy and reliability of fault detection in three-phase induction motors. Additionally, the integration of comprehensive fault diagnostic systems that account for various operational scenarios and noise sources can significantly contribute to improving the effectiveness of fault detection methodologies.

6 Conclusion

In conclusion, the landscape of fault diagnosis techniques for electrical machines has undergone significant evolution to ensure the secure and reliable operation of these critical systems. The comprehensive exploration within this review article has delved into a myriad of diagnostic techniques ranging from traditional methods like temperature measurement and infrared recognition to more advanced approaches such as vibration analysis, MCSA, and artificial intelligence and neural network techniques.

The article provides a comprehensive exploration of numerous fault detection techniques for electrical machines, covering advancements in traditional methods and cutting-edge approaches. Some of the advanced techniques discussed in the article include Incremental Broad Learning (IBL), Non-Negative Matrix Factorization (NMF), rectified stator current analysis, measurement of space and time dependencies of air gap flux, artificial intelligence-based methods, and various other machine learning and signal processing approaches.

The article underscores the paramount importance of fault detection methods tailored for different types of faults inherent in electrical machines. The spotlight was cast on diverse fault categories, including eccentricity, rotor faults (broken bars and end rings), stator or armature faults, and bearing faults. Recognizing the dynamic nature of modern electrical machines, the article delved into advanced fault detection methods. These encompassed cutting-edge technologies like Incremental Broad Learning and Non-Negative Matrix Factorization, rectified stator current analysis, measurement of space and time dependencies of air gap flux, and artificial intelligence-based methods.

The efficiency of these advanced techniques lies in their capacity to offer robust solutions for fault detection. By enabling the timely identification of faults, they play a pivotal role in preventing unexpected machine downtime and mitigating potential financial losses. However, the article aptly acknowledges that the field is a dynamic one, and it advocates for continued research and development. This call to action emphasizes the need for ongoing efforts to enhance fault diagnosis capabilities for electrical machines, ensuring that diagnostic methodologies stay ahead of evolving challenges in the ever-changing landscape of electrical engineering.

Data availability

No datasets were generated or analysed during the current study.

References

Okwuosa CN, Akpudo UE, Hur J-W. A cost-efficient MCSA-based fault diagnostic framework for SCIM at low-load conditions. Algorithms. 2022;15(6):212.

Naha A, Thammayyabbabu KR, Samanta AK, Routray A, Deb AK. Mobile application to detect induction motor faults. IEEE Embed Syst Lett. 2017;9(4):117–20. https://doi.org/10.1109/LES.2017.2734798.

Elias GS, Guy C, Hubert R, Abdenour S. Fault Diagnosis and Prognosis for Reliability Enhancement. In: Diagnosis F, editor. Prognosis, and Reliability for Electrical Machines and Drives. New York: IEEE; 2022. p. 345–414.

Bednarz SA, Dybkowski M. On-Line Detection of the Rotor Faults in the Induction Motor Drive Using Parameter Estimator. In: 2018 International Symposium on Electrical Machines (SME), pp. 1–5; 2018.

Dorrell DG, Makhoba K. Detection of inter-turn stator faults in induction motors using short-term averaging of forward and backward rotating stator current phasors for fast prognostics. IEEE Trans Magn. 2017;53(11):1–7. https://doi.org/10.1109/TMAG.2017.2710181.

Nandi S, Ahmed S, Toliyat HA. Detection of rotor slot and other eccentricity related harmonics in a three phase induction motor with different rotor cages. IEEE Trans Energy Convers. 2001;16(3):253–60. https://doi.org/10.1109/60.937205.

Almounajjed A, Sahoo A, Kumar M, Bakro M. Condition Monitoring and Fault Diagnosis of Induction Motor - An Experimental Analysis. 2021, pp. 433–438.

Corral-Hernandez JA, Antonino-Daviu JA. Thorough validation of a rotor fault diagnosis methodology in laboratory and field soft-started induction motors. Chin J Electr Eng. 2018;4(3):66–72. https://doi.org/10.23919/CJEE.2018.8471291.

Benbouzid M. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans Industrial Electronics. 2000;47:984–93. https://doi.org/10.1109/41.873206.

Faiz J, Moosavi SMM. Detection of mixed eccentricity fault in doubly-fed induction generator based on reactive power spectrum. IET Electr Power Appl. 2017;11(6):1076–84.

Faiz J, Ebrahimi BM, Toliyat HA. Effect of magnetic saturation on static and mixed eccentricity fault diagnosis in induction motor. IEEE Trans Magn. 2009;45(8):3137–44.

Yassa N, Rachek MH, Houassine H. Motor Current Signature Analysis for the Air Gap Eccentricity Detection In the Squirrel Cage Induction Machines. Energy Procedia. 2019;162:251–62. https://doi.org/10.1016/j.egypro.2019.04.027.

Mafruddin MM, Suwarno S, Abu-Siada A. Finite element simulation of a 126 MW salient pole synchronous generator with rotor eccentricity. In: 2019 2nd International Conference on High Voltage Engineering and Power Systems (ICHVEPS), 2019: IEEE, pp. 1–96.

Mansour F. Induction Motors: Construction, Principle of Operation, Power and Torque Calculations, Characteristics and Speed Control. 2020.

Kumar RS, Ray KK, Kumar KV. Fault diagnosis of industrial drives using MCSA techniques. In: 2009 International Conference on Control, Automation, Communication and Energy Conservation, 4–6 June 2009 2009, pp. 1–7.

Liu Z, Zhang P, He S, Huang J. A review of modeling and diagnostic techniques for eccentricity fault in electric machines. Energies. 2021;14(14):4296.

Bouchareb I, Lebaroud A, Cardoso AJM, Lee S. Towards Advanced Diagnosis Recognition for Eccentricities Faults. Application on Induction Motor. 2019;45:271–82.

Polat A, Ertuğrul YD, Ergene LT. IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), 1–4(2015). Sept. 2015;2015:284–8. https://doi.org/10.1109/DEMPED.2015.7303703.

Torkaman H, Afjei E, Yadegari P. Static, dynamic, and mixed eccentricity faults diagnosis in switched reluctance motors using transient finite element method and experiments. IEEE Trans Magn. 2012;48(8):2254–64.

N. Lashkari, H. Azgomi, J. Poshtan, and M. Poshtan, Robust stator fault detection under load variation in induction motors using AI techniques. 2015, pp. 1446–1451.

Park Y, Choi H, Lee S, Gyftakis K. Flux-based Detection of Non-adjacent Rotor Bar Damage in Squirrel Cage Induction Motors. 2019, pp. 7019–7026.

Asad B, Eensalu L, Vaimann T, Kallaste A, Rassõlkin A, Belahcen A. The FEM Based Modeling and Corresponding Test Rig Preparation for Broken Rotor Bars Analysis. In: 2019 IEEE 60th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), 2019: IEEE, pp. 1–9.

Jerkan DG, Reljić DD, Marčetić DP. Broken rotor bar fault detection of im based on the counter-current braking method. IEEE Trans Energy Convers. 2017;32(4):1356–66. https://doi.org/10.1109/TEC.2017.2696578.

Lee HJ, Im SH, Um DY, Park GS. A design of rotor bar for improving starting torque by analyzing rotor resistance and reactance in squirrel cage induction motor. IEEE Trans Magn. 2018;54(3):1–4. https://doi.org/10.1109/TMAG.2017.2764525.

William TT, Ian C. MCSA Case Histories—Diagnosis of Cage Winding Defects in SCIM s Fitted with End Ring Retaining Rings. In: Current Signature Analysis for Condition Monitoring of Cage Induction Motors: Industrial Application and Case Histories: IEEE, 2017, pp. 147–172.