Abstract

The progressive increase in the rate of production of plastic bottles by the beverage and food industries in Nigeria has increased considerably over time, constituting large volume of waste generations from plastic waste bottles. Also, increasing demand for eco-friendly soil improvement materials and the growing desire to minimize waste generated daily, prompted the need for this study to look into ways to use such wastes and other sustainable materials in soil improvement. This study investigated the potential use of sisal fiber and plastic waste strips as partial replacement for cement to enhance the geotechnical characteristics of lateritic soils. Various laboratory experiments were conducted, encompassing specific gravity determination, grain size distribution, compaction assessment, Atterberg limit, unconfined compressive strength (UCS), and microscopic analysis. Sisal fiber and plastic waste strips were each varied at 0, 0.5, 1.0, 1.5, 2.0 and 2.5% while maintaining a constant 5% cement added to all the mix proportions. Results of investigation revealed an enhancement in plasticity of the soils with both treatment methods. Liquid limit shows a steady drop from 43% in its natural state to 42% and 41% at 1% sisal fiber and 1% plastic strips content respectively, while plasticity index showed a decline from 14.8% in its natural form to 12.69% and 10.8% at 2% sisal fiber and 1% plastic waste strips content respectively. Strength properties of the treated soil increased with increase in admixtures content. Microanalysis of the natural and optimally modified soils showed alteration in the fabric arrangement of the particles of soils. Based on the results of the study, optimally 1–1.5% sisal fiber/5%cement and 1–1.5% plastic waste strips/5%cement meaningfully improved the soil strength and can both be used as sub-base materials for light trafficked roads.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The growing desire for a sustainable infrastructure especially roads has turn out to be a global concern, particularly in developing countries like Nigeria [1]. Problematic and deficient lateritic soils in many regions of Nigeria have affected the effective performance of many flexible road pavements. Thus, the need to improve such deficient soils that does not meet the basic requirement for use as subbase or base materials in flexible pavements. In addition, challenges associated with deficient soils that fail to meet certain engineering requirements, for its application as construction materials in flexible pavements have significantly increased the cost of roads construction in such areas [2,3,4,5]. These challenges necessitate the complete elimination of the entire soil in such areas and substituting them with granular soils that has better bearing capacity.

Nevertheless, replacing such deficit soils is cost-effective and will results to a significant rise in the construction cost. Stabilizing such deficient soils with famous additives like cement improves the soil geotechnical properties. However, there is an increasing concern on the requirement for deployment of industrial as well as agricultural wastes for valuable use. The mentioned challenges have triggered an examination into the stabilizing potential of sustainable materials such as plastic waste strips and sisal fiber for flexible pavement applications.

Over time, heavy reliance on cement and other chemically engineered soil stabilizers has been shown to escalate environmental pollution and construction costs [2]. Consequently, substituting these materials with industrial and agricultural wastes such as sisal fiber, locust bean waste ash [6, 7] and industrial waste like marble dust and iron ore tailings [8, 9] for engineering applications can lessen the environmental issues caused by cement and lime production. Previous research by Osinubi et al. [2], indicated that cement production processes emit significant amounts of carbon dioxide (CO2). Therefore, using alternatives like sisal fiber can help in mitigating the environmental impact of CO2 emissions. The adoption of eco-friendly soil improvement methods is on the rise.

Several literatures documented results of previous research works [10,11,12,13,14] where eco-friendly sustainable construction materials such as microbial induced calcite precipitation (MICP), plastic waste, sisal fibers etc. were used. For instance, Yasmeen and Rabinder [14] in their study blended sisal fiber (i.e. at 0 cm, 2 cm, 4 cm, 6 cm length) with bagasse ash to enhance the strength of the soil. Results of their study revealed an improvement in both the UCS and the California bearing ratio (CBR) of the modified soil. A study was reported by Sharma et al. [15], on the use of both sisal fiber and polyvinyl alcohol (PVA) for improvement of loam soil. Findings from their study revealed that sisal fiber recorded better performance in terms of improving the soil properties than PVA.

Quite a lot of other investigators [16,17,18,19] described soil improvement performed using sisal fiber, jute fiber as well as cone fiber, with encouraging outcomes. The utilization of fibers for diverse engineering uses has been described in literatures [11, 20,21,22,23,24,25,26,27]. Muthukkumaran et al. [27], reported on the effect of alkaline activated fly ash with sisal fiber inclusion for improvement of expansive soils. Tests carried out include free swell, unconfined compressive strength test, cyclic triaxial test and micro structural investigations. Results of the study revealed that addition of alkaline activated fly ash with sisal fiber inclusion reduced the permeability of the soil and improved the mechanical strength of the treated soil.

Several researchers in their studies considered the utilization of plastic waste strips for improving soil properties to meet certain engineering requirements [10, 28]. These studies revealed a significant improvement in the engineering properties of the modified soils. Studies have shown that, plastic waste strips blended with cement kiln dust [29], recorded significant improvement in the modified soil. Other reports of similar investigation have been documented in Venkata et al. [30], who used plastic waste strips with lime. Amena [31] in their study considered the use of plastic waste strips blended with brick powder. Reddy et al. [32], made use of waste brick powder blended with lime. Researches conducted on the influence of plastic waste strips on soils for use in flexible pavement applications has been documented in literatures [33]. Report of studies conducted by Niteen [33] revealed that construction of flexible pavements using soils improved by the use of waste plastic bottles chips is a good alternative technique.

Niyomukiza et al. [34], investigated the influence of polyethylene terephthalate (PET) plastic bottle strips on the properties of clayed soils. Soil samples were treated with PET plastic bottle strips in concentrations of 0.1, 0.2, 0.3 and 0.4% of the dry unit weight of soil. Results of the study recorded an improvement in the plasticity and California bearing ratio of the treated soils with optimal blend at 0.3% of PET plastic bottle strips content. Shelema and Worku [35] studied the mechanical behaviour of expansive soils treated with a blend of plastic waste strips and marble dust. The marble dust was added in step concentrations of 10, 15, and 20% of the dry mass of soil, while the plastic waste strips were varied from 0.25, 0.5, and 0.75% of 5 × 8 mm2 plastic strips of the dry mass of soil. Findings from the study showed that the California bearing ratio and the unconfined compressive strength increased with increased in the percentage of admixtures. Recent investigations conducted by Hoque et al. [36] on the improvement of shear strength and permeability of black cotton soils treated with plastic waste strips recorded a significant improvement in the properties of the soil. Soil samples were admixed with about 0, 5, 6, 7, 8, 9, and 10% plastic waste strips. Findings from the study showed that soil samples treated with 5–9% plastic waste strips recorded better shear strength and permeability properties than the untreated soil.

Several studies have established the usefulness of both sisal fibers and plastic waste strips as alternative materials for soil improvement, but limited researches have been conducted on the blend of cement and plastic waste strips or sisal fiber. Also report of previous works on the use of plastic waste strips and sisal fiber as stand-alone soil improvement materials by same authors, suggest that sisal fiber and plastic waste strips cannot be use as stand-alone stabilizers, hence the need for introducing cement [1]. The novelty of this study aims to determine the influence of both additives with an optimal cement content on the strength properties of lateritic soils, and establish the optimal blends of the admixtures for field applications.

2 Materials and methods

2.1 Materials

2.1.1 Soil sample

The soil has a reddish-brown colour and a fine-grained texture. Soil samples were collected from a borrow pit in Kwang, Rayfield (9°50'24.6''N 8°55'14.1''E), Jos south local government area of Plateau state, Nigeria. Samples were collected at a depth of approximately 1 m below the ground surface. The top soil at about 0.5 m was stripped away in order to remove the unwanted materials in the upper most part of the sample area, before the soil sample was dug and packaged in sacks. The study area map is shown in Fig. 1. Figure 2a shows the soil samples used in the study.

2.1.2 Polyethene

The polyethene waste bottles used were obtained from a dump site in Jos north local government area, Faringada market, plateau state, with latitude 9˚57′36’N’ and longitude 8˚52′15’E. The PET bottles used were from the spring waters Nigeria Ltd SWAN packaging company due to its availability. The bottles were washed properly to remove the dust and dirt and then dried in a shady area. The plastic waste strips were then obtained by cutting the washed plastic bottles into little pieces of average length of about 5 mm by 2 mm. Figure 2b shows samples of the plastic waste strips after cutting.

2.1.3 Sisal fiber

Sisal fiber use for the study were gotten from a local market in Jos, plateau state. The sisal fiber considered for this study was first cut to an average length of about 1 cm then followed by treatment using sodium borohydride (NaBH4) (1% wt/Vol) as suggested by Moraes et al. [37] in order to remove the cellulose content of the fiber which is responsible for its decomposition over time when mix with the soil. The aspect ratio, tensile strength of the sisal fiber used were tested and documented in previous study carried by same authors [38]. Figure 2c shows samples of the sisal fiber after cutting.

2.1.4 Ordinary portland cement (OPC)

The ordinary Portland cement used for the investigation is greenish in colour and was sourced from an open market in Jos, Plateau state, Nigeria.

2.2 Methods

2.2.1 Atterberg limit

The Atterberg limit test was performed based on the requirement of BS 1377 [39] part 2 for the natural soil and BS 1924 [40] for treated soils. Atterberg limits tests include liquid limit (LL), plastic limit (PL) and plasticity index (PI) of both the natural and the modified soil samples. The soil samples used for the tests were first air dried and sieved through 425 µm aperture sieve. 200 g of the sieved sample was used for the test considering the varying proportion of the admixtures. Tests for LL, PL and the PI were conducted for the natural and modified soil samples (i.e. samples mixed with 5% cement and 0, 0.5, 1, 1.5, 2 and 2.5% plastic waste strips/sisal fiber content), as recommended in previous literatures [1]. The additions of 5% cement is inline with reports of previous studies that suggested an optimal 4–6% cement content is required to achieve maximum strength improvement in soil [41].

2.2.2 Compaction test

Compaction tests were conducted first on the natural soil and the modified soils (in accordance with BS 1377 [39] Part 2 for the natural soil and BS 1924 [40] for the modified soils, by keeping the percentage of cement at 5% of the dry mass of soil sample and varying the composition of the plastic waste strips/sisal fiber content by 0, 0.5, 1, 1.5, 2 and 2.5% of the dry mass of soil. Tests were conducted using the British standard light (BSL) energy level.

2.2.3 Unconfined compressive strength (UCS)

UCS tests were done in accordance with BS 1377 [39] using the BSL energy. The compaction of both plastic waste strips/sisal fiber mix and keeping the percentage of cement at 5% of the dry mass of soil was done using 1000cm3 mould at respective optimum moisture contents obtained from compaction test. The samples were then removed from the moulds and the top potion of the cylinder was neatly cut into a cylinder with diameter of 38 mm and height of 78.2 mm. The samples were then cured for respective duration of 7, 14 and 28 days in accordance with the normal practice prior to UCS machine crushing. The UCS was computed using Eq. 1.

2.2.4 Microstructural analysis

Micro structural studies were carried out using phenom world scanning electrons microscope (SEM) in line with the procedure outlined in literatures [42, 43]. Soil samples were prepared by sieving through BS No 4, and then compacted at optimum moisture content, followed by slicing. Sliced soil specimens were then air dried, mounted and secured onto the stage which is controlled by a goniometer. The SEM generated a 2-dimensional image which displays a spatial variation in the soil properties. SEM images were determined for the untreated soil and soils optimally treated with sisal fiber and plastic waste strips respectively. The SEM also performed analyses of selected point locations on the samples which was used in qualitatively and quantitatively determination of chemical compositions using energy dispersive spectroscopy (EDS). The flow chart for the various tests conducted is presented in Fig. 3.

3 Results and discussion

3.1 Properties of the natural soil

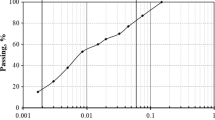

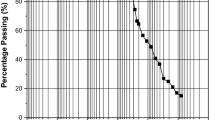

The natural soil has a natural moisture content of 20%. The soil has LL of 43% and a PL of 28%. The PI of the soil is 15%. The soil is classified as lean clay with sand; CL using the unified soil classification system, USCS [44]. The soil is A-7-5(3) using the American association of state highway and transportation officials (AASHTO) classification [45]. This indicates that the soil is prone to volumetric change. Table 1 shows a summary of the index properties of the soil. Grain size plot of the natural soil is shown in Fig. 4. Particle passing 75µ sieve (i.e. 62.93%) revealed that the soil contains significant proportion of silts and clay thus the need to improve the soil.

3.2 Effect of plastic waste strips/sisal fiber—cement mixes on Atterberg limits

3.2.1 Effect of plastic waste strips/sisal fiber and cement on the liquid limit

Changes in LL of soil treated with treated sisal fiber-cement mixes and plastic waste strips -cement mixes are shown in Fig. 5. Generally, LL of the soil declined from 43.0% at 0% sisal fiber content to 42.0% at 1.0% sisal fiber content and there after increased to 42.5, 44.0 and 45% at 1.5, 2.0 and 2.5% sisal fiber content respectively. In the event of soil treated with plastic waste strips-cement mixes, similar pattern of results was recorded. Result shows a steady drop from 43% in its natural state to 41.5% and 41% at 0.5 and 1% plastic waste strips content respectively. However, there was a steady increase in the further addition of plastic waste strips. Liquid limit values of 41, 41.5, 42 and 42.4% were documented at 1, 1.5, 2, and 2.5% plastic waste strips content respectively. The possible reason for the initial reduction in LL with the addition of plastic waste strips up to 1%, may perhaps be related with an increment in soil stiffness with higher concentrations of plastic waste strips. Also, improvement seen in the soil workability may perhaps be the reason for the progressive reduction in LL with higher plastic waste strips content [1]. The increase in LL with higher proportion of plastic waste strips could be as a result of the reduced friction in the soil, due to excess amount of plastic waste strips added to the soil, which act as a lubricant and result in easier movement of the soil particles, resulting in higher liquid limits. Similar findings of decrease in LL and swelling percentage of the treated soil with plastic waste strips has been stated in literatures [1, 46, 47]. The observed increase in liquid limit (LL) with higher sisal fiber content can be attributed to the water absorption capacity of sisal fiber. This observation aligns with findings reported by Sani et al. [38], and Bo et al. [48]. On the two treatment methods used, it could be observed that soil treated with plastic waste strips-cement mix recorded slightly lower liquid limit values when compared with samples treated with sisal fiber.

Analysis of variance (ANOVA) results show that there is considerable statistical significance of the effect of both plastic waste strips/sisal fiber- cement mixes on LL of lateritic soils (FCAL = 4922.354 > FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 7107.194 > FCRIT = 4.9646) for plastic waste strips-cement treated soil. However, a comparison of the two results show that soil treated with plastic waste strips-cement mixes recorded more significant effect than sisal fiber-cement treated soil. Table 2 shows a summary of the ANOVA for liquid limits with varying plastic waste strips/sisal fiber/cement content.

3.2.2 Effect of plastic waste strips/sisal fiber-cement on the plastic limit

The PL of soil treated with sisal fiber-cement mixes and plastic waste strips -cement mixes is shown in Fig. 6. A progressive increase in PL was noted with increment in the sisal fiber content from 0% sisal fiber-cement mix with a value 28.23% to highest value of 31.31% at 2% sisal fiber-cement mix and subsequently decreased. In the case of plastic waste strips- cement treated soil, result shows an increase in PL from its natural values of 28.23% to a peak value of 30.1% at 2% plastic waste strips, and subsequently decreased to a value of 27.98% at 2.5% plastic waste strips content. PL values at 0, 0.5, 1, 1.5, 2 and 2.5% plastic waste strips contents were 28.23, 29.61, 30.23, 30.01, 30.2 and 27.98% respectively. The peak value of PL of 30.2% was observed at 2% plastic waste strips content.

The increase in PL with sisal fiber- cement content could be link to the water absorption rate of the fiber. The increase in PL as more plastic waste strips is added can be attributed to the plastic waste strips occupying the void spaces in the soil, thereby increasing the void ratio. This higher void ratio decreases the soil's water retention capacity, reducing its tendency to exhibit plasticity and consequently raising the PL [1].

Further analysis from (ANOVA) shows that there is considerable statistical significance of the effect of both plastic waste strips/sisal fiber- cement mixes on plastic limits of lateritic soils (FCAL = 1376.054 > FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 2542.878 > FCRIT = 4.9646) for plastic waste strips-cement treated soil. However, a comparison of the two results show that soil treated with plastic waste strips- cement mixes recorded more significant effect than sisal fiber-cement treated soil. Table 3 shows a summary of the ANOVA for plastic limits with varying plastic waste strips/sisal fiber-cement content.

3.2.3 Effect of plastic waste strips/sisal fiber–cement on the plasticity index

The PI of lateritic soil mixed with sisal fiber-cement mixes and plastic waste strips-cement mixes shows an initial decrease in the PI values for both treatments (see Fig. 7). PI for sisal fiber-cement mix from its natural value of 14.76% decreased to 12.69% at 2.0% sisal fiber content, and thereafter increased. When compared with soil treated with the plastic waste strips-cement mixes, the PI values showed a decline from 14.76% in its natural form to 10.8% at 1% plastic waste strips content and thereafter increased. The decrease in PI with both treatment could be attributed to the increasing frictional resistance within the soil fabrics with addition of the both blended cement/sisal fiber and cement/plastic waste strips mixes. Amena and Chakeri [49] in their research also observed a decrease in the PI and ascertained that the reduction in the PI leads to a drop in the plasticity of the soil, which in turn results to increment in strength of the soil.

ANOVA results show that there is considerable statistical significance of the effect of both plastic waste strips/sisal fiber- cement mixes on plasticity index of lateritic soils (FCAL = 644.4095 > FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 213.5009 > FCRIT = 4.9646) for plastic waste strips -cement treated soil. However, a comparison of the two results show that soil treated with sisal fiber -cement mixes recorded more significant effect than plastic waste strips -cement treated soil. Table 4 shows a summary of the ANOVA for plasticity index with varying plastic waste strips/sisal fiber -cement content.

3.3 Effect of plastic waste strips/sisal fiber -cement on the compaction characteristics

3.3.1 Maximum dry density (MDD)

Figure 8 illustrates the MDD of lateritic soil treated with varying percentages (0, 0.5, 1.0, 1.5, 2, and 2.5%) of plastic waste strips/sisal fiber-cement mixtures, compacted using BSL energy. There is a noticeable difference in the MDD between the natural and modified soils. Specifically, the MDD of the soil decreased significantly as the content of sisal fiber-cement increased. The natural soil has an MDD of 1.75 Mg/m3, while the MDDs for the sisal fiber-cement mixtures at 0.5, 1, 1.5, 2, and 2.5% are 1.75, 1.75, 1.65, 1.66, and 1.63 Mg/m3, respectively. In contrast, soil treated with plastic waste strips-cement mixtures shows a general increase in MDD from its natural value of 1.75 Mg/m3 to a peak value of 1.79 Mg/m3 at 2.5%. Similar trends were observed by Kassa et al. [50].

The drop in MDD with increment in sisal fiber-cement mix could be as a result of lower weight of sisal fiber compare to that of the soil, thus reducing the average weight of the mixtures [40, 51]. The increase in MDD with increase in plastic waste strips-cement mix could be due to the decrease in voids as a result of the addition of plastic waste strips. However, reports of studies conducted by Prasanna [52] as well as Amena and Chakeri [49] recorded a decrease in the MDD with plastic waste strips.

ANOVA studies carried out on the results show that there is no statistical significance of the effect of both plastic waste strips/sisal fiber- cement mixes on the MDDs of lateritic soils (FCAL = 1.383024 < FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 1.860816 < FCRIT = 4.9646) for plastic waste strips—cement treated soil. Table 5 shows a summary of the AVONA for MDD with varying plastic waste strips/sisal fiber-cement content.

3.3.2 Optimum moisture content (OMC)

Figure 9 illustrates the OMC of soil treated with plastic waste strips and sisal fiber-cement mixtures. The OMC increased as the sisal fiber content rises, going from its natural value of 18.5% to a maximum of 21.5% at 2.5% sisal fiber-cement blend. Specifically, OMC values of 18.5, 20.5, 20.4, and 21.5% were observed at 1, 1.5, 2, and 2.5% sisal fiber-cement blends, respectively. The high-water absorption capacity of sisal fiber, which increases from 19 to 21.5%, is likely responsible for the rise in OMC values. This pattern aligns with findings by Prabakar and Sridhar [51]. The literature suggested that sisal fiber's significant moisture absorption during compaction is the reason for the observed progressive increase in OMC with higher sisal fiber content [47, 51, 53].

In the case of plastic waste strips- cement mix, OMC showed an initial increase from 18.5% for the natural soil to 21% at 1.5% and subsequently lessened to 17.8% at 2.5% plastic waste strips content. OMCs values of 18.5, 20.5, 20.5, 21, 18 and 17.8% were documented at 0, 0.5, 1, 1.5, 2 and 2.5% plastic waste strips content respectively. The initial increase in OMC could be associated with increase in the surface of contact by the addition of plastic waste strips and cement to the mixtures. The decline in OMC at higher plastic waste strips content could be credited to the fact that plastic waste strips does not absorb water which will led to reduction in OMC. Similar results were also obtained in the study carried out by Munirwan et al. [54]. They used a variation of 0.5% increment of plastic shreds and observed from their study a sharp decrease in OMC at 1.5%. They also attributed the drop in OMC to the zero-absorption capacity of plastic shreds. Eltayeb [55] used the same plastic content variation of 0.5% increment and observed a steady drop in OMC after 2% to 3% plastic shreds.

ANOVA results show that there is considerable statistical significance of the effect of both plastic waste strips/sisal fiber-cement mixes on the OMC of lateritic soils (FCAL = 846.4425 > FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 671.8184 > FCRIT = 4.9646) for plastic waste strips-cement treated soil. However, a comparison of the two results show that soil treated with sisal fiber- cement mixes recorded more significant effect than plastic waste strips -cement treated soil. Table 6 shows a summary of the ANOVA for OMCs with varying plastic waste strips/sisal fiber -cement content.

3.4 Effect of plastic waste strips/sisal fiber-cement on the unconfined compressive strength (UCS)

The UCS of soil treated with plastic waste strips/sisal fiber- cement mixes are shown in Figs. 10, 11. The UCS values are presented for curing age of 7, 14 and 28 days. The adding of sisal fiber-cement mix to the soil led to an increment in the UCS of the modified soils. The UCS values progressively increased with the addition of 0 up to 1.5% sisal fiber-cement mix and subsequently decreased to minimal values at 2.5% sisal fiber-cement mix for all the curing periods considered. UCS values of 36.03, 993.13, 1065.12, 1062.04, 1041.43 and 746.15 kN/m2 were documented at 0, 0.5, 1, 1.5, 2 and 2.5% sisal fiber content cured for 7 days (see Fig. 10). Similar development was observed for 14 and 28 days curing age. These findings agree with previous studies by Prabakar and Sridhar [44] who report similar behaviour.

Also, for soil treated with plastic waste strips- cement mix, there was significant increase in the UCS values with increment in the plastic strips- cement content. Results revealed that the UCS values increased from their natural values for the curing age of 7, 14 and 28 days considered (see Fig. 11). Values of 36.03, 81.47 and 182.03 kN/m2 were recorded for the natural soil which increased to peak values of 428.9, 518.3 and 712.23 kN/m2 at 0.5% plastic strips-cement mix, and thereafter slightly decline to 263.92, 364.08 and 398.40 kN/m2 at 2.5% plastic waste strips-cement blend, cured for 7, 14 and 28 days periods respectively. The early increase in UCS values may be credited to increase in the frictional resistance between the soils particles as a result of addition of the additives. Researchers in the past who worked with plastic waste strips for soil improvement reported similar findings [1, 13].

ANOVA analysis shows that there is considerable statistical significance of the effect of both sisal fiber- cement mix and curing age on UCS of lateritic soils (FCAL = 65.65125 > FCRIT = 4.9646) for sisal fiber-cement treated soil and (FCAL = 18.56848 > FCRIT = 4.9646) for curing age of sisal fiber-cement treated soil. However, a comparison of the two results shows that sisal fiber -cement treated soil mix recorded more significant effect than the effect of curing age. Table 7 shows a summary of the ANOVA for UCS with varying sisal fiber -cement content.

In addition, ANOVA analysis shows that there is considerable statistical significance of the effect of both plastic waste strips -cement mix and curing age on UCS of lateritic soils (FCAL = 59.18439 > FCRIT = 4.9646) for plastic waste strips -cement treated soil and (FCAL = 37.05188 > FCRIT = 4.9646) for curing age of plastic waste strips-cement treated soil. However, a comparison of the two results show that plastic waste strips-cement treated soil mix recorded more significant effect than the effect of curing age. Table 8 shows a summary of the ANOVA for UCS with varying plastic waste strips -cement content.

3.5 Regression analysis

The connection among strength properties (i.e., UCS of sisal fiber-cement treated soil and UCS of plastic waste strips-cement treated soil) established in Eqs. 2, 3 shows a strong association between UCS as dependent soils variable with sisal fiber content (SF), plastic waste strips content(PWS), maximum dry density (MDD), optimum moisture content (OMC), liquid limit (LL), and Plastic limit (PL), while curing age was considered as a deterministic parameter with curing age index of -1, 0 and 1 for 7, 14 and 28 days respectively. Results of the regression analysis shows a strong correlation between the variables and the UCS values of both treated soils. Correlation coefficient (R2) values of 95.41% and 95.1% for sisal fiber-cement treated soil and plastic waste strips-cement treated soil were documented. In general, all the parameters considered has significant influence on the UCS values of the treated soils signified by their high coefficients in the equations.

Consequently, in the course of field compaction, attention should be given to ensure adequate quantities of additives were added and mixed appropriately prior to compaction in the field to achieve desired compaction density at optimum moisture content of optimally 1.5–2% sisal fiber/cement bend, for sisal fiber-cement treated soil and 0.5–1.5% plastic waste strip/cement blend for plastic waste strips-cement treated soil. Plot of predicted UCS values against the measured UCS of sisal fiber/cement treated soil and plastic waste strips/cement treated soil are presented in Figs. 12, 13 in that order. Both results show a strong link between the measured UCS values and the predicted values gotten from the regression models, with R2 value of 0.976 (see Fig. 12) for sisal fiber/cement treated soil and R2 value of 0.968 (see Fig. 13) for plastic waste strips/cement treated soil. The high R2 values of 0.976 and 0.968 statistically indicate that the developed regression models can be used for predicting UCS of lateritic soils treated with such additives for future applications, since the predicted results have close numerical values when compared with the laboratory measured values, signified by the high R2 values recorded.

where

3.6 Micro analysis

3.6.1 Micrograph of the natural and optimally modified lateritic Soils.

The micrograph analysis was performed using a Phenom World Scanning Electron Microscope at a 100 µm scale and 1000 × magnification. Figure 14 and Fig. 15a display the microscopic characteristics for natural lateritic soil and soil treated with an optimal blend of 1.5% sisal fiber/5% cement, respectively. Figure 15b shows the micrograph of soil treated with an optimal blend of 1.5% plastic waste strips/5% cement. The natural soil micrograph reveals smooth, scaly surfaces with a cemented texture. In contrast, the micrograph of soil treated with 1.5% sisal fiber (Fig. 15a) shows a rough, coarse-grained texture. These changes in orientation and morphology are likely due to a reduction in soil cohesiveness from the cation exchange reaction induced by the addition of cement, consistent with Osinubi et al. [2]. The inclusion of sisal fiber also increased the frictional forces among soil grains, altering interparticle orientation and fabric, which enhances soil properties. The agglomeration of soil particles post-treatment improves workability and strength parameters. The micrograph of soil treated with the 1.5% plastic waste strips/cement blend (Fig. (15b)) reveals a gravelly texture with some black patches. The gravelly texture is likely due to the plastic waste strips increasing frictional forces within the soil grains, altering interparticle orientation and fabric, thus changing the soil morphology.

3.6.2 Elemental analysis of the natural and optimally modified lateritic soil

The natural soil underwent energy-dispersive X-ray spectroscopy (EDS) elemental analyses, revealing a composition consistent with typical alumino silicate minerals as reported by Reyes et al. [56] and Osinubi et al. [2]. Figure 16 displays the EDS results for the natural soil, while Fig. 17 and Fig. 18 showcases the EDS for the modified soils. The natural soil exhibits a higher silicon content than the modified soils (see Figs. 16, 17, 18), with weight percentages of 47.72, 34.58 and 39.52% respectively, for natural soil, treated soil with sisal fiber/cement mix and treated soil with plastic waste strips/cement mix respectively, as presented in Table 9, 10. 11 in the appendix. The higher silicon content in natural soil could be due to the absence of cement in the natural soil. Addition of cement in the modified may be responsible for the formation of new compounds and changes in the modified soil micro structures. Thus, these new compounds form may be responsible for the reduction in the silicon content. It is worth noting that silicon and aluminum are the dominant elements in both the natural and modified soils. However, the presence of calcium in the modified soils may contribute to the stable formation of calcium silicate hydrate and calcium aluminates hyrate, which enhance long-term strength gain and improve soil properties [57]. The variations in the quantities of chemical compounds, such as carbonate, iron oxide, aluminium, and silicon, which precipitate at interparticle contacts and act as cementing agents, could be responsible for the changes in interparticle and fabric orientation of the soil [5]

4 Conclusion

The natural properties of the soil indicate that it is reddish-brown with a fine-grained texture. The natural soil exhibits a liquid limit of 43%, a plastic limit of 28.2%, and a plasticity index of 14.8%. The liquid limit decreased from 43% in its natural state to 42% at 1% sisal fiber and 41% at 1% plastic waste strips content. The plasticity index drops from 14.8% naturally to 12.69% at 2% sisal fiber and 10.8% at 1% plastic waste strips content. MDD values decreased with increase in sisal fiber content but increased with more plastic waste strips content. For OMC, values generally decreased with higher sisal fiber and plastic waste strips content. There is a notable improvement in the UCS values of the treated soils. Statistical analysis shows a significant effect on most measured parameters. Microanalysis of the natural and optimally modified soils reveals changes in the fabric orientation of soil particles. The study results suggest that optimal blends of 1–1.5% sisal fiber with 5% cement and 1–1.5% plastic waste strips with 5% cement significantly enhance soil strength properties, making them suitable as sub-base materials for light-trafficked roads. It is recommended that further research should consider higher compaction energies and California bearing ratio test on the modified soils.

Data availability

Data used in this reearch paper are gotton through laboratoty experiments. The main data has been attached with the other documents . The corresponding authors email has been updated on the paper as suggested. Thank you.

References

Yohanna P, Badamasi A, Ishola K, Odoh KC, Abdulkadir MN, Fwangshak GM. A comparative study on the effect of sisal fibre and waste plastic strips in structural strength improvement of tropical black clay. J Eng Stud Res. 2022;28(2):81–91.

Osinubi KJ, Yohanna P, Eberemu AO. Cement modification of tropical black clay using iron ore tailing as admixture. J Transport Geotech. 2015;5:35–49. https://doi.org/10.1016/j.trgeo.2015.10.001.

Moses G, Etim RK, Sani JE, Nwude M. Desiccation effect of compacted tropical black clay treated with concrete waste leonardo electronic. J Practi Technol. 2018;33:69–88.

Moses G, Etim RK, Sani JE, Nwude M. Desiccation-induced volumetric shrinkage characteristics of highly expansive tropical black clay treated with groundnut shell ash for barrier consideration. Civil Environ Res. 2019;11(8):58–74. https://doi.org/10.7176/CER/11-8-06.

Etim RK, Ekpo DU, Ebong UB, Usanga IN. Influence of periwinkle shell ash on the strength properties of cement-stabilized lateritic soil. Int J Pavement Res Technol. 2021. https://doi.org/10.1007/s42947-021-00072-8.

Obeta IN, Ikeagwuani CC, Attama CM, Okafor J. Stability and durability of saw dust ash-lime stabilised black cotton soil. Niger J Technol. 2019;38(1):75–80.

Basha SJR, Kavin RP. Stabilization of soft subgrade and embankment soil by using alkaline solution and reinforcing with sisal fibre. Int J Magazine Eng Technol Manage Res. 2016;3(8):704–21.

Neeladharan PS. Stabilization of soil by using marble dust with sodium silicate as binder. Int J Adv Res Trends Eng Technol. 2018;5(5):45–9.

Yohanna P, Oluremi JR, Eberemu AO, Osinubi KJ, Sani JE. Reliability assessment of bearing capacity of cement-iron ore tailing blend black cotton soil for strip foundation. Geological Geotech Eng. 2019;37(2):915–29.

Peddaiah S, Burman A, Sreedeep S. Experimental study on effect of waste plastic bottle strips in soil improvement. Geotech Geol Eng. 2018;365(36):52907–20. https://doi.org/10.1007/S10706-018-0512-0.

Consoli NC, deMoraes RR, Festugato L. (2012) “Parameters controlling tensile and compressive strength of fiber reinforced cemented soil.” J Mater Civ Eng. 2012;25(10):1568–73.

Osinubi KJ, Eberemu AO, Ijimdiya TS, Yakubu SE, Gadzama EW, Sani JE, Yohanna P. Review of the use of microorganisms in geotechnical engineering applications. SN Appl Sci J. 2020. https://doi.org/10.1007/s42452-020-1974-2.

Shelema A. Utilizing solid plastic wastes in subgrade pavement layers to reduce plastic environmental pollution cleaner. Eng Technol. 2022;7(2022): 100438. https://doi.org/10.1016/j.clet.2022.100438.

Yasmeen YM, Rabinder S. Improvement the Soil Subgrade using Sisal Fiber and Bagasse Ash. In J Innov Re Comput Sci Technol. 2022;10(4):1–5. https://doi.org/10.5552/ijircst.2022.10.4.1.

Sharma AK, Prasannan S, Kolathayar S. Comparative study of sisal and PVA fiber for soil improvement. In Geo-Congress 2019: Soil Improvement. American Society of Civil Engineers: Virginia; 2019.

Giridhar J, Kishore, and Rao, R. M. V. G. K. Moisture absorption characteristics of natural fibre composites. J Reinf Plast Compos. 1986;5(2):141–50.

Ramesh, H. N. ManojKrishna, K. V. and Mamatha, H. V. (2011) Strength performance of lime and sodium hydroxide treated-coir fibre reinforced soil, In Proceedings of Indian Geotechnical Conference, pp. 523–525.

Sani JE, Etim RK, Joseph A. Compaction behaviour of lateritic soil-calcium chloride mixtures. Geotech Geol Eng. 2019;37(4):2343–62.

Gobinath R, Akinwumi II, Afolayan OD, Karthikeyan S, Manojkumar M, Gowtham S, Manikandan A. (2020) Banana fibre-reinforcement of a soil stabilized with sodium silicate. Silicon. 2020;12(2):357–63.

Hamidi A, Hooresfand M. (2013) Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotextile Geomembranes. 2013;36:1–9.

Xue Q, Lu HJ, Li ZZ, Liu L. Cracking, water permeability and deformation of compacted clay liners improved by straw fiber”. Eng Geol. 2014;178(21):82–90.

Venda OPJ, Correia AAS, Teles JMNPC, Custódio DG. Effect of fibre type on the compressive and tensile strength of a soft soil chemically stabilised. Geosynth Int. 2016;23(3):171–82.

Correia AAS, Oliveira PJV, Custodio DG. (2015) Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext Geomembr. 2015;43(2):97–106.

Consoli NC, deMoraes RR, Sharma LAK, Prasannan S, Kolathayar S. Comparative study of sisal and PVA fiber for soil improvement”, In Geo-Congress 2019: Soil Improvement. Reston, VA: American Society of Civil Engineers; 2019. p. 298304.

Ehrlich M, Almeida MSS, Curcio D. Hydro-mechanical behavior of a lateritic fiber-soil composite as a waste containment liner”. Geotextile Geomembr. 2019;47(1):42–7.

Festugato L, Menger E, Benezra F, Kipper EA, Consoli NC. (2019) Fibre-reinforced cemented soils compressive and tensile strength assessment as a function of filament length. Geotext Geomembr. 2017;45(1):77–82.

Muthukkumaran K. Sindhujha, R and Anusudha, V (2023) Effect of alkali-treated sisal fibres on expansive clay. Proc Inst Civil Eng–Ground Improve. 2023;176(4):233–48.

Alzaidy MNJ. (2019) Experimental study for stabilizing clayey soil with eggshell powder and plastic wastes. IOP Conference Series Mater Sci Eng. 2019;518(2): 022008. https://doi.org/10.1088/1757-899X/518/2/022008.

Shafat H. Strength improvement of clayey soil with waste plastic strips and cement kiln dust. Int Res J Eng Technol. 2019;6:11.

Venkata N, Reddy H, Manjusha P, Kulayappa T, Tech M. Utilisation of waste bottle plastic strips and lime as a soil stabilizer in construction of flexible pavements. Int Res J Eng Technol. 2017;4:4.

Amena S. Experimental study on the effect of plastic waste strips and waste brick powder on strength parameters of expansive soils. Heliyon. 2021;7(11):e08278. https://doi.org/10.1016/j.heliyon.2021.

Reddy SS, Prasad ACSV, Krishna NV. Lime-stabilized black cotton soil and brick powder mixture as subbase material. Adv Civ Eng. 2018. https://doi.org/10.1155/2018/5834685.

Niteen K, S. K. Study on improvement of sub grade soil using soil-reinforcement technique. Int J Appl Eng Res. 2018;13(7):126–34.

Niyomukiza JB, Bitekateko A, Nsemerirwe J, Kawiso B, Kiwanuka M. (2021) Investigating the effect of PET plastic bottle strips on the strength and compressibility properties of clayey soil. IOP Conference Series: Int Conf Earth Environ Sci. 2021;894: 012021. https://doi.org/10.1088/1755-1315/894/1/012021.

Shelema A, Worku FK. Mechanical behavior of plastic strips-reinforced expansive soils stabilized with waste marble dust. Adv Civil Eng. 2022. https://doi.org/10.1155/2022/9807449.

Hoque MdI, Hasan M, Datta SD. Effect of waste plastic strip on the shear strength and permeability characteristics of black cotton soil. J Appl Sci Eng. 2023;27(2):2019–28.

Moraes GO, Sierakowski MR, Abreu TM, Amico SC. Sodium borohydride as a protective agent for the alkaline treatment of sisal fibers for polymer composites. Compos Interfaces. 2011;18(5):407–18.

Sani JE, Yohanna P, Chukwuma IA. Effect of rice husk ash mixed wiyh treated sisal fibre on properties of lateritic soil as road construction material. J King Saudi Univ- Eng Sci. 2018. https://doi.org/10.1016/j.jksues.2018.11.001.

British Standard (1377). Methods of test for soils for civil engineering properties. London: British Standard Institution; 1990.

Standard B. Methods of testing for stabilized soils. London: British Standards Institute; 1924. p. 1990.

Mengue E, Mroueh H, Lancelot L, Eko RM. Mechanical improvement of a fine-grained lateritic soil treated with cement for use in road construction. J Mater Civ Eng. 2017. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002059.

Kozłowski T, Warianek KK, Walaszczyk L. Application of SEM to analysis of permeability coefficient of cohesive soils. J Archiv Hydro-Eng Environ Mech. 2011;58:47–64.

Yohanna, P. (2015) The Use of Iron Ore Tailings as Admixtures in Cement Modification of Black Cotton Soil. Unpublished M.Sc Thesis, Civil Engineering Department, Ahmadu Bello University: Zaria, Nigeria.

ASTM. Annual book of standards Philadelphia 04.08. Pennsylvania: American Society for Testing and Materials; 1992.

AASHTO. Standard specification for transportation, material and methods of sampling and testing. 14th ed. Washington: Amsterdam association of state highway and transportation official; 1986.

Entesar JI. The performance of shear strength and volume changes of expansive soils utilizing different additives. IOP Conf Series Mater Sci Eng. 2019. https://doi.org/10.1088/1757-899X/518/2/022043.

Kassahun T, Birara E, Mulugeta A. Composition, generation and management method of municipal solid waste in Addis Ababa city, Central Ethiopia: a review. Asian J Environ Ecol. 2019;9(2):1–19. https://doi.org/10.9734/ajee/2019/v9i230088.

Bo R, Shilong Z, Jidong T, Hui D, Chao M. Analysis on the triaxial shear behavior and microstructure of cement-stabilized clay reinforced with glass fibers. Adv Civil Eng. 2020. https://doi.org/10.1155/2020/8842091.

Amena S, Chakeri D. A study on the effects of plastic waste strips and lime on strength. Ad Civil Eng. 2022. https://doi.org/10.1155/2022/6952525.

Kassa RB, Workie T, Abdela A, Fekade M, Saleh M, Dejene Y. Soil stabilization using waste plastic materials. Open J Civil Eng. 2020;10(01):55–68. https://doi.org/10.4236/ojce.2020.101006.

Prabakar J, Sridhar RS. Effect of random inclusion of sisal fibre on strength behaviour of soil. Construct Build Mater. 2002;16(2):123–31.

Prasanna S. Utilization of waste plastic shreds for stabilization of soil in lecture notes in civil engineering, vol. 29. Singapore: Springer; 2019. https://doi.org/10.1007/978-981-13-6713-7_49.

Lawer AK, Ampadu SIK, Owusu-Nimo F. The effect of randomly distributed natural fibers on some geotechnical characteristics of a lateritic soil. Appl Sci. 2021. https://doi.org/10.1007/s42452-021-04634-0.

Munirwan RP, Sahara O, Apriyanti Y, Fahriani F. A study on the effect of waste plastic strips in the stabilization of clay soil. IOP Conf Ser: Mater Sci Eng. 2020. https://doi.org/10.1088/1757-899X/981/3/032062.

Eltayeb A. The use of shredded plastic water bottles in soil stabilization. Eurasia Proceed Sci Technol Eng Math. 2021;13:37–44.

Reyes LRG, Remoro ETG, Cabral AP, Rodriguez RC. Characterization of chromium in contaminated soil studied by SEM, EDS, XRD and mossbauer spectroscopy. J Miner Mater Character Eng. 2007;7(1):59–70.

Sharma N, Sahoo U. Stabilisation of a clayed soil with fly ash and lime: a micro level investigation. J Geotech Geolog Eng. 2012;30(1197):2005.

Author information

Authors and Affiliations

Contributions

Paul Yohanna is the main supervisor for the undergraduate project carried out by 6 students as team project. He wrote the draft paper Roland Etim Kufre reviewed and edited the manuscripts Nodebe Inechi Ekene is an undergraduate project student who did the laboratory work and project writing Joshua Adekeye Toluwase is an undergraduate project student who did the laboratory work and project writing Ernest Obasi Mbah is an undergraduate project student who did the laboratory work and project writing Oladapo Olatunde Ayodeji is an undergraduate project student who did the laboratory work and project writing Umar Muhammed Aliyu is an undergraduate project student who did the laboratory work and project writing Moses Okoko Owoicho is an undergraduate project student who did the laboratory work and project writing Kanyi Iaana Mauris is the co- writer of the manuscript who wrote the introduction.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yohanna, P., Etim, R.K., Ekene, N.I. et al. Case evaluation of structural strength improvement of cement stabilized lateritic soil reinforced with sisal fibers and plastic waste strips. Discov Civ Eng 1, 66 (2024). https://doi.org/10.1007/s44290-024-00069-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44290-024-00069-9