Abstract

Stringent measures by water authorities worldwide on water clarification has resulted in the use of chemical-based coagulants to be a formidable challenge. This has driven the need to find alternative sustainable coagulants such as plant-based bio coagulants which are readily available, abundant and cost effective in developing countries such as Zimbabwe. In this regard, the effectiveness of treating effluent from a brewery malting processing plant using bio-coagulants (Aloe vera, Cactus opuntia and Okra seeds) was investigated compared to that of a chemical coagulant (Alum). The water pollution parameters that were investigated include turbidity, total dissolved solids, electrical conductivity, temperature and pH. The results showed that Alum was the most effective coagulant as it reduced the turbidity from 734 NTU to 68.3 NTU and Total Dissolved Solids (TDS) from 19,800 ppm to 880 ppm at a dosage of 40 mg/L. Okra seeds had an optimum dosage of 35 mg/L with a turbidity and TDS removal of 88.83% and 95.25% respectively. Aloe Vera had an optimum dosage of 40 mg/L with a turbidity and TDS removal of 74.25% and 95.40% respectively. For Cactus opuntia it was 50 mg/L obtaining turbidity and TDS removal of 74.66% and 95% respectively. The best blend of the bio coagulants had a ratio of (0.17, 0.17, and 0.67) for Aloe vera, Cactus opuntia and Okra seeds respectively. At a dosage of 40 mg/L the turbidity removal was 83.92% and TDS removal was 95.12%. The results indicated that blending the plant-based coagulants had a positive synergistic effect.

Graphical Abstract

Highlights

Aluminium sulphate (Alum) is more effective in reduction of suspended solids and dissoved solids compared to Aloe vera, Cactus and Okra seeds.

The effectiveness of Aloe vera, Cactus and Okra seeds as plant-based coagulants indicates that they have active compounds effective as coagulation agents.

There were positive synergistic effects upon blending Aloe vera, Cactus and Okra seeds this was observed in the reduction of turbidity this was higher than when Aloe vera and Cactus were used individually as coagulants.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

The environmental, social and economic issues stemming from water stress, whether due to overuse, scarcity or pollution are a result of exceeding extraction limits and degradation of water resources as a result of pollution. Consequently, it is imperative to utilize sustainable means for wastewater management to conserve this scarce resource. The beer brewing sector is known for producing significant volumes of wastewater. It has been estimated that, to produce 1L of beer, 3-10L of wastewater is produced, with the variation depended on production methods and water usage patterns [18]. Malting processing plants are a significant part of the beer production process, these are primarily used for the production of sorghum malt or barley malt which is critical in beer brewing to convert starches to sugars. These malting processing plants generate industrial wastewater with mostly organic complexes and particulate matter in effluent streams [16]. As a result, the effluent should be treated before discharging so that it meets the World Health Organisation [21], Environmental Management Authority (EMA) and Standards Association of Zimbabwe (SAZ) guidelines [15]. In order to achieve, Sustainable Development Goal (SDG) 6 which is access to clean water and sanitation it is imperative to have effective sustainable wastewater management practices in place [9]. This can be achieved by minimizing pollution, reducing the release of hazardous materials and chemicals thus, reducing the amount of untreated wastewater and in turn it will increase recycling and safe reuse globally.

Wastewater from the malting plant typical has a high organic/biochemical oxygen demand, various wastewater treatment methods can be adopted to treat the water. These include chemical treatment, filtration, coagulation, flocculation, electro-dialysis, reverse osmosis, ion exchange, adsorption, oxidation and reduction [17] and many others. Most of these treatment methods are not cost effective at large scale treatment due to high costs of chemicals, plant maintenance and technical expertise requirements [10]. Inherently, to curb the socio economic aspects, use of plant based bio coagulants for treating malting plant waste water is explored in this study. The proven ability for plant-based coagulants to remove pollutant parameters such as turbidity, suspended solids, colour and organic compounds make them attractive for this study [1,2,3].

The primary processes of coagulation take place in four distinct manners. These include double-layer compression, polymer bridging, neutralization of charge, and scanning coagulation [2, 4]. Traditionally, coagulation has been utilized to counteract the negative charge of suspended colloidal particles. These colloidal particles can be either hydrophilic or hydrophobic. Hydrophilic particles attract water molecules, while hydrophobic particles repel water molecules. Hydrophilic colloidal particles are typically of organic origin, such as natural organic matter. Hydrophilic colloids are more resistant to destabilization compared to hydrophobic ones. The stability of these particles relies on their charge, which causes repulsion and hinders the formation of flocs. In the case of plant-based coagulants, the mechanism involves two key processes: adsorption with charge neutralization and adsorption with polymer bridging [8]. The effectiveness of a coagulant is affected by the mixing rate, pH and coagulant dose. Coagulants are essential in reducing the turbidity and removal of other contaminants in water [20]. Coagulants are in 2 forms namely bio coagulants (natural coagulations) and chemical (synthesized) coagulants. Chemical coagulants are mainly inorganic and usually aluminium and ferric salts. Bio coagulants are extracts from animals, plants and microorganisms. Both forms of coagulants can be used to treat drinking water and wastewater. Currently in the industries chemical coagulants are mostly used, although the use of bio coagulants in water treatment in gaining interest. Bio coagulants since being safe to the human health and the environment [11], they have greatly attracted use in the emerging economies. In this study, plant-based bio coagulants which include, Aloe vera, Cactus opuntia and Okra seeds were chosen to be investigated as they are readily available and abundant in Zimbabwe. Moreover, the aforementioned plants contain active compounds which include polysaccharides, proteins, carbonyl, carboxyl, hydroxyl groups which are effective in charge neutralization, sweep coagulation, adsorption and patch flocculation. The bio coagulants have a variation of these active compounds therefore it was necessary to explore blending of the bio coagulants to take advantage of the synergistic effects of these active compounds on reduction of total suspended solids and total dissolved solids.

2 Material and methods

2.1 Plant based coagulants preparation

Aloe vera and Cactus opuntia were harvested from a garden whilst dry Okra seeds were purchased from a vegetable market in (Bulawayo, Zimbabwe). Initially, Aloe vera and Cactus opuntia leaves were thoroughly washed with running tap water to remove all visible dirt particles. Thereafter, the outer skin of the cactus leaves were peeled off and the leaves were further washed. The plant material were then cut into very thin strips. These strips of Aloe vera and Cactus opuntia leaves were dried in the oven at a temperature between 100 and 120 °C. The dried Aloe vera, Cactus opuntia leaves and Okra seeds were ground into powders using pestle and mortar. The powders were sieved using 250 and 500 µm sieves to obtain fine powders. The final powder products are shown in the Fig. 1. These powders were stored in air insulated containers to prevent oxidation.

2.2 Simplex centroid experimental design

Simplex centroid experimental design obtained from MINITAB SOFTWARE was used to model the experimental procedure. The three bio coagulants in the blends are Aloe Vera as A, Cactus Opuntia B as and Okra seeds as C. The simplex centroid design using all possible blends of the three bio coagulants gives six (6) different mixtures for the {3, 2} design where the bio coagulants A, B and C are in equal proportions 0, 0.5 and 1 and, four (4) different mixtures for the {3, 3} design where the bio coagulants are A, B and C are in equal proportions of 1/6, 1/3 and 2/3.

The simplex triangle represents all the possible blends. Pure blends containing only one component are represented by the simplex coordinates on the corner of the simplex triangle as shown in Fig. 2. The blend containing all the three components in equal proportions is represented by the simplex co-ordinates for the centre point. The mid points of the simplex triangle sides represent binary points, that is, blends with only two components [13].

Using the MINITAB software version19.0, Table 1 was extracted and it shows the possible test runs that were carried out. One set of the experiment has 10 runs and the test runs were done at three different dosages.

2.3 Jar test procedure

The wastewater sample obtained from a brewery malting plant in (Bulawayo, Zimbabwe) represented an average of the raw wastewater that is discarded daily. The sample was added to six 1 Litre beakers and different amounts of coagulants including powdered Aluminium Sulphate (Alum) which was obtained from the Bulawayo City works, Aloe vera, Cactus opuntia, Okra seeds and the blends according to ratios from Table 1, ranging from 30 to 55 mg/L were added. The beakers were placed in the jar test apparatus and a constant mixing rate of 200 rpm was adopted for 2 min, followed by slow mixing at 30 rpm for 10 min then allowed to settle for 30 min, all experiments were conducted in duplicate.

2.4 Quality of treated wastewater

The following parameters were measured from the supernatant, turbidity, pH, temperature, total dissolved solids and electrical conductivity. Turbidity was measured using a turbidimeter (Lovibond-TB211 IR), pH and temperature using a pH meter (Eutech-pH 700),whereas total dissolved solids and electrical conductivity were measured using TDS meter (HANNA-HI 86302) and Conductivity meter (HANNA-HI 2315) respectively.

This procedure was repeated for all the samples under investigation. The percentage removal of turbidity and total dissolved solids was calculated using Eq. 1.

3 Results and discussion

3.1 Raw wastewater quality

Table 2 shows the physical and chemical properties of the brewery malting plant wastewater. The permanganate value can be used to estimate the COD, BOD and TOC values.

3.2 Effects of each coagulant on the wastewater quality

3.2.1 Effect of the individual coagulants on turbidity

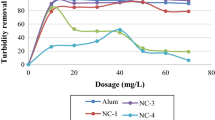

Figure 3 shows that Aloe vera, Cactus opuntia and Okra seeds were all effective in reducing the turbidity from 734 NTU to a range between 55 and 255 NTU. This indicates that these plant materials have active compounds that are effective in the coagulation process. For instance, Aloe vera contains long chain proteins which are known to be effective in inter particle interactions forming a bridge with colloidal particles in the wastewater resulting in heavier particles with better ease of settling (Benalia et al., 2021). Whereas Cactus opuntia, has a significant amount of polysaccharides, which similarly absorb onto suspended particles forming flocs that can settle faster [6]. On the other hand, coagulation using okra seeds was more effective than that of Cactus and Aloe Vera and similar to that of alum as okra seeds. Colloidal particles are charged which is one of the reasons for continued dispersion. Okra seeds have anionic polyelectrolytes as well as carbonyl and hydroxyl groups inherently the coagulant can simultaneously achieve charge neutralization to prevent the dispersion and adsorption onto the surface of colloidal particles paving way for formation of flocs [19]. Furthermore, Fig. 3 indicates that in all instances investigated there was a sharp decrease in the turbidity between a dosage of 0–30 mg/L, whereas after a dosage of 35 mg/L there was a statistically insignificant change in the turbidity.

The optimal reduction of turbidity using Alum was 68.3 NTU which was observed at a dosage of 40 mg/L. attaining a removal efficiency of 90.69%. Whereas for Aloe Vera, the minimum turbidity achieved was 189 NTU at a dosage of 40 mg/L achieving an efficiency of 74.25%. Whilst for Cactus opuntia the minimum turbidity achieved was 186 NTU at a dosage of 50 mg/L resulting in an efficiency of 74.66%. Okra seeds had a minimum turbidity of 82 NTU at 35 mg/L attaining an efficiency of 88.83%.

3.2.2 Effect of the coagulants on pH

Figure 4 shows that all the coagulants reduced the pH of treated wastewater, however Alum was noted to have the greatest reduction to a least value of 5.07 at a dosage of 55 mg/L. This is attributed to the fact that a dose of 1 mg/L of Alum in water reacts with 5.55 mg/L of alkalinity expressed as CaCO3 and simultaneously increases the CO2 content by 4.9 mg/L. Consequently if an alkaline substance is not added this results in pH reduction [5, 8].

On the other hand, plant-based coagulants (Aloe vera, Cactus opuntia and Okra seeds) reduced the pH from 6.41 to a final pH range between 5.98 and 6.14. At the dosage of 30 mg/L Aloe vera attained a pH of 6.40 which was closest to the initial pH of the raw wastewater used for these experiments. The initial pH of 6.41 was already below the standard range of 6.5–8.5 required by EMA prior to discharge of the wastewater [7].

3.2.3 Effect of the coagulants on temperature

The initial temperature of the raw wastewater was 22.7 ºC. Upon treatment with coagulants, the temperatures ranged from 21.8 to 22.4 ºC as shown in Fig. 5. This indicated there was a slight variation in the temperature which may be attributed to that there is no significant energy either being adsorbed or released with the reactions taking place during coagulation which include adsorption and charge neutralization. All the samples of treated wastewater were within the standard range of 20 to 35 ºC [7] as required prior to the discharge.

3.2.4 Effect on the coagulants on Electrical conductivity

It was observed that all the coagulant dosages reduced the electrical conductivity from an initial value of 66.7 mS/m to a range of 1.4 to 2.1 mS/m thus, electrical conductivity removal was 96.9 to 97.9%. From Figs. 3, 4 it can be seen that the final electrical conductivities were almost similar, that is their range was very small. Wastewater treated by Alum had the highest electrical conductivities as seen in Fig. 6. This is due to the dissociation of the coagulant (alum) producing ions with a high valency [8], consequently the electrical conductivity of the treated wastewater will have slightly higher electrical conductivities than other wastewater samples treated using the plant-based coagulants. Cactus opuntia generally has lower electrical conductivities than Alum. The least electrical conductivity value of 1.4 mS/m was obtained from wastewater treated by 55 mg/L of Cactus opuntia. According to (Marobhe, 2007), Cactus opuntia has less dissociation capacity in water than Alum. According to S.I. 274 of 2000 (Nhapi, 2004), the standard effluent in Zimbabwe should be discharged with conductivity below 100 mS/m (1000 µS/cm). Comparing the obtained results with the standard effluent discharge value, it was observed that the electrical conductivity of all the treated wastewater by different coagulants was within the permissible limits.

3.2.5 Effect of the coagulants on total dissolved solids

As illustrated in Fig. 7 there was a significant reduction in total dissolved solids from a concentration of 19,800 ppm in the initial raw wastewater to a range of 880 to 1130 ppm in the treated wastewater. This accounted for TDS removal between 94.25 to 95.56%. The results show that the coagulants neutralized charged particles as well as had a sweeping effect separating the charged particles through formation of flocs which thereafter settle. Figure 7 indicates that Alum was the most effective in the reduction of TDS removal, having the best results of 880 ppm at a dosage of 40 mg/L as shown in Fig. 7. Cactus opuntia was the least effective in the TDS removal, having the least TDS of 990 ppm at a dosage of 50 mg/L. For Okra seeds the best result was 940 ppm at a dosage of 35 mg/L while for Aloe Vera it was 910 ppm at 40 mg/L.

The effectiveness of okra seeds in removing TDS is due to presence of polysaccharides which contain functional groups that serves as actives sites for colloidal particle removal (Zin, 2016). Therefore, the TDS obtained by using all the four coagulants was still below 1500 ppm which the acceptable green limit for standard effluent in Zimbabwe [7].

3.3 Effects of blending coagulant on the wastewater quality

The performance of the coagulants when they are blended at different proportions at the optimum dosages obtained in the first runs was investigated. Modelling of the experiments at different coagulant ratios was done using Simplex Centroid Experimental from MINITAB 19.

3.3.1 Effect of blended coagulants on Turbidity at 40 mg/L

From the experiments carried out at different blends and different coagulant dosages it was observed that the turbidity removal was in the range 70.98 to 87.82% from an initial turbidity of 734 NTU as shown in Fig. 8. The best turbidity removal for all the blends was 83.92% (at 118 NTU) at a dosage of 40 mg/L and coagulant ratios of 0.17, 0.17 and 0.67 for Aloe vera, Cactus opuntia and Okra seeds respectively. The observed turbidity removal by the blends were lower than the obtained turbidity removal of 90.69%, when using Alum alone and that of using Okra seeds alone (88.83%). However, compared a turbidity reduction of 74.66% was obtained from using Cactus opuntia whereas 74.25% was achieved when Aloe Vera was used indicating that the blends had a higher turbidity reduction. This may be attribute to that each plant based coagulant has a different variation of active ingredients that cause coagulation and combining these active compounds results in a combined positive effect on turbidity reduction.

3.4 Effect of blended coagulants on total dissolved solids at 40 mg/L

All the coagulant blends at 40 mg/L attained TDS removal in the range of 94.19 to 95.28%. The highest TDS removal efficiency was 95.28% observed at the coagulant ratios of (0.17, 0.17, and 0.67) for Aloe vera, Cactus opuntia and Okra seeds, respectively as shown in Fig. 9. The blends had a lower TDS removal efficiency than Alum (95.56%) obtained at the same dosage of 40mg/l but higher than that obtained by using Aloe vera (94.44%), Okra seeds (94.44%) and Cactus opuntia (94.19%) separately.

4 Conclusion

Plant based coagulants such as Aloe vera, Cactus opuntia and Okra seeds are readily available and abundant in countries like Zimbabwe which is not producing chemical-based coagulants such as Alum locally. The results in this study indicate that these coagulants can be effectively used individually or blended to take advantage of the synergistic effects of the various active components that they contain. All the three plant based coagulants had less turbidity reduction on the brewery malting plant wastewater compared to Alum. However, the turbidity reduction for all the coagulants under investigation was within acceptable limits. Alum had the most significant pH reduction which indicated further pH adjustment would be required to ensure the wastewater pH is within acceptable limits. on the waste . Alum had an optimum dosage of 40 mg/L. Of all the three bio coagulants, Okra seeds had the best results. Its optimal dosage was 35 mg/L. For Aloe vera and Cactus opuntia the optimum dosages were 40 mg/L and 50 mg/L respectively. For the blends, the best results were obtained at a blend ratio of (0.17, 0.17, and 0.67) for Aloe vera, Cactus opuntia and Okra seeds respectively. At a dosage of 40 mg/L the turbidity removal was 83.92% and TDS removal was 95.12 %.

All the results of the final temperature, electrical conductivity and TDS were within the acceptable limits of EMA. Consequently, the plant based coagulants were successful and effective as promising alternative coagulants in treating the malting processing plant effluent. Most of the plant based coagulants are multipurpose, therefore it is important that they are blended to increase effectiveness and to reduce the amount of each coagulant used as they could be inadequacies in supply for large industrial process applications.

Data availability

DATA AVAILABILITY STATEMENT DEAR Dr Piyush Shinde; Assistant Editor; Discover Civil Engineering The information is openly available in public repository that issues datasets with DOI or URL: The data that support the findings of the background research on the “Treatment of effluent using bio-coagulants" are acquired through existing literature collection traceable via the references list below, while the images of Fig. 1 were captured by camera during laboratory trials and the information are openly available in: EMA (Environmental Management Agency) [7]. Effluent and Waste Disposal Regulations, SI 6 of 2007. Gandiwa [8].Optimisation of using a blend of plant based natural and synthetic coagulants for water treatment: (Moringa Oleifera-Cactus Opuntia-Alum Blend). South African Journals of Chemical Engineering. 34,158-164 [9]. Reconciling global aspirations and local realities: Challenges facing the Sustainable Development Goals for water and sanitation. World Development, 118, 106– 117. Magaji [10]. Biocoagulation Activity of Moringa Oleifera seeds for Water treatment. The International Journal of Engineering and Science (IJES), 4(2), pp. 19–26. Majeed [11]. Reducing the Turbidity of Wastewater by some plant Based Coagulants. International Journal of Science and Research (IJSR), 6(10). [12]. Investigation of the performance of the local plant materials for coagulation of turbid river water. Journal of the Institution of Engineers Tanzania, 8(3), pp. 50–62. Table 1 and Fig. 2 graphical plot were compiled through the data collection of Montgomery D.C., 2013. Design and analysis of experiments. 8th ed. Arizona: John Wiley & Sons, Inc. New York. Miller [14]. Occurrence of aluminium in drinking waters. Journal of American Water Works. 76(1), 84–91. Reference Numbers [9,10,11, 13, 15,16,17, 20, 21]. The data that support the information under the sections for “Results and discussions that comprise the data for (Table 2, Figs. 3, 4, 5, 6, 7, 8 and 9), and the “Conclusions section” were cumulative assessed grounded on laboratory fundings via the aid of existing literature which are openly accessed in the repository name; [Miller [14]. Occurrence of aluminium in drinking waters. Journal of American Water Works. 76(1), 84–91. Nhapi [15]. Wastewater management in Zimbabwe in the context of sustainability. Water Policy, Volume 6, pp. 501–517. Okolo [16]. Optimising Bio-coagulants For Brewery Wastewater Treatment using Response Surface Methodology. Nigerian Journal of Technology (NIJOTECH), 36(4), pp. 1104–1113. Putra [17]. Turbidity removal of synthetic wastewater using biocoagulants based on protein and tannin. AIP Conference Proceeding. 2242, 040028-1–040028-6. Ugwu [20] Comparative study of the use of natural and artificial coagulants for the treatment of sullage (domestic wastewater), Cogent Engineering, 4:1, 1,365,676, 10.1080/23311916.2017.1365676. [21]. Guidelines for drinking-water quality: fourth edition incorporating the first addendum. Geneva, Licence: CC BY-NC-SA 3.0 IGO. Zin [22]. Study the effectiveness of biocoagulant between Aloe vera (L.). Burm. F and Okra mucilage in coagulation and flocculation Treatment. In e-Prosiding Seminar ENVIROPOLY 2016; Oleh, D., Penerbit, P., Eds.; Politeknik Sultan Idris Shah: Selangor, Malaisie,]. Reference Number [7, 8, 12, 14, 15, 22] Author Names: 1. V. Murisa, S. 2. Ncube, 3. L. B. Moyo, 4. G. Danha, 5. T.A. Mamvura.

References

Baatache O, Derbal K, Benalia A, Khalfaoui A, Bouchareb R, Panico A, Pizzi A. Use of pinecone as bio-coagulant for heavy metal removal from industrial wastewater: use of box-behnken design. Ind Crops Prod. 2024;210: 118185. https://doi.org/10.1016/j.indcrop.2024.118185.

Benalia A, Atime L, Baatache O, Khalfaoui A, Ghomrani AF, Derbal K, Pizzi A, Panico A, Bouchareb EM, Bouchareb R, Amirou S. Removal of lead in water by coagulation flocculation process using cactus-based natural coagulant: optimization and modeling by response surface methodology (RSM). Environ Monitor Assess. 2024. https://doi.org/10.1007/s10661-024-12412-9.

Benalia A, Chaibraa W, Djeghar S, Derbal K, Khalfaoui A, Mahfouf A, Bouchareb R, Panico A, Pizzi A. Use of extracted proteins from oak leaves as bio-coagulant for water and wastewater treatment: optimization by a fractional factorial design. Water. 2023;15(11):1984. https://doi.org/10.3390/w15111984.

Benalia, A., Derbal, K., Amrouci, Z., Baatache, O., Khalfaoui, A., & Pizzi, A. (2024). Application of plant-based coagulants and their mechanisms in water treatment: A Review. Journal of Renewable Materials, 0(0), 1–10. https://doi.org/10.32604/jrm.2024.048306.

Brandt M, Johnson M, Ephilston A, Rathnaka D.. Storage Clarification and chemical treatment. In Tworts Water Supply (7th ed., pp. 323–366). essay. 2017. https://doi.org/10.1016/B978-0-08-100025-0.00008-9.

Choudhary M, Ray MB, Neogi S. Evaluation of the potential application of cactus (opuntia ficus-indica) as a bio-coagulant for pre-treatment of oil sands process-affected water. Sep Purif Technol. 2019;209:714–24. https://doi.org/10.1016/j.seppur.2018.09.033.

EMA (Environmental Management Agency), 2007. Effluent and Waste Disposal Regulations, SI 6 of 2007.

Gandiwa BI, Moyo LB, Ncube S, Mamvura TA, Mguni LL, Hlabangana N. Optimisation of using a blend of plant based natural and synthetic coagulants for water treatment: (Moringa Oleifera-Cactus Opuntia-Alum Blend). South Afr J Chem Eng. 2020;34:158–64.

Herrera V. Reconciling global aspirations and local realities: challenges facing the sustainable development goals for water and sanitation. World Dev. 2019;118:106–17.

Magaji UF, Sahabi DM, Abubaka MK, Muhammad AB. Bio coagulation activity of Moringa Oleifera seeds for water treatment. Int J Eng Sci. 2015;4(2):19–26.

Majeed MR, Jasim HA. Reducing the turbidity of wastewater by some plant based coagulants. Int J Sci Res. 2017;6(10):1014.

Marobhe N, Renman G, Jackson M. Investigation of the performance of the local plant materials for coagulation of turbid river water. J Ins Eng Tanzania. 2007;8(3):50–62.

Montgomery DC. Design and analysis of experiments. 8th ed. Arizona: John Wiley & Sons, Inc., New York; 2013.

Miller GR, Kopfler CK, Kelty CK, Stober AJ, Ulmer SN. Occurrence of aluminium in drinking waters. J Am Water Works. 1984;76(1):84–91.

Nhapi I, Gijzen HJ. Wastewater management in Zimbabwe in the context of sustainability. Water Policy. 2004;6:501–17.

Okolo BI, Nnaji PC, Oke EO, Adenkunle KF, Ume CS, Onukwuli OD. Optimising bio-coagulants for brewery wastewater treatment using response surface methodology. Nigerian J Technol. 2017;36(4):1104–13.

Putra RS, Amri RY, Ayu M. Turbidity removal of synthetic wastewater using biocoagulants based on protein and tannin. AIP Conf Proc. 2020;2242:040028-1–040028-6.

Simate GS, Cluett J, Iyuke SE, Musapatika ET, Ndlovu S, Walubita LF, Alvarez AE. The treatment of brewery wastewater for reuse: state of the art. Desalination. 2011;273(2–3):235–47. https://doi.org/10.1016/j.desal.2011.02.035.

Sui Kim IT, Sethu V, Arumugasamy SK, Selvarajoo A. Fenugreek seeds and okra for the treatment of palm oil mill effluent (pome)—characterization studies and modeling with backpropagation Feedforward Neural Network (BFNN). J Water Process Eng. 2020;37: 101500. https://doi.org/10.1016/j.jwpe.2020.101500.

Ugwu SN, Umuokoro AF, Echiegu EA, Ugwuishiwu BO, Enweremadu CC. Comparative study of the use of natural and artificial coagulants for the treatment of sullage (domestic wastewater). Cogent Eng. 2017;4(1):1365676. https://doi.org/10.1080/23311916.2017.1365676.

WHO, 2017. Guidelines for drinking-water quality: fourth edition incorporating the first addendum. Geneva, Licence: CC BY-NC-SA 3.0 IGO.

Zin NS, Kamaruzaman WN, Lee CS. Study the effectiveness of biocoagulant between Aloe vera (L.). Burm. F and Okra mucilage in coagulation and flocculation Treatment. In e-Prosiding Seminar Enviropoly 2016; Oleh, D., Penerbit, P., Eds.; Politeknik Sultan Idris Shah: Selangor, Malaisie. 2016.

Acknowledgements

The research related to Treatment of effluent from a malting processing plant using bio-coagulants, has been supported by the Botswana International University of Science and Technology through the Department of Chemical, Materials and Metallurgical Engineering, Department of Chemical Engineering, National University of Science and Technology, Bulawayo, Zimbabwe, together with the School of Chemical and Metallurgical Engineering, University of the Witwatersrand, Johannesburg, South Africa. To promote bio-coagulants deployment in the vast industry hence encourage economic sustainability in business structures. I am appreciative of all the efforts from authors and technicians involved from all institutions that were engaged through-our the investigation.

Author information

Authors and Affiliations

Contributions

Author Contributions Statement (V. Murisa: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.) V. Murisa (murisa.v@nust.ac.zw). Conceptual idea, Write up, Literature Reviewing, background Investigations. S. Ncube (sokesimbone.ncube@nust.ac.zw). Conceptual idea, Write up, Literature Reviewing, Experimentation and Results Analysis. L. B. Moyo (langa.moyo@nust.ac.zw). Conceptual idea, Write up, Literature, Editing and Article Improvement. Gwiranai Danha (danhag@biust.ac.bw). Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper. T.A. Mamvura (mamvurat@biust.ac.bw). Conceptual idea, Write up, Literature, Editing and Article Improvement.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Murisa, V., Ncube, S., Moyo, L.B. et al. Treatment of effluent from a malting processing plant using bio-coagulants. Discov Civ Eng 1, 29 (2024). https://doi.org/10.1007/s44290-024-00030-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44290-024-00030-w