Abstract

The development of Zambia has brought increased large-scale infrastructure construction that has necessitated the need for improved foundation techniques that are both economical and adequate in capacity. Clay and soft soils with low bearing capacities and high compressibility could render structural foundations to perform poorly and shorten the design life of the bridges and structures. This study used a bridge case study in Northern Province, Zambia to investigate the use of geosynthetic encased columns (GECs) to support the bridge embankments to reduce differential settlements. End bearing fully encased columns were compared to floating columns of varying lengths by numerical modelling in PLAXIS 3D. The Hardening Soil and Mohr–Coulomb soil models were used for the column surrounding soil and the GECs in the finite element analysis. The results showed that the end bearing columns had the least differential settlements at the soil surface, whilst the reduction in floating column length increased the punching settlements. Moreover, the shear stress along the interface of the GECs and surrounding soil varied from 20 kN/m2 to 142 kN/m2, where the end bearing GEC had the least shear stress.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid urbanisation in Lusaka province, and Zambia at large, in the last 15 years has seen an increase in construction of various developmental projects. Despite the increasing number of modern infrastructures in the country, Zambia continues to rely on traditional construction methods and design with a seeming averseness to assess emerging trends and technologies in construction methods. Concrete quantities and costs used for foundation systems continue to increase in order to meet demand loads.

An inventory and conditional survey of all major bridges and culverts in Zambia indicated that of the total 2,355 structures, 50% of them were found to be in critical to marginal condition [1]. When constructing in deep layers of poor clay or silty soils, it is impractical to use only soil replacement methods, moreover, the cost would be tremendous. Therefore, it is imperative that developing countries such as Zambia employ the use of methods that would improve the durability and performance of the structures whilst maintaining tolerable costs for construction and maintenance.

Ground improvement techniques can improve the structural performance of foundations by increasing the shear strength and bearing resistance of the founding soil; increasing the density of the soil; reducing permeability; limiting deformations caused by settlement, heaving, or distortions; accelerating consolidation; increasing drainage and; transferring embankment loads to more stable subsurface layers [2,3,4]. The suitability and choice of ground improvement method depend on the soil encountered at the site, as well as economic factors.

Studies have shown that Geosynthetic Encased Columns (GECs) are able to increase the average unit weight of soils by replacement; rapidly drain excess pore pressures generated; act as strong and stiff elements that are capable of carrying relatively high stresses; and are cost effective in construction and environmentally friendly [5,6,7]. The combination of desirable material and strength properties makes GECs an attractive solution to reducing soil settlements, improve soil stiffness and bearing capacity and improve the overall ground conditions.

Some scholars carried out laboratory studies to investigate the use of ordinary stone columns on South African clay soil. They, however, did not consider the effect of geosynthetic encasement to reduce bulging or punching failure [8]. The use of GECs has been extensively studied in developed parts of the world [9,10,11]. However, there seems to be insignificant research that has been done in Africa and Zambia in particular regarding the applicability of this technology with our local soils. Due to the karstic topography in southern Zambia, there are many areas that are vastly covered by clay soils and overlain by superficial surface deposits that are highly compressible and possess low bearing capacities. GECs could offer a sustainable solution to reducing embankment settlements when founded on heterogenous soils.

This paper seeks to investigate the viability of GECs in reducing soil settlements in heterogenous soil layers in Zambia. This paper will also focus on the behaviour of these different soil layers when reinforced with GECs of varying lengths. In this study, GECs are numerically modelled and the finite element analysis (FEA) done in PLAXIS 3D. Thereafter, settlement improvements are noted on the bridge embankments where GECs are analysed from the results of the FEA.

1.1 Literature review

GECs are constructed as stone piles that are wrapped around with a geosynthetic material or geogrid to enhance the lateral support. The stone piles are rammed into the untreated soil using stone aggregates or stabilised earth to form vertical piles in the ground, thereby densifying the soil [2]. GECs, however, lack the rigidity of piled foundations as they are not connected with beams and pile caps. Therefore, the load settlement behaviour and the bulging at the pile head are the most critical parameters to check for in design. It was observed from a study that poor lateral confinement in stone piles leads to bulging failure in unreinforced and encased stone piles [12].

In very soft soils, the effectiveness of stone piles will be reduced as the confining pressure on the stone piles may not be sufficient enough. In this case, extra support on stone piles can be achieved by using geosynthetic encasement, where the geosynthetic can provide high confining pressure to the stone piles to improve their bearing capacity and stiffness [8, 9, 13]. In order to improve the load capacity and reduce settlements in the soil the bearing capacity of the stone piles is of utmost importance in their design and performance. Studies have also shown that using a stiff geotextile encasement reduces column settlement and bulging at the column head in comparison to non-encased columns [13,14,15]. From the literature studied, it is observed that the choice of geosynthetic material to use is of great importance and the diameter of the pile and spacing of this reinforcement impact its performance and capacity.

Yoo, C. [16] carried out a numerical study to observe the settlement behaviour of embankments constructed on GECs in soft ground. It was concluded that GECs had enhanced performance over ordinary stone columns by decreasing excess pore pressures and increasing column stiffness [16]. Alkhorshid, N.R. et al. [17] analysed the behaviour of GECs supporting an embankment using numerical modelling and found that for partially encased columns, the increase in length of encasement decreased settlements [17].

1.2 Case study: Kalungu Bridge, Northern Province, Zambia

1.2.1 Bridge data

Short span bridges in Zambia are often found in the rural regions where the road carriage widths are smaller than in urban regions. These bridges often connect rural towns and serve as a major transportation route for agricultural produce to market places. However, heavy rainfall events and flash floods often wash away embankment and foundation soils, comprising the structural integrity of these bridges. Alluvial soils that are synonymous with heterogeneity in layers are found at these bridge sites of interest. The high presence of silts and clays may also contribute to the significant differential settlements noted on embankments in the region.

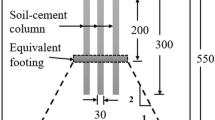

The case study is a bridge design based on the Kalungu Bridge in Northern Province, Zambia. The Kalungu Bridge was constructed around 1950 and is located along the Kasama – Isoka road. The bridge, which is over 70 years old, has not been regularly maintained and has since deteriorated. It is 9.5 m wide and 34 m long with a continuous reinforced concrete flat slab deck supported by three piers each at three bents. The elevation drawing of the bridge is shown in the Fig. 1 below. A new design of the bridge will provide a total of 4 spans and 2 post-grouted piles supporting each bent. The bridge superstructure analysis indicates that each pile group should carry a load of 3,900 kN.

1.2.2 Site geotechnical data

The bridge site is situated in the Chambeshi River Basin and is underlain by alluvial deposits. It is characterised by heterogeneous soil layers and is overlain by clay, silt and sand. The geological map indicated that the area is predominantly clayey and silty soils. The geological map indicates that the bridge locality has a geological formation of lithological units of various ages, including granite rock and lower quartzite.

Site investigations were done by carrying out Standard Penetration Tests (SPTs) at both abutments and the results are presented in Fig. 2. Borehole logs were also done to study the heterogeneity of the soil profile. From the SPT and borehole data it was noted that there was a thick clayey sandy layer overlain by a silty sandy stratum of soil. There was a significant decrease in SPT values in the lower clay stratum.

Silty and clayey soils typically have poor strength properties in terms of shear and bearing capacity. Moreover, these soils are known to exhibit low permeability, making them unsuitable for drainage properties in the embankment. The low bearing capacity of clay soils also necessitates the need for ground improvement in order for the bridge foundation to withstand expected loads.

The application of GECs is restricted to supporting only the bridge embankment area, whilst the post-grouted piles will be applied to the bridge pier foundations. The embankment and bridge foundation will be modelled separately using the FEA software, PLAXIS 3D.

1.2.3 GEC design

The GECs are designed to be constructed with stone aggregates as this avoids the possibility of either clogging of the geosynthetic textile, or perforating it. The limitation with GECs is that they cannot be used within the river bed for the bridge foundation. Scouring and clogging of the piles would be expected even with the geotextile encasement, therefore, in this study the GEC support is restricted only the embankments. The GEC design adopts the procedure stipulated in the Chinese Technical Code for Ground Treatment of Buildings [18]. It was, thus, determined that an area replacement ratio of 0.1 and GEC spacing of 1.8 m in a square pattern would suffice.

1.3 GEC numerical model in PLAXIS 3D

1.3.1 Validation of GECs numerical modelling

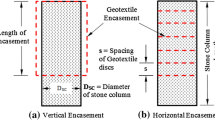

The modelling approach adopted in this study is similar to that used by Alkhorshid, N.R. et al. [17] in Reference [17] where the researchers used numerical analyses and FEA to observe the influence of stone column design approach on its performance. In their study, the authors investigated the behaviour of partly encased and fully encased GECs when they are end bearing and floating columns as shown in Fig. 3 below. The unit cell concept was adopted, where the diameter of the area of influence is represented by the two times the radius of a cylindrical column-soil system [18, 19]. Furthermore, the displacement method of constructing GECs was adopted in this FEA using PLAXIS 3D.

Though the validation studies were carried out in PLAXIS 2D, this research uses PLAXIS 3D for all numerical analyses. The advantage of using a 3D FEA software is that the meshing it produces is much more refined than that of the 2D, thus allowing for more precise node selection when reading the output data. The second advantage of using 3D FEA software over a 2D FEA is that the fictitious roller support boundary conditions of the unit cell for the GECs can be more accurately modelled in 3-dimensions than in 2-dimensions.

The GECs were modelled as axisymmetric elements with the vertical sides fixed in horizontal translation only, whilst the bottom boundary was set as fixed. The materials parameters were input in PLAXIS as shown in Table 1. Parameters used in the validation were summarised from the material properties used in similar previous studies [17, 20]. These studies carried out numerical analyses on embankments supported by GECs. The Hardening Soil and Mohr–Coulomb soil models were used for the soft soil and GECs respectively.

After running the numerical model in PLAXIS 3D, it was found that the validation results of the settlement at the soil surface and the settlement at the column tip closely correlated as shown in Figs. 4 and 5. The settlement for GECs was compared by analysing different floating ratios for the floating columns. The floating ratio, ρ, is denoted as the ratio of the length of column to the height of soil.

1.3.2 PLAXIS 3D model

The FEA validation and numerical model calibration in the previous section allowed for the correct modelling and subsequent analysis of the GECs in PLAXIS 3D. The GECs were modelled as axisymmetric stone columns with full 10-noded triangular elements. The unit cell concept was followed in this 3D model by stipulating the vertical boundary conditions to have fictitious roller supports at the sides as shown in Fig. 6. The bottom boundary of the axisymmetric model is fixed against translational and rotational movement by placing a rigid support at the base. Using the unit cell boundaries for analysis in the 3D model allows for the observation of settlement around the GEC, as well as the effect on the surrounding soil after loads are applied. The GEC performance in the embankment after loading is analysed by comparing the fully encased GEC against the floating fully encased GECs with different floating ratios, ρ.

The geosynthetic material was modelled as a linear-elastic material with a stiffness of 2000 kN/m as modelled in another similar study [20]. The Mohr–Coulomb and Hardening Soil models were adopted to this numerical study. The Mohr–Coulomb model is based on the Mohr–Coulomb failure criterion of soils which simulates the elastic behaviour of soils up to the plastic failure point. A summary of the material parameters used in the FEM is indicated in Table 2. The values for parameters used were obtained from laboratory and field tests carried out on samples from the case study site.

An end bearing fully encased GEC and GECs with different floating ratios were modelled and the corresponding results compared. The dimension for the diameter of the circle of effective influence (De) for the GECs and OGC was calculated as 1.13s, where s is the spacing of columns with a rectangular layout [18]. The generated 3D mesh for the stone column and geosynthetic encasement is shown in Fig. 7. A negative interface was placed between the geosynthetic material and the surrounding soil to simulate the friction action of the GEC once the loads are applied.

2 Results and discussion

The settlement of soil at the top surface of the GECs was noted after applying loads to the top of the embankment soil in PLAXIS 3D. The FEA results showed that the end bearing fully encased column (ρ = 1) had the least settlements, with the settlement increasing towards the surrounding soil perimeter. A closer examination indicates that for the end bearing column, there is a greater differential settlement between the GEC and the surrounding soil than the floating columns with floating ratios ρ = 0.1 – 0.5 as shown in Fig. 8. In addition, it was noted that soil settlements increased as the GEC floating ratios decreased. The changes in soil layers did not have any significant effect on the surface settlements.

The results in Fig. 9 indicate that the base of the GECs exhibited some degree of punching settlement, which is a behaviour synonymous with soft foundation soils when loads are applied or the when the loads applied are too great to be sustained by the soil beneath the column. There was a distinct change in the amount of settlement at the column tip of the floating column with ρ = 0.8 and 0.5.

Furthermore, the floating columns with lesser floating ratios exhibited greater punching settlement, with greater differential punching settlement noted on GECs with ρ = 0.1 and 0.3. The end bearing fully encased GEC is supported by a stiff sand stratum and this could have the positive effect of reducing the punching settlements when compared to the floating GECs in the silty sand and clayey sand layers. Moreover, the GECs with floating ratios ρ = 0.1 and 0.3 only go up to the depth of the silty gravel and silty sand layers.

Figure 10 shows the soil principal strain (ε1) deformations in the different GECs after the FEA was complete. There were notably higher principal strain values at the column tips in the clayey sand layer of soil (at z = 9 m) for the end bearing GEC and floating ratios ρ = 0.8, 0.5 and 0.1. However, the geosynthetic encasement for the end bearing GEC (ρ = 1) only exhibited slight variations in ε1 values. The floating GEC with floating ratio 0.8 indicated significantly higher amounts of principal strain deformation of soil in the clayey sand layer, though without bulging failure or punching settlement.

The punching settlement on the strain deformation images is most prominent on the floating columns with ratios from 0.1 – 0.5, whilst the geosynthetic encasing GEC with floating ratio 0.3 had the greatest strain deformation of all the columns. From this data, it can be seen that the clayey sand layer of soil was the least capable of transferring loads to the stiff sand layer and soil collapse could be anticipated in this stratum.

The shear stresses along the interface of the GECs and the surrounding soil plays a role in the load transfer along the shaft of the column. Figure 11 illustrates the variation of shear stress with soil depth within the different strata. As the end bearing GECs showed the least settlements with load application, the gradual increase of shear stress along the GEC interface indicates that that column has a more efficient load transfer to the soil. The end bearing GEC had highest shear stress in the silty gravel and silty sand soil layers and a gradual reduction of shear stress towards the column tip in the clayey sand layer. The shear stress vividly increases sharply from the top of the column as the floating ratios reduce.

3 Conclusions

This study investigated the viability of using GECs to reduce embankment settlements on Zambian clayey soils by FEA in PLAXIS 3D. This was done by using a case study to compare end bearing GECs with floating GECs of different lengths in the soil. The following conclusions were drawn:

-

1)

The end bearing fully encased GEC showed the least different settlements both at the soil surface and the column tip.

-

2)

The reduction of floating ratio increased the punching settlements with the floating GEC with ρ = 0.1 exhibiting the most settlements. The lower floating ratios only went as far as the silty gravel and silty sand soil layers and this showed that the type of soil affects the punching settlement of the floating GECs.

-

3)

The end bearing fully encased column also had the least soil strain deformations and no deformation in the geosynthetic material. The punching settlements for the floating ratios is vividly seen in the strain deformation figures. The floating GEC with ratio of 0.5 had the largest geosynthetic encasement deformation.

-

4)

The length of end bearing and floating GECs influences the shear stress transfer along the column and soil interface. The shear stress along the interface sharply increased as the floating ratios reduced.

Availability of data and materials

Data will be made available on request.

References

Road Development Agency (2014) “Road Maintenance Strategy: 2014 – 2024.” Lusaka. Road Development Agency

U.S. Department of Transportation Federal Highway Administration (2017) Ground Modification Methods Reference Manual – Volume I. National Highway Institute, Washington DC, Chapter 5: pp. 510–551

Department of Transportation Federal Highway Administration (2017) Ground Modification Methods Reference Manual – Volume II. National Highway Institute, Washington DC, Chapter 6: pp. 610–671.

Nicholson PG (2014) Emerging Technologies, Trends, and Materials, In: Soil Improvement Ground Modification Methods. Elsevier Ltd., Chapter 2: pp. 433–438

Alexiew D, Raithel M (2015) Geotextile-Encased Columns: Case Studies over Twenty Years. Elsevier Ltd., Chapter 17: pp. 451–477

Abhishek SV, Rajyalakshmi K, Madhav MR (2016) Engineering of ground with granular piles: a critical review. Int J Geotech Eng 10(4):337–357

Gao J, Zhang Y, Wang C, Yuan C (2021) “Behavior characteristics of geosynthetic-encased stone column under cyclic loading,.” Transportation Geotechnics 28:100554

Sobhee-Beetul L, Kalumba D (2015) Stone column reinforcement of a soft South African clay: A laboratory investigation. Geotech Eng 46(4):81–86

Miranda M, Da Costa A, Castro J, Sagaseta C (2017) Influence of geotextile encasement on the behaviour of stone columns: Laboratory study. Geotext Geomembr 45(1):14–22

Ghazavi M, Ehsani Yamchi A, Nazari Afshar J (2018) “Bearing capacity of horizontally layered geosynthetic reinforced stone columns,.” Geotextiles and Geomembranes 46(3):312–318

Zhang X, Yoo C, Chen J-F, Gu Z-A (2022) Numerical modeling of floating geosynthetic-encased stone column-supported embankments with basal reinforcements. Geotext Geomembr 50:720–736

Hasan M, Samadhiya NK (2017) Performance of geosynthetic-reinforced granular piles in soft clays: Model tests and numerical analysis. Comput Geotech 87:178–187

Zhang L, Zhao M (2014) Deformation Analysis of Geotextile-Encased Stone Columns. Int J Geomech 15:4014053

Zhang L, Zhao M, Shi C, Zhao H (2013) Settlement Calculation of Composite Foundation Reinforced with Stone Columns. International Journal Geomechanics 13:248–256

Etezad M, Hanna A, Ayadat T (2014) Bearing Capacity of a Group of Stone Columns in Soft Soil. Int J Geomech 15:4014043

Yoo C (2015) Settlement behavior of embankment on geosynthetic-encased stone column installed soft ground - A numerical investigation. Geotext Geomembr 43(6):484–492

Alkhorshid NR, Araujo GLS, Palmeira EM (2021) Consolidation of soft clay foundation improved by geosynthetic-reinforced granular columns: Numerical evaluation. Journal Rock Mechanics Geotechnical Engineering 13(5):1173–1181

China Academy of Building Research (2002) Technical Standard of the People’s Republic of China, JGJ 79-2002: Chinese Technical Code for Ground Treatment of Buildings. Beijing. Ministry of Construction of the People’s Republic of China, Beijing.

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns. Geosynth Int 14(6):346–354

Keykhosropur L, Soroush A, Imam R (2012) 3D numerical analyses of geosynthetic encased stone columns. Geotext Geomembr 35:61–68

Acknowledgements

The authors would like to acknowledge the assistance rendered by the Road Development Agency, Zambia in providing necessary data from the case study.

Funding

The authors of this research did not receive any grant from funding agencies in the public, commercial, or non-profit sectors.

Author information

Authors and Affiliations

Contributions

AFS wrote the manuscript, provided the data for analysis and discussion sections. GM critically reviewed the draft manuscript and contributed to the introduction section.

Corresponding author

Ethics declarations

Competing interest

The authors confirm that there are no known conflicts of interest, personal relationships or financial support that could have influences the outcomes reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shaba, A.F., Masheka, G. Evaluation of geosynthetic encased columns in Zambian heterogenous soils. Urban Lifeline 2, 5 (2024). https://doi.org/10.1007/s44285-024-00015-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44285-024-00015-2