Abstract

Exposure to benzene and other volatile organic compounds (VOCs) like toluene, ethylbenzene, o-, m-, and p-xylene (BTEX) at a fuel station is hazardous for the workers. This study aims to estimate the health risk for worker due to the exposure of BTEX after implementation of vapour recovery system (VRS) at fuel stations. Air samples were collected using low-flow sampling pump as per NIOSH method by using Tenax (sorbent) tubes and charcoal (sorbent) tubes. Target compounds were extracted using acetone and analysed by gas chromatography equipped with flame ionization detector (FID). The cancer risk (CR) and hazard quotient (HQ) were estimated to assess the cancer and non-cancer risk following the United States of Environmental Protection Agency (USEPA) updated methodology. The average concentration of VOCs at the fuel station is found in the order toluene > benzene > xylene > ethylbenzene which may be attributed to the composition of fuel (petrol/diesel). Benzene is the most carcinogenic among BTEX, which is found to be 217 ± 9 µg m−3 and 158 ± 9 µg m−3 in the month of November 2021 using Tenax sorbent and charcoal sorbent tubes, respectively. The high concentration observed using Tenax sorbent may be attributed to its high adsorption efficacy than charcoal due to larger surface area and porosity. The 7-month average CR value of benzene was 9 × 10−4 using Tenax sorbent and exceeds the acceptable range of 1 × 10−6. CR of benzene exposure at the fuel station under study is also compared with that of outdoor ambient air exposure. Benzene measurement data for the same duration was taken from nearby online monitoring station of Delhi Pollution Control Committee (DPCC) PUSA to estimate CR value for outdoor ambient air benzene exposure. The value of HQ for benzene was observed > 1 which exceeds the acceptable value and hence increased the non-cancer health risk also. Hazard index (HI) value for BTEX is also greater than 1 which indicates adverse health effects of benzene and other VOCs at the fuel station. The high CR and HQ values for benzene are a matter of concern for fuel station workers.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, degradation in air quality at occupational environment is a major area of threat. Exposure to pollution increases under certain occupational scenarios in a variety of workplaces and community like oil refineries, fuel station, solvent manufacturing industries, paint manufacturing industries, and petrochemical facilities. Air pollution is directly related to the specific activities occurring at working place and is inhaled by workers due to the long exposure periods. Vapours released from fuel stations of petrol/diesel constitute one of the main sources of air pollutants. Air quality is degrading even with the significant advancement in fuel quality and engine technologies. Different types of volatile organic compounds (VOCs) present at workplace and urban sites are because of evaporative emissions from fuel service stations during dispensing, loading, unloading, transportation of petrol/diesel and vehicular emissions. Among all VOCs, BTEX (benzene, toluene, ethylbenzene, and xylene) is a very hazardous aromatic group of toxic pollutants and is considered as predominant pollutants in urban area and near large cities which have adverse effects on both humans and environment like tropospheric ozone formation, global warming, photochemical smog, and stratospheric ozone depletion (Eisaei et al., 2015; Franco et al., 2012). These VOCs mainly come from gasoline vapour emission and motor vehicle exhaust (Caselli et al., 2010).

“Benzene” is considered as group 1 human carcinogen according to several international organizations such as IARC (International Agency for Research on Cancer) and American Conference of Governmental Industrial Hygienist (ACGIH) and EPA (2010). At workplace, human exposure to benzene occurs through inhalation route from gasoline vapours, tobacco smoke, and automotive emissions. Individuals exposed to benzene can exhibit bone marrow depression, anaemia (decreased RBC count), leukopenia (decreased WBC count), and/or thrombocytopenia (decreased platelet count) (US EPA, 2002). Toluene exposure to human can affect the central nervous system and ethylbenzene and xylene can have neurological effects (Dennison et al., 2005; Tunsaringkarn et al., 2012).

The World Health Organization (WHO) estimated the range of the excess lifetime risk of leukaemia at an air concentration of benzene, e.g. 17 μg m−3 airborne benzene concentrations correspond to leukaemia risk of 1 in 104, and 1.7 μg m−3 of the same correspond to 1 in 105 (WHO, 2010). BTEX pollutants in ambient air become major concern because about 50% of inhaled BTEX in air by any person is absorbed into the body (Sippy et al., 2014). Most countries established occupational exposure limit for BTEX at workplace. In India, the limit for benzene prescribed by the Central Pollution Control Board in National Ambient Air Quality Standard is 5 μg m−3 annual-based time-weighted averages (CPCB, 2009). According to OSHA, permissible exposure limit (PEL) for short-term exposure (STEL) to benzene is 5 ppm (15950 μg m−3) for 15-min exposure and threshold limit values (TLV)-time-weighted average (TWA) set as 1 ppm (3190 μg m−3) over 8 h. The National Institute of Occupational Safety and Health (NIOSH) recommended lower exposure limit of benzene is 1 ppm (3190 μg m−3) over 15 min (STEL), and TLV-TWA is 0.1 ppm (319 μg m−3) over 8 h (NIOSH 2007).

Many studies have been conducted on BTEX pollutants at different types of locations in urban areas worldwide. But a very few studies are conducted at fuel stations (Salama et al., 2021; Correa et al., 2012; Esmaelnejad et al., 2015; Srivastava et al., 2005) that have large contribution towards exposure of BTEX pollutants on human beings. The cancer potency values are calculated for carcinogenic chemical by different governmental bodies for health risk assessment (Lloyd & Denton, 2005). For public health purposes, it is necessary to find out relationship between exposure to hazardous pollutants and their related health risk. In refuelling stations, being a very critical and continuous source of BTEX exposure, a very few studies targeted the health risk assessment of the workers working at fuel stations on the basis of very short duration measurement. The aim of this study is to find out the concentration of BTEX pollutants from September 2021 to March 2022 and its exposure to worker at fuel station. It aims to do risk analysis for cancer and non-cancer exposure through inhalation route at a fuel station of Delhi by active sampling using two different types of sorbent tubes. Also, it aims to compare the cancer risk value from exposure at fuel station with ambient air pollution exposure.

2 Material and methods

All chemicals, i.e. benzene, ethylbenzene, toluene, o-xylene, m-xylene, and p-xylene, were of > 99.8% purity, purchased from Sigma Aldrich. HPLC grade acetone was used as solvent.

2.1 Site description

Delhi is located in the northern part of India between the latitudes of 28°-24′-17″ and 28°-53′-00″ North and longitudes of 76°-50′-24″ and 77°-20′-37″ East. The city is bordered by two states of India, namely Uttar Pradesh and Haryana and cover an area of 1483 km2. Its maximum length is 51.90 km, and greatest width is 48.48 km. Two fuel stations are situated adjacently, out of which one is petrol/diesel fuel station and other is LPG fuel station. The sampling has been conducted at a petrol/diesel fuel station near NPL-PUSA which is located approx. 10 m away from the main road Dr. KS Krishnan Marg and surrounded with govt. offices and residential areas. This site is 200 to 300 m away from the major traffic intersection. Figure 1 shows the study area map representing the site location of fuel station. It also represents a pollution measurement station of DPCC (Delhi Pollution Control Committee) approx 4 km away and a CPCB monitoring station approx at 3-km distance from fuel station under study. The tapography of the fuel station is almost flat, and the orientation of the fuel station under study with respect to sampling point is given in Fig. S1 which represents the operational situation of the fuel station and topographical features with direction. Table 2 showed the meteorological data (temperature, wind direction, and wind speed) of sampling period. The data was taken from DPCC-PUSA and nearby CPCB monitoring station.

2.2 Sampling method

In this study, NPL-PUSA fuel station was selected for observation of BTEX concentration by active sampling using sorbent tubes. Petrol pump is implemented with vapour recovery system (VRS) and located at high traffic road, surrounded by institutes. Sampling was done from September 2021 to March 2022 once in alternate weeks during afternoon (1 PM to 2 PM). The sampling location is approx. 6 m far from the fuel filling point and at about 2–3-m vertical height from the ground level which is almost breathing zone for working employees at petrol pumps. The sampling and analysis are done as per NIOSH method 1501. A continuous monitoring online data (from September 2021 to March 2022) of benzene is also taken from central pollution control-board website from DPCC-PUSA station for ambient air exposure measurement of benzene.

Air sampling was done by a battery-operated low-flow sampler (Enviro Tech; APM 800). A calibrated rotameter was used to control the flow rate. Air sampling was performed at 100 mL/min flow rate for 60 min for both the charcoal sorbent and Tenax sorbent tubes. Coconut charcoal sorbent tubes (SKC, Anasorb CSC, 6 × 70-mm size, 2 sections, 50/100-mg sorbent) and Tenax tube (SKC, Anasorb CSC, 8 × 110-mm size, 2 sections, 50/100-mg sorbent, and 20/35 mesh) were used for air sampling. Sorbent tubes hold vertical position to minimize the breakthrough. After completion of the air sampling period, sampling pump turned off, and both open sides of sorbent tubes were closed with cap to avoid any desorption or contamination. Both sorbent tubes were sealed by wrapping with aluminium foil and mark the sample no. and stored in refrigerator (~4 ℃) to prevent further adsorption of compounds. Then the analysis was done within 1 to 2 h by gas chromatography using flame ionization detector (Agilent 6890N).

2.3 Analysis

Sample preparation for analysis was done for each section of both the sorbent tubes (front and back sections). Front and back sections are separated by a separating foam. After sampling, both front and back section’s charcoal is taken in separate vial of 5 ml each and poured 2-ml acetone into each vial, and then sample was put about 30 min for ultrasonic bath for agitation and then filtered. Separation and detection were done in GC-FID (6890N, Agilent Technologies, USA), using a HP-5 (5% phenylmethyl siloxane) capillary column (30 m, 320 µm, 0.25 μm) and 5N pure nitrogen gas as the carrier gas at 1.0 ml/min flow. Air and hydrogen flow were 400 ml min−1 and 60 ml min−1, respectively. A 5-µl liquid tight Hamilton syringe was used for injecting the 1-µl sample with split ratio 5:1. The injector and detector temperatures were 200 and 250 °C, respectively. The oven temperature of GC was programmed for 50 °C and held for 2 min, raised to 100 °C at a rate of 20 °C min−1 and held for 0 min, then raised to 150 °C at a rate of 30 °C min−1 and held for 2 min, and again raised up to 180 °C at a rate of 40 °C min−1 and held for 8 min. Total run time was 32 min including cooling time.

Both front and back sections of the both tubes were analysed separately to ensure no sample remain in back section, i.e. small part of the sorbent’s tubes. Recovery of analytical method was tested by known amount of the standard solution; average recovery of > 95% was obtained. To check the blank value for the sorbent tubes, same analytical measurement procedure was carried out using sorbent tubes without sampling. A 5-point calibration curve was obtained for each component separately by standard solution of BTEX in acetone by GC-FID. The concentration of standard solutions was 1 ppm, 2 ppm, 5 ppm, 10 ppm, and 20 ppm, and the linear correlation coefficient values of 0.999, 0.996, 0.997, 0.998, 0.999, and 0.996 were obtained for benzene, ethylbenzene, toluene, and o-xylene, p-xylene, and m-xylene, respectively.

3 Health risk assessment methodology

The Environmental Protection Agency (EPA) has updated approach for estimation of the human health risk associated with inhalation exposure to contaminated air by the Inhalation Dosimetry Methodology in part F (USEPA, 2009). The exposure concentrations (ECs) are estimated by EPA recommended method (USEPA, 2009) for each receptor exposed to contaminants via inhalation pathway. The cancer risk and non-cancer risk of BTEX pollutants through inhalation pathway are determined by estimating EC for these contaminants. In the inhalation dosimetry methodology, when estimating human health risk via inhalation route, the concentration of contaminants in air is used as the exposure metric (EC in mg/m3) in RAGS, part F (USEPA, 2009) rather than inhalation intake of a contaminant in air based on inhalation rate (IR) and body weight (BW) present in RAGS, part A (USEPA, 1989). The EC typically takes the form of a CA (concentration in ambient air) that is time-weighted average over the duration of exposure.

Benzene is responsible for the carcinogenic risk (CR), i.e. calculated maximum risk using Eq. 1 considering mean exposure concentration continuously inhaled by worker at workplace. Exposure concentration was calculated using Eq. 2. The noncarcinogenic risks for all BTEX pollutants were estimated by using Eq. 3. Inhalation unit risk (IUR) and toxicity values (RfC) published for inhalation route are used for cancer and non-cancer health risk assessment.

The CR is calculated using Eq. (1).

where CR is the excess cancer risk and IUR is the inhalation unit risk of benzene. The IUR of benzene is 0.0000078 (µg/m3)−1 as give in the Risk Assessment Information System (RAIS) (RAIS, 2010).

The EC of employees is calculated using Eq. (2).

where,

EC (µg/m3) = Exposure concentration

CA (µg/m3) = Contaminant concentration in air

ET (h/day) = Exposure time (8 h/day for workers)

EF (days/week) = Exposure frequency (6 days/week; working days at fuel station)

ED (weeks/exposure period) = Exposure duration (here 4 weeks/month)

AT (hours/exposure period) = Averaging time

IUR (µg/m3)−1= Inhalation unit risk

All the risk assessment parameter values used in Eq. (2) are given in Table 1.

The CR value ˃ 1 × 10−6 was considered as carcinogenic effects of concern; a value ≤ 10−6 was considered as an acceptable level (Zhang et al., 2012). For all BTEX compounds, risk assessment for non-cancer risk was expressed by HQ value, calculated according to the following equation:

where RfC is the inhalation toxicity value in mg/m3. RfC values for benzene, toluene, xylenes, and ethylbenzene are 0.03, 5, 0.1, and 1 mg/m3, respectively (USEPA, 2009https://iris.epa.gov/AtoZ/?list_type=alpha).

The value of HQ ˃ 1 indicates adverse noncarcinogenic effects of concern, and a value HQ of ≤ 1 was considered as an acceptable level (Zhang et al., 2012).

At fuel station, exposure of all the pollutants in BTEX occurs simultaneously; hence, hazards from multiple chemicals can be summed to calculate hazard index (HI) as per Eq. 4 given in RAGS, part F (USEPA, 2009).

where HQ i is the hazard quotient of the ith pollutant.

4 Result and discussion

4.1 BTEX concentrations at fuel station

The monthly variation in BTEX concentration measured using both Tenax and charcoal sorbent tube from September 2021 to March 2022 at the fuel station is given in supplementary Table S1 and graphically depicted in Fig. 2a and b, respectively. The variation in the BTEX concentration during different months may be attributed to different meteorological factors like temperature, humidity, and precipitation. The monthly average meteorological parameter such as wind speed, wind direction, and temperature data was taken from nearby online monitoring stations and given in Table 2. The concentration of all the species in November month was found to be comparatively higher than other months. In November month, sampling was done before Deepawali festival. During that period, the usage of paints, household decoration items, and furniture work is high comparatively other months. So, these factors may also affect the concentrations of benzene and toluene. Some studies reported high concentration of BTEX in renovated homes than in old homes, and this situation remained at least 5 years (Liu et al., 2013) (Du et al., 2014). In January month, the observed BTEX concentration was low because sampling was done after rainy days, i.e. low concentration can be justified by washing out of atmosphere, high solubility of BTEX in water which is also supported by other studies (Rattanajongjitrakorn & Prueksasit, 2014). Wind direction and speed may also be the other reasons. The online monitoring data of benzene from DPPC-PUSA given in Table S2 also showed the same pattern in January as shown in its graphical representation Fig. 4.

To determine the relation between the benzene concentrations measured by Tenex sorbent tube with meteorological variables, the correlation coefficients have been calculated. The correlation strength was evaluated in terms of magnitude of r-values. The results revealed that the benzene concentration is negatively correlated with temperature (−0.525) and wind speed (−0.298) and given in Table S4.

From pollution rose and polar plot, Fig. 3, it is clearly seen that benzene concentration is observed high when wind speed is slow and blew from SE-SW direction. So, at lower wind speed, the concentration of pollutant is high, whereas at higher wind speed, the concentration becomes low due to dispersion.

Figure 4 and Table S2 represent the DPCC-PUSA ambient air benzene data taken from CPCB site for the same duration from September 2022 to March 2022 in which the lowest benzene concentration (0.34 μg/m3) was observed in month of September and highest concentration (14.94 μg/m3) was observed in the month of December (CPCB https://www.cpcb.nic.in/).

Table 3 shows the maximum, minimum, and 7-month average of BTEX concentration with standard deviation during overall study at the fuel station. The average concentration of benzene, toluene, ethylbenzene, m-, p-xylene, and o-xylene at the fuel station was observed as 112 ± 54, 219 ± 159, 85 ± 20, 104 ± 76, and 95 ± 66 μg/m3 for Tenax and 84 ± 40, 168 ± 135, 71 ± 22, 84 ± 64, and 77 ± 51 μg/m3 for charcoal sorbent tubes, respectively. It is clearly seen in Table 3 that the concentration of toluene is maximum for both the sorbent tubes, i.e. (507 ± 11) µg/m3 and (418 ± 9) µg/m3 for Tenax and charcoal tubes, respectively. Benzene concentration was observed second high (217 ± 9) µg/m3 and (158 ± 9) µg/m3 for both sorbent tubes out of BTEX. The maximum concentration of toluene throughout the measurement time can be attributed to the fuel composition as toluene is added to the fuel to increase the octane rating, and also, it is having the maximum density among BTEX (Salameh et al., 2019). Vapour pressure of benzene and toluene is more as compared to other two components (Lide, 1996), which may also contribute in the higher observed values. Also, long lifetime of benzene and toluene, 12.5 and 2.0 days, respectively, in ambient air, might be the other reason. But xylene have lifetime 7.8 h only, hence not exist long time into atmosphere. Concentration of xylene, and ethylbenzene, was found to be low as compared to benzene and toluene which may be attributed to their more photochemical reactive nature as compared to benzene and toluene (Kashyap et al., 2019). Literature data given in Table 5 also depicts the same BTEX concentration variation trend in fuel.

The concentration of benzene observed at fuel station is more than the annual TWA limit given in NAAQS, i.e. 5 μg/m3 but not exceed the occupational exposure limit given by OSHA and NIOSH (2007). Online recorded concentration of benzene from DPCC-PUSA station mostly exceed the NAAQS limit, i.e. 5 μg/m3 given by CPCB in ambient air. Standard exposure limit of BTEX is given in OSHA and NIOSH shown in Table 4. However, it may be noted from health perspective of worker at fuel station that the benzene concentration inhaled is at high level.

BTEX concentration is found to be higher in Tenax tube samples as compared to charcoal tube samples which might be due to the more efficient adsorbing nature of Tenax as compared to charcoal for VOCs (Tomasz, 1998). Also, the toluene concentration is the highest among all BTEX which is supported by all other studies done at petrol pumps in different countries including India as given in Table 5. It represents the data of BTEX studies done at fuel stations in different countries including India which also support the current study data. It also shows that some of the studies reported higher BTEX levels.

In Delhi, the VOCs measurement studies were usually done before the implementation of vapour recovery system (VRS) at fuel stations. A detailed study of measurement of VOCs at petrol pumps in Delhi is reported by TERI—the nergy and Resource Institute (Sehgal et al., 2011), and the results are given in Table 5. The current study represents a fuel station VOCs data for 7-month measurement where VRS is fully implemented. Also, the sampling time was afternoon when the temperature was the highest (35–40 °C), and hence, evaporation is also high. So, the values given in Table 5 in current study are the maximum average of the 7-month study. The percentage abundance of BTEX is shown as pie chart in Fig. 5 in which toluene is the most abundant species, i.e. approximately 35% which is consistent with earlier reported results (Table 5). Other species benzene, m-, p-xylene, o-xylene, and ethylbenzene estimated as 18%, 17%, 16% and 14%, respectively, of the total BTEX concentration.

4.2 Health risk assessment

High vapour pressure and longer half-life of BTEX make it important to measure their concentration and associated health risk. Cancer and non-cancer risk assessment of worker were determined by estimating exposure concentration (EC) considering inhalation pathway following the updated USEPA method given in RAGS, part F. The estimated cancer risk (CR) of benzene calculated using Eqs. (1) and (2) and non-cancer risk (HQ) of benzene, toluene, ethylbenzene, m-, p-xylene, and o-xylene was calculated as per Eq. (3). The monthly average CR values calculated for benzene are given in Table S3. The cancer risk value for benzene exposure is found to be > 10−6 hence higher than acceptable limit prescribed. It is a matter of concern for occupational health of workers. Maximum value of cancer risk for benzene (1.6 × 10−3) was observed in November month as the concentration of benzene is found to be high in this month. Table 6 represents the individual HQ values for all the components and the mean cancer risk with standard deviation for workers exposed to benzene for Tenax sorbent tubes.

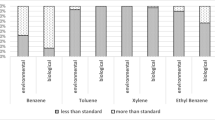

In current study, the exposure of BTEX concentration at fuel station for non-cancer health risk is estimated in form of HQ value which exceeds the unit value for benzene as shown in Table 6. The value HQ > 1 indicates adverse noncarcinogenic effects of concern. The HQ values for toluene and ethylbenzene are very less. The order of HQ value is benzene > m-, p-xylene > o-xylene> ethylbenzene > toluene by Tenax sorbent tubes. Hazard index (HI) was calculated by summation of average HQ value as per Eq. (4). The value of HI was found as 5.86 for Tenax sorbent tubes (HQ values to calculate HI is given in Table 6). HI > 1 indicates adverse human health risk due to reported concentration in this study.

Benzene being carcinogenic, exposure concentration (EC) is estimated on the basis of 7-month average concentration of benzene in air (i.e. CA) at fuel station using ET = 8 h/day, EF = 6 days/week, ED = 30 weeks, and AT (averaging time in hours for 7-month exposure duration). EC for ambient air monitoring site of CPCB (DPCC-PUSA) is estimated on the basis of 7-month average concentration of benzene in ambient air (CA) using ET = 24 h/day, EF = 7 days/week, ED = 30 weeks, and AT (averaging time in hours for same duration). Equations (1), (2), and (3) are used for the estimations of CR, EC, and HQ. Comparison of non-cancer hazard (HQ) and cancer risk (CR) for benzene for both types of exposure scenario is shown in Table 7.

Worldwide, very few studies are focused on the exposure risk assessment of BTEX following original RAGS approach given in part A, USEPA 1989, which was based on inhalation rate (IR) and body weight (BW) of the receptor (Zhang et al., 2012, Hazrati et al., 2015). The HQ value reported was 27.95 in one of the similar study done at refuelling station in Iran (Hazrati et al., 2015) using the older approach. RAGS-part A approach was used before EPA issued the inhalation dosimetry methodology. In this paper, the estimation of risk is as per the USEPA updated method given in RAGS-part F (USEPA 2009) in which IR and BW are not used, but exposure concentration is estimated as per Eq. (2) which can be used for both short-term and long-term exposure.

5 Conclusion

BTEX concentration was observed for 7 months at fuel station in Delhi which had implemented the vapour recovery systems (VRS), to assess the occupational exposure for the workers. The 7-month average concentration of benzene is found to be (112 ± 54) and (84 ± 40) µg/m3 using Tenax sorbent and charcoal sorbent, respectively. The standard deviation in 7-month benzene concentration is almost 50% for both types of sorbent tubes, and also, the same deviation was observed at online monitoring station for the time period under study. The deviation observed in monthly concentration of benzene at fuel station varies from 6 to 11% (Table S1) for both types of sorbent tubes. The concentration of BTEX was found highest in the month of November implying fuel frequency, anthropogenic activities along with the meteorological parameters like wind speed and directions. Among the BTEX compounds, toluene has the highest average concentration followed by benzene, xylenes, and ethylbenzene. However, none of these compound’s concentration at fuel station air observed is higher than short-term exposure (STEL) limits recommended by NIOSH-REL and OSHA-PEL. Also, the estimation of cancer risk (CR) and non-cancer adverse effect (HQ) is done on the basis of updated RAGS approach part F of USEPA. The assessment of health risk for benzene on the basis of data reported reveals that the CR value for benzene is > 10−6 which is of major concern for the occupational health of workers at fuel station. Additionally, the benzene concentration at fuel station is compared with typical outdoor ambient air benzene concentration (higher than reported NAAQS limit of 5 µg/m3) to compare the occupational health risk. CR value and HQ values of benzene for the 7-month exposure are compared, and in both cases, these are > 10−6. The average CR value is estimated to be 9 × 10−4 ± 4 × 10−4 which is having the same 50% variation as shown in the benzene concentration in 7 months for Tenax sorbent tubes. The HQ value for fuel station is found to be 26 and 20 using Tenax and charcoal sorbent tubes, respectively, which is almost ≥ 20 times the WHO limit (i.e. 1) and is of major concern for non-cancer adverse health effects of benzene. Also, the assessment of biological exposure is needed as in some literature (Chauhan et al., 2014), it is reported that 50% of inhaled BTEX is absorbed in body. Long-term exposure to the benzene may lead to both cancer and non-cancer health risks for the workers of fuel station, so effective control measures are needed for ensuring the proper functioning and servicing of VRS at fuel station.

References

Caselli, M., Gennaro, de, G., Marzocca, A., Trizio, L., & Tutino, M. (2010). Assessment of the impact of the vehicular traffic on BTEX concentration in ring roads in urban areas of Bari (Italy). Chemosphere, 81(3), 306–311. https://doi.org/10.1016/j.chemosphere.2010.07.033

Chauhan, K Sippy, et al. (2014). Recent trends of volatile organic compounds in ambient air & its health impacts: a review. International Journal for Technological Research in Engineer, 1, 2347–4718.

Chaurasia, Sadhana, & Ashok, Kumar, Tiwari. (2018). Status of benzene, toluene and xylene near petrol pumps of Satna city M.P. International Journal of Applied Research and Technology, 2(6), 257–263. https://doi.org/10.24163/ijart/

Correa, S.-M., Arbilla, G., Marques, M.-R.-C., & Oliveira, K.-M.-P.-G. (2012). The impact of BTEX emissions from gas stations into the atmosphere. Atmospheric Pollution Research, 3(2), 163–169. https://doi.org/10.5094/APR.2012.016

CPCB Central Pollution Control Board. (2009). Retrieved June 2, 2022. from https://www.cpcb.nic.in/

Dennison, J.-E., Bigelow, P.-L., Mumtaz, M.-M., Andersen, M.-E., Dobrev, I.-D., & Yang, R.-S. (2005). Evaluation of potential toxicity from co-exposure to three CNS depressants (toluene, ethylbenzene, and xylene) under resting and working conditions using PBPK modeling. Journal of Occupational and Environmental Hygiene, 2(3), 127–35.

Du, Z., Mo, J., Zhang, Y., & Xu, Q. (2014). Benzene, toluene and xylenes in newly renovated homes and associated health risk in Guangzhou, China. Building and Environment, 72, 75–81. https://doi.org/10.1016/J.BUILDENV.2013.10.013

Egeghy, P.-P., Tornero-Velez, R., & Rappaport, S.-M. (2000). Environmental and biological monitoring of benzene during self-service automobile refueling. Environmental Health Perspectives, 108(12), 1195–1202. https://doi.org/10.1289/EHP.001081195

Eisaei, H.-R., Dehrashid, A., Shaho, S., Khani, M.-R., & Hashemi, S.-M. (2015). Assessment and control of VOCs emitted from gas stations in Tehran. Iran. Pollution, 1(4), 363–71.

EPA (Environmental Protection Agency) (2010) Toxicological review of. Rev. Lit. Arts Am. 39, 759–786. https://doi.org/http://www.epa.gov/iris/toxreviews/0070tr.pdf.

Esmaelnejad, F., Hajizadeh, Y., Pourzamani, H., & Amin, M.-M. (2015). Monitoring of benzene, toluene, ethyl benzene, and xylene isomers emission from Shahreza gas stations in 2013. International Journal of Environmental Health Engineering, 4(1), 17. https://doi.org/10.4103/2277-9183.157716

Franco, M., Chairez, I., Poznyak, T., & Poznyak, A. (2012). BTEX decomposition by ozone in gaseous phase. Journal of Environmental Management, 95, S55-60. https://doi.org/10.1016/j.jenvman.2011.09.009

Hazrati, S., Rostami, R., Fazlzadeh, M., & Pourfarzi, F. (2015). Benzene, toluene, ethylbenzene, and xylene concentrations in atmospheric ambient air of gasoline and CNG refueling stations. Air Quality, Atmosphere & Health, 9(4), 403–409. https://doi.org/10.1007/S11869-015-0349-0

Kashyap, Prabhat, Kumar, Amit, & Kumar, Krishan. (2019). BTEX concentrations and associated health risks at urban vegetative sites in Delhi India. Environmental Claims Journal, 31(4), 349–365. https://doi.org/10.1080/10406026.2019.1640441

Lide, D. R. (1996). Handbook of Chemistry and Physics. CRC Press.

Liu, Q., Liu, Y., & Zhang, M. (2013). Personal exposure and source characteristics of carbonyl compounds and BTEXs within homes in Beijing, China. Building and Environment, 61, 210–216. https://doi.org/10.1016/J.BUILDENV.2012.12.014

Lloyd, A.-C., Denton, J.-E. (2005) Technical support document for describing available cancer potency factors. Secretary for Environmental Protection California Environmental Protection Agency.

NIOSH POCKET GUIDE TO CHEMICAL HAZARDS, (2007). (NIOSH) DHHS. 2005-149. http://www.cdc.gov/niosh

Rattanajongjitrakorn, P., & Prueksasit, T. (2014). Temporal variation of BTEX at the area of Petrol Station in Bangkok, Thailand. APCBEE Procedia, 10, 37–41. https://doi.org/10.1016/J.APCBEE.2014.10.011

Rezazadeh, A. M., Naghavi Konjin, Z., Zayeri, Salehpour, F. S., & Seyedi, M. (2012). Occupational exposure of petroleum depot workers to BTEX compounds. International Journal of Occupational Environmental Medicines, 3(1), 39–44.

Risk Assessment Information System [RAIS]. (2010). Toxicity profile. http://rais.ornl.gov/tools/tox_profiles.html

Salama, K., Omer, E., & Zafar, M. (2021). Assessment of BTEX concentration around fuel station in Eastern Province Kingdom of Saudi Arabia. International Journal of Environmental Health Engineering, 10(1), 2. https://doi.org/10.4103/IJEHE.IJEHE_8_19

Salameh, T., Sauvage, S., Locoge, N., Gauduin, J., Perrussel, O., & A.B., Orbon. (2019). Spatial and temporal variability of BTEX in Paris megacity: Two-wheelers as a major driver. Atmospheric Environment :X, 1, 10003. https://doi.org/10.1016/j.aeaoa.2018

Sandhya, Chaudhary, & Ashok, Kumar. (2012). Study on refueling pump stations caused by BTEX compounds in Firozabad city. International Archive of Applied Sciences and Technology, 3(2), 75–79.

Sehgal, Meena, et al. (2011). Variation in air quality at filling stations, Delhi, India. International Journal of Environmental Studies, 68(6), 845–849. https://doi.org/10.1080/00207233.2012.620320

Srivastava, A., Joseph, A.-E., More, A., & Patil, S. (2005). Emissions of VOCs at urban petrol retail distribution centres in India (Delhi & Mumbai). Environmental Monitoring and Assessment, 109, 227–242. https://doi.org/10.1007/s10661-005-6292-z

Tomasz, et al. (1998). Sorbents for trapping organic pollutants from air. International Journal of Occupational Safety and Ergonomics, 4(2), 153–167. https://doi.org/10.1080/10803548.1998.11076387

Tunsaringkarn, T., Siriwong, W., Rungsiyothin, A., & Nopparatbundit, S. (2012). Occupational exposure of gasoline station workers to BTEX compounds in Bangkok, Thailand. International Journal of Occupational Environmental Medicines, 3(3), 117.

US EPA (United States Environmental Protection Agency). (2002). Toxicologycal Review of Benzene, Washington, D.C. EPA/635/R-02/001F.

US EPA (United States Environmental Protection Agency) (1989) Risk Assessment Guidance for Superfund, Volume 1, Part A. Office of Emergency and Remedial Response, Washington,D.C.EPA/540/1-89/002. http://www.epa.gov/oswer/riskassessment/ragsa/index.htm

US EPA (United States Environmental Protection Agency). (2009). Risk Assessment Guidance for Superfund (Part F, Supplemental Guidance for Inhalation Risk Assessment. https://www.epa.gov/risk/risk-assessment-guidance-superfund-rags-part-f

WHO. (2010). WHO guidelines for indoor air quality: selected pollutants (p. 38) https://apps.who.int/iris/rest/bitstreams/1095016/retrieve .

Zhang, Yujie, Mu, Yujing, Liu, Junfeng, & Mellouki, Abdelwahid. (2012). Levels, sources and health risks of carbonyls and BTEX in the ambient air of Beijing. China. Journal of Environmental Sciences, 24(1), 124–130. https://doi.org/10.1016/S1001-0742(11)60735-3.100003

Acknowledgements

Poonam Kumari and Gazal are thankful to Council of Scientific and Industrial Research (CSIR) for providing the fellowship under CSIR-SRF scheme (P-81-101). Authors thank the director, CSIR-NPL, for providing a platform to carry out experimental work and for providing research facilities under OLP 210332. Authors are also thankful to head of ESBM Division (CSIR-NPL) and all staff members of Gas Metrology for their encouragement and support.

Author information

Authors and Affiliations

Contributions

Daya Soni conceptualised the research idea and supervise the research activity planning and execution. Poonam Kumari and Gazal (Ph. D Students) did the sampling, and analysis. Poonam Kumari did data interpretation and wrote the original draft. Shankar G aggarwal and Daya Soni reviewed the article along with discussion of results with all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1:

Table S1. Monthly Average data of BTEX in µg m-3 for Tenax & Charcoal sorbent tubes from September 2021 to March 2022 at a fuel station in Delhi. Table S2. Online monitoring data of benzene (µg m-3) in ambient air from DPCC-PUSA. Table S3. Cancer Risk (CR) value of benzene for both the sorbent tube. Table S4. Correlation of benzene concentration ((µg m-3) with meteorological parameter. Fig. S1. Schematic diagram of Fuel pump and Sampling point orientation at the fuel station.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kumari, P., Garg, G., Soni, D. et al. Measurement of benzene and other volatile organic compounds: implications for its inhalation health risk associated with the workers at a fuel station in Delhi. Asian J. Atmos. Environ 17, 7 (2023). https://doi.org/10.1007/s44273-023-00007-8

Accepted:

Published:

DOI: https://doi.org/10.1007/s44273-023-00007-8