Abstract

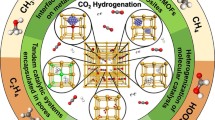

Catalytic CO2 hydrogenation to valuable chemicals is an excellent approach to address the increasingly serious “greenhouse effect” caused by CO2 emission generated from the utilizations of nonrenewable fossil energies, while such a process is limited by chemical inertia and thermal stability of the CO2 molecule and complex hydrogenation routes. In this review, we first summarized the recent progresses of metal-oxide nanocatalysts considered as a category of the most promising catalysts in CO2 hydrogenation to value-added C1 chemicals including CH4/CO, formic acid/formate, and methanol. These studies involve with different structural factors affecting the metal-oxide interfacial catalysis including the structures of both the metals (type, particle size, morphology/crystal plane, and bimetal alloy) and the supports (type, particle size, crystal phase, morphology/crystal plane, and composite) and their (strong) metal-support interactions so as to identify the key factor determining the reaction activity, product selectivity, and catalytic stability in CO2 hydrogenation. Finally, we further discuss challenging coupling with future research opportunities for tunable interfacial catalysis of metal-oxide nanocatalysts in CO2 conversion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the industrial revolution in the eighteenth century, the increasing human activities in the utilization of fossil fuels (coal, oil, and natural gas) have been gradually breaking the balance of the carbon cycle in nature, leading to a dramatic increase of the CO2 concentration in the atmosphere from ~ 280 ppm before the industrial revolution, to above 400 ppm today, and predicted to be ~ 570 ppm by the end of this century [1, 2]. The increasing amount of CO2 emission as one of the major components of greenhouse gases impacts negatively on global temperature, climate change, and ocean acidification [3, 4]. Considering these, the leading countries in CO2 emission have pledged to reduce CO2 concentration in the atmosphere in the near future, including ours, which has set goals of “Carbon peak” in 2030 and “Carbon neutrality” in 2060. To address so, reducing anthropogenic CO2 emission is the optimal approach, nonetheless, it is still difficult to realize this idea due to increasing human demands for energy from utilization of fossil fuels.

Taking CO2 as the feedstock reacting with green hydrogen (H2) to produce value-added chemicals such as formic acid (FA), alcohols, and hydrocarbons is considered as a more efficient route to cope with this issue [1, 2, 5,6,7,8,9,10], while this process proceeds very slowly due to highly chemical inertia of CO2 though it is reachable in view of thermodynamical point. Catalytic CO2 hydrogenation can (selectively) accelerate the reaction to reach the equilibrium without structural changes of the catalysts. The core of a catalytic reaction is the catalyst, thus, choosing suitable catalysts for efficient CO2 conversion is crucial. Nowadays, there are mainly two categories of heterogeneous catalysts in this reaction reported in literature, respectively are zeolite-based catalysts [11, 12] and oxide-based catalysts [13, 14]. In terms of a diversity of redox and acid–base properties, the oxide-based catalysts have been widely used to exhibit excellent performance in CO2 hydrogenation [13,14,15,16]. For instance, ZnO has been demonstrated as a superb support to use in commercial CO2-containing syngas to methanol process back to 1960s [15].

As the most typical category in oxide-based catalysts, the metal-oxide nanocatalysts have been frequently used in CO2 hydrogenation [17,18,19,20]. It has been widely recognized that the catalysis of metal-oxide nanocatalysts arises from the synergetic effect of metal-oxide interfaces [13, 21,22,23,24,25], whose structures are determined by the nature of both the metals and the oxides, and their metal-oxide interactions [24, 26,27,28]. As known to us, catalytic CO2 hydrogenation to desirable products is challenging because of chemical inertia and thermal stability of the CO2 molecule with a high C = O bond energy of 806 kJ mol−1 and a π34 bond, and complex catalytic hydrogenation routes [29]. Therefore, tailoring the interfacial structures of metal-oxide nanocatalysts by smart designs are contributive to accurate the identification of catalytic active sites and fundamental understanding of catalysis mechanism, consequently, guiding the catalyst design for CO2 hydrogenation to desirable products.

In this review, we devote to summarizing present studies of the interfacial catalysis of metal-oxide nanocatalysts in CO2 hydrogenation to value-added C1 chemicals including CH4/CO, FA/formate, and methanol. The purpose of this work is not to recollect relevant literature regarding the interfacial catalysis of metal-oxide nanocatalysts in CO2 hydrogenation but rather to explore the factors (types, particle sizes, bimetal, crystal phase, morphology/crystal plane, composites etc.) affecting the interfacial structures and subsequently their interfacial catalysis in CO2 hydrogenation so as to unveil the key factors determining the activity and selectivity for CO2 conversion (Fig. 1). This review is organized as follows: a review of the interfacial catalysis in CO2 hydrogenation to CH4/CO via an atmospheric reaction (Section 2), FA/formate via a high-pressure batch reaction (Section 3), methanol via a high-pressure flow reaction (Section 4), and ending with a summary and outlook where future opportunities and challenges in elucidating the interfacial catalysis for guiding the catalyst design in CO2 hydrogenation are outlined.

2 Methane / Carbon monoxide

As one of the typical conversion processes of inert CO2 to value-added C1 chemicals [30,31,32,33], CO2 hydrogenation under atmospheric pressure can generate two competitive products of CH4 and CO, respectively arising from the Sabatier reaction (Eq. 1) and the reverse water–gas shift reaction (RWGS, Eq. 2). Such a process is of importance for the sustainable development of human society with many potential commercial applications [34,35,36]. For instance, the renewable CH4 gas from CO2 hydrogenation could be utilized in the existing natural gas infrastructure to replace the underground natural gas sources, as well as efficiently used in the fuel cell and ammonia synthesis industry to remove trace CO from H2-rich atmosphere to avoid catalyst poisoning [35, 37], while the CO is valuable as one of the feed gases in the Fischer–Tropsch synthesis to produce CH3OH or long-chain hydrocarbons [38, 39]. Thermodynamically, CO2 hydrogenation to CH4 is an exothermic reaction (Eq. 1, ∆H298K = -165 kJ mol−1) and thus highly favored at low temperature. On the contrary, the competitive RWGS reaction is endothermal (Eq. 2, ∆H298K = 41.2 kJ mol−1) and normally generates CO at elevated reaction temperatures [40]. A significant challenge in this reaction is to tune the selectivity towards desirable products with a high conversion efficiency due to high chemical inertness of CO2 molecule and competitive reaction pathways of CO2 hydrogenation [13].

It has been extensively validated that oxide-supported metal catalysts exhibit excellent performance in this reaction and have drawn considerable attentions [41,42,43]. Previous studies revealed that the catalytic performance of oxide-supported metal catalysts in CO2 hydrogenation is sensitive to the metal-oxide interfaces whose structures are determined by both the oxide supports and the supported metals, and their metal-support interactions (MSIs) [13, 23, 24, 44, 45]. Over the past decade, different factors, including the type [23, 46,47,48,49,50], the particle size [24, 26, 51,52,53,54,55,56,57], and the bimetal alloying degree [58,59,60,61,62,63,64,65] of supported metals, and the type [21, 46, 66,67,68,69,70,71,72], the morphology/crystal plane [23, 24, 73,74,75,76,77,78,79,80], and the composite [72, 81,82,83,84,85,86,87,88] of the supports, as well as the (strong) MSIs [23, 28, 89,90,91,92,93,94,95,96], have been comprehensively investigated to elucidate the interfacial catalysis of oxide-supported metal catalysts in this reaction. In this section, we will focus on the discussions of these structural factors in affecting the interfacial properties and thus the catalytic performance, in order to unveil the key factors determining the activity and selectivity of CO2 hydrogenation catalyzed by oxide-supported metal catalysts.

2.1 The nature of supported metals

Supported metal nanoparticles (NPs) play crucial roles in CO2 hydrogenation, which not only serve as the active sites for H2 activation, but also act as adsorption sites of CO intermediate to contribute to the generation of CH4 [23, 24, 57]. Consequently, the catalytic performance is strongly dependent on the nature of supported metals [46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65]. Apparently, the type of supported metals directly determines their properties. The commonly-used metals in CO2 hydrogenation contain Ni, Ru, Rh, Co, and Pd etc., where the inherent nature of metals determines the H2 dissociation and hydrogenation performance [23, 46,47,48,49,50]. For instance, Quindimil et al. [47] reported that 4%Ru/Al2O3 catalyst was quite more active than 12%Ni/Al2O3 in CO2 hydrogenation, which is probably due to the H2 dissociation capacity greater on the Ru sites. Similarly, Panagiotopoulou’s group [48] compared the catalytic performance of different metals supported on TiO2 in CO2 hydrogenation and found the turnover frequencies (TOFs) follow an order of Rh > Ru > Pt > Pd (Fig. 2a). Moreover, the CH4 productions over supported Rh and Ru catalysts are significantly higher than those over supported Pt and Pd catalysts (Fig. 2b), which is mainly ascribed to stronger CO adsorption capacities for the former two to facilitate the reaction of adsorbed CO species with hydrogen atoms to produce CH4. Our group also compared two commonly-used metals (Ru and Ni) supported on ZnO for CO2 hydrogenation [23]. Solid experimental evidences confirm the product selectivity is determined by the binding strength of adsorbed CO species on metal sites. A weak CO adsorption capacity on Ni sites contributes to high CO selectivity on all Ni/ZnO catalysts (Fig. 2c1 and c2), while CH4 is preferentially produced on Ru/ZnO catalysts with stronger CO binding capacity on low-coordination Ru sites (Fig. 2d1 and d2). As a result, Ru/p-ZnO catalyst possessing more amount of low-coordination Ru species induced by stronger Ru-ZnO interactions contributes to higher CH4 selectivity (Fig. 2d2).

(a) CO2 conversions as a function of reaction temperatures and (b) product selectivity at 350 oC obtained over Rh, Ru, Pt and Pd catalysts (0.5 wt.%) supported on TiO2. (c1, c2) CO selectivity and in situ CO-DRIFTS spectra of different Ni/ZnO catalysts. (d1, d2) CH4 selectivity and in situ CO-DRIFTS spectra of different Ru/ZnO catalysts. Reprinted with permission from Refs. [23] and [48], Copyright 2022 and 2017, Elsevier

Besides the types, another key factor affecting the interfacial catalysis is the particle size of supported metals, which strongly varies the geometric and electronic structures and thus largely affects their catalytic behaviors [24, 26, 51,52,53,54,55,56,57]. This phenomenon has been frequently observed over supported Ni catalysts [52,53,54, 56, 57]. Hao et al. [52] reported that the CO2 conversion efficiency decreases with increased Ni particle size from 8 to 21 nm, which could be related to the Ni-CeO2 interactions and the available surface oxygen vacancies that promote the CO2 activation. Adversely, the results reported by Lin et al. [53] revealed the catalytic performance catalyzed by Ni/CeO2 catalysts increase with the Ni particle size growing from 2 to 8 nm, which is demonstrated to be associated with the enhanced hydrogenation property over larger Ni particles. Similar results were also observed by ours [57]. In our previous study, via finely altering the particle size of supported Ni species on CeO2 from nearly-atomic dispersion to large NPs (Fig. 3a-c), a series of Ni/CeO2 catalysts were prepared and subsequently used for CO2 hydrogenation. The results reveal that both the catalytic activity and the CH4 selectivity increase with the Ni particle size growing up (Fig. 3d and e). With the increased Ni loading accompanied by increased Ni particle size, more interfacial oxygen vacancies probed by a combination of XPS and Raman spectra are responsible for the adsorption and activation of CO2 that is regarded as the key step for CO2 hydrogenation, beneficial for the reaction activity; Moreover, the increased mentality of supported Ni species is not only in favor of the H2 dissociation and hydrogenation properties, but also greatly enhances the CO binding capacity, jointly contributing to the generation of CH4.

(a-c) Representative TEM images with corresponding size distributions of NiO nanoparticles. (d) Catalytic activity and (e) product selectivity of CO2 hydrogenation over various Ni/CeO2 catalysts at 290 °C. Reprinted with permission from Ref. [57], Copyright 2022, American Chemical Society

The introduction of an additional metal into the catalyst system can efficiently contribute to reaction activity and stability, and tunable selectivity, which mostly arise from the modified electronic properties and dispersions of active sites via the formation of bimetal alloys [58,59,60,61,62,63,64,65]. Typically, Guo et al. [58] reported that the increased percentage of In atoms in In-Ni intermetallic compounds can facilitate the CO production from CO2 hydrogenation via the RWGS reaction (Fig. 4a), which could be ascribed to the inhibited CO adsorption at increased In/Ni ratio by isolating the active site of Ni species. In addition to the activity, the formation of bimetal alloy can also promote the product selectivity. The results reported by Wang et al. [59] found that the atomically-dispersed Zn species can stabilize a higher valence state of Ni (Niδ+) over NiZn/ZrO2 catalysts, leading to the product selectivity in CO2 hydrogenation shifting from CH4 to CO (Fig. 4b). Furthermore, the enhanced stability was also realized after introducing an additional metal. Mutz et al. [60] revealed that, compared to commercial Ni-based methanation catalyst, an improved activity and most notably a high stability were observed over Ni3Fe catalyst (Fig. 4c). Kinetic measurements demonstrate the superior performance for Ni3Fe catalyst arising from the intimately synergetic effect between Ni and Fe. These results clearly demonstrate the interfacial catalysis of oxide-supported metal catalysts in CO2 hydrogenation is strongly dependent on the nature of supported metals.

a CO selectivity varying with the In/Ni atomic ratio. b CO2 conversion and CO selectivity for CO2 hydrogenation over different catalysts at 400 °C. c CO2 conversion of the commercial Ni-based methanation and 17 wt % Ni3Fe/Al2O3 catalysts. Reprinted with permission from Refs. [58, 59], and [60], Copyright 2022, 2022, and 2017, American Chemical Society, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim, and American Chemical Society

2.2 The nature of the oxide supports

The support plays a crucial role in CO2 hydrogenation by assisting the dispersion of the active sites, and promoting the activity, selectivity and stability [66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88]. Generally, there are mainly three aspects of the support in affecting the catalyst properties: (1) improving the dispersion of the active sites; (2) weakening the fabrication of the inactive phases; and (3) modifying the reducibility by tuning the active phase-support interactions. Metal oxides have been widely used as catalyst support in CO2 hydrogenation on basis of their unique redox and acid–base properties [13, 14]. The commonly-used oxides contain ZnO, ZrO2, CeO2, Al2O3, Y2O3, and TiO2, among which CeO2 is regarded as a superior catalyst support in CO2 hydrogenation [21, 46, 66,67,68,69,70,71,72]. Díez-Ramírez et al. [66] compared the catalytic performance of different oxides supported Co catalysts in CO2 hydrogenation and found that the catalytic performance in terms of CH4 yield follows an order of Co/CeO2 > Co/ZnO > Co/G2O3 > Co/ZrO2. Spectroscopic results demonstrate that the superior catalytic performance over Co/CeO2 catalyst could be ascribed to the enhanced reducibility that is related to the Co-CeO2 interactions. A large number of studies show that the oxygen vacancies in CeO2 surface are pivotal in CO2 hydrogenation, generally responsible for the activation of CO2 [67, 70, 72]. A typical example was reported by Tada et al. [67], who demonstrate a higher catalytic performance over Ni/CeO2 catalyst than over Ni/α-Al2O3 and Ni/TiO2 catalysts in CO2 hydrogenation (Fig. 5a). This is mainly ascribed to higher surface oxygen vacancy concentrations over CeO2 support that is beneficial for the adsorption and activation of CO2 and thus the CO2 conversion. Moreover, Wang et al. [72] found that the surface oxygen vacancies in CeO2 not only contribute to a much lower activation temperature, but also determine the reaction mechanism (Fig. 5b). In their study, two types of oxides (CeO2 with surface oxygen vacancies and α-Al2O3 without surface oxygen vacancies) were used as supported to load Ru for CO2 hydrogenation. Operando spectroscopy characterizations demonstrate that the CO2 hydrogenation catalyzed by Ru/CeO2 catalyst undergoes a formate route to produce CH4, in which the formate dissociation to methanol over surface oxygen vacancies is the rate-determining step (RDS). On the contrary, a CO reaction route emerges over Ru/α-Al2O3 catalyst due to the absence of oxygen vacancies. These results unravel the active site dependent catalytic mechanism tuned by surface oxygen vacancies for CO2 hydrogenation.

a Effect of support materials on CO2 conversion and CH4 selectivity over Ni/CeO2, Ni/α-Al2O3, Ni/TiO2, and Ni/MgO. b Schematic illustration of the formate route for CO2 methanation over the Ru/CeO2 catalyst. Reprinted with permission from Refs. [67] and [72], Copyright 2012 and 2016, Elsevier and American Chemical Society

According to Wulff’s rule [97], the morphology determines the exposed facets that affect their surface compositions and structures. It is therefore that the morphology effect, also called crystal plane effect, of oxide supports has been extensively investigated in heterogeneous catalysis [98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116], including CO2 hydrogenation [23, 24, 73,74,75,76,77,78,79,80]. As one of the commonly-used oxides, the morphology-dependent catalysis of CeO2-based catalysts in CO2 hydrogenation has been frequently observed over a variety of supported metals including Ru, Ni, Co and Rh [24, 73,74,75,76,77,78, 80]. Wang et al. [73] found the oxygen vacancies in CeO2-based catalysts playing a crucial role in CO2 hydrogenation, serving as the active site for CO2 activation and thus significantly enhancing the low-temperature catalytic activity. By preparing different CeO2 nanocrystal supported Ru catalysts including nanocubes (r-CeO2), nanorods (r-CeO2), and nanopolyhedra (p-CeO2) dominantly exposing {100}, {110}, and {111} facets, they demonstrated that the supported Ru NPs could promote the formation of oxygen vacancies in c-CeO2, resulting in the highest reaction rate observed over Ru/c-CeO2 catalyst. Differently, the best catalytic performance was observed over r-CeO2 for CeO2-supported Co, Ni or Rh catalysts [24, 73,74,75,76,77,78,79,80]. In Xie et al.’s study [76], the superior performance over Co/r-CeO2 catalyst could be correlated to the oxygen vacancies and strong Co-CeO2 interactions that promote the formation of Co0 active species, while the solid frustrated Lewis pair (FLP) structures are preferentially formed over Ni/r-CeO2 catalyst that act as the active sites for enhanced catalytic performance in CO2 hydrogenation.

In our previous report [24], an incipient wetness impregnation method was employed to synthesis the Rh/CeO2 catalysts with different CeO2 morphologies and Rh loadings of around 2 wt. %. Microscopic characterization results reveal the original CeO2 morphologies unchanged after Rh loadings with an averaged Rh particle sizes of ca. 1.5, 2.1 ± 0.4, and 2.6 ± 0.6 nm over Rh/r-CeO2, Rh/c-CeO2, and Rh/p-CeO2 catalysts, respectively (Fig. 6a1-a3). The catalytic performance of these Rh/CeO2 catalysts in CO2 hydrogenation present an order of Rh/r-CeO2 > Rh/c-CeO2 > Rh/p-CeO2 (Fig. 6b), and CH4 is the exclusive product with the selectivities of nearly 100% (Fig. 6c). However, the intrinsically catalytic performance is very similar over three Rh/CeO2 catalysts (Fig. 6d), indicating that the different catalytic activity over these Rh/CeO2 catalysts could be associated with the different density instead of the intrinsic structure of the active sites. Kinetic experiments (Fig. 6e and f) indicate the catalytic performance is determined by the adsorption and activation of CO2, which is further verified by spectroscopic characterizations to exhibit identical interfacial oxygen vacancy concentrations to their catalytic activity (Fig. 6g). These clearly demonstrate the Rh/CeO2-catalyzed CO2 hydrogenation is determined by interfacial oxygen vacancies that varies with the CeO2 morphologies.

(a1-a3) Representative TEM images with corresponding size distributions of Rh nanoparticles. (b) Catalytic activity, (c) CH4 selectivity, (d) Arrhenius plots, reaction orders of (e) CO2 and (f) H2 at 230 °C, and (g) CO2-TPD profiles of various 2%Rh/CeO2 catalysts. Reprinted with permission from Ref. [24], Copyright 2023, American Chemical Society

It is widely accepted that the composite oxides generally possess advantages by inheriting favorable properties of the individual metal oxide supports [72, 81,82,83,84,85,86,87,88]. Taking Al2O3 support as an example [87], the introduction of CeO2 into the Ni/Al2O3 catalysts can remarkably improve the reducibility by altering the Ni-Al2O3 interactions. However, the introduction of TiOx species or ZrO2 was found to greatly suppress the formation of NiAl2O3 spinel phase and weaken the Ni-Al2O3 interactions, resulting in more Ni species exposed and thus promoting the CO2 adsorption capacity. Additionally, it was also found that the Ti4+/Ti3+ pairs can contribute to an electron transfer that increases the electron cloud density of supported Ni species and thus facilitates the CO2 dissociation on catalyst surface. Therefore, the formation of the composite oxides can efficiently improve the catalytic performance of oxide-supported metal catalysts via the modifications of the reducibility, chemisorption capacity, or dispersion of the active species.

2.3 Strong metal-support interactions

The MSIs widespreadly exist for all the supported metal catalysts in different forms, nonetheless, the strength was strongly influenced by various factors, including the electronic properties and geometric structures of oxide support and supported metal NPs as well as their exiting conditions [33, 107]. It has been widely reported that the metal-oxide interfacial structures strongly depend on the MSIs involving diversity electronic transfers and structural evolutions [89, 90, 117]. Consequently, the interfacial catalysis dynamically varies with the MSIs. In other words, optimizing the MSIs could become a superb strategy to tune the metal-oxide interfacial structures and thus their catalytic performance of oxide-supported metal catalysts. Parastaev et al. [89] developed an approach to tune the MSIs via varying the particle size of the support. They prepared a series of ceria-zirconia supported Co catalysts (CoCZ) and the particle size of ceria-zirconia support was varied in a range of 9–120 nm by changing the calcined temperatures of the initial precipitation (Fig. 7a-c). A volcano-like activity trend in CO2 hydrogenation appears with the calcination temperature, at which the CoCZ700 catalyst with an intermediate CZ particle size of ~ 20 nm exhibits the best activity (Fig. 7c and d). The CO2 conversion at 225 °C for CoCZ700 catalyst is ca. 2.9 and 5.8 times higher than those for CoCZ1000 and CoCZ500 catalysts. The characterization results reveal that an optimal strength of the Co-CZ interactions could result in the enhanced stability of supported Co NPs during the reduction conditions. With such an optimal MSI, reverse oxygen spillover from the support during reduction treatment is beneficial for the facile formation of oxygen vacancies in ceria that contributes to the dissociation of CO2 and thus becomes pivotal for the high activity of CO2 hydrogenation to CH4 (Fig. 7e).

EDX mapping of as-prepared a CoCZ500 and b CoCZ700. c Cobalt particle size estimated by X-ray diffraction for calcined and reduced samples and by CO chemisorption for reduced samples. d Catalytic performance at 225 °C of cobalt-based catalysts supported on CZ calcined at different calcination temperatures. e Schematic representation of the reverse oxygen spillover effects in the CoCZ700 catalyst. Reprinted with permission from Ref. [89], Copyright 2020, Nature Publishing Group

Moreover, strong metal-support interactions (SMSIs) referred to the migration of support-involved species over the supported metal NPs to produce ultrathin encapsulation overlayers, have also been widely observed in atmospheric CO2 hydrogenation, which contribute to the enhancements of activity, selectivity towards the target product, and stability [91,92,93,94,95,96]. Typically, this process emerges in reducible oxide-supported group VIII metals during thermal pretreatments at high temperatures in a specific atmosphere such as H2, CO, or O2 [91,92,93,94,95,96, 118, 119]. For example, a co-reduction strategy in H2 atmosphere was used to prepare the encapsulation of the TiOx overlayers on metallic Ru NPs via the improved SMSIs over Ru/TiO2 catalysts with the formation of RuxTi2-xO2 oxide interphase by increasing the calcination temperature (Fig. 8a) [92], which exhibits a superior activity in CO2 hydrogenation with a CH4 selectivity of 100%. Additionally, the SMSIs often happen upon the reaction conditions induced by the reactant or product molecules on catalyst surfaces at high temperature, which could give rise to different catalytic modes in CO2 hydrogenation. Xin et al. [93] reported an adsorbate-induced SMSI structure over Ru-MoO3 catalyst by a CO2-H2 mixture gas that enables dynamic tuning of the catalytic selectivity in CO2 hydrogenation. During the reaction, the MoO3 support is reduced below 500 °C via the promotion effect of Ru NPs to generate active MoO3-x overlays with rich oxygen vacancies covered over Ru NPs, i.e. the Ru@MoO3−x structure (Fig. 8b), which leads to the occurrence of different catalytic reaction in CO2 hydrogenation compared to unencapsulated Ru-MoO3 structure. A CH4 selectivity of 100% generated by the Sabatier reaction is acquired on the unencapsulated Ru-MoO3 structure while the Ru@MoO3−x structure facilitates the RWGS reaction to generate CO with a selectivity of above 99% (Fig. 8c). Spectroscopic characterizations together with DFT calculations demonstrate such sensitive changes of catalytic selectivity arising from the different exposed surface sites, in which the Sabatier reaction mostly occurs over the exposed Rh sites over unencapsulated Ru-MoO3 structure, however, the MoO3-x overlayers over Ru@MoO3−x structure with rich oxygen vacancies facilitate the RWGS reaction. Compared between the MSIs and SMSI effects, the MSIs are more easily to occur over metal/oxide catalysts. For instance, ZrO2, as a weak reducible support, can promote the MSIs but suppress the SMSI effect, contributing to the charge transfer from oxygen vacancies in the ZrOx surface region to adjacent Ru NPs, which finally lead to strong Ru-CO bonding and enhanced CH4 production [120]. These results nicely confirm the metal-oxide interfacial structures strongly dependent on the (S)MSIs.

a Classic support migration mechanism for SMSI formation, as in the case of the Ru/TiO2-200Air sample and proposed Ru–O-Ti co-reduction mechanism for the facile formation of SMSI, as in the case of the Ru/TiO2-xAir (x = 300, 400, or 500 °C) samples. b Schematic diagrams of the 1.9 wt % Ru-Mo-Ox-250 and 1.9 wt % Ru-Mo-Ox-500 catalysts. c Catalytic performance evolution of the Ru-Mo-oxide catalysts in CO2 hydrogenation: fresh 1.9 wt %Ru-Mo-Ox catalyst and spent catalyst after the reaction in 1.9 wt %Ru-Mo-Ox-spent. Reprinted with permission from Refs. [92] and [93], Copyright 2022, American Chemical Society

3 Formic acid / Formate

As one of the important commodity chemicals, FA and its derivative (formate) exhibit a diversity of applications in chemical industry such as medical, leather, and preservation [121, 122]. Traditionally, the FA production arises from either the oxidation of biomass or the hydrolysis of methyl formate [123, 124], which is uneconomical due to the introduction of some unexpected by-products that are separated difficultly. An efficient strategy to address this issue is to develop new and sustainable catalytic routes to produce FA/formate. Catalytic CO2 hydrogenation to FA/formate is regarded as an excellent approach, which not only utilizes the greenhouse gas of CO2 caused by the massive utilization of fossil fuels, but also produce FA/formate without the generation of other by-products because such a reaction is atomically economical (CO2 + H2 → HCOOH). Meanwhile, the FA/formate product is also an important material for hydrogen storage that is beneficial for the realization of CO2-mediated hydrogen energy cycle [125, 126]. Thermodynamically, the direct CO2 hydrogenation to FA/formate is unfavorable (Eq. 3, ∆G = 33 kJ mol−1), but can be proceeded in aqueous solution (Eq. 4, ∆G = -4 kJ mol−1). Moreover, this reaction could be further promoted with the addition of bases such as bi/carbonates, hydroxides, and amines due to the efficient suppression of the reverse reactions containing the dehydration/dehydrogenation of FA [127,128,129]. Therefore, the development of efficient catalysts for FA/formate production from CO2 hydrogenation is of great significance and high desire.

Previously, significant efforts have been devoted to develop efficient homogeneous catalysts for FA/formate production from CO2 hydrogenation which are mainly focused on homogeneous transition metal complexes based on Rh, Ru, Ir, and Fe [130,131,132]. Although high FA/formate productivity is acquired using homogeneous catalysts, unfortunately, high costs and tedious separations for catalyst reproduction seriously limit this process. By contrast, heterogeneous catalysts that can remedy these drawbacks that have aroused considerable interests. Among various heterogeneous catalysts reported in literature [133,134,135,136,137,138,139,140,141], supported-Pd catalysts exhibit exceptional activity and become the most promising, generally more than one order of magnitude performance than other supported metal catalysts [133,134,135,136]. However, their catalytic performance is still inferior in comparison to homogeneous catalysts, which limits the applications. It has been widely reported that the catalysis of supported Pd catalysts in CO2 hydrogenation to FA/formate arises from the synergetic effect between Pd and support, in which Pd is responsible for the H2 dissociation while the adsorption and activation of CO2 generally occur on the support [136, 142,143,144,145]. Therefore, tuning the structures of Pd and support are crucial in affecting the kinetic equilibrium and thus the catalytic activity.

3.1 The electronic structure of supported Pd species

As one of two pivotal reaction sites, supported Pd species is responsible for the adsorption and activation of H2 and thus strongly affects the hydrogenation performance [142]. Theoretically, reducing the metal particle size to expose more surface sites can promote the catalytic reaction. However, such a strategy is not suitable for supported Pd catalysts in CO2 hydrogenation to FA/formate. Previous studies indicated the electronic properties of supported Pd species acting as the key role in this reaction [136, 142,143,144,145,146], which has an intrinsic influence on catalytic hydrogenation performance. For instance, in Pd/CeO2 catalyzed CO2 hydrogenation to FA [142], the electronic structures of supported Pd species were finely tailored by altering the Pd loading to generate changing Pd particle sizes from atomic dispersion to large NPs (ca. 3.4 nm). The TOF value calculated on basis of surface Pd atoms over large Pd NPs is more than 9 times higher than that over atomically dispersed Pd atoms, indicating that metallic Pd species is more beneficial for the adsorption and activation of H2 and thus the hydrogenation performance. Similar results were also observed on Pd/ZnO, Pd/ZrO2, and Pd/TiO2 catalysts [136, 143, 144].

In addition to the electronic properties modified by altering the particle size, the bimetal alloy can be also employed to tune the electronic properties of supported Pd species [147, 148]. It is thus regarded as an efficient approach to boost the catalytic activity by introducing a weakly-electronegative metal atoms to increase Pd metallicity such as Ag, Cu, Mn, and Co [134, 135, 149,150,151,152,153,154,155]. Sun et al. prepared the zeolite-encaged Pd-Mn nanocatalysts for CO2 hydrogenation to formate [134]. The results demonstrated the introduction of Mn atoms greatly improving the metallicity of supported Pd atoms which results in an unprecedented high formate generation rate of 2151 molformate molPd−1 h−1 at 353 K over PdMn0.6@S-1 catalyst (Fig. 9a). However, the precise structures are still ambiguous due to the alloy complexity. To catch this point, Mori et al. [135] prepared a series of TiO2-supported PdAg catalysts with different PdAg alloy structures including Pd covered on Ag (Ag@Pd), Ag covered on Pd (Pd@Ag), and PdAg mixed uniformly. Compared to monometallic Pd/TiO2 catalyst, the improved catalytic activities were observed for all Pd–Ag/TiO2 catalysts, among which the Pd@Ag/TiO2 catalyst exhibits a maximum turnover number of 14,839 calculated on basis of surface Pd atoms that is more than tenfold increase in comparison to corresponding Pd/TiO2 catalyst (Fig. 9b). The CO-DRIFTS spectra coupling with Pd 3d XPS spectra (Fig. 9c and d) demonstrate the decreased electron density of active Pd atoms observed for all TiO2-supported PdAg catalysts, which results from a synergistic effect of Pd atoms alloying with Ag atoms. Meanwhile, the strongest metallicity emerges over Pd@Ag/TiO2 catalyst (Fig. 9e), which contributes to the facilitation of the hydrogenation step of adsorbed HCO3− species that is rate-determining for formate production (Fig. 9f), resulting in the highest formate production observed. These results elucidate the importance of tailoring the electronic properties of supported Pd species in CO2 hydrogenation to FA/formate.

a Comparison of the formate generation rates from the CO2 hydrogenation over various catalysts and CO2 hydrogenation over the PdMn0.6@S-1 catalyst in the NaOH solution at different temperatures. b Comparison of the catalytic activities of a series of supported PdAg catalysts with different surface compositions and Pd/TiO2 during CO2 hydrogenation. c FT-IR spectra of CO chemisorbed on Pd and PdAg samples. d XPS spectra of Pd and PdAg samples. e Relationship between the TON for CO2 hydrogenation based on surface-exposed Pd atoms (as determined by CO pulse adsorption) and the Pd 3d binding energy (as determined by XPS). f Possible reaction mechanism. Reprinted with permission from Refs. [134] and [135], Copyright 2020 and 2018, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim and American Chemical Society

3.2 The nature of the oxide supports

As mentioned above, the support plays a crucial role in CO2 hydrogenation to FA/formate, which can not only govern the adsorption and activation of CO2 that is responsible for the reaction activity, but also tailors the electronic properties of supported Pd species via the MSIs that is influential to H2 dissociation and hydrogenation process, jointly contributing to the catalytic performance [136, 142,143,144,145]. During a long period, the carbon-based supports such as active carbon and carbon nitride are considered as the best category supports for FA/formate production, which generally exhibit high activities and recycle stabilities compared to other supported catalysts [133, 156,157,158]. Recently, another class of supports called metal oxides also exhibit great potential in this reaction in view of their versatile redox/acid–base properties and high stability. In contrast to numerous studies on the carbon-based supports, the metal oxide supports with high catalytic performance are few demonstrated for CO2 hydrogenation, mainly focused on some reducible oxides like TiO2, CeO2 and ZrO2 with rich surface oxygen vacancies capable of adsorption and activation of CO2 upon reduction [135, 136, 142,143,144,145]. It has been confirmed that the nature of oxide supports including the type [142], crystal phase [143] and morphology/crystal plane [136, 144, 145] has a significant effect on the catalytic performance, which will be detailedly introduced below.

Previously, it was commonly believed that the catalytic activity for oxide-supported Pd catalysts is inferior to Pd deposited on carbon-based supports until the results reported by ours using Pd/TiO2 catalysts with both the surface basicity and the H2 activation capacity tailored finely [142]. We first prepared a series of Pd/CeO2 and Pd/ZnO catalysts with changing Pd particle size, taking as model catalysts. An adverse variation trend with the Pd particle size was observed on two different oxide supports (Fig. 10a). Interestingly, the calculated TOF values are similar over Pd/ZnO catalysts but different distinctly over Pd/CeO2 catalysts (Fig. 10b). These suggest the type of oxide supports strongly affecting the catalytic behaviors. The kinetic results together with in situ DRIFTS spectra demonstrate the bidentate carbonate and bicarbonate species serving as the key intermediates for formate production (Fig. 10c). For Pd/ZnO catalysts with barren basic properties, the adsorption and activation of CO2 are seriously limited to suppress the generations of surface carbonaceous species, consequently, the CO2 activation to yield surface carbonaceous species is the RDS and thus the catalytic performance is less affected by the electronic properties of supported Pd species (Fig. 10d). In contrast, the RDS is switched to the hydrogenation of surface carbonaceous species over Pd/CeO2 catalysts due to the abundant surface basic sites of CeO2 that can accelerate the CO2 conversion to carbonaceous species. As a result, the catalytic activity is strongly dependent on the electronic structures of supported Pd species that are responsible for the H2 dissociation and hydrogenation process (Fig. 10d). Based on these results, we found that the FA/formate formation from CO2 hydrogenation is determined by two crucial parameters, i.e. the surface basic sites and the electronic properties of supported Pd species, which are responsible for CO2 activation and H2 dissociation, respectively. By these principles, a highly efficient Pd catalyst with an averaged particle size of 4.6 nm deposited on TiO2 featuring strongly basicity than CeO2 was developed to afford a TOF of up to 909 h−1 at 40 °C (Fig. 10e), far higher than that on Pd/CeO2 catalysts and even comparable to the top results reported on carbon-based supports [133, 156,157,158]. These clearly reveal the importance of choosing a suitable oxide support for FA/formate production from CO2 hydrogenation.

a Formation rate of FA calculated by total Pd atoms on various Pd loadings of Pd/CeO2 and Pd/ZnO catalysts at 373 K; b TOFs of FA calculated by surface Pd atoms on 0.05%Pd/CeO2, 2%Pd/CeO2, 0.05%Pd/ZnO, and 2%Pd/ZnO catalysts at 373 K. c In situ DRIFTS spectra of CO2 hydrogenation reaction under an atmosphere of CO2 and H2 (1:1) on 2%Pd/CeO2 and 2%Pd/ZnO catalysts at 373 K. d Proposed reaction mechanism of CO2 hydrogenation to formate over Pd/CeO2 and Pd/ZnO catalysts. e Representative TEM images and TOFs for the FA production calculated by surface Pd atoms on 2%Pd/TiO2 catalyst. Reprinted with permission from Ref. [142], Copyright 2019, Elsevier

Following up this thought, we further prepared a series of Pd/ZrO2 catalysts for CO2 hydrogenation to formate [143], whose structures are tuned by altering the crystal phase of ZrO2 supports including monoclinic ZrO2 (ZrO2-M), tetragonal ZrO2 (ZrO2-T), and hybrid ZrO2 (ZrO2-M&T) (Fig. 11a). Due to the distinctly different surface basicity, a remarkable dependence of the catalytic activity on the crystal plane of ZrO2 was observed for three Pd/ZrO2 catalysts, among which Pd/ZrO2-T catalyst displays the best activity with a TOF value of up to ca. 2817 h−1 at 100 °C (Fig. 11b and c). Kinetic studies coupling with in situ DRIFTS spectra unveil the activation of CO2 as the key step in determining the reaction activity and thus regarded as the RDS. As a result, the highest concentration of surface basicity over ZrO2-T and Pd/ZrO2-T catalysts enable enough surface sites to activate CO2 that is responsible for the excellent activity of Pd/ZrO2-T catalyst in CO2 hydrogenation to formate (Fig. 11d).

a Models of different ZrO2-supported Pd for CO2 hydrogenation to formate and XRD patterns of various ZrO2 supports. Production rate of formate on various Pd/ZrO2 catalysts based on the b total amount of Pd atoms and c surface Pd atoms. d CO2-TPD profiles of various ZrO2 and Pd/ZrO2 catalysts. Reprinted with permission from Ref. [143], Copyright 2019, Elsevier

Analogously, the morphology/crystal plane of oxide supports also strikingly affect the catalytic activity of supported Pd catalysts for FA/formate production, as verified over CeO2, ZnO, and TiO2 supports [136, 144, 145]. A typical example is the Pd/TiO2 catalyzed CO2 hydrogenation to formate [136], where a morphology-engineered strategy was employed to develop improved Pd/TiO2 catalyst with extremely high activity and recycle stability. Three types of anatase TiO2 nanocrystals predominantly exposing {001}, {100}, or {101} facets were used as supports to synthesize Pd/TiO2 catalysts for CO2 hydrogenation to formate and morphology-dependent catalysis was observed (Fig. 12a-c). Compared to Pd/TiO2{101} and Pd/TiO2{001} catalysts, Pd/TiO2{100} catalyst exhibits an unprecedentedly high activity, giving a TOF value of up to ca. 1369 h−1 at 40 °C (Fig. 12d and e), and keeps stable with seldom unchanged activity after 6 cycles (Fig. 12f). The characterization results (Fig. 12 g-i) demonstrate that the excellent activity over Pd/TiO2{100} catalyst is ascribed to its high density of moderate basic sites and relatively more surface Pd(0) species, responsible for CO2 and H2 activations, respectively, while high oxygen vacancy concentrations in TiO2{100} support are beneficial for the Pd-TiO2 interactions that can stabilize Pd structures and thus contributing to the catalytic stability. The above reports highlight the importance of the nature of oxide supports in FA/formate formation and demonstrate the possibilities of tailoring the oxide structures for developing efficient supported Pd catalysts for CO2 hydrogenation.

Representative TEM images with corresponding models f (a) TiO2{100}, (b) TiO2{101}, and (c) TiO2{001} nanocrystals. (d) Production rate of formate calculated by the total amount of Pd atoms on various Pd/TiO2 catalysts at 313 K; (e) Production rate of formate calculated by the surface amount of Pd atoms on various representative 2%Pd/TiO2 catalysts at 313 K and corresponding (f) course of successive reaction rounds. (g) Pd 3d XPS spectra without exposure to air and (h) CO2-TPD profiles of various 2%Pd/TiO2 catalysts. (i) Reaction order of NaHCO3 of various 2%Pd/TiO2 catalysts over CO2 hydrogenation into formate as a function of the intensity of the fitted peak α and β normalized by the specific BET surface area in CO2-TPD results, respectively. Reprinted with permission from Ref. [136], Copyright 2022, Elsevier

4 Methanol

As one of the top five commodity chemicals around the world, methanol (CH3OH) has been widely used as a solvent, an alternative fuel, and an important intermediate in chemical industry for the production of a diversity of chemicals such as olefins, acetic acid, and methyl tert-butyl ether [159, 160]. Historically, methanol was first obtained from the charcoal production by wood as a byproduct and thus called wood alcohol [159]. Until the 1920s, a commercial schema was developed by the syngas-to-methanol synthesis process using ZnO-Cr2O3 catalysts operating at 320–450 °C and 250–350 bar [15]. Later on, this process was further optimized to conduct under milder reaction conditions of 200–300 °C and 50–100 bar over Cu/ZnO/Al2O3 catalysts [161]. Nowadays, as an alternative feedstock, the carbon source of methanol synthesis in syngas atmosphere (CO) could be replaced by CO2 that has also been considered as an efficient approach for CO2 utilization [162].

During CO2 hydrogenation to methanol (Eq. 5), a competing RWGS reaction (Eq. 6) could be occurred [163] that, on the one hand, suppresses the methanol synthesis from direct CO2 hydrogenation, on the other hand, likely opens a new methanol synthesis way from CO, formed via the RWGS reaction, further hydrogenation (Eq. 7) [164]. In view of thermodynamic point, CO2 hydrogenation to methanol is exothermal (Eq. 5, ∆H298K = -49.5 kJ mol−1) and decompressive. Thus, the decreased reaction temperature and increased reaction pressure could be favorable for the methanol production. However, enhanced reaction temperature promotes the CO2 activation that takes advantage of the kinetic modes to accelerate the reaction activity. Unfortunately, the undesired byproducts such as CO and hydrocarbons are also generated. Therefore, tailoring the catalyst structure with both good activity and high selectivity is pivotal form methanol synthesis reaction.

In the past, numerous studies have been devoted to the development of efficient heterogeneous catalysts for CO2 hydrogenation to methanol and various materials aspects have also been investigated [1, 2, 6, 162, 165,166,167]. It is well-known that there are two main categories of catalysts in this reaction, i.e. oxide-based catalysts and zeolite-based catalysts, among which the former is considerably desirable in particular the Cu–ZnO-Al2O3 catalyst that has been commercialized [13,14,15,16]. For oxide-based catalysts, the key component is metal-oxide composites, whose interfacial structures strongly affect the catalytic performance [168,169,170,171,172]. The followings provide comprehensive introductions of different structural factors including the type [173,174,175,176,177,178], the particle size [179,180,181,182,183,184], the morphology/crystal plane [185,186,187,188,189], and the bimetal synergy [190,191,192,193,194,195] of the metals, the particle size [196], the crystal phase [197,198,199,200,201,202,203], the morphology/crystal plane [174, 204,205,206,207,208], and the composite [30, 209,210,211] of the oxides, adverse oxide/metal catalysts [172, 187, 212,213,214,215,216], and their (S)MSIs [217,218,219,220,221,222] on affect the interfacial structures and thus the interfacial catalysis for CO2 hydrogenation to methanol so as to govern the key elements in determining the activity and selectivity.

4.1 The nature of the metals

Until now, catalytic CO2 hydrogenation to methanol has been reported on different metal-based catalysts including Cu, Ag, Au, Cd, and Pd [173,174,175,176,177,178], among which Cu-based catalysts are regarded as the most promising in terms of their excellent catalytic performance and low costs [175, 178]. Thus, the Cu–ZnO-Al2O3 catalysts have been commercially employed in this reaction [15, 161]. Typically, a commercial Cu–ZnO-Al2O3 catalyst contains ca. 50–70% of CuO (precursor), 20–50% of ZnO and 5–20% of Al2O3, where Cu is the main active component, ZnO acts as promoters, and Al2O3 enhances the thermal stability. At the initial stage, several studies reported that the methanol synthesis reaction catalyzed by exposed Cu surface is structure-insensitive and thus the catalytic performance presents a linear relationship with Cu surface area [223,224,225,226,227]. However, limited by the measure conditions, the measured Cu surface areas by N2O titration could result in differences between the measured and the real values of exposed Cu surface areas [228, 229]. Recent studies demonstrated a structure-sensitive reaction observed over Cu-catalyzed methanol synthesis that is strongly dependent the particle sizes and the morphologies/crystal planes of Cu over Cu-based catalysts [181, 183,184,185,186,187,188].

Altering the Cu particle sizes, both the geometric and the electronic structures are changing correspondingly which will significantly affect the interfacial catalysis of Cu-based catalysts in CO2 hydrogenation to methanol [181, 183, 184]. This conclusion was comprehensively verified over bare Cu and supported Cu catalysts including Cu/ZnO and Cu/Zn-silicate by Berg et al. [184]. In their study, they prepared a series of Cu and supported Cu catalysts with changing Cu particle sizes range from ca. 2 nm to ca. 15 nm for methanol synthesis reaction. The results display that the formation rates of methanol based on surface Cu atoms (h−1) present similar variation trends to Cu particle sizes over both the Cu and the supported Cu catalysts (Fig. 13). As the increase of Cu particle size, the catalytic performance is prominently enhanced by a factor of ca. 3 with Cu particle size growing up from 2 to 8 nm, and subsequently keeps almost unchanged. This indicates that the methanol synthesis reaction is predominantly taken place at copper surface sites with a unique configuration of Cu atoms such as step-edge sites while finer Cu particles are not accommodated.

The surface-specific activity (TOF) for methanol synthesis after 2–10 h on stream at 260 °C and 40 bar plotted as a function of the number-averaged copper particle size for different Cu-containing catalysts. Reprinted with permission from Ref. [184], Copyright 2016, Nature Publishing Group

The exposed Cu crystal planes are another factor in affecting surface Cu structures in particular Cu coordination numbers [230], resulting in different catalytic behaviors for methanol synthesis [185,186,187,188,189]. For instance, on bare Cu surfaces, the catalytic activity for methanol production was confirmed to follow an order of Cu(110) > Cu(100) > Cu(111) using single-crystal-based model catalysts [186]. Furthermore, this phenomenon was also extended to ZnO-covered Cu surfaces, with the activity order of ZnO/Cu(100) > ZnO/Cu(111) [187]. Due to the instability of Cu exposed in air, the crystal-plane effect of Cu in methanol synthesis is still unrealized under real reaction conditions until the Cu nanocrystals successfully derived from corresponding Cu2O nanocrystals during reduction conditions recently [100]. Kordus et al. [189] employed this method to prepare ZnO-supported Cu cube catalysts with partial loss of the Cu(100) facets during CO2 hydrogenation (Fig. 14a-d). The results solidly demonstrate that ZnO-supported Cu(100) (cubes) catalysts (NC) are more active for methanol production than similarly sized sphere Cu supported on ZnO (NP) and commercial reference catalyst (CR) (Fig. 14e and f). Combined with DFT calculations, the excellent catalytic activity for NC catalyst arises from a weaker adsorption capacity of formate and a lower reaction energy between HCOOH and TS-H2COOH on ZnCu(100) surface compared to ZnCu(211) surface.

STEM images and corresponding EDX maps of cubic Cu2O NPs supported on nanocrystalline ZnO: a, b as prepared Cu2O; c, d after the CO2 hydrogenation reaction at 170 °C for over 100 h. e Methanol yield and f selectivity of Cu2O nanocubes (NC) on ZnO, spherical Cu NPs on ZnO (NP), and the commercial reference catalyst (CR). Reprinted with permission from Ref. [189], Copyright 2022, American Chemical Society

Besides single Cu NPs, the introduction of an additional metal into the catalyst system to form bimetal compounds could greatly boost the catalytic performance [190,191,192,193,194,195]. Pasupulety et al. [191] studied the influence of Au into the Cu–ZnO-Al2O3 catalysts for methanol synthesis and a positive promotion was observed with 1% Au loading, which mainly arises from the formed Cu-Au interfaces that are beneficial for the hydrogen spillover effect and adsorption capacities of CO and H2 during CO2 hydrogenation. Melian-Cabrera et al. [194, 195] found the introduced noble metal such as Pd into Cu/ZnO or Cu/Zn/Al2O3 catalysts could efficiently enhance the H2 activation, which could spill over the neighboring sites. Such a process results in the formation of a highly reduced catalyst surface, which could facilitate the catalytic hydrogenation behavior to produce methanol. These results clearly elucidate the importance of the metal nature by using Cu-based catalysts as examples in CO2 hydrogenation to methanol.

4.2 The nature of the oxides

The oxides generally act as the support in CO2 hydrogenation to methanol, which not only serve as the structural promoters, but also is the key active sites for CO2 activation [196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212]. The commonly-used oxides in methanol synthesis reaction contain ZnO, ZrO2, CeO2, In2O3, and TiO2 and so on, among which the most promising is ZnO [15, 161]. However, it is still controversial about the role of ZnO in this reaction. Behrens et al. thought the in situ formed CuZn(211) alloy from Cu interacting with defective ZnO sites as the active sites for methanol production [161], while the synergy of Cu and ZnO at the interface, i.e. the Cu–ZnO interface, was confirmed as the active sites in Kattel et al.’s report [168]. Both points were well verified by others in later studies. Moreover, the recent studies demonstrated In2O3 as a superb candidate support for methanol production from CO2 hydrogenation [231, 232]. For instance, Cai et al. [231] used TCPP(Pd)@MIL-68(In) as precursors for the preparation of Pd/In2O3 catalysts, which exhibits extremely high performance for CO2 hydrogenation, with a maximum methanol space–time yield of 81.1 gMeOH h−1 gPd−1 at 295 °C. Similar results were also observed by Frei et al. [232], who found that the InNi3 patches formed on In2O3 surface with Ni loadings of no more than 10% can selectively drive CO2 hydrogenation towards methanol over Ni/In2O3 catalysts. In any cases, these clearly reveal the importance of oxides in CO2 hydrogenation to methanol. Next, we will present comprehensive introductions of the particle size [196], the crystal phase [197,198,199,200,201,202,203], the morphology/crystal plane [174, 204,205,206,207,208], and composite [30, 209,210,211,212, 233,234,235] of the oxides in determining the catalysis of oxide-based catalysts for methanol production, respectively.

The particle sizes are always the crucial influencing factor in heterogeneous catalysis, not only restricted to metal NPs, but also extended to the oxide supports. Therefore, optimizing the particle size of the oxide supports is also proposed as an attractive approach for developing improved catalysts for methanol production. Chen et al. [196] prepared a series of ZnO-supported Au catalysts with the increase of ZnO particle size ranging from 22 to 103 nm but keeping constant Au particle size (Fig. 15a). The catalytic activity in CO2 hydrogenation presents a volcano-type variation with increased ZnO particle size while the methanol selectivity increases continuously (Fig. 15a). The Au 4f XPS spectra coupling with EPR spectra (Fig. 15b and c) demonstrate that the volcano-type dependence could be related to the increasing surface oxygen vacancy concentrations with the ZnO particle size growing up that contributes to the MSIs together with the SMSI effects causing partial overgrowth of a ZnOx layer, resulting in an increasing charge density on interfacial Au sites and their adsorption strength. Consequently, an optimum Au NP density supported on ZnO with moderate particle size exhibits the maximum methanol formation rate according to the Sabatier principle. The increasing methanol selectivity could arise from the differences of methanol formation and CO formation varying with the ZnO particle size by different optimum oxygen vacancy concentrations and electronic structures of the active sites.

(a) TOFs, product selectivity, and oxygen vacancy concentrations of the Au/ZnO catalysts varying with ZnO particle size increase. (b) EPR spectra collected after the reaction at high pressures at 240 °C in a CO2/H2 gas mixture and relative intensities of the O-vacancy signal (g = 1.96). (c) Au 4f XPS and Zn 3p XPS spectra of the Au/ZnO catalysts after calcination (calcined) and after reaction at high pressures at 240 °C in a CO2/H2 gas mixture (spent), and corresponding surface atomic Au:Zn ratios. Reprinted with permission from Ref. [196], Copyright 2021, American Chemical Society

The crystal phases of oxide support also significantly affect the interfacial catalysis in CO2 hydrogenation to methanol, which has been frequently observed on ZrO2 supports [197,198,199,200,201,202]. For Cu/ZrO2-catalyzed methanol synthesis reaction, Samson et al. [199] found the tetrahedral phase ZrO2 supported Cu catalyst was more active for methanol synthesis (Fig. 16a), which was associated with the complexes formed preferentially on t-ZrO2 to build the Cu+ cations and oxygen vacancies as acidic centers. Thus, the catalytic activity for methanol production increases with the t-ZrO2 content increase. Similar results were also observed by Witoon et al. [200], who reported that Cu/t-ZrO2 catalyst was more intrinsically active with the calculated TOF value on basis of surface copper sites ca 1.10–1.15 times and 1.62–3.59 times higher than Cu/a-ZrO2 (amorphous) and Cu/m-ZrO2 catalysts, respectively (Fig. 16b). Such a high TOF over Cu/t-ZrO2 catalyst could be ascribed to a stronger Cu-ZrO2 interaction and a higher surface concentration of hydrogenation atoms for CO2 conversion.

In addition to the crystal phases, the exposed crystal planes of oxide support by tuning the morphologies play a crucial role in determining the catalytic performance [174, 204,205,206,207,208]. Taking ZnO as an example, Liao et al. [205] found the polarity of exposed crystal planes strongly affecting the Cu–ZnO interactions and thus results in different interfacial catalysis in CO2 hydrogenation. They first prepared two types of ZnO supports, respectively platelike ZnO (p-ZnO) predominantly exposing polar (002) facets and rodlike ZnO (r-ZnO) predominantly exposing nonpolar (100) and (101) facets (Fig. 17a-d). A physically mixed method was employed to synthesize Cu–ZnO catalysts, whose selectivity in methanol synthesis was sensitive to ZnO morphology. A higher methanol selectivity over Cu/p-ZnO mixed with Al2O3 catalysts, affording a value of 71.6% at 280 °C, was observed (Fig. 17e), which was associated with stronger Cu–ZnO interactions occurring between Cu and p-ZnO support. This result clearly demonstrated the concept of morphology-dependent MSIs that are of importance in determining reaction selectivity for CO2 hydrogenation.

TEM images of a ZnO plate particles and b ZnO nanorods. c HRTEM image of ZnO rod. d Crystallographic relationship between ZnO plate and rod. e Catalytic performance of ZnO plate and rod particles mixed with copper and alumina in the synthesis of methanol from hydrogenation of CO2. Reprinted with permission from Ref. [205], Copyright 2011, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim and American Chemical Society

The composite oxides acting as the support generally exhibit better catalytic performance in methanol synthesis from CO2 hydrogenation than corresponding single component, which could be ascribed to diverse factors [30, 209,210,211,212]. Graciani et al. [16] found that the existence of TiO2(110) can promote the formation of small wirelike ceria structures with stable Ce(III) and Ce(IV) states. Compared to CeOx/Cu(111) model catalyst, the intrinsic activity for methanol production over Cu/CeOx/TiO2(110) was greatly enhanced with a TOF of 8.1 molecule per active site per second. Zhan et al. [210] prepared a quaternary Cu–ZnO-ZrO2-TiO2 catalyst by a coprecipitation method. They found that the addition of ZrO2 and TiO2 into Cu–ZnO catalyst can result in a decreased crystallite size for both CuO and ZnO that are beneficial for the increases of Cu surface area and the Cu–ZnO interaction, contributing to increased methanol yield in CO2 hydrogenation. Similarly, Angelo et al. [211] demonstrated that, compared to CeO2, the addition of ZrO2 into Cu–ZnO-Al2O3 catalyst efficiently promoted the methanol production from CO2 hydrogenation. Recently, Wang et al. [233] found that ZnO-ZrO2 solid solution catalyst exhibits a high selectivity and stability for CO2 hydrogenation to methanol. Using this as the support, Yan et al.’s group developed ZnZrOx solid solution supported Pd single atom [234] and an optimized integration of ZnZrOx solid solution and Pd supported on carbon nanotube [235] for enhanced methanol production from CO2 hydrogenation.

In addition to the support, the oxides can also be supported on metal over inverse oxide/metal catalysts that sometimes exhibit enhanced interfacial reactivity compared to corresponding metal/oxide catalysts, which have been well verified in well-defined ZnO/Cu(111) and CeOx/Cu(111) model catalysts for methanol synthesis [187, 213, 214]. Recently, this process was also experimentally demonstrated over a ZrO2/Cu inverse configuration for CO2 hydrogenation reported by Wu et al. [215]. An oxalate coprecipitation method was employed to prepare inverse ZrO2/Cu catalysts with a tunable Zr/Cu ratio (Fig. 18a). The optimal activity in CO2 hydrogenation was observed over inverse ZrO2/Cu catalyst with a Zr/Cu ratio of 1:9, affording a mass-specific methanol formation rate of 524 gMeOH kgcat−1 h−1 at 220 °C (Fig. 18b), which is 3.3 times higher than that over traditional Cu/ZrO2 catalyst (159 gMeOH kgcat−1 h−1). Microscopic characterizations demonstrated that the formed ZrO2 is partially reduced amorphous and exists in the form of islands with a particle size of 1–2 nm (Fig. 18a). In situ DRIFTS spectra showed that the formation and consumption of formate and methoxy intermediates are much faster over inverse ZrO2/Cu catalysts than over Cu/ZrO2 catalysts (Fig. 18c). Therefore, the excellent methanol formation rate over inverse ZrO2/Cu configuration could be ascribed to the activation of CO2 and hydrogenation of all the surface oxygenate intermediates proceeded easily.

a High-resolution HAADF-STEM images/FFT patterns with simulated results and the EDS elemental mapping of ZrO2/Cu-0.1 catalyst. b CO2 conversion, product selectivity and space time yield (STY) of methanol as a function of the percentage of ZrO2 in the ZrO2/Cu catalysts. c Normalized intensities of the typical surface species versus reaction time (first 90 min in 75% H2/25% CO2 atmosphere at 220 °C and the inlet was switched to 75% H2/25% He at 90 min and maintained at the same temperature for another 90 min) over ZrO2/Cu-0.2 catalyst. Reprinted with permission from Ref. [215], Copyright 2020, Nature Publishing Group

The (S)MSIs, contributing to the methanol production from CO2 hydrogenation, have also been frequently observed over metal/oxide catalysts [217,218,219,220,221,222]. Typical in Cu-based catalysts for CO2 hydrogenation to methanol associated with the MSIs, Wang et al. [219] found the interactions at the Cu/CeO2 interfaces are more efficient than those at the Cu/ZrO2 interfaces, which could improve the dispersion of supported Cu species and the formation of surface oxygen vacancies, and consequently accelerate the methanol production from CO2 hydrogenation via the formation of surface carbonates intermediates. For the SMSI effect, Zhang et al. [222] observed a size-dependent SMSIs in Pd/ZnO catalysts, in which the Pd NPs with larger sizes are more prone to be encapsulated by ZnO support during reducible conditions than those of smaller ones. This will lead to the different formation of Pd-ZnO interfaces and thus varied CO binding strength. Consequently, the Pd/ZnO catalysts with larger Pd particle sizes exhibit best catalytic activity and methanol selectivity that that with a Pd particle size of 1.6 nm.

5 Summary and outlook

To face the global warming and changing climate caused by CO2 emission generated from the utilizations of nonrenewable fossil energies, the urgent issue in modern society is to reduce CO2 content in the atmosphere. Catalytic CO2 hydrogenation to value-added chemicals is regarded as a superior approach to address this issue, while this process is seriously limited by highly chemical inertia of CO2 and complexly catalytic routes of CO2 hydrogenation reaction. In this review, we summarized the recent progress of metal-oxide nanocatalysts for CO2 hydrogenation to value-added C1 chemicals (CH4/CO, FA/formate, and methanol) and revealed that the structures of metal-oxide interfaces were crucial in determining both the catalytic activity and the product selectivity. The various factors affecting the interfacial structures of metal-oxide nanocatalysts are presented, including the type, the particle size, the crystal plane/morphology, and the bimetal alloy of the metal NPs, the type, the particle size, the crystal phase, the crystal plane/morphology, and the composite of the oxides, and their (S)MSIs. By these studies, the interfacial catalysis of metal-oxide nanocatalysts in CO2 hydrogenation is in depth elucidated and the key factors determining the reaction activity, product selectivity, and catalytic stability are efficiently unveiled, which provide the guides for the structural design of metal-oxide nanocatalysts with good activity and high selectivity in CO2 conversion.

Nonetheless, the current studies are less comprehensive and the following points still need to be considered that will also offer challenging opportunities in the future research. Firstly, the interfacial structures are extremely complex with affected factors diversely, not limited to the summarized contents in this review. This will lead to the results reported in literature not wholly, giving an incomplete conclusion to the readers. Secondly, the interfacial numbers at atomic level are hardly counted due to the irregular shapes and random contacts between metals and oxides for powder catalysts, which are unbeneficial for comprehensive understanding the interfacial catalysis in CO2 hydrogenation. Thirdly, the interfacial change transfer associated with the (S)MSIs is hardly supervised and quantitative. The current studies mostly employing spectroscopic characterizations such as XPS and in situ CO-DRIFTS only give an average electronic information of supported metal species to compare the charge transfer relatively. Due to the complexity of powder catalysts, the electronic information from non-interfacial sites can also be detected, which could bring about undesirable results. Fourth, an interfacial reconstruction could occur during reaction conditions, which may result in a wrong relationship between the probed ex situ structures and the catalytic performance, restricting the precise identification of the active site in CO2 hydrogenation.

Currently, as the significant promotion of nanosynthesis technology as well as the continuous development of in situ characterizations, the design and corresponding detection of interfacial structures have been gradually improved to bring new opportunities for the studies of interfacial catalysis of metal-oxide nanocatalysts in CO2 hydrogenation. Considering the complex structures of powder catalysts, this study is still challenging and the development of efficient and operable approach is very impending. Oppositely, this also provides new opportunities for further study in the future. Totally, this is a research subject with both opportunities and challenges.

Change history

23 January 2024

A Correction to this paper has been published: https://doi.org/10.1007/s44251-023-00023-4

References

Wang W, Wang S, Ma X et al (2011) Recent advances in catalytic hydrogenation of carbon dioxide. Chem Soc Rev 40:3703–3727

Wang L, Chen W, Zhang D et al (2019) Surface strategies for catalytic CO2 reduction: from two-dimensional materials to nanoclusters to single atoms. Chem Soc Rev 48:5310–5349

Knutson TR, Tuleya RE (2004) Impact of CO2-induced warming on simulated hurricane intensity and precipitation: sensitivity to the choice of climate model and convective parameterization. J Clim 17:3477-3495

Hansen J, Sato M, Ruedy R et al (2006) Global temperature change. Proc Natl Acad Sci U S A 103:14288

Appel AM, Bercaw JE, Bocarsly AB et al (2013) Frontiers, opportunities, and challenges in biochemical and chemical catalysis of CO2 fixation. Chem Rev 113:6621–6658

Álvarez A, Bansode A, Urakawa A et al (2017) Challenges in the greener production of formates/formic acid, methanol, and DME by heterogeneously catalyzed CO2 hydrogenation processes. Chem Rev 117:9804–9838

Zhou W, Cheng K, Kang J et al (2019) New horizon in C1 chemistry: breaking the selectivity limitation in transformation of syngas and hydrogenation of CO2 into hydrocarbon chemicals and fuels. Chem Soc Rev 48:3193–3228

Xu D, Wang Y, Ding M et al (2021) Advances in higher alcohol synthesis from CO2 hydrogenation. Chem 7:849–881

Gao P, Zhang L, Li S et al (2020) Novel heterogeneous catalysts for CO2 hydrogenation to liquid fuels. ACS Cent Sci 6:1657–1670

Zhou Z, Gao P (2001) Direct carbon dioxide hydrogenation to produce bulk chemicals and liquid fuels via heterogeneous catalysis. Chin J Catal 43:2045–2056

Arakawa H, Aresta M, Armor JN et al (2001) Catalysis research of relevance to carbon management: progress, challenges, and opportunities. Chem Rev 101:953–996

Hua Z, Yang Y, Liu J (2023) Direct hydrogenation of carbon dioxide to value-added aromatics. Coord Chem Rev 478:214982

Kattel S, Liu P, Chen JG (2017) Tuning selectivity of CO2 hydrogenation reactions at the metal/oxide interface. J Am Chem Soc 139:9739–9754

Khdary NH, Alayyar AS, Alsarhan LM et al (2022) Metal oxides as catalyst/supporter for CO2 capture and conversion, review. Catalysts 12:300

BASF (1923) German Patents 415686, 441433, 462837

Graciani J, Mudiyanselage K, Xu F et al (2014) Highly active copper-ceria and copper-ceria-titania catalysts for methanol synthesis from CO2. Science 345:546–550

Kattel S, Yu W, Yang X et al (2016) CO2 hydrogenation over oxide-supported PtCo catalysts: the role of the oxide support in determining the product selectivity. Angew Chem Int Ed 55:7968–7973

Caparrós FJ, Soler L, Rossell MD et al (2018) Remarkable carbon dioxide hydrogenation to ethanol on a palladium/iron oxide single-atom catalyst. ChemCatChem 10:2365–2369

Yan Y, Wong RJ, Ma Z et al (2022) CO2 hydrogenation to methanol on tungsten-doped Cu/CeO2 catalysts. Appl Catal B: Environ 306:121098

Sha B, Wang Z-Q, Gong X-Q et al (2023) Synergistic promotions between CO2 capture and in-situ conversion on Ni-CaO composite catalyst. Nat Commun 14:996

Yan B, Zhao B, Kattel S et al (2019) Tuning CO2 hydrogenation selectivity via metal-oxide interfacial sites. J Catal 374:60–71

Parastaev A, Muravev V, Osta EH et al (2022) Breaking structure sensitivity in CO2 hydrogenation by tuning metal-xide interfaces in supported cobalt nanoparticles. Nat Catal 5:1051–1060

Liao W, Tang C, Zheng H et al (2022) Tuning activity and selectivity of CO2 hydrogenation via metal-oxide interfaces over ZnO-supported metal catalysts. J Catal 407:126–140

Liao W, Yue M, Chen J et al (2023) Decoupling the interfacial catalysis of CeO2-supported Rh catalysts tuned by CeO2 morphology and Rh particle size in CO2 hydrogenation. ACS Catal 13:5767–5779

Lam E, Corral-Pérez JJ, Larmier K et al (2019) CO2 hydrogenation on Cu/Al2O3: role of the metal/support interface in driving activity and selectivity of a bifunctional catalyst. Angew Chem Int Ed 58:13989–13996

Cao F, Song Z, Zhang Z et al (2021) Size-controlled synthesis of Pd nanocatalysts on defect-engineered CeO2 for CO2 hydrogenation. ACS Appl Mater Interfaces 13:24957–24965

Senanayake SD, Ramírez PJ, Waluyo I et al (2016) Hydrogenation of CO2 to methanol on CeOx/Cu(111) and ZnO/Cu(111) catalysts: role of the metal-oxide interface and importance of Ce3+ sites. J Phys Chem C 120:1778–1784

Guo Y, Liu Z, Zhang F et al (2021) Modulation of the effective metal-support interactions for the selectivity of ceria supported noble metal nanoclusters in atmospheric CO2 hydrogenation. ChemCatChem 13:874–881

Zhang S, Fan Q, Xia R et al (2020) CO2 reduction: from homogeneous to heterogeneous electrocatalysis. Acc Chem Res 53:255–264

Aziz MAA, Jalil AA, Triwahyono S et al (2016) CO2 methanation over heterogeneous catalysts: recent progress and future prospects. Green Chem 17:2647–2663

Miao B, Ma SSK, Wang X et al (2016) Catalysis mechanisms of CO2 and CO methanation. Catal Sci Techno 6:4048–4058

Ashok J, Pati S, Hongmanorom P et al (2020) A review of recent catalyst advances in CO2 methanation processes. Catal Today 356:471–489

Chen S, Abdel-Mageed AM (2023) Methanation reactions for chemical storage and purification of hydrogen: overview and structurereactivity correlations in supported metals. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2022.12.196

Rostrup-Nielsen, JR (1984) Catalytic steam reforming, vol. 5. Catal Sci Technol 5:1-117

Dagle RA, Wang Y, Xia G-G et al (2007) Selective CO methanation catalysts for fuel processing applications. Appl Catal A: Gen 326:213–218

Vogt C, Monai M, Kramer GJ et al (2019) The renaissance of the Sabatier reaction and its applications on earth and in space. Nat Catal 2:188–197

Tian D, Liu Z, Li D et al (2013) Bimetallic Ni-Fe total-methanation catalyst for the production of substitute natural gas under high pressure. Fuel 104:224–229

Xiang Y, Kruse N (2016) Tuning the catalytic CO hydrogenation to straight and long-chain aldehydes/alcohols and olefins/paraffins. Nat Commun 7:13058

Shi Z, Yang H, Gao P et al (2018) Effect of alkali metals on the performance of CoCu/TiO2 catalysts for CO2 hydrogenation to long-chain hydrocarbons. Chin J Catal 39:1294–1302

Zhang Z, Shen C, Sun K et al (2022) Advances in studies of the structural effects of supported Ni catalysts for CO2 hydrogenation: from nanoparticle to single atom catalyst. J Mater Chem A 10:5792–5812

Rui N, Zhang X, Zhang F et al (2021) Highly active Ni/CeO2 catalyst for CO2 methanation: preparation and characterization. Appl Catal B: Environ 282:119581

Gao M, Zhang J, Zhu P et al (2022) Unveiling the origin of alkali metal promotion in CO2 methanation over Ru/ZrO2. Appl Catal B: Environ 314:121476

Xu J, Li L, Pan J et al. (2022) Boosting the catalytic performance of CuOx in CO2 hydrogenation by incorporating CeO2 promoters. Adv Sustainable Syst 6:2100439

Li Y, Men Y, Liu S et al (2021) Remarkably efficient and stable Ni/Y2O3 catalysts for CO2 methanation: effect of citric acid addition. Appl Catal B: Environ 293:120206

Moiolia E, Züttel A (2020) A model-based comparison of Ru and Ni catalysts for the Sabatier reaction. Sustain Energy Fuels 4:1396–1408

Martin NM, Velin P, Skoglundh M et al (2017) Catalytic hydrogenation of CO2 to methane over supported Pd, Rh and Ni catalysts. Catal Sci Technol 7:1086–1094

Quindimil A, De-La-Torre U, Pereda-Ayo B et al (2020) Effect of metal loading on the CO2 methanation: a comparison between alumina supported Ni and Ru catalysts. Catal Today 356:419–432

Panagiotopoulou P (2017) Hydrogenation of CO2 over supported noble metal catalysts. Appl Catal A: Gen 542:63–70

Varun Y, Sreedhar I, Singh SA (2020) Highly stable M/NiO-MgO (M = Co, Cu and Fe) catalysts towards CO2 methanation. Int J Hydrogen Energy 45:28716–28731

Martin NM, Hemmingsson F, Schaefer A et al (2019) Structure-function relationship for CO2 methanation over ceria supported Rh and Ni catalysts under atmospheric pressure conditions. Catal Sci Technol 9:1644–1653

Kwak JH, Kovarik L, Szanyi J et al (2013) CO2 reduction on supported Ru/Al2O3 catalysts: cluster size dependence of product selectivity. ACS Catal 3:2449–2455

Hao Z, Shen J, Lin S et al (2021) Decoupling the effect of Ni particle size and surface oxygen deficiencies in CO2 methanation over ceria supported Ni. Appl Catal B: Environ 286:119922

Lin L, Gerlak CA, Liu C et al (2021) Effect of Ni particle size on the production of renewable methane from CO2 over Ni/CeO2 catalyst. J Energy Chem 61:602–611

Feng K, Tian J, Guo M et al (2021) Experimentally unveiling the origin of tunable selectivity for CO2 hydrogenation over Ni-based catalysts. Appl Catal B: Environ 292:120191

Guo Y, Mei S, Yuan K et al (2018) Low-temperature CO2 methanation over CeO2-supported Ru single atoms, nanoclusters, and nanoparticles competitively tuned by strong metal-support interactions and H-spillover effect. ACS Catal 8:6203–6215

Wang D, Yuan Z, Wu X et al (2023) Ni single atoms confined in nitrogen-doped carbon nanotubes for active and selective hydrogenation of CO2 to CO. ACS Catal 13:7132–7138

Zheng H, Liao W, Ding J et al (2022) Unveiling the key factors in determining the activity and selectivity of CO2 hydrogenation over Ni/CeO2 catalysts. ACS Catal 12:15451–15462

Guo J, Wang Z, Li J et al (2022) In-Ni intermetallic compounds derived from layered double hydroxides as efficient catalysts toward the reverse water gas shift reaction. ACS Catal 12:4026–4036

Wang Y, Feng K, Tian J et al (2022) Atomically dispersed Zn-stabilized Niδ+ enabling tunable selectivity for CO2 hydrogenation. Chemsuschem 15:e202102439

Mutz B, Belimov M, Wang W et al (2017) Potential of an alumina-supported Ni3Fe catalyst in the methanation of CO2: impact of alloy formation on activity and stability. ACS Catal 7:6802–6814

Lu H, Yang X, Gao G et al (2016) Metal (Fe Co, Ce or La) doped nickel catalyst supported on ZrO2 modified mesoporous clays for CO and CO2 methanation. Fuel 183:335–344

Moghaddam SV, Rezaei M, Meshkani F et al (2018) Carbon dioxide methanation over Ni-M/Al2O3 (M: Fe, CO, Zr, La and Cu) catalysts synthesized using the one-pot sol-gel synthesis method. Int J Hydrogen Energy 43:16522–16533

Luo L, Wang M, Cui Y et al (2020) Surface iron species in palladium-iron intermetallic nanocrystals that promote and stabilize CO2 methanation. Angew Chem Int Ed 59:14434–14442

Arandiyan H, Wang Y, Scott J et al (2018) In situ exsolution of bimetallic Rh-Ni nanoalloys: a highly efficient catalyst for CO2 methanation. ACS Appl Mater Interfaces 10:16352–16357