Abstract

Oxytetracycline (OTC) and ciprofloxacin (CIP) contamination have caused serious risks to human health, and modified biochar is considered as a potential adsorbent for their removal. The typical agricultural waste of cotton husk was used as the feedstock, then was combined with γ-Fe2O3 and ball milling to innovatively synthesize nano zero-valent iron (nZVI) supporting magnetic cotton hush-derived biochar (Fe2O3@BMBC) by reductive calcination. Fe2O3@BMBC performed excellent adsorption performance with a maximum adsorption capacity for OTC (266.7 mg·g−1) and CIP (83.36 mg·g−1), and its adsorption capacity was 1.6 and 2.3 times that of cotton husk biochar (BC). Characterization analysis showed that Fe2O3@BMBC contained abundant oxygenated functional groups (e.g., -OH, C = O and Fe–O) and its surface was covered by diverse iron oxides. The high magnetization sensitivity of Fe2O3@BMBC guaranteed that it was easily to be separated by a magnet. Oxygenated functional groups (e.g., -OH, C = O and Fe–O) participated in the adsorption process, and solution pH significantly affected the adsorption behaviour, and pseudo-second-order model and Freundlich model better fitting the kinetics and isotherms data. These results confirmed that π-π conjugation, H-bonding, Fe–O complexation and electrostatic interactions contributed to the greater adsorption capacity of Fe2O3@BMBC. Ethanol + ultrasound could efficiently regenerate the used Fe2O3@BMBC and maintain its sustainable adsorption performance for OTC and CIP. Additionally, Fe2O3@BMBC performed a good environmental security in a wide pH range (from 3 to 11) in view of the low leaching risk of Fe.

Graphical Abstract

Highlights

• Fe2O3@BMBC was synthesized from cotton hush and γ-Fe2O3 by reductive calcination and ball milling.

• Fe2O3@BMBC showed the excellent adsorption performance for OTC and CIP.

• Multiple physicochemical forces contributed to OTC and CIP removal by Fe2O3@BMBC.

• Ethanol + ultrasound could efficiently regenerate the used Fe2O3@BMBC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The overuse of antibiotics has aroused widespread concern because of their potential adverse impacts on ecosystems and human health (Bilal et al. 2020). Oxytetracycline (OTC) and ciprofloxacin (CIP) are the most commonly used antibiotics because of their board-spectrum, high efficiency and low price in preventing and curing bacterial infections (Kamal et al. 2024; Zhang et al. 2023). After use, only a fraction of OTC and CIP could be assimilated by human /animals, and others will be discharged into nature environment through urine and faeces (Chen et al. 2024; Sathishkumar et al. 2024). Notably, conventional sewage treatment plants are not able to efficiently remove OTC and CIP because of their stable chemical structure and weak biodegradability. As a result, they have been frequently and widely detected in various waters (e.g., river, lake, sewage effluent and livestock wastewater) (Teymur and Güzel. 2024; Ma et al. 2021). The long half-life and high water solubility of OTC and CIP make them persist in aquatic environment and easily spread/accumulate through the food chain (Teymur and Güzel. 2024; Zeng et al. 2024). Previous studies showed that antibiotics (e.g., OTC and CIP) exposure would trigger the spread of antibiotic resistance genes and promote the development of antibiotic-resistant strains even at a very low concentration level (Santos-Santórum Suárez et al. 2023; Jia et al. 2024). Consequently, it is of significance to develop feasible technologies to eliminate antibiotics (e.g., OTC and CIP) from water.

Currently, the commonly used technologies for antibiotics elimination including adsorption (Liu et al. 2019), biodegradation (Shao et al. 2019), advanced oxidation (Pelalak et al. 2020), and membrane separation (Palacio et al. 2020). Among them, adsorption is recognized as a promising technology for antibiotics elimination because of its high removal efficiency, low cost, and simple operation (Cao et al. 2023; Sachin et al. 2023; Wen et al. 2023). Biochar is a typical carbonaceous porous adsorbent derived from biomass waste, which has abundant feedstock resource and good biocompatibility (Wen et al. 2023). These characteristics enable it to be a prospective adsorbent for antibiotics adsorptive removal. Large amounts of cotton husk waste will be generated during the harvesting process of cotton (Cheng et al. 2021). The high cellulose content (> 80%) in the compact framework of cotton husk creates the favorable conditions for biochar production (Al Afif et al. 2020; Guo et al. 2022). Notably, the large-scale and practical applications of cotton husk biochar (BC) are still limited by its poor surface physical and chemical properties. Generally, the usefulness of biochar can be improved by boosting its adsorption capacity using various modification approaches (e.g., H3PO4, NaOH and ball milling) (Meng et al. 2020; Wei et al. 2022; Xiang et al. 2020). Therefore, the modified cotton husk biochar may be useful in the removal of multiple antibiotics from water, but relevant studies are still lacking.

Specially, the rapid collection and reuse of adsorbent is still a great challenge because this is able to decrease the release risk of adsorbed contaminant and beneficial for reducing its application cost. The superior physiochemical properties of nano zero-valent iron (nZVI) including strong reducibility, large specific surface area and good magnetic sensitivity (Zou et al. 2016) have enabled its application in various water pollutants treatments (Li and Liu. 2021). However, the strong transferability, undesired oxidation, and easy agglomeration of nZVI limit its practical application (Li and Liu. 2021). Various technologies have been developed to optimize the use of nZVI, mainly including supporting nZVI onto materials with well-developed porous structures, such as biochar (Zhu et al. 2020). Simultaneously, this provides a workable approach for biochar collection and reuse after adsorption. Notably, liquid phase reduction method is one of the most commonly used methods for carbon-supported nZVI composites, which generally requires various agents and hash reaction conditions (Cai et al. 2023). Additionally, ball milling is confirmed as an emerging technology for biochar functionalization because it is capable of enlarging the internal/external surface area and enriching the oxygenated functional groups of biochar by their particles rubbing each other under mechanical force without addition of any chemical (Lyu et al. 2018; Ma et al. 2024). To our knowledge, nZVI and ball milling have not been combined to modify BC. Due to the different enhancement mechanisms of ball milling and nZVI for bicohar, their adsorption capacity for OTC and CIP are to be expected.

This work aimed to (1) synthesize a novel nZVI and ball milling co-functionalized cotton hush-derived biochar (Fe2O3@BMBC) to efficiently adsorptive removal of OTC and CIP from water; (2) elucidate the main adsorption mechanism of Fe2O3@BMBC for OTC and CIP by characterization, models (e.g., kinetics and isotherms) fitting and adsorption experiments; (3) assess the reusability of Fe2O3@BMBC and develop the efficient regeneration technology; (4) evaluate the environmental security of Fe2O3@BMBC.

2 Materials and methods

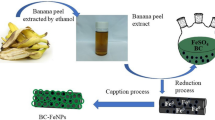

2.1 Preparation of adsorbents

The cotton husks were purchased from Plain Renewable Resource Recycling (Dezhou, Shandong), crushed into power (0.15 mm diameter), and pyrolyzed at 800 °C for 1 h with a heating rate of 10 °C/min under nitrogen atmosphere to produce BC. The cotton husks and Fe precursors were mixed (mass ratio of cotton husk: γ-Fe2O3 = 20: 1) and pyrolyzed to acquire iron-biochar composite (Fe2O3@BC). The mixture of cotton husks and γ-Fe2O3 was broken into nanoparticles by a ball milling machine (350 rpm, 2.5 h), and then it was pyrolyzed to synthesize Fe2O3@BMBC. The pyrolysis conditions of Fe2O3@BC and Fe2O3@BMBC referred to that of BC production.

2.2 Characterization of adsorbents

The zeta potentials of magnetic cotton husk-derived biochar were determined by zeta potential analyzer (Zeta PALS, Brookhaven, USA). The X-ray diffraction (XRD) patterns of adsorbents before and after adsorption were characterized by an X-ray diffraction analyzer (Rigaku MiniFlex II, Rigaku Corporation, Japan) ranging from 5° to 90° two theta with a Cu Kα radiation source (k = 0.15418 nm) at 40 kV/40 mV. The morphologies of adsorbents before and after adsorption were measured using transmission electron microscopy (TEM) (Tecnai G2 F20, FEI, USA). X-ray photoelectron spectrometer (XPS) (Rigaku MiniFlex II, Rigaku Corporation, Japan) was used to determine the C, O, and Fe chemical states on adsorbent surface before and after adsorption. A vibrating sample magnetometer (VSM, Lake Shore 7404) was used to determine the magnetic properties.

2.3 Adsorption experiments

Batch adsorption experiments were performed to investigate the processes and mechanism of OTC and CIP adsorption onto different adsorbents. All experiments (e.g., kinetics, isotherms, thermodynamics, and effect of pH experiments) arranged in this study were in triplicate to guarantee the accuracy and repeatability of this study. The samples were collected at the pre-set reaction time, and then they were filtered by 0.22 μm membrane and determined by an ultraviolet spectrophotometer (Cary 3500, Agilent, USA) at λ = 353 nm (OTC) and 270 nm (CIP), respectively. Pseudo-first-order, pseudo-second-order, intra-particle diffusion (Webber-Morris) were employed to fit the kinetics data. Langmuir and Freundlich models were used to describe the isotherms data (the detailed information were given in Supporting Information). To evaluate the regeneration performance of Fe2O3@BMBC, 50 mg of Fe2O3@BMBC was added into OTC or CIP solution with the initial concentration of 500 mg·g−1 (V = 0.2 L). The mixture solution was shaken (250 rpm) at 25 °C for 24 h. After that, the used Fe2O3@BMBC was separated and injected into ethanol (V = 0.5 L) for ultrasonic treatment (500 W) 60 min. The control was washed using ultrapure water (V = 0.5 L). Subsequently, they were separated and dried to constant weight at 70 °C, and reused for OTC or CIP adsorption. The recycling tests were performed five times. The detailed experimental conditions are listed as follows:

-

(1) Effect of solution pH and environmental security of adsorbents: C0(OTC or CIP) = 50 mg·L−1, m (adsorbent) = 5 mg, V = 0.02 L, T = 25 °C, and t = 24 h;

-

(2) Kinetics: C0(OTC or CIP) = 50 mg·L−1, m (adsorbent) = 5 mg, V = 0.02 L, T = 25 °C, and t = 0–24 h;

-

(3) Isotherms: C0(OTC or CIP) = 5–200 mg·L−1, m (adsorbent) = 5 mg, V = 0.02 L, T = 25 °C, and t = 24 h;

-

(4) Regeneration of Fe2O3@BMBC: C0(OTC or CIP) = 500 mg·L−1, m (adsorbent) = 50 mg, V = 0.02 L, T = 25 °C, and t = 24 h.

3 Results and discussion

3.1 Characterization

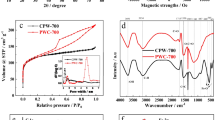

The crystal structures of the as-prepared Fe2O3@BMBC were analyzed by XRD (Fig. S2a). The peaks located at 2θ = 44.67° (110), 65.02° (200), and 82.33° (211) corresponded to the planes of Fe0 (PDF #06–0696) (Li et al. 2019). The diffraction peaks at 2θ = 30.10° (200), 35.42° (311), 56.94° (511), and 62.52° (440) were defined as the magnetic media of Fe3O4 (PDF #19–0629). This depicted that some nZVI particles were oxidized to Fe2+ and Fe3+ (Li et al. 2019). It could be speculated that the Fe3O4 produced by surface oxidation largely prevented the internal nZVI from contacting with air, which allowed it to be easily separated after adsorption by a magnet. These sharp peaks indicated that the loaded iron particles were in the form of crystalline state. The TEM images of Fe2O3@BMBC showed that iron particles were uniformly and tightly distributed on its rough surface (Fig. 1a, b). The magnetic properties of Fe2O3@BMBC were studied by VSM (Fig. 1c). The hysteresis curve of Fe2O3@BMBC passed through the coordinate origin which suggested that it was a soft magnetic material with superparamagnetization, which guaranteed Fe2O3@BMBC to be easily separated from solution by a magnet (Fig. 1c). The zeta potential of BC, Fe2O3@BC and Fe2O3@BMBC were measured at different pH values to identify their surface charge. The zero potential points (pHpzc) of BC, Fe2O3@BC and Fe2O3@BMBC were 6.55, 4.30 and 3.59, respectively (Fig. 3c). Generally, the adsorbent is protonated and positively charged when pH < pHpzc. Otherwise it is negatively charged. This suggested that the introduction of magnetic groups onto the biochar would decrease the pHpzc of adsorbents. FTIR (Figs. 1d and S2b) was employed to identify the change of functional groups on Fe2O3@BMBC before and after adsorption. The adsorption peaks around 3450 cm−1, 1600 cm−1 and 1050 cm−1 were related to the stretching vibrations of -OH, C = O and C–O, respectively (Gao et al. 2020). Compared with BC and Fe2O3@BC, Fe2O3@BMBC had more above mentioned oxygenated functional groups. Notably, the stretching intensities of -OH was decreased and its position shifted after adsorption, illustrating that H-bonding was involved between -OH (electron donor) of Fe2O3@BMBC and oxygen/nitrogen-containing groups of OTC and CIP (electron acceptors) (Ma et al. 2021). Additionally, the position and stretching intensity of C = O/C–O on Fe2O3@BMBC after adsorption were reduced compared to that of Fe2O3@BMBC, demonstrating that π-π conjugation took place between C = O/C-O of Fe2O3@BMBC and aromatic ring/-NH2/-NH- of OTC or CIP (Geng et al. 2021; Wu et al. 2021).

The O1s spectrum of Fe2O3@BMBC was divided into three contributions of 530.8 eV (C–O), 532.1 eV (C = O), and 529.8 eV (Fe–O) (Fig. 2a, b). The C1s peak was decomposed into two related peaks including deoxygenated carbon (283.5 eV) and oxygenated carbon (284.1 eV) (Fig. 2c, d; (Ma et al. 2023). The peaks around the binding energy of 711 eV and 725 eV in the Fe 2p spectra were assigned to Fe 2p3/2 (γ-Fe2O3) and Fe 2p1/2 (FeOOH) (Fig. 2e, f), respectively (Tang et al. 2018). Moreover, they were further split into Fe (0) (717.9 eV), Fe (II) (710.3 eV and 724.2 eV), and Fe (III) (712.5 eV and 733.4 eV) (Liu et al. 2023). This result further confirmed that the loaded iron were primarily in the forms of Fe (0) and Fe3O4 by ball-milling assisting and one-pot reductive calcination method. This suggested that the pyrolysis of biomass at the high temperature under oxygen-limited conditions would generate a reductive environment which was able to reduce metal compounds into pure metals. The generated Fe0 would contact with air and be oxidized into different iron oxides (Zhu et al. 2020).

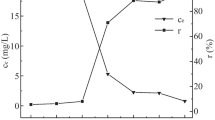

3.2 Effect of solution pH on adsorption performance of adsorbents

The effects of solution pH (3–11) on the adsorption capacity of BC, Fe2O3@BC and Fe2O3@BMBC for OTC and CIP are depicted in Fig. 3a, b, respectively. The physicochemical properties of OTC and CIP are given in Table S1. OTC (pKa1 = 3.22, pKa2 = 7.46, pKa3 = 8.94) and CIP (pKa1 = 5.76, pKa2 = 8.68) are typical amphoteric molecules, so they exhibit different forms at different pH values (Fig. S1a, b; Orellana et al. 2010; Zhang et al. 2021). Herein, OTC is mainly in the form of OTC+ at pH < 3.22, OTC± at 3.22 < pH < 7.46, OTC− at 7.46 < pH < 8.94 and OTC2− at pH > 8.94. Similarly, CIP is primarily in the specie of CIP+ at pH < 5.76, CIP± at 5.76 < pH < 8.68 and CIP− at pH > 8.68. Figure 3a, b depicts that BC performed the optimal adsorption capacity for OTC (Qe = 54.9 mg·g−1) and CIP (Qe = 17.0 mg·g−1) at pH = 7, and their adsorption capacities were inhibited at either side of this pH value. This phenomenon might be attributed to the weakest electrostatic repulsion between BC and OTC/CIP at pH = 7, because BC surface carried a small amount of negative charge and OTC/CIP was mainly in the form of neutral ions. Notably, Fe2O3@BC (Qe(TC) = 82.1 mg·g−1, Qe(CIP) = 47.4 mg·g−1) and Fe2O3@BMBC (Qe(TC) = 107.3 mg·g−1, Qe(CIP) = 40.3 mg·g−1) exhibited their optimized adsorption performance for OTC/CIP at pH = 6, and the electrostatic interaction was similar with the mechanism between BC and OTC/CIP. The greater electrostatic repulsion under acidic or alkaline environment was unfavorable for OTC/CIP adsorption by BC, Fe2O3@BC and Fe2O3@BMBC. Overall, Fe2O3@BMBC was capable of maintaining its stable adsorption capacity for OTC and CIP in a wide pH range, suggesting that other interactions (e.g., π-π conjugation and H-bonding) participated in overcoming the electrostatic repulsion under acidic or alkaline environment (Jang et al. 2018; Ling et al. 2016). These forces of π-π conjugation and H-bonding had been confirmed in the changes of functional groups (e.g., -OH, C = O and C–O) on Fe2O3@BMBC after adsorption.

3.3 Adsorption kinetics

The adsorption processes of OTC and CIP onto as-prepared biochar were fitted by the kinetics models (pseudo-first-order and pseudo-second-order) and mass transfer models (Webber–Morris model) (Fig. 4, Tables 1 and 2). The adsorbed amounts of OTC and CIP onto the BC, Fe2O3@BC and Fe2O3@BMBC were contact-time-dependent, and the processes were divided into three stages of rapid adsorption stage, low adsorption stage and equilibrium stage (Fig. 4). The adsorption capacity of these as-prepared biochars for OTC and CIP increased rapidly at the initial 6 h and 4 h, respectively. Their adsorption capacity were gradually increased and finally reached equilibrium (Fig. 4a, b). The fast adsorption stage could be assigned to large amounts of unoccupied active sites on adsorbent surface and high initial concentrations of OTC and CIP (Guo et al. 2021). All the adsorption processes were better fitted by pseudo-second-order kinetics model with the higher R2 than those of pseudo-first-order kinetic model (Table 1). It suggested that chemisorption including electron exchange and valence forces might be involved in the adsorption processes, which increased their affinity for OTC and CIP (Tan et al. 2022). Compared with BC and Fe2O3@BC, Fe2O3@BMBC exhibited the greater initial adsorption rate for OTC and CIP (h = k2qe2) (Table 1). This might be due to H-bonding and π-π conjugation that took part in overcoming transfer resistance between OTC/CIP and Fe2O3@BMBC (Wang et al. 2015).

Kinetic models (pseudo-first-order and pseudo-second-order) fitting curves of (a) OTC and (b) CIP adsorption onto BC, Fe2O3@BC and Fe2O3@BMBC; intra-particle diffusion model fitting curves of (c) OTC and (d) CIP adsorption onto BC, Fe2O3@BC and Fe2O3@BMBC (C0[OTC or CIP] = 50 mg·L.−1, V = 0.02 L, m = 5 mg, T = 25 °C, and t = 0–24 h)

The mass transfer models fitting results showed that intra-particle diffusion (Webber–Morris) model fitting curves were divided into two linear sections (rapid adsorption phase and slow adsorption phase). The slope of the linear portion reflected the diffusion rate at the corresponding stage and intercept of the linear portion was releated to the thickness of boundary layer (Fig. 4c, d). None of liner section passed through the origin of coordinate axis, suggesting that intra-particle diffusion was not the independent rate-controlling step (Park et al. 2019). The highest diffusion rate of Fe2O3@BMBC in the rapid adsorption stage was related to its more binding sites. Compared with those of BC and Fe2O3@BC, the higher boundary layer constant of Fe2O3@BMBC at either stage was obtained, which illustrated that the external mass transfer effect between it and the adsorbate was more significant than those of other adsorbents. The greater k3 and b values at the slow adsorption stage in OTC adsorption processes indicated that the contributions of both film diffusion and intraparticle diffusion of OTC were greater than those of CIP (Table 2; Li et al. 2020).

3.4 Adsorption isotherms

Langmuir and Freundlich isotherm models were employed to fit the isotherms data of OTC and CIP adsorption onto BC, Fe2O3@BC and Fe2O3@BMBC (Fig. 5) and the related parameters were summarized in Table 3. Clearly, Freundlich model agreed better with the obtained isotherms data with the higher R2 > 0.99. This demonstrated that multilayer physisorption of OTC and CIP occurred on the heterogeneous surfaces of BC, Fe2O3@BC and Fe2O3@BMBC (Atugoda et al. 2021). The values of 1/n (0 < 1/n < 1) indicated that all adsorption processes were favorable. Initially, strong bonding occurred at the high-energy active sites, followed by weak bonding at the low-energy active sites (Fang et al. 2018). The maximum adsorption capacity of BC and Fe2O3@BMBC for OTC/CIP were 170.12/35.96 mg·g−1 and 278.02/83.36 mg·g−1, respectively. The maximum adsorption capacity of Fe2O3@BMBC for OTC and CIP was 1.6 and 2.3 times that of BC, respectively. This indicated that the ball-milling-assisted one-pot pyrolysis method increased the number of binding sites of BC for OTC and CIP. Additionally, the maximum adsorption capacity of Fe2O3@BMBC for OTC and CIP was higher than most of other adsorbents listed in Table S2 (Liang et al. 2019; Lin et al. 2013; Ma et al. 2021, 2020; Song et al. 2020; Tang et al. 2013). This might be attributed to that ball milling and the introduced nZVI by reductive calcination were capable of boosting the binding sites of BC (Gao et al. 2020). Also, these adsorbents performed the greater affinity for OTC than that of CIP. This might be assigned to that OTC contained more aromatic structures and oxygen-containing functional groups, which enabled it to be easily adsorbed through H-bonding and π-π interactions. Herein, it is of great significance to develop various adsorbents for antibiotics removal because of their unique molecular structures.

3.5 Adsorption mechanism

XRD and TEM analysis confirmed that nZVI particles were successfully and uniformly distributed on the surface of Fe2O3@BMBC, and some nZVI particles formed an Fe0 core surrounded by shells made of oxides. Antibiotics adsorption did not significantly affect the crystal structure of Fe2O3@BMBC. The chemical states of elements on Fe2O3@BMBC before and after adsorption were determined by XPS analysis. Compared with the fresh Fe2O3@BMBC, the contents of Fe–O, C = O and C–O on Fe2O3@BMBC after OTC and CIP adsorption were decreased (Fig. 2), illustrating that OTC and CIP could be adsorbed onto Fe2O3@BMBC through π-π conjugation and Fe–O complexation (Gao et al. 2020). The C1s peaks on Fe2O3@BMBC shifted to 283.7 eV and 285.0 eV after adsorption, respectively (Fig. 2), suggesting that oxygen-containing functional groups participated in the adsorption (Ma et al. 2021). After adsorption, five split peaks shifted to those of different chemical states to Fe (0) (718.6 eV), Fe (II) (710.2 eV and 723.9 eV), and Fe (III) (712.1 eV and 727.1 eV), which indicated that iron oxides on Fe2O3@BMBC surface could capture OTC and CIP by surface complexation. The stretching vibration of -OH on Fe2O3@BMBC after adsorption was decreased and its position shifted compared to that of fresh Fe2O3@BMBC, illustrating that H-bonding was involved between -OH (electron donor) of Fe2O3@BMBC and oxygen/nitrogen-containing groups of OTC and CIP (electron acceptors). Also, stretching vibration and position of C = O/C–O on Fe2O3@BMBC after adsorption reduced, which implied that π-π conjugation took place between C = O/C–O of Fe2O3@BMBC and aromatic ring/-NH2/-NH- of OTC or CIP.

The behaviors of OTC and CIP adsorption onto Fe2O3@BMBC were studied by investigating the effect of initial pH, kinetics and isotherm experiments. Fe2O3@BMBC was capable of maintaining its stable adsorption capacity for OTC and CIP over a wide pH range (3–11), suggesting that electrostatic interaction was one of the main adsorption mechanisms. The pseudo-second-order model and Freundlich model better fitted the kinetics data and isotherms data, respectively, indicating that monolayer chemisorption and multilayer physisorption were simultaneously involved in the adsorption processes of Fe2O3@BMBC for OTC and CIP. Intra-partical diffusion model fitting results demonstrated that liquid film diffusion and intraparticle diffusion simultaneously controlled the processes of OTC and CIP adsorption onto Fe2O3@BMBC. The main adsorption mechanism of Fe2O3@BMBC for antibiotics (e.g. OTC) were described in Fig. 6.

3.6 The reusability of Fe2O3@BMBC and its leching risks of Fe

The regeneration of adsorbent decided its sustainable adsorption performance and its application cost. The technology of ethanol combined with ultrasound (ethanol + ultrasound) was employed to regenerate the used Fe2O3@BMBC, and H2O washing was used as the control. As shown in Fig. 7a, b, the adsorption capacities of the used Fe2O3@BMBC after OTC and CIP adsorption were 21.2% and 19.7% of its fresh one by H2O washing at the fifth recycle. Particularly, ethanol + ultrasound co-processing was able to efficiently regenerate the used Fe2O3@BMBC, and its adsorption capacities were 86.8% (for OTC) and 91.1% (for CIP) of the fresh one after five reuse cycles.

Additionally, the leaching levels of Fe from Fe2O3@BC and Fe2O3@BMBC at different solution pH values were also determined to assess its environmental security. Figure 7c depicts that the leaching concentrations of Fe from Fe2O3@BC and Fe2O3@BMBC were lower than 0.4 mg·L−1 in a wide pH rang (from 3 to 11). This demonstrated that Fe2O3@BC and Fe2O3@BMBC synthesized in this study exhibited good environmental safety. Therefore, the as-prepared biochar has potential to be a promising adsorbent for antibiotics elimination in view of its outstanding adsorption capacity, good environmental safety, easy collection and regeneration performances.

4 Conclusions

In this work, a novel Fe2O3@BMBC was innovatively synthesized by ball milling and magnetization co-functionalized cotton hush-derived biochar, and it exhibited the outstanding performance for adsorptive removal of OTC (266.69 mg·g−1) and CIP (83.36 mg·g−1) from water. The experimental results showed that Fe2O3@BMBC was able to maintain its stable adsorption ability at the tested pH ranges (from 3 to 11). The characterization and experimental results showed that physicochemical forces of π-π conjugation, H-bonding, Fe–O complexation and electrostatic interactions worked together to control the processes of OTC and CIP adsorption onto Fe2O3@BMBC. Liquid film diffusion and intraparticle diffusion simultaneously controlled adsorption processes of OTC and CIP. Ethanol and ultrasound co-processing was able to efficiently regenerate the used Fe2O3@BMBC. Additionally, Fe2O3@BMBC performed a favorable environmental security in view of the low leaching risk of Fe. The outstanding adsorption, good environmental security, easy separation and regeneration performances guaranteed it to be a promising adsorbent for antibiotics (e.g., OTC and CIP) elimination in actual waters (e.g., sewage effluent and surface water). The study is beneficial for simultaneously realizing antibiotics elimination and resource utilization of agricultural waste.

Availability of data and materials

The original contributions presented in the study are included in the article material; further inquiries can be directed on request.

Abbreviations

- OTC:

-

Oxytetracycline

- CIP:

-

Ciprofloxacin

- nZVI:

-

Nano zero-valent ion

- Fe2O3@BC:

-

Iron-biochar composite

- Fe2O3@BMBC:

-

Ball milling co-functionalized cotton hush-derived biochar

- Zeta:

-

Zeta potential analyzer

- XRD:

-

X-ray diffraction

- TEM:

-

Transmission electron microscopy

- XPS:

-

X-ray photoelectron spectrometer

- VSM:

-

Vibrating sample magnetometer

References

Al Afif R, Anayah S, Pfeifer C (2020) Batch pyrolysis of cotton stalks for evaluation of biochar energy potential. Renew Energ 147:2250–2258. https://doi.org/10.1016/j.renene.2019.09.146

Atugoda T, Gunawardane C, Ahmad M, Vithanage M (2021) Mechanistic interaction of ciprofloxacin on zeolite modified seaweed (Sargassum crassifolium) derived biochar: Kinetics, isotherm and thermodynamics. Chemosphere 281:130676. https://doi.org/10.1016/j.chemosphere.2021.130676

Bilal M, Mehmood S, Rasheed T, Iqbal H (2020) Antibiotics traces in the aquatic environment: persistence and adverse environmental impact. Cur Opin Environ Sci Heal 13:68–74. https://doi.org/10.1016/j.coesh.2019.11.005

Cai M, Li J, Wu F, Voyard G, Mailhot G, Brigante M (2023) Synergistic degradation of bisphenol A in heterogeneous Fenton and photo-Fenton systems catalyzed by graphitized carbon-nano zero valent iron. J Environ Chem Eng 11:110959. https://doi.org/10.1016/j.jece.2023.110959

Cao X, Liu Q, Yue T, Zhang F, Liu L (2023) Facile preparation of activated carbon supported nano zero-valent iron for Cd(II) removal in aqueous environment. J Environ Manage 325:116577. https://doi.org/10.1016/j.jenvman.2022.116577

Chen M, Yang T, Zhao L, Shi X, Li R, Ma L, Huang Y, Wang Y, Lee S (2024) Manganese oxide on activated carbon with peroxymonosulfate activation for enhanced ciprofloxacin degradation: Activation mechanism and degradation pathway. Appl Surf Sci 645:158835. https://doi.org/10.1016/j.apsusc.2023.158835

Cheng J, Hu S, Sun G, Kang K, Zhu M, Geng Z (2021) Comparison of activated carbons prepared by one-step and two-step chemical activation process based on cotton stalk for supercapacitors application. Energy 215:119144. https://doi.org/10.1016/j.energy.2020.119144

Fang Y, Wen J, Zeng G, Jia F, Zhang S, Peng Z, Zhang H (2018) Effect of mineralizing agents on the adsorption performance of metal–organic framework MIL-100(Fe) towards chromium(VI). Chem Eng J 337:532–540. https://doi.org/10.1016/j.cej.2017.12.136

Gao J, Han D, Xu Y, Liu Y, Shang J (2020) Persulfate activation by sulfide-modified nanoscale iron supported by biochar (S-nZVI/BC) for degradation of ciprofloxacin. Sep Purif Technol 235:116202. https://doi.org/10.1016/j.seppur.2019.116202

Geng X, Lv S, Yang J, Cui S, Zhao Z (2021) Carboxyl-functionalized biochar derived from walnut shells with enhanced aqueous adsorption of sulfonamide antibiotics. J Environ Manage 280:111749. https://doi.org/10.1016/j.jenvman.2020.111749

Guo C, Wu S, Gao X, Li M, Long H (2021) Mechanistic study of Cr (VI) removal by modified alginate/GO composite via synergistic adsorption and photocatalytic reduction. Int J Biol Macromol 189:910–920. https://doi.org/10.1016/j.ijbiomac.2021.08.203

Guo H, Ogawa S, Isoda Y, Shen F, Smith R (2022) Weak-acid biochar catalyst prepared from mechanochemically-activated biomass and humic acid for production of 5-hydroxymethylfurfural. Biochar 4:42. https://doi.org/10.1007/s42773-022-00170-1.

Jang H, Yoo S, Choi Y, Park S, Kan E (2018) Adsorption isotherm, kinetic modeling and mechanism of tetracycline on Pinus taeda-derived activated biochar. Bioresour Technol 259:24–31. https://doi.org/10.1016/j.biortech.2018.03.013

Jia X, Zhang J, Huang Q, Xiong C, Ji H, Ren Q, Jin Z, Chen S, Guo W, Chen J, Ge Y, Ding Y (2024) Efficient degradation of ciprofloxacin in wastewater by CuFe2O4/CuS photocatalyst activated peroxynomosulfate. Environ Res 241:117639. https://doi.org/10.1016/j.envres.2023.117639

Kamal N, Saha A, Singh E, Pandey A, Bhargava P (2024) Biodegradation of ciprofloxacin using machine learning tools: Kinetics and modelling. J Hazard Mater 470:134076. https://doi.org/10.1016/j.jhazmat.2024.134076

Li X, Liu L (2021) Recent advances in nanoscale zero-valent iron/oxidant system as a treatment for contaminated water and soil. J Environ Chem Eng 9:106276. https://doi.org/10.1016/j.jece.2021.106276

Li S, You T, Guo Y, Yao S, Zang S, Xiao M, Zhang Z, Shen Y (2019) High dispersions of nano zero valent iron supported on biochar by one-step carbothermal synthesis and its application in chromate removal. RSC Adv 9:12428–12435. https://doi.org/10.1039/c9ra00304e

Li X, Wang C, Tian J, Liu J, Chen G (2020) Comparison of adsorption properties for cadmium removal from aqueous solution by Enteromorpha prolifera biochar modified with different chemical reagents. Environ Res 186:109502. https://doi.org/10.1016/j.envres.2020.109502

Liang G, Wang Z, Yang X, Qin T, Xie X, Zhao J, Li S (2019) Efficient removal of oxytetracycline from aqueous solution using magnetic montmorillonite-biochar composite prepared by one step pyrolysis. Sci Total Environ 695:133800. https://doi.org/10.1016/j.scitotenv.2019.133800

Lin Y, Xu S, Li J (2013) Fast and highly efficient tetracyclines removal from environmental waters by graphene oxide functionalized magnetic particles. Chem Eng J 225:679–685. https://doi.org/10.1016/j.cej.2013.03.104

Ling C, Li X, Zhang Z, Liu F, Deng Y, Zhang X, Li A, He L, Xing B (2016) High adsorption of sulfamethoxazole by an amine-modified polystyrene–divinylbenzene resin and its mechanistic insight. Environ Sci Technol 50:10015–10023. https://doi.org/10.1021/acs.est.6b02846

Liu J, Zhou B, Zhang H, Ma J, Mu B, Zhang W (2019) A novel Biochar modified by Chitosan-Fe/S for tetracycline adsorption and studies on site energy distribution. Bioresour Technol 294:122152. https://doi.org/10.1016/j.biortech.2019.122152

Liu X, Pei Y, Cao M, Yang H, Li Y (2023) Magnetic CuFe2O4 nanoparticles anchored on N-doped carbon for activated peroxymonosulfate removal of oxytetracycline from water: Radical and non-radical pathways. Chemosphere 334:139025. https://doi.org/10.1016/j.chemosphere.2023.139025

Lyu H, Gao B, He F, Zimmerman A, Ding C, Huang H, Tang J (2018) Effects of ball milling on the physicochemical and sorptive properties of biochar: Experimental observations and governing mechanisms. Environ Pollut 233:54–63. https://doi.org/10.1016/j.envpol.2017.10.037

Ma Y, Li P, Yang L, Wu L, He L, Gao F, Qi X, Zhang Z (2020) Iron/zinc and phosphoric acid modified sludge biochar as an efficient adsorbent for fluoroquinolones antibiotics removal. Ecotox Environ Saf 196:110550. https://doi.org/10.1016/j.ecoenv.2020.110550

Ma Y, Li M, Li P, Yang L, Wu L, Gao F, Qi X, Zhang Z (2021) Hydrothermal synthesis of magnetic sludge biochar for tetracycline and ciprofloxacin adsorptive removal. Bioresour Technol 319:124199. https://doi.org/10.1016/j.biortech.2020.124199

Ma Y, Wang R, Gao C, Han R (2023) Carbon nanotube-loaded copper-nickel ferrite activated persulfate system for adsorption and degradation of oxytetracycline hydrochloride. J Colloid Interf Sci 640:761–774. https://doi.org/10.1016/j.jcis.2023.03.001

Ma Y, Yao Y, Deng Z, Tang J, Liu Y, Ma J, Zhang Z (2024) Ball milling and phosphoric acid hydrothermally co-functionalized sludge biochar for efficiently adsorptive removal of environmental concentration sulfamethoxazole: Experimental, characterization and DFT study. Sep Purif Technol 328:125051. https://doi.org/10.1016/j.seppur.2023.125051

Meng Q, Zhang Y, Meng D, Liu X, Zhang Z, Gao P, Lin A, Hou L (2020) Removal of sulfadiazine from aqueous solution by in-situ activated biochar derived from cotton shell. Environ Res 191:110104. https://doi.org/10.1016/j.envres.2020.110104

Orellana S, Soto C, Toral M (2010) UV–vis, IR and 1H NMR spectroscopic studies and characterization of ionic-pair crystal violet–oxytetracycline. Spectrochim Acta A 75:437–443. https://doi.org/10.1016/j.saa.2009.11.002

Palacio D, Leiton L, Urbano B, Rivas B (2020) Tetracycline removal by polyelectrolyte copolymers in conjunction with ultrafiltration membranes through liquid-phase polymer-based retention. Environ Res 182:109014. https://doi.org/10.1016/j.envres.2019.109014

Park J, Wang J, Kim S, Kang S, Jeong C, Jeon J, Park K, Cho J, Delaune R, Seo D (2019) Cadmium adsorption characteristics of biochars derived using various pine tree residues and pyrolysis temperatures. J Colloid Interf Sci 553:298–307. https://doi.org/10.1016/j.jcis.2019.06.032

Pelalak R, Alizadeh R, Ghareshabani E, Heidari Z (2020) Degradation of sulfonamide antibiotics using ozone-based advanced oxidation process: Experimental, modeling, transformation mechanism and DFT study. Sci Total Environ 734:139446. https://doi.org/10.1016/j.scitotenv.2020.139446

Sachin Singh N, Shah K, Pramanik BK (2023) Synthesis and application of manganese-doped zinc oxide as a potential adsorbent for removal of Congo red dye from wastewater. Environ Res 233:116484. https://doi.org/10.1016/j.envres.2023.116484

Santos-Santórum Suárez C, Sanders P, Gaugain M, Viel A, Paboeuf F, Taillandier J, Houée P, Valentin C, Perrin-Guyomard A (2023) Selection of antibiotic resistance in pigs after exposure to feed cross- contaminated with oxytetracycline. Vet Microbiol 287:109924. https://doi.org/10.1016/j.vetmic.2023.109924

Sathishkumar M, Anitha A, Ponmurugan P, Arunkumar D, Esath Natheer S, Kannan S (2024) Oxytetracycline degradation and antidermatophytic activity of novel biosynthesized MoS2 photocatalysts. Mater Sci Eng B 301:117164. https://doi.org/10.1016/j.mseb.2023.117164

Shao S, Hu Y, Cheng J, Chen Y (2019) Biodegradation mechanism of tetracycline (TEC) by strain Klebsiella sp. SQY5 as revealed through products analysis and genomics. Ecotox Environ Saf 185:109676. https://doi.org/10.1016/j.ecoenv.2019.109676

Song Y, Chen S, You N, Fan H, Sun L (2020) Nanocomposites of zero-valent Iron@Activated carbon derived from corn stalk for adsorptive removal of tetracycline antibiotics. Chemosphere 255:126917. https://doi.org/10.1016/j.chemosphere.2020.126917

Tan Y, Wan X, Ni X, Wang L, Zhou T, Sun H, Wang N, Yin X (2022) Efficient removal of Cd (II) from aqueous solution by chitosan modified kiwi branch biochar. Chemosphere 289:133251. https://doi.org/10.1016/j.chemosphere.2021.133251

Tang Y, Guo H, Xiao L, Yu S, Gao N, Wang Y (2013) Synthesis of reduced graphene oxide/magnetite composites and investigation of their adsorption performance of fluoroquinolone antibiotics. Colloid Surface A 424:74–80. https://doi.org/10.1016/j.colsurfa.2013.02.030

Tang L, Yu J, Pang Y, Zeng G, Deng Y, Wang J, Ren X, Ye S, Peng B, Feng H (2018) Sustainable efficient adsorbent: Alkali-acid modified magnetic biochar derived from sewage sludge for aqueous organic contaminant removal. Chem Eng J 336:160–169. https://doi.org/10.1016/j.cej.2017.11.048

Teymur YA, Güzel F (2024) Microwave-assisted synthesis, characterization, and oxytetracycline antibiotic sorption performance of a novel magnetic nanohybrid material: MnFe2O4@black cumin solid waste- derived activated carbon. J Environ Chem Eng 12:112641. https://doi.org/10.1016/j.jece.2024.112641

Wang F, Sun W, Pan W, Xu N (2015) Adsorption of sulfamethoxazole and 17β-estradiol by carbon nanotubes/CoFe2O4 composites. Chem Eng J 274:17–29. https://doi.org/10.1016/j.cej.2015.03.113

Wei M, Marrakchi F, Yuan C, Cheng X, Jiang D, Zafar F, Fu Y, Wang S (2022) Adsorption modeling, thermodynamics, and DFT simulation of tetracycline onto mesoporous and high-surface-area NaOH-activated macroalgae carbon. J Hazard Mater 425:127887. https://doi.org/10.1016/j.jhazmat.2021.127887

Wen C, Liu T, Wang D, Wang Y, Chen H, Luo G, Zhou Z, Li C, Xu M (2023) Biochar as the effective adsorbent to combustion gaseous pollutants: Preparation, activation, functionalization and the adsorption mechanisms. Prog Energ Combust 99:101098. https://doi.org/10.1016/j.pecs.2023.101098

Wu Y, Cheng H, Pan D, Zhang L, Li W, Song Y, Bian Y, Jiang X, Han J (2021) Potassium hydroxide- modified algae-based biochar for the removal of sulfamethoxazole: Sorption performance and mechanisms. J Environ Manage 293:112912–112912. https://doi.org/10.1016/j.jenvman.2021.112912

Xiang W, Wan Y, Zhang X, Tan Z, Xia T, Zheng Y, Gao B (2020) Adsorption of tetracycline hydrochloride onto ball-milled biochar: Governing factors and mechanisms. Chemosphere 255:127057–127057

Zeng Y, Wu L, Luo J, Lu X, Jia B, Liang L, Zhang J (2024) Photocatalytic degradation of ciprofloxacin by Gd-Co/g-C3N4 under low-power light source: Degradation pathways and mechanistic insights. J Water Process Eng 58:104849. https://doi.org/10.1016/j.chemosphere.2020.127057

Zhang H, Zhao F, Xia M, Wang F (2021) Microscopic adsorption mechanism of montmorillonite for common ciprofloxacin emerging contaminant: Molecular dynamics simulation and Multiwfn wave function analysis. Colloid Surface A 614:126186. https://doi.org/10.1016/j.colsurfa.2021.126186

Zhang S, Hou J, Zhang X, Cheng L, Hu W, Zhang Q (2023) Biochar-assisted degradation of oxytetracycline by Achromobacter denitrificans and underlying mechanisms. Bioresour Technol 387:129673. https://doi.org/10.1016/j.biortech.2023.129673

Zhu F, Wu Y, Liang Y, Li H, Liang W (2020) Degradation mechanism of norfloxacin in water using persulfate activated by BC@nZVI/Ni. Chem Eng J 389:124276. https://doi.org/10.1016/j.cej.2020.124276

Zou Y, Wang X, Khan A, Wang P, Liu Y, Alsaedi A, Hayat T, Wang X (2016) Environmental Remediation and Application of Nanoscale Zero-Valent Iron and Its Composites for the Removal of Heavy Metal Ions: A Review. Environ Sci Technol 50:7290–7304. https://doi.org/10.1021/acs.est.6b01897

Acknowledgements

The work was financially supported by the National Key Research and Development Program of China (2022YFD1601103, 2023YFD1701403), the Central Public-interest Scientific Institution Basal Research Fund (Y2024QC28), and the Science & Technology Innovation Program of the Chinese Academy of Agricultural Sciences, and the Scottish Government’s Rural and Environment Science and Analytical Services Division (RESAS). The authors would like to thank Dr. Feng Shen for reviewing the manuscript and providing constructive insights.

Funding

National Key Research and Development Program of China (2022YFD1601103), and the National Natural Science Foundation of China (42277033), and the Scottish Government’s Rural and Environment Science and Analytical Services Division (RESAS).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Chen Chen, Fengxia Yang and Yongfei Ma. The first draft of the manuscript was written by Chen Chen and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Completing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Fengchang Wu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, C., Yang, F., Ma, Y. et al. Ball milling boosted magnetic cotton husk-derived biochar adsorptive removal of oxytetracycline and ciprofloxacin from water. Carbon Res. 3, 63 (2024). https://doi.org/10.1007/s44246-024-00146-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-024-00146-9