Abstract

Soft carbon has been recognized as a promising anode material for potassium-ion batteries (PIBs), due to low cost, high conductivity and low voltage platform. However, their practical application is hampered by slow storage kinetics and unsatisfactory cycle life. In this work, pitch-derived needle coke, a typical soft carbon, was incorporated with oxygenated functional groups through liquid phase oxidation by using H2O2 oxidant. When used as anode materials for PIBs, the oxidized needle coke delivers a high reversible capacity of 322.7 mAh g−1, significantly superior to that of the needle coke (237.9 mAh g−1). The enhanced electrochemical performance can be attributed to the abundant oxygenated functional groups and resultant defects on the surface of oxidized needle coke, which not only serve as extra active sites for potassium storage, but also provide sufficient pathways for K+ migration across the adjacent carbon layers. Moreover, the expanded interlayer spacing derived from H2O2 oxidation facilitates rapid K+ intercalation and deintercalation. This work offers an effective modification strategy for the fabrication of high-performance pitch-based soft carbon anodes for PIBs.

Graphical Abstract

Highlights

-

Oxygenate functional groups were introduced into pitch-derived needle coke by H2O2 treatment.

-

The needle coke with a moderate oxidization level delivers an enhanced electrochemical performance.

-

The abundant oxygenated functional groups and resultant defects facilitate K+ migration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Potassium-ion batteries (PIBs) have drawn widespread attention for their abundant raw materials and cost-effectiveness (Luo et al. 2024; Qiu et al. 2024; Zhang et al. 2023). Carbon materials have been widely utilized as anode materials in PIBs, due to their tunable structure, high specific surface areas, high electrical conductivity, and environmental friendliness (Ouyang et al. 2023; Shen et al. 2023; Xu et al. 2023; Yu et al. 2023). Graphite, commonly employed as anode materials in lithium-ion batteries, presents a specific capacity of 279 mAh g−1 when used in PIBs (Yin et al. 2023, 2021). However, the narrow interlayer spacing and huge volume expansion of graphite occurred during rapid charging and discharging cycles significantly impacted the cycling stability and overall lifespan (Destiarti et al. 2023; Zhao et al. 2023a, b). Hence, it is crucial to rapidly advance carbon-based anode materials for practical applications.

Pitch-based carbon materials (Chen et al. 2023; Hu et al. 2022; Ouyang et al. 2023; Zhang et al. 2021a, b), have attracted significant attention as promising electrode materials in the field of energy storage, especially for anodes in PIBs. As an affordable pitch-based soft carbon, needle coke (NC) exhibits a unique layered configuration that facilitates rapid intercalation and deintercalation of potassium ions (Zhu et al. 2020). However, several challenges and limitations would restrict its further applications (Liu et al. 2023a, b; Liu et al. 2020). For instance, the relatively larger radius of potassium ions and the compact carbon layers spacing present difficulties in efficient ion diffusion (Zhang et al. 2021a, b). Additionally, enhancing the electrochemical characteristics remains a formidable challenge. Despite the impressive electronic conductivity of NC, it may lack sufficient porosity and defect to accommodate a substantial number of potassium ions and facilitate the interlayer ion transport. To address these challenges, two strategies can be employed to enhance the performance of the NC anode in PIBs: (1) increasing the potassium storage capacity and accelerating ion transport by expanding the interlayer spacing; and (2) introducing more defects into the material to generate additional active sites, thereby providing more options for ion insertion and improving the overall performance.

Recent studies have revealed that the introduction of oxygen atoms not only induces defects but also serves as an active site for potassium ion storage (Chen et al. 2018). Lu et al. (2018) employed a pre-oxidation strategy to modify the microstructure of pitch-based carbon, contributing to a capacity increase from 94.0 to 300.6 mAh g−1 and Coulombic efficiency from 64.2% to 88.6%. Sun et al. (2024) suggested reducing hysteresis through oxygen-driven bulk defect engineering in carbon for rapid potassium storage at low voltages, achieving a reversible capacity of 192 mAh g−1 at 1 A g−1. Zhao et al. (2020) demonstrated that introducing oxygen functional groups into needle coke can augment sodium storage sites (C = O) and the distance between carbon layers from 0.344 nm to 0.384 nm, attaining a high reversible capacity of 385 mAh g−1 at 0.05 A g−1. It was reported that increasing the number of active sites on carbon anode surfaces can attribute to a superior adsorption capacity. After oxidation treatment, oxygenated functional groups can be incorporated into carbon materials (Qiu et al. 2023). Yin et al. (2021) using fly ash carbon (FAC), as an anode material for alkali metal-ion batteries, demonstrated that the charge storage mechanism of the FAC anode was shown to be intercalation coupled with redox reactions of oxygen functional groups. Moderate oxidation during the process can boost the electrochemical performance of carbon materials, while excessive oxidation may degrade this performance. For instance, an excess of defects can damage the material and compromise its electronic transport properties. Therefore, the manipulation of oxidation conditions is pivotal for augmenting the electrochemical attributes of carbon materials. Chemical oxidation serves as a quintessential approach to introduce defects into the structural integrity of carbon materials (Wang et al. 2022; Wu et al. 2023a, b). The prevalent strong oxidizing agents employed in various applications encompass potassium permanganate (KMnO4) (Wu et al. 2023a, b), nitric acid (HNO3) (Liu et al. 2023a, b) and hydrogen peroxide (H2O2) (Morales-Ospino et al. 2024). Among these oxidizing agents, H2O2 is used as the oxidizing agent because it is relatively mild, safe, and environmentally friendly compared to HNO3 and KMnO4. To the best of our knowledge, there have been limited reports on the oxidation of needle coke using H2O2 in PIBs.

In this work, oxygenated functional groups are incorporated into the NC through a single step of liquid phase oxidation using H2O2 with various concentrations. At the optimal oxidation level, it exhibits expanded carbon interlayer spacing, and abundant oxygenated functional groups and resultant defects on the surface of the NC serve as active sites for potassium storage and provide sufficient pathways for K+ migration. When applied as anodes for PIBs, the optimal oxidized NC achieves an enhanced reversible capacity, rate and cycle performance. This work offers novel insights for the industrialization and technological advancement of PIBs.

2 Materials and methods

2.1 Preparation of the ONC

Needle coke (NC), a typical pitch-based soft carbon material, was used as the raw material. It was firstly ball milled at 360 rpm for 8 h under an Ar atmosphere and then sieved with a 300-mesh sieve (less than 48 μm). Then, the sieved NC was washed with hydrofluoric acid and hydrochloric acid to eliminate the residual ash, followed by being washed with DI water to neutral and dried overnight in vacuum dried at 60 ℃. After drying, the deashed NC were added into H2O2 solutions with different concentrations, and stirred at room temperature for 12 h. After filtration and drying at 60 ℃ for 12 h, the solid samples were obtained and denoted as ONC-x (x = 3, 5, 7, 9) based on the concentration of H2O2 (3, 5, 7, and 9 mol L−1).

2.2 Materials characterizations

The high-resolution electron microscope (HR-TEM) was performed on a JEM 2100. The field emission scanning electron microscope (FE-SEM) was conducted on Nova 450. The X-ray Diffraction (XRD) was carried out using Rigaku D/Max 2400. The X-ray photoelectron spectroscopy (XPS) was performed using a Thermo ESCALAB 250. Raman spectroscopy was with a 532 nm laser. The N2 adsorption isotherms were obtained on a Micrometrics ASAP 2020 at 77 K. Elemental analysis was conducted by an elemental analyzer (Element, Vario EL III).

2.3 Electrochemical tests

Firstly, the NC and ONCs were sieved with a 300-mesh sieve (less than 48 μm). Subsequently, the slurries were prepared by mixing 70 wt.% deashed NC or ONCs, 20 wt.% acetylene black with polyvinylidene fluoride (PVDF, 10 wt.%) binder solution in N-methylpyrrolidinone (NMP). The slurry was homogeneously applied onto carbon-coated Al foils and vacuum dried at 60 ℃ for 12 h. The 2025 half cells were assembled in an Ar-filled glovebox (O2 and H2O below 0.1 ppm) with NC as active materials, K foil as counter anodes, and glass fiber mat as separators. The electrolyte was 0.8 mol L−1 KPF6 in a 1:1 (vol./vol.) mixture of EC/DEC. This amount of electrolyte for each cell is 180 μL. And the loading of the electrode is ~ 1.0 mg cm−2. Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) tests were recorded on a VMP-300 multichannel electrochemical workstation with a scan of 0.1 mV s−1 at 0.01–3.0 V and a frequency of 100 kHz to 10 mHz, respectively. Galvanostatic charge/discharge (GCD) measurement was conducted on a NEWARE battery test system (CT-4008, Shenzhen, China) with a voltage window of 0.01–3.0 V. The apparent diffusion coefficient of K+ (DK) in the anodes was measured using the galvanostatic intermittent titration technique (GITT) by applying a pulse current of 0.1 A g−1 for 30 min between rest intervals for 2 h.

3 Results and discussions

The fabrication process of ONC-x samples is shown in Fig. 1a. Typically, the pulverized and deashed NC was added to H2O2 solution with different concentrations. This mixture was stirred for a duration of 12 h to facilitate an optimal reaction between the NC and H2O2 solution. During this process, the surface and edges of ONC-x were attacked by O2 produced by H2O2 decomposition. The distance between the carbon layers experienced an increase due to the high pressure exerted by expanding gases exceeding the van der Waals interaction forces between the interlayers (Sun et al. 2022). As shown in Fig. S1, the strong peaks (002) at around 26° demonstrate that the samples have a better graphitic crystal structure. Upon magnifying the pattern in Fig. 1b, it is evident that as the degree of oxidation increases, the width of half-maximum (FWHM) progressively widens compared to that of the NC, and the diffraction peaks (002) gradually shift to lower angles. In Table S1, the structural characterizations of oxidized NC were calculated by XRD pattern. From the results of structural characterizations, the d002 of ONC-5 was larger than that of NC, presenting that liquid oxidized treatment could make the interlayer spacing expand. This suggests that oxygenated functional groups may be incorporated onto the surface of the ONC-x samples, with an increase in carbon layer spacing (Sun et al. 2022). The increasing d002 potentially facilitates the potassiation/depotassiation to a certain extent.

Raman spectroscopy serves as an effective method for the characterization of carbon materials. As shown in Fig. 1c, the G band can be assigned to the degree of graphitization of NC, and the D band represents the defects and impurities of the NC. Thus, the ratio of the D-band to the G-band intensities (AD/AG) can serve as an indicator for evaluating the defect density in the sample (Zhang et al. 2021a, b). The AD/AG values are 1.8, 2.2, 2.3, 1.6, and 1.5 for NC, ONC-3, ONC-5, ONC-7, and ONC-9, respectively. The AD/AG value of ONC-5 sample was the biggest among all the samples, indicating that the ONC-5 sample had the highest defect density. The result demonstrates that the oxidation treatment successfully introduced defects in ONC-x samples, and the defect density in ONC-5 was the highest among all the samples. Subsequently, the D band was further fitted into three bands (Fig. S2 and Table S2), demonstrating that the irregular section of the ONC-x samples was constitutive of disordered graphitic lattice from edges (D1 ~ 1351.6 cm−1) and surface (D2 ~ 1482 cm−1), as well as amorphous carbon (D3 ~ 1213 cm−1) (Table S2; Liu et al. 2022). D1 presents a higher ratio of area than that of D2 and D3, suggesting that graphene edge sites primarily contributed to the observed defects. From Table S2, it is evident that both values of AD2/AG and AD3/AG of ONC-5 sample significantly increased in comparison with the other ONC-x samples, indicating an increased defect sites in ONC-5 sample. Therefore, ONC-5 may possess more active sites for potassium ion storage, improving its potassium storage performance.

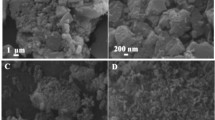

As shown in Fig. 1d and Fig. S3, as the oxidation degree increased, the specific surface area of the ONC-3 and ONC-9 increased from 5.6 m2 g−1 up to 7.9 m2 g−1, and that of the oxidized samples was greater than that of the untreated NC sample (4.4 m2 g−1). Furthermore, there was a marked increase in both micropores and mesopores in the ONC-x samples in Fig. 1d. In contrast, the number of mesopores and micropores in the ONC-9 sample diminished, with a notable presence of pores measuring between 40–60 nm. This suggests that the excessive oxidation could be attributed to the high concentration of H2O2 solution. The SEM images in Fig. 1e and Fig. S4 clearly demonstrated the flake stacked structure of the ONC-5 sample and other ONC-x samples. The microstructures of the NC and ONC-x samples were further examined through TEM analysis, as shown in Fig. 1f and Fig. S5. Figure 1g displays a distinct carbon lattice stripe in the ONC-5 sample, with a lattice spacing of 0.351 nm. However, as the H2O2 solution concentration was over 5 mol L−1, the lattice fringes gradually disappeared, indicating that the carbon layer structure was damaged.

In Fig. S6a, the XPS spectra displays two primary peaks at 284 and 531 eV, corresponding to O 1 s and C 1 s, respectively. As depicted in Fig. S6b, the peak intensity and peak area of the O 1 s spectra increase with the degree of oxidation, which indicates an augmented content of oxygen elements. Figs. S7 and S8 present the fitting curves for the C 1 s and O 1 s spectra for NC, ONC-3, ONC-5, ONC-7, and ONC-9, respectively. In Fig. S7, the C 1 s spectra for the NC can be segmented into three distinct peaks at 284.0, 285.1, and 288.7 eV, which correspond to C–C, C = O, and HO-C = O bonds, respectively (Xia et al. 2015; Zhao et al. 2023a, b). Moreover, a new peak emerged at approximately 284.5 eV can be associated with the C-O bond. As shown in Fig. S9, the O 1 s was then fitted by three peaks at 533.0, 532.0, and 530.8 eV, corresponding to HO-C = O, O-C-O/C–OH, and C = O bonds, respectively. To analyze variations in oxygen content, the ratio of the fitting area of the O 1 s peak to the XPS spectrum is presented in Table S3. Notably, the ONC-5 sample exhibits the highest content of superficial oxygenated functional groups. These findings suggest that the ONC-5 sample contained a greater number of oxygen functional groups acting as active sites, potentially leading to superior electrochemical performance compared to other oxygen samples. In Fig. S9, the elemental analysis reveals that the ONC-5 sample possessed the highest oxygen content, aligning with the XPS results.

Figure 2a–e displays the second discharge curves of NC and ONC-x anodes at 0.05 A g−1. Soft carbon, as the anode, could storage potassium ions by the mechanisms of adsorption and intercalation. In PIBs, the regions of adsorption and intercalation can be divided by the voltage during charge and discharge process (Zhang et al. 2020). In general, the adsorption reaction usually occurs in the higher voltage region, while the intercalation reaction occurs in the lower voltage region. Combining with CV curves (Fig. 3a and Fig. S10), there is a cathodic peak in the low voltage region, which corresponds to the reaction of potassium ions intercalation/deintercalation. Therefore, the intercalation/deintercalation of K-ions mainly occurs in the low voltage region (< 0.4 V), whereas above 0.4 V, the capacity is attributed to the K+ adsorption mechanism (He et al. 2023; Zhang et al. 2019; Zhong et al. 2022). Figure 2a presents the discharge curve for the NC electrode, revealing an adsorption capacity of 32.2 mAh g−1 and an intercalation capacity of 205.8 mAh g−1. After the oxidation treatment, the adsorption and intercalation capacities of the ONC-x anodes significantly enhanced compared to the original NC anode. The adsorption capacities of the ONC-3, ONC-5, ONC-7, ONC-9 anodes were 71.1, 80.2, 62.6, and 54.8 mAh g−1, respectively, while their corresponding intercalation capacities were 263.8, 277.2, 249.2, and 252.5 mAh g−1, respectively. The adsorption and intercalation capacities of the NC and other ONC-x anodes are summarized in Fig. 2f. The observed capacity variation trend indicates that electrochemical performance correlates proportionally with the concentration of the oxidizing agent when the H2O2 solution concentration remains below 5 mol L−1. However, when the H2O2 solution concentration exceeds 5 mol L−1, there is an inverse correlation between sample capacity and oxidation degree. Based on these findings, it can be postulated that the oxidation process may compromise the structural integrity of NC to some extent, which is not conducive to preserving the structural characteristics of the ONC-7 and ONC-9 anodes (Liu et al. 2022; Zhong et al. 2015).

Figure 3a and Fig. S10 illustrate the CV curves conducted within 0–3 V, with a scan rate of 0.1 mV s−1. In Fig. 3a, two cathodic peaks in the initial CV curve of the ONC-5 anode are observed at approximately 0.64 V and 0.31 V, suggesting the formation of solid electrolyte interphase (SEI) films and decomposition of the organic electrolyte. The subsequent cycles of the ONC-5 anode closely overlap with the subsequent cycles, indicative of its high reversibility. Additionally, a redox peak around 0.01 V is evident in the CV curves of all anodes, signifying the reversible nature of the potassium intercalation/de-intercalation process. Figure 3b presents the galvanostatic charge and discharge (GCD) curves of ONC-5 anode at the current density of 0.05 A g−1. For the ONC-5 anode, the initial coulombic efficiency (ICE) is 55.7%, which is higher than the ICE (43.5%) of the NC anode in Fig. S11. As shown in Fig. S12, from the charging and discharging curves with different rates, it can be seen that the capacity of NC anode decays rapidly, while the capacity of ONC-5 anode can maintain high voltage and capacity, indicating that the oxidized NC anode has a better electrochemical performance. Figure 3c illustrates the electrochemical rate performance of all anodes at the current density from 0.05 to 2 A g−1. The electrochemical performance of ONC-5 anode shows a reversible capacity of 322.7 mAh g−1 at 0.05 A g−1. In detail, the reversible capacities for ONC-3, ONC-7, and ONC-9 anodes were recorded as 289.5, 289.4, and 260.6 mAh g−1, respectively. Furthermore, it was noted that the capacity of the ONC-5 anode could reach up to 98.9 mAh g−1 at 2 A g−1, nearly twice less than that of the NC anode. Upon returning to a current density of 0.05 A g−1, the reversible capacity of the ONC-5 anode recovered to 277.5 mAh g−1, highlighting its superior rate performance. And when the current density returned to 0.05 A g−1, the reversible capacities of ONC-3/7/9 were 266.9, 272.0, and 1.3 mAh g−1, respectively. Though the electrochemical performance across all anodes exhibited minimal variation at 0.05 A g−1, the ONC-5 anode demonstrated superior rate performance at 2 A g−1. Notably, the ONC-9 anode lost its flexibility after operating at this higher current density, hypothesizing that the ONC-9 anode may have been dislodged from the collector. As shown in Fig. 3d, the performance of ONC-5 anode exhibited excellent reversible capacity of 106.4 mAh g−1 at 1 A g−1 after 500 cycles. While the capacities reached 17.2, 36.3, 63.2, and 34.4 mAh g−1 for NC, ONC-3, ONC-7, and ONC-9, respectively. It is evident that as oxidation increases, electrochemical performance increases as H2O2 below 5 mol L−1, and decreases above 5 mol L−1. In Fig. S13 , compared with the relevant reported researches (Xiao et al. 2023; Yu et al. 2022; Ma et al. 2021; Wu et al. 2023a, b; Jian et al. 2017; Chang et al. 2023; Mohamed et al. 2023), the electrochemical performance of ONC-x anodes was higher than others. This enhancement may be attributed to the introduction of oxygen functional groups, which create more active sites on the surface of ONC-x anodes. Additionally, increasing carbon layer spacing positively impacts the electrochemical performance. Nonetheless, excessive oxidation can lead to diminished electrical conductivity (Xia et al. 2015), consequently reducing electrochemical performance.

To further investigate intercalation/de-intercalation mechanism, CV test at different scan rates, galvanostatic intermittent titration technique (GITT), and electrochemical impedance spectroscopy (EIS) were conducted. As shown in Fig. 4a and Fig. S14, the CV curves of ONC-5 anode and other anodes were tested at the scan rates ranged from 0.1 to 1.0 mV s−1. As shown in Fig. S16, the capacitive contributions of all anodes were integrated to obtain the diffusion and capacitive capacity at different scan rates. Figure 4d shows that the capacitive contributions of NC, ONC-3, ONC-5, ONC-7, and ONC-9 anodes were 14%, 37%, 59%, 72%, and 51%, respectively at 0.4 mV s−1. Among these anodes, the NC anode exhibited the lowest capacitive contribution while the ONC-5 anode demonstrated the highest. This can be attributed to the structural integrity and minimal defects of the NC anode, which leads to the intercalation of the potassium storage to contribute to a large extent to the capacity. Additionally, the ONC-5 anode contains more active sites enhancing its adsorption capacity for potassium ion storage. Following oxidation treatment, an abundance of active sites and a large specific surface area on the surface can augment the capacitive contribution ratio.

As shown in Fig. 4b, the Fick second law was conducted to calculate the diffusion coefficient of K+ (DK). According to the potential-diffusion coefficient curve (Fig. 4e), the DK value of the ONC-5 anode is the highest during charge/discharge process. This can be attributed to the increased interlayer spacing and surface defect density. EIS was employed to investigate the kinetics of charge carrier transport. In Fig. 4c, the diameter of the measured semicircle represents the charge transfer resistance (Rct), while the slope of the straight line in the low-frequency part may suggest the ion diffusion resistance (Fan et al. 2018). Based on the equivalent circuit, the Warburg constant (σ; Fig. 4f; Feng et al. 2022) was identified as the slope of the linear relationship between the Z’ versus ω−1/2 (Eq. [1]) in the low frequency region. The diffusion of K+ was calculated by using the Eq. (2) (Zhao et al. 2020) in Table S4.

where σ is the Warburg constant, Rs is the electrolyte resistance, and Rct refers to the charge transfer resistance at the electrolyte-anode interface in the Eq. (1). In Eq. (2), DK represents the K+ diffusion, n is the number of transfer electrons, F is Faraday’s constant, C represents the concentration, T refers the temperature, and A represents the anode area with the electrolytes. The results demonstrate that the Rct increases with the increasing oxidation level, potentially due to the oxygen functional groups on the surface of ONC-x anodes that hinder the charge transfer process. It was observed that within an optimal concentration range, the DK increases proportionally to the degree of oxidation. This suggests that the expansion of carbon layer spacing facilitates the movement of K+ between adjacent carbon layers more efficiently.

Based on the aforementioned kinetic results, the ONC-5 anode demonstrates superior kinetic properties and K+ storage performance. These outcomes can be attributed to the following three factors: (1) after oxidation reaction, the defects provide active sites for electron transfer and K+ storage, thereby enhancing electrochemical performance; (2) the increased spacing between carbon layers facilitates rapid K+ intercalation; (3) the ONC-5 anode mitigates charge transfer resistance with the moderate oxidization treatment. Potassium ions can be stored across the adjacent carbon layers within the ONC-5 anode through its edges and defects, contributing to a higher reversible capacity and K+ transfer kinetics (Fig. 5). In contrast, the NC anode features relatively parallel carbon layers, resulting in fewer storage active sites and slower electrochemical kinetics compared to the ONC-5 anode. However, the ONC-9 anode contains an excessive number of defects, which reduce the conductivity of the carbon material and result in an inferior potassium storage performance.

4 Conclusion

In conclusion, the direct oxidation method enables the introduction of oxygenated functional groups onto the surface of soft carbon materials through H2O2 oxidation. The oxygen produced during this process can contribute to the swelling of the carbon layer. Oxidation creates negatively charged oxygenate functional groups, which readily adsorb positively charge potassium ions. The oxidation treatment could adjust the structure of NC, thus creating defects and channels, enhancing the diffusion rate of potassium ions, and accelerating the storage rate of potassium ions. According to the structural characterizations of ONC-x anodes, these oxygenated functional groups can serve as active sites for potassium ions adsorption, the introducing defects improve the conductivity and the expansion of interlayers spacing benefits for the improvement of K+ storage. The results show that the optimal oxidized ONC-5 maintains a high reversible capacity of 322.7 mAh g−1 at 0.05 A g−1. However, excessive oxidation may compromise the NC structure, resulting in an inferior potassium storage performance. However, excessive oxidation may compromise the NC structure, resulting in an inferior potassium storage performance. This work offers a feasible approach to enhance the potassium storage performance of soft carbon anodes.

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Chang X, Sun N, Zhou H, Soomro RA, Xu B (2023) Soft carbon-coated bulk graphite for improved potassium ion storage. Chin Chem Lett 34:107312. https://doi.org/10.1016/j.cclet.2022.03.035

Chen M, Wang W, Liang X, Gong S, Liu J, Wang Q, Guo S, Yang H (2018) Sulfur/oxygen codoped porous hard carbon microspheres for high-performance potassium-ion batteries. Adv Energy Mater 8:1800171. https://doi.org/10.1002/aenm.201800171

Chen L, Yuan Y, Orenstein R, Yanilmaz M, He J, Liu J, Liu Y, Zhang X (2023) Carbon materials dedicate to bendable supports for flexible lithium-sulfur batteries. Energy Storage Mater 60:102817. https://doi.org/10.1016/j.ensm.2023.102817

Destiarti L, Riyanto R, Roto R, Mudasir M (2023) Electrolyte effect in electrochemical exfoliation of graphite. Mater Chem Phys 302:127713. https://doi.org/10.1016/j.matchemphys.2023.127713

Fan Y, Ouyang D, Li B, Dang F, Ren Z (2018) Two-dimensional VO2 mesoporous microarrays for high-performance supercapacitor. Nanoscale Res Lett 13:142. https://doi.org/10.1186/s11671-018-2557-7

Feng W, Wang H, Jiang Y, Zhang H, Luo W, Chen W, Shen C, Wang C, Wu J, Mai L (2022) A strain-relaxation red phosphorus freestanding anode for non-aqueous potassium ion batteries. Adv Energy Mater 12:22103343. https://doi.org/10.1002/aenm.202103343

He X, Zhong L, Qiu X, Wen F, Sun S, Zu X, Zhang W (2023) Sustainable polyvinyl chloride-derived soft carbon anodes for potassium-ion storage: electrochemical behaviors and mechanism. Chemsuschem 16:202300646. https://doi.org/10.1002/cssc.202300646

Hu C, Chu H, Zhu Y, Xu Y, Cheng J, Gao L, Lai S, Zhao X (2022) Differences and correlations between microstructure and macroscopic properties of mesophase cokes derived from the components of high temperature coal tar pitch. Fuel 310:122330. https://doi.org/10.1016/j.fuel.2021.122330

Jian Z, Hwang S, Li Z, Hernandez AS, Wang X, Xing Z, Su D, Ji X (2017) Hard-soft composite carbon as a long-cycling and high-rate anode for potassium-ion batteries. Adv Funct Mater 27:1700324. https://doi.org/10.1002/adfm.201700324

Liu Y, Lu Y, Xu Y, Meng Q, Gao J, Sun Y, Hu Y, Chang B, Liu C, Cao A (2020) Pitch-derived soft carbon as stable anode material for potassium ion batteries. Adv Mater 32:2000505. https://doi.org/10.1002/adma.202000505

Liu C, Zheng H, Wang Y, Xiao N, Yu K, Li H, Zhang X, Bai H, Ma T, Qiu J (2022) Microstructure regulation of pitch-based soft carbon anodes by iodine treatment towards high-performance potassium-ion batteries. J Colloid Interface Sci 615:485–493. https://doi.org/10.1016/j.jcis.2022.01.178

Liu H, Zhu S, Chang Y, Hou W, Han G (2023a) Pitch-based carbon materials: a review of their structural design, preparation and applications in energy storage. New Carbon Mater 38:459–473. https://doi.org/10.1016/s1872-5805(23)60743-7

Liu X, Lu Y, Pan D, Xiao G, Zhao H, Hu Z, Zhu J, Liu Z (2023b) Comparative study on flower-like polyimide-based carbon electrodes activated by KOH and HNO3. J Energy Storage 72:108506. https://doi.org/10.1016/j.est.2023.108506

Lu Y, Zhao C, Qi X, Qi Y, Li H, Huang X, Chen L, Hu Y (2018) Pre-oxidation-tuned microstructures of carbon anodes derived from pitch for enhancing Na storage performance. Adv Energy Mater 8:1800108. https://doi.org/10.1002/aenm.201800108

Luo Q, Liu Y, Ren Q, Zhang W, Yi L, Yang J, Liu G, Huang Z, Liu L (2024) BiPO4 is embedded in reduced graphene oxide as an anode for potassium ion batteries. Appl Surf Sci 645:158841. https://doi.org/10.1016/j.apsusc.2023.158841

Ma X, Xiao N, Xiao J, Song X, Guo H, Wang Y, Zhao S, Zhong Y, Qiu J (2021) Nitrogen and phosphorus dual-doped porous carbons for high-rate potassium ion batteries. Carbon 179:33–41. https://doi.org/10.1016/j.carbon.2021.03.067

Mohamed AMA, Dong S, Elhefnawey M, Dong G, Gao Y, Zhu K, Cao D (2023) A comparison of the electrochemical performance of graphitized coal prepared by high-temperature heating and flash Joule heating as an anode material for lithium and potassium ion batteries. Chem Phys Lett 815:140362. https://doi.org/10.1016/j.cplett.2023.140362

Morales-Ospino R, Canevesi RLS, Schaefer S, Celzard A, Fierro V (2024) Is heteroatom doping of activated carbons always a good strategy for enhancing CO2 adsorption? Chem Eng J 479:147638. https://doi.org/10.1016/j.cej.2023.147638

Ouyang D, Yang L, Wang Y-n, Li Y, Yu F, Yin J (2023) Amorphous carbon with N-S bond active center for enhanced capacitive contribution of potassium-ion batteries. Sustain Mater Technol 37:00672. https://doi.org/10.1016/j.susmat.2023.e00672

Qiu C, Jiang L, Gao Y, Sheng L (2023) Effects of oxygen-containing functional groups on carbon materials in supercapacitors: A review. Mater Des 230:111952. https://doi.org/10.1016/j.matdes.2023.111952

Qiu X, Shi L, Xu Z, Qian J, Song M, Sun L, Xu X, Xu Y, Fu Y, Ren J, Zhuang W, Zhuang Q, Ju Z, Chen Y (2024) Edge defect protection of graphitic carbon nanocages for stable potassium storage at low voltage. J Alloys Compd 970:172539. https://doi.org/10.1016/j.jallcom.2023.172539

Shen N, Lai Q, Chen N, Pang Y, Chen H, Zhang W, Liu Z (2023) Hard carbon anode synthesized by an in situ porous strategy for advanced potassium-ion batteries. ACS Sustainable Chem Eng 11:14572–14581. https://doi.org/10.1021/acssuschemeng.3c04086

Sun D, Zhao L, Xiao Z, Zhao K, Lin R, Song H, Zhang X, Ma X, Peng C, Huang X, Li X, Gao J, Xu C (2022) Boosting of reversible capacity delivered at a low voltage below 0.5 V in mildly expanded graphitized needle coke anode for a high-energy lithium ion battery. J Energy Chem 74:100–110. https://doi.org/10.1016/j.jechem.2022.07.013

Sun Z, Chen Y, Geng C, Li Y, Guo W, Jiang J, Cui Y, Shi Y, Zhuang Q, Ju Z (2024) Oxygen-driven bulk defect engineering in carbon to reduce voltage hysteresis for fast potassium storage at low voltage. Appl Catal B 343:123473. https://doi.org/10.1016/j.apcatb.2023.123473

Wang P, Pu S, Zhang W, Shi L, Zhang D (2022) Revisiting the influence of chemical oxidation on the adsorption properties of carbonaceous materials with different structures: Non-dispersible versus dispersible structure. Sep Purif Technol 286:120516. https://doi.org/10.1016/j.seppur.2022.120516

Wu S, Song Y, Lu C, Yang T, Yuan S, Tian X, Liu Z (2023a) High-rate soft carbon anode in potassium ion batteries: the role of chemical structures of pitches. Carbon 203:211–220. https://doi.org/10.1016/j.carbon.2022.11.058

Wu W, Li P, Su W, Yan Z, Wang X, Xu S, Wei Y, Wu C (2023b) Polyaniline as a nitrogen source and lignosulfonate as a sulphur source for the preparation of the porous carbon adsorption of dyes and heavy metal ions. Polymers 15:4515. https://doi.org/10.3390/polym15234515

Xia G, Shen S, Zhu F, Xie J, Hu Y, Zhu K, Zhang J (2015) Effect of oxygen-containing functional groups of carbon materials on the performance of Li–O2 batteries. Electrochem Commun 60:26–29. https://doi.org/10.1016/j.elecom.2015.07.011

Xiao N, Guo H, Xiao J, Wei Y, Ma X, Zhang X, Qiu J (2023) KOH-treated mesocarbon microbeads used as high-rate anode materials for potassium-ion batteries. New Carbon Mater 38:327–334. https://doi.org/10.1016/s1872-5805(21)60059-8

Xu H, Cheng B, Du Q, Zhang Y, Duan H, Egun I, Yin B, He H (2023) Strengthening synergistic effects between hard carbon and soft carbon enabled by connecting precursors at molecular level towards high-performance potassium ion batteries. Nano Res 16:10985–10991. https://doi.org/10.1007/s12274-023-5853-1

Yin J, Zhang W, Huang G, Alhebshi NA, Salah N, Hedhili MN, Alshareef HN (2021) Fly ash carbon anodes for alkali metal-ion batteries. ACS Appl Mater Interfaces 13:26421–26430. https://doi.org/10.1021/acsami.1c06543

Yin J, Jin J, Chen C, Lei Y, Tian Z, Wang Y, Zhao Z, Emwas A-H, Zhu Y, Han Y, Schwingenschlogl U, Zhang W, Alshareef HN (2023) Preferential pyrolysis construction of carbon anodes with 8400 h Lifespan for high-energy-density K-ion batteries. Angew Chem Int Ed 62:202301396. https://doi.org/10.1002/anie.202301396

Yu K, Liu C, Wang Y, Zheng H, Li H, Zhang X, Bai H, Ma T, Qiu J (2022) Molecular tuning of sulfur doped quinoline oligomer derived soft carbon for superior potassium storage. Carbon 191:10–18. https://doi.org/10.1016/j.carbon.2022.01.034

Yu J, Jiang M, Zhang W, Li G, Soomro RA, Sun N, Xu B (2023) Advancements and prospects of graphite anode for potassium-ion batteries. Small Methods 7:2300708. https://doi.org/10.1002/smtd.202300708

Zhang W, Ming J, Zhao W, Dong X, Hedhili MN, Costa PMFJ, Alshareef HN (2019) Graphitic nanocarbon with engineered defects for high-performance potassium-ion battery anodes. Adv Funct Mater 29:1903641. https://doi.org/10.1002/adfm.201903641

Zhang W, Yin J, Sun M, Wang W, Chen C, Altunkaya M, Emwas A-H, Han Y, Schwingenschlögl U, Alshareef HN (2020) Direct pyrolysis of supermolecules: an ultrahigh edge-nitrogen doping strategy of carbon anodes for potassium-ion batteries. Adv Mater 32:2000732. https://doi.org/10.1002/adma.202000732

Zhang L, Gu T, Lu K, Zhou L, Li D, Wang R (2021a) Engineering synergistic edge-N dipole in metal-free carbon nanoflakes toward intensified oxygen reduction electrocatalysis. Adv Funct Mater 31:2103187. https://doi.org/10.1002/adfm.202103187

Zhang W, Sun M, Yin J, Lu K, Schwingenschlögl U, Qiu X, Alshareef HN (2021b) Accordion-like carbon with high nitrogen doping for fast and stable K ion storage. Adv Energy Mater 11:2101928. https://doi.org/10.1002/aenm.202101928

Zhang W, Huang R, Yan X, Tian C, Xiao Y, Lin Z, Dai L, Guo Z, Chai L (2023) Carbon electrode materials for advanced potassium-ion storage. Angew Chem Int Ed 62:202308891. https://doi.org/10.1002/anie.202308891

Zhao D, Zhao H, Ye J, Song W, Miao S, Shen H, Zhao Y, Kang M, Li Z (2020) Oxygen functionalization boosted sodium adsorption-intercalation in coal based needle coke. Electrochim Acta 329:135127. https://doi.org/10.1016/j.electacta.2019.135127

Zhao H, Chang G, Gao X, Huang C, Li Z (2023a) Fe catalysed transformation of oxygen functional groups on coal based needle coke for sodium storage. Carbon 203:68–75. https://doi.org/10.1016/j.carbon.2022.11.049

Zhao L, Sun S, Lin J, Zhong L, Chen L, Guo J, Yin J, Alshareef HN, Qiu X, Zhang W (2023b) Defect engineering of disordered carbon anodes with ultra-high heteroatom doping through a supermolecule-mediated strategy for potassium-ion hybrid capacitors. Nanomicro Letters 15:41. https://doi.org/10.1007/s40820-022-01006-0

Zhong L, Anand C, Lakhi KS, Lawrence G, Vinu A (2015) Bifunctional mesoporous carbon nitride: highly efficient enzyme-like catalyst for one-pot deacetalization-knoevenagel reaction. Sci Rep 5:12901. https://doi.org/10.1038/srep12901

Zhong L, Zhang W, Sun S, Zhao L, Jian W, He X, Xing Z, Shi Z, Chen Y, Alshareef HN, Qiu X (2022) Engineering of the crystalline lattice of hard carbon anodes toward practical potassium-ion batteries. Adv Funct Mater 33:2211872. https://doi.org/10.1002/adfm.202211872

Zhu Y, Liu H, Xu Y, Hu C, Zhao C, Cheng J, Chen X, Zhao X (2020) Preparation and characterization of coal-pitch-based needle coke (part III): The effects of quinoline insoluble in coal tar pitch. Energy Fuels 34:8676–8684. https://doi.org/10.1021/acs.energyfuels.0c01049

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 52071171, 52202248, 22208138, 22308139), Natural Science Foundation of Liaoning Province (2023-MS-140), Liaoning BaiQianWan Talents Program (LNBQW2018B0048), Shenyang Science and Technology Project (21-108-9-04), Young Scientific and Technological Talents Project of the Department of Education of Liaoning Province (LQN202008), Key Research Project of Department of Education of Liaoning Province (LJKZZ20220015), Australian Research Council (ARC) through Future Fellowship (FT210100298, FT210100806), Discovery Project (DP220100603), Linkage Project (LP210100467, LP210200504, LP210200345, LP220100088), and Industrial Transformation Training Centre (IC180100005) schemes, and the Australian Government through the Cooperative Research Centres Projects (CRCPXIII000077).

Funding

National Natural Science Foundation of China (Nos. 52071171, 52202248, 22208138, 22308139), Natural Science Foundation of Liaoning Province (2023-MS-140), Liaoning BaiQianWan Talents Program (LNBQW2018B0048), Shenyang Science and Technology Project (21–108-9–04), Young Scientific and Technological Talents Project of the Department of Education of Liaoning Province (LQN202008), Key Research Project of Department of Education of Liaoning Province (LJKZZ20220015), Australian Research Council (ARC) through Future Fellowship (FT210100298, FT210100806), Discovery Project (DP220100603), Linkage Project (LP210100467, LP210200504, LP210200345, LP220100088), and Industrial Transformation Training Centre (IC180100005) schemes, and the Australian Government through the Cooperative Research Centres Projects (CRCPXIII000077).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Junjun Yao and Chang Liu. The first draft of the manuscript was written by Junjun Yao and Chang Liu. Yaming Zhu contributed to the resources and methodology of the study. Ying sun contributed to the validation and methodology of the study and Daming Feng contributed the methodology of the study. Yali Yao and Quanxing Mao conducted to the investigation of the study. Tianyi Ma contributed to the reviewing and editing of the article. And all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Handling Editor: Wenli Zhang

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1:

Fig. S1. XRD pattern of all samples, Fig. S2. Raman fitting spectrum. (a) NC; (b) ONC-3; (c) ONC-5; (d) ONC-7; (e) ONC-9, Fig. S3. Pore size distribution of all samples, Fig. S4. The SEM images of (a-b) NC; (c-d) ONC-3; (e-f) ONC-7; (g-h) ONC-9, Fig. S5. The TEM images of (a-b) NC, (c-d) ONC-3, (e-f) ONC-7, and (g-h) ONC-9, Fig. S6. (a) XPS spectra and (b) O 1s peaks of all samples, Fig. S7. C 1s fitting spectrum of (a) NC, (b) ONC-3, (c) ONC-5, (d) ONC-7, and (e) ONC-9, Fig. S8. O 1s fitting spectrum of (a) NC, (b) ONC-3, (c) ONC-5, (d) ONC-7, and (e) ONC-9, Fig. S9. The contents of C and O elements of all samples by elements analysis, Fig. S10. CV curves of (a) NC, (b) ONC-3, (c) ONC-7, and (d) ONC-9 anodes at 0.1 mV s-1, Fig. S11. GCD curves of (a) NC, (b) ONC-3, (c) ONC-7, and (d) ONC-9 anodes at 0.05 A g-1, Fig. S12. GCD curves of (a) NC, (b) ONC-3, (c) ONC-5, (d) ONC-7, and (e) ONC-9 anodes at different current density from 0.05 to 2 A g-1, Fig. S13. Comparison of the rate performance of different carbonaceous materials for PIBs, Fig. S14. CV curves of (a) NC, (b) ONC-3, (c) ONC-7, and (d) ONC-9 anodes at different scan rates in the range from 0.1 to 1.0 mV s-1, Fig. S15. The b value of (a) NC, (b) ONC-3, (c) ONC-5, (d) ONC-7 and (e) ONC-9 anodes, Fig. S16. The capacitive contribution ratio of (a) NC, (b) ONC-3, (c) ONC-5, (d) ONC-7, and (e) ONC-9 anodes, Table S1. The structure of the all samples, Table S2. Raman spectral peaks fitting data, Table S3. The content of each oxygen species by XPS, Table S4. The impedance value.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yao, J., Liu, C., Zhu, Y. et al. Liquid phase oxidation enables stable soft carbon anodes for potassium-ion batteries. Carbon Res. 3, 23 (2024). https://doi.org/10.1007/s44246-024-00106-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-024-00106-3