Abstract

Dyes and heavy metals pollute the environment. Biochar-based hydrogel is an excellent adsorbent, but the competitive adsorption mechanism associated with the removal of pollutants using biochar is yet to be understood in detail. Biochar was prepared following the process of high-temperature lysis of marine green tide (Enteromorpha prolifera). The prepared biochar was cross-linked with water-soluble chitosan and compounded with nano-Fe3O4 to synthesize magnetically-modified Enteromorpha prolifera-based biochar hydrogel (MM-EBC-HD). The competitive removal performance of the hydrogel was studied, and the pollutant removal mechanism was analyzed against a binary system consisting of common environmental pollutants (methyl orange [MO] and hexavalent chromium [Cr (VI)]. The physical and chemical properties of the composites were studied before and after contaminant removal, and the associated pollutant removal mechanisms were analyzed by SEM, EDS, FTIR, XRD, and XPS techniques. The effects of pH, temperature and initial pollutant concentration on the adsorption performance of the materials were examined. The maximum adsorption of MO on MM-EBC-HD was 71.18 mg g−1, and adsorption equilibrium was attained at approximately 60 min. Electrostatic forces, hydrophobic bonds, and hydrogen bonds were exploited for MO adsorption. And the maximum adsorption amount of Cr (VI) was recorded to be 115.41 mg g−1, and equilibrium was attained in approximately 10 min. Electrostatic and ion exchange effects were exploited to adsorb Cr (VI) efficiently. The MO and Cr (VI) adsorption processes could be explained by the second-order kinetic model and Langmuir adsorption isotherms, respectively. The adsorption performance recorded for the binary adsorption system was poorer than that recorded for the single adsorption system for both pollutants. MO and Cr (VI) adsorption decreased from 74.88% to 47.65% and from 62.33% to 42.4%, respectively. Competition between MO and Cr (VI) in the dual system can be attributed to the presence of amino and hydroxyl groups. The MO–Cr complex, which was more compact in structure than a single contaminant, was formed, allowing few reactive groups to be exposed to the surface of the hydrogel. Additionally, MM-EBC-HD nanocomposites presented a recovery rate of 87% after 5 cycles and thus could be used to avoid adsorbents-caused environmental hazards.

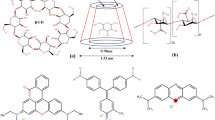

Graphical Abstract

Highlights

• Used Enteromorpha prolifera to prepare biochar hydrogel realized waste utilization.

• Hydrogel significantly removed Methyl Orange and Cr (VI) composites in water.

• The competitive adsorption mechanism of combined pollutants in water was proved.

• The excellent magnetic properties of hydrogels made them recyclable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Environmental pollution is one of the world’s biggest problems today, causing serious and irreparable damage to the earth. According to statistical data, the production of dyes for textiles worldwide exceeds 400,000 tons, and the production and use of dyes results in the generation of large amounts of dye-containing wastewater with high chromaticity (ranging from 500° to 5,000,000°) and toxicity (Tang et al. 2018). Methyl orange (MO) is a p-aminoazobenzene (p-AAB)-based dye that is widely used as an acid-base indicator in the textile dyeing industry and to conduct chemical experiments. The aqueous solution of MO is highly toxic and causes environmental pollution (Zhu et al. 2014). Hexavalent chromium [Cr (VI)] is widely used in leather manufacturing as a tanning preparation. Soluble Cr (VI) is extremely noxious, highly oxidizing, and carcinogenic to biological systems. In addition, it is reported that Cr (VI) was often used as mordant in printing and dyeing, which competed with other pollutants in the dye wastewater for the active sites of activated carbon (Deng et al. 2022; Ding et al. 2020). As different types of pollutants necessitate distinct chemical processes, remediation techniques, and treatment objectives, the remediation of Cr (VI) and MO co-polluted water bodies presents numerous difficulties. The interaction between organics and heavy metals can involve a variety of reaction types, including complexation reaction, REDOX reaction, and acid-base reaction. In solution, the presence of Cr (VI) may affect the solubility, stability, or aggregation state of MO dyes (Zhang et al. 2020). Therefore, it is crucial to find a suitable method to remove MO and Cr (VI) from aqueous solutions.

Various methods are followed for removing MO and Cr (VI) from wastewater, including physicochemical, biological, adsorption, and electrochemical methods (Gan et al. 2015). The adsorption method offers several advantages over others. This method is cost-effective and easy to operate and can be used to achieve high regenerative capacity (Kismir and Aroguz 2011). Currently, biochar is attracting great interest as a renewable, efficient, environmentally friendly, economic, and green biomaterial for environmental remediation practices. The abundance of surface functional groups (e.g., hydroxyl, carboxyl, and amino), high porosity, large surface area, and excellent ion-exchange capacity result in a signifificantly high adsorption efficiency of biochar-based adsorbents (Wang et al. 2017; Tan et al. 2015). Due to global climate change, water eutrophication, and other factors, large-scale outbreaks of the marine algae Enteromorpha prolifera (EP) green tide frequently occur. The outbreak caused a series of ecological problems, such as a reduction in biodiversity, depletion of dissolved oxygen in water, and the production of toxic and harmful substances that affected the growth of algae in seawater. It also affected tourism and different human activities, including water sports (Sahraei et al. 2017). The preparation of biochar from EP as a biomass feedstock not only improves the adsorption capacity, but also enhances its mechanical structure, which is a better direction for application.

To increase biochar’s adsorption capacity and environmental applicability, modifification of raw biochar, either by chemical or physical route, is a current research focus. Recent studies have demonstrated that polymeric biochar adsorbents offer better mechanical strength, enhanced durability, high adsorption capacity, and improved recyclability. Hydrogels are cross-linked polymeric materials, which belong to a class of natural/synthetic polymeric materials that can absorb large amounts of water (Fan et al. 2017; Ju et al. 2009). In addition, hydrogels can provide a matrix for the adsorption of antiparticles by immobilizing them and preventing them from being released into the environment due to their three-dimensional network structure, high solubility properties, and porous structure (Tang et al. 2014; Dong et al. 2018). Therefore, due to the combination of porous network of biochar and high chemical affinity of polymer hydrogel, polymer biochar hydrogel is a good adsorbent for removing complex pollution (Akl et al. 2021).

It is essential to recover the used hydrogels, particularly tiny hydrogel particles, from a solution after the completion of the adsorption or desorption process (Liu et al. 2020). Magnetic modification techniques can facilitate the rapid separation of magnetic adsorbents from aqueous solutions, effectively addressing the difficulty in recovering adsorbents after adsorbing target contaminants (Li et al. 2013). Tang et al. (2010) investigated a new magnetic hydrogel for the removal of Cr (VI), and the reaction reached equilibrium within 5 min. The removal capacity exhibited by the prepared hydrogen was approximately 200 mg g−1. The magnetic hydrogels can be magnetically separated within minutes as the embedded γ-Fe2O3 antiparticles exhibit magnetic properties. Owing to the size quantization effect mediated by their large surface area and high active surface sites, magnetic nanoparticles in adsorbents have a greater adsorption capacity than their non-magnetic counterparts (Gao et al. 2022; Ji et al. 2021). In a study by Hasan Fahmi et al. (2022), it was found that iron-encapsulated pure fruit biochar (IC-EFBB) had a larger specific surface area, a higher content of functional groups, and the highest adsorption capacity for Pb (II) compared to unencapsulated pure fruit biochar (EFBB), while IC-EFBB could be easily separated from an aqueous solution by utilizing external magnetic forces. These properties of magnetic hydrogels can be combined with the magnetic separation technique to achieve efficient and sustainable wastewater treatment.

Exploring pollutant removal mechanisms and developing cost-effective and easy-to-purify adsorbent materials with high adsorption capacity are crucial in addressing heavy metals and dyes composite contamination in the environment. The aim was to prepare magnetically-modified Enteromorpha prolifera-based biochar hydrogel (MM-EBC-HD) with a three-dimensional network structure for the removal of target pollutants (MO and Cr [VI]). The physicochemical properties (surface structure, crystalline state, functional groups, surface potential, etc.) of MM-EBC-HD were characterized and analyzed. The target was to investigate the adsorption performance of MM-EBC-HD and study the mechanism of adsorption associated with the removal of MO and Cr (VI). The hydrogels were used for the individual separation of MO and Cr (VI) as well as for the adsorption of the binary system containing both MO and Cr (VI). The researchers also aimed to investigate the effects of experimental conditions, such as pH, temperature, and initial pollutant concentration, on the adsorption kinetics and isotherm characteristics associated with MM-EBC-HD. A series of adsorption experiments were performed to evaluate the adsorption performance of the material. The aim was to develop an adsorbent that could be recycled and used to efficiently purify dye- and heavy metal-containing wastewater.

2 Materials and methods

2.1 Experimental materials

Chitosan (CS, CAS 9012-76-4, [C6H11NO4] n, deacetylation degree: 80% ~ 95%) was purchased from Sinopharm Group Chemical Reagent Corporation (Shanghai, China). Glutaraldehyde (50% in water) was purchased from Tianjin Damao Corporation (Tianjin, China). Potassium dichromate (K2Cr2O7) was purchased from Tianjin Guangcheng Chemical Reagent Corporation (Tianjin, China). Methyl orange (MO) was selected from Sinopharm Group Chemical Reagent Corporation (Shanghai, China). Other chemicals such as NaOH, CH3COOH, FeSO4•7H2O, FeCl3•6H2O, and HCl were of reagent grade and also purchased from Sinopharm Group Chemical Reagent Corporation (Shanghai, China). All chemicals are analytical grade chemicals. Enteromorpha prolifera was from Qingdao Sea Bathing Beach (Longitude: 120.32. Latitude: 36.06).

2.2 Preparation of MM-EBC-HD

Enteromorpha prolifera was washed with deionized water, dried, and powdered. The powdered sample was passed through sieves (100 mesh) and placed inside a muffle furnace for carbonization at 700 °C (time: 2 h). Chitosan (1 g) and 2% acetic acid solution (40 mL) were mixed, and the mixture was mechanically stirred until a homogenous mixture was formed. Following this, biochar obtained from Enteromorpha prolifera (0.1 g) was added to the mixture, and the resulting mixture was continuously stirred to form an even dispersion of the biochar. Subsequently, 8 mL of 2% glutaraldehyde was added dropwise into the mixture to initiate the cross-linking reaction. The formed gel was heated inside an oven operated at 60 °C for drying to yield Enteromorpha prolifera biochar hydrogels (EBC-HD). Standard solutions of FeCl3•6H2O (1 mol L−1) and FeSO4•7H2O (0.5 mol L−1) were prepared by adding 50 mL of ultrapure water to FeCl3•6H2O (13.56 g) and FeSO4•7H2O (27.8 g), respectively. The prepared EBC-HD was dissolved in 100 mL of an aqueous solution containing Fe3+ and Fe2+ (Fe3+:Fe2+ = 2:1) for 5–6 h. The hydrogel was filtered and sieved when the dissolution equilibrium was attained, and the resulting sample was soaked in 50 mL of an aqueous NaOH solution (0.5 moL L−1) for 2–3 h. The sample was filtered and washed several times with deionized water. Subsequently, it was refrigerated for 4–5 h and then freeze-dried to prepare the magnetically-modified Enteromorpha prolifera-based biochar hydrogels (MM-EBC-HD).

2.3 Characterization analysis

The surface morphology of the MM-EBC-HD was characterized by scanning electron microscopy (SEM, Zeiss, Gemini 300, Germany). The distribution and variation of elemental content on the adsorbent surface were probed by X-ray energy spectroscopy (EDS, X-max-50). The functional groups and chemical bonds of the adsorbents were determined by Fourier transform infrared spectroscopy (FTIR, Thermo Nicolet, Is50, USA). A zeta potential analyzer (Zeta, MalvernZetasizer) was used to probe the charge changes before and after adsorption. X-ray diffraction (XRD, PANalytical Xpert-3, the Netherlands) was used to test the crystalline state of the hydrogel composites. X-ray photoelectron spectroscopy (XPS, ESCALAB 250 Xi, USA) was used to evaluate the surface elemental composition and valence distribution of the adsorbed materials.

2.4 Adsorption experiments

Solutions of MO and Cr (VI) (1 g L−1) were prepared separately. The solutions were preserved in brown bottles for future use. All MO and Cr (VI) solutions required in this experiment were prepared by diluting this stock solution with ultrapure water.

Adsorption kinetics study: MM-EBC-HD (10 mg) was mixed with 10 mL of MO solution (50 mg L−1) and 10 mL of Cr (VI) solution (25 mg L−1). The mixture was shaken at 160 rpm, and the absorbance was measured at 5, 10, 15, 20, 30, 45, 60, 90, 120, and 240 min using a UV spectrophotometer at the wavelength of 272 nm. The absorbance of Cr (VI) was measured at 30 s, 1 min, 2 min, 3 min, 4 min, 5 min, 10 min, 15 min, and 20 min using the same UV spectrophotometer at a wavelength of 540 nm. The absorbance of the blank (ultrapure water) was used to correct the absorbance data obtained for the samples. The kinetics of adsorption for the processes of MO and Cr (VI) absorption on MM-EBC-HD were investigated to determine the changes in the adsorption amount and adsorption efficiency with time. The adsorption process was analyzed following the process of model fitting. The proposed primary (Eq.[1]) and secondary (Eq.[2]) kinetic models were used to identify the suitable kinetic model.

qt represents the adsorption amount of contaminations adsorption at moment t (mg g−1); qe represents the equilibrium adsorption amount (mg g−1); t is the adsorption time (min); k1 represents the kinetic model constant (min−1); k2 represents the kinetic adsorption rate constant (g [mg min]−1).

Adsorption isotherm study: MM-EBC-HD was dosed at 1 g L−1, and the adsorption experiments were carried out using different concentrations of MO solutions (50, 60, 70, 80, 100, 110, 120, 140, and 150 mg L−1). The absorbance of the solutions was determined at a constant temperature under conditions of constant stirring (160 rpm) over 2 h. The adsorption experiments were carried out for different concentrations of Cr (VI) solutions (25, 50, 60, 75, 90, 110, 120, 130, and 150 mg L−1), and the absorbance of the solutions was determined at a constant temperature under conditions of constant stirring (160 r/min) over 20 min. The saturation adsorption of MO and Cr (VI) in the presence of the MM-EBC-HD was determined, and the data were fit using the adsorption isotherm equation to calculate the correlation coefficients. Two adsorption isotherm models, Langmuir (Eq.[3]) and Freundlich (Eq.[4]) were used to explore the suitability of the models.

qm is the saturation adsorption volume; KL is the Langmuir isotherm equation adsorption equilibrium constant; Ce is the remaining contaminations concentration in solution at adsorption equilibrium; KF and n are the Freundlich isotherm equation adsorption constants.

The effects of solution pH, temperature, and initial concentration on the adsorption effect were evaluated separately: ① MM-EBC-HD (10 mg) was mixed with MO solution (10 mL) and Cr (VI) solution (10 mL) separately, and the pH of the MO and Cr (VI) solution was varied as 1, 3, 5, 7, 9, and 11. The pH of the solution was adjusted with hydrochloric acid (0.01–0.1 mol L−1) and sodium hydroxide. ② MM-EBC-HD (10 mg) was mixed with MO solution (10 mL) and Cr (VI) solution (10 mL) separately, and the temperature of the water bath was varied as 30 °C (303.15 K), 40 °C (313.15 K), and 50 °C (323.15 K). The mixtures were shaken at a constant temperature (speed: 160 rpm), and the adsorption time was set to 120 min for MO and 20 min for Cr (VI). ③ MM-EBC-HD (10 mg) adsorbed single pollutant MO and Cr (VI), respectively. The adsorbed MO concentrations were 10, 20, 50, 100, 100, and 150 mg L−1, and the adsorbed Cr (VI) concentrations were 25, 50, 75, 100, and 150 mg L−1. The adsorption experiments were allowed to proceed under conditions of continuous shaking at a constant temperature (speed: 160 rpm). The solutions were sampled at different times over 5–240 min.

The competition between the two pollutants during adsorption was studied. A solution of MO (100 mL; 80 mg L−1) was mixed with a solution of Cr (VI) (100 mL; 80 mg L−1) to prepare the composite solution containing MO and Cr (VI) (80 mg L−1): ① The composite pollutant solution (10 mL) was taken in a centrifuge tube, and MM-EBC-HD (10 mg) was added to the solution. Samples were collected at different times (1, 2, 3, 5, 10, 15, 20, 40, and 80 min) to analyze the adsorption process, and the residual MO and Cr (VI) contents were determined. ② The quantitative MM-EBC-HD was mixed with MO (80 mg L−1) solution, and after 60 min adsorption of MO was saturated, MM-EBC-HD (10 mg) was taken and mixed with Cr (VI) (80 mg L−1) to investigate the adsorption performance of MM-EBC-HD. The same method described above was used to investigate the adsorption performance of MM-EBC-HD on MO after saturated adsorption of Cr (VI).

The supernatant was collected, and the residual concentrations of MO and Cr (VI) in the solution were determined using a double-beam UV-vis spectrophotometer following the completion of the adsorption experiments. The adsorption equilibrium capacity Qe (Eq.[5]) and the adsorption rate (Eq.[6]) were determined.

C0 is the initial concentration of the contaminations (mg L−1); Ce is the equilibrium concentration of the contaminations (mg L−1); m is the mass of the adsorbent (g); V is the volume of the contaminations solution (L); Qe is the mass of the contaminations adsorbed per gram of adsorbent (mg g−1); η is the removal rate of the contaminations (%).

2.5 Recycling performance research

The recovery of MM-EBC-HD was studied. MO and Cr (VI) were adsorbed on the MM-EBC-HD and removed by desorption experiment. The experimental steps were as follows: add 0.1 g MM-EBC-HD to MO and Cr (VI) (100 mL; 100 mg L−1) aqueous solution, and stir for 60 minutes until the adsorption reached equilibrium. After balancing, a magnetic field can be used to rapidly separate MM-EBC-HD from the aqueous dispersion. After 5 minutes, MM-EBC-HD was completely attracted to the magnet. Magnetism were used to recycle MO and Cr (VI)-loaded MM-EBC-HD, which were then washed with deionized water. The recycled MM-EBC-HD were utilized in the cycle experiment.

3 Results and discussion

3.1 Analysis of SEM images and EDS profiles

The SEM images of MM-EBC-HD recorded before and after the adsorption of MO and Cr (VI) are shown in Fig. 1. Figure 1a reveals that MM-EBC-HD presents a loose structure. The particle surface appeared rough but uniform and contained numerous small protrusions that overlapped to form a sphere. This morphology resulted in an increase in the contact area. Figure 1b presents the SEM image of MM-EBC-HD after the adsorption of MO. Analysis of the image revealed that small numbers of pores were present on the material. The surface appeared smooth, and the materials presented a compact structure. The images also revealed the presence of large protrusions on the surface and a prominent MO significant agglomeration phenomenon. Figure 1c presents the SEM image of MM-EBC-HD recorded following the adsorption of Cr (VI). The images were similar to the images presented in Fig. 1b. The results indicated that the contaminants entered the pores of the hydrogel, and some of them were loaded on the surface of the hydrogels. Figure 1d presents the EDS profiles recorded for pure MM-EBC-HD, Fig. 1e presents the EDS profiles of MM-EBC-HD loaded with MO, and Fig. 1f presents the EDS profiles of MM-EBC-HD loaded with Cr (VI). Analysis of the profiles revealed the presence of C, O, N, Na, Fe, Cl, and Ca in MM-EBC-HD. The surface elements present in MM-EBC-HD were studied before and after the adsorption of MO and Cr (VI). It was observed that there was little difference in the composition of the main elements (C, O, N, and Fe). The appearance of Fe proved that the hydrogel derived from Enteromorpha prolifera biochar was magnetically modified. The primary elements in MO were found to be C, O, S, etc. S is a characteristic element of MO, and the analysis of Fig. 1e shows that the content of C and O elements increased after the adsorption of MO by MM-EBC-HD, and the content of C elements increased from 39.66% to 42.45%, and the content of O elements increased from 35.95% to 40.18%, revealing the successful adsorption of MO. Analysis of Fig. 1f revealed the successful adsorption of Cr (VI). It was also observed that the content of elemental C increased from 39.66% to 42.27%, and the content of O decreased from 35.95% to 34.90%. The results revealed that the structure of MM-EBC-HD remained undamaged following adsorption.

3.2 Analysis of FTIR profiles, XRD patterns, and zeta potential

Figure 1g presents the FTIR profiles recorded for pristine MM-EBC-HD, MO-adsorbed MM-EBC-HD, Cr (VI)-adsorbed MM-EBC-HD, and MO- and Cr (VI)-adsorbed MM-EBC-HD. The peak at 2879.49 cm−1 corresponds to the stretching vibration of the -NH unit in the material, and the broad band at 3362.50 cm−1 corresponds to the stretching vibration of the -OH group. The strong adsorption capacity of the hydrogel can be attributed to free amino and hydroxyl groups on the surface of the adsorbent (Zhu et al. 2012). The band at 1462 cm−1 corresponds to the stretching vibrations of the -COOH and C-N units, and the peak corresponding to the stretching vibration of -SO3 appears at 1377.90 cm−1 (Pawar et al. 2019). The peak at 1068.48 cm−1 corresponds to the stretching vibration of the C-OH bond, the peak at 1589.83 cm−1 corresponds to the stretching vibration of the C-O and C=O bonds, and the peak at 600.79 cm−1 corresponds to the stretching vibration of the Fe-O bond in Fe3O4 (Wang et al. 2018). The peak corresponding to the stretching of -OH shifted to 3357.92 cm−1 when MO adsorption by hydrogen occurred. The shift in the peak position indicates the presence of intramolecular hydrogen bonds between the molecular chains of the hydrogel and the MO molecules. The peaks corresponding to the C-O and C=O bonds shifted to 1595.62 cm−1, and the peak corresponding to -SO3 stretching shifted to 1378.61 cm−1 following MO adsorption (Yu et al. 2013). The peak corresponding to C-O-C appeared at 1153.97 cm−1. The intensity of the peak corresponding to N-H bending (at 2879.49 cm−1) and the intensity of the peak corresponding to the stretching vibration of -OH (at 3362.50 cm−1) reduced significantly. These findings proved that N-H interacted with -OH. The absorption peak representing -SO3 vibration appeared at 1419.19 cm−1, indicating the successful adsorption of the anionic dye. The peaks corresponding to C-O and C=O bonds shifted to 1638.12 cm−1, the peak corresponding to the stretching vibration of -OH shifted to 3361.27 cm−1, and the peak corresponding to the -NH unit shifted to 2877.43 cm−1 when MM-EBC-HD adsorbed Cr (VI). The peak intensities in these cases were lower than the peak intensities recorded for the pristine sample. The results suggested that the amino and hydroxyl groups in MM-EBC-HD were the adsorption sites for Cr (VI). The peak corresponding to the bending vibration of the -COOH group appeared at 1462 cm−1, indicating that carboxyl groups were also involved in the reaction. The intensity of the original band at 1589.83 cm−1 decreased after Cr (VI) adsorption, indicating that Cr ions were also adsorbed on the active site via van der Waals interactions. The FTIR profiles corresponding to the MO and Cr (VI) adsorbed MM-EBC-HD materials were also recorded. It was observed that the peak corresponding to -NH vibration appeared at 2878.64 cm−1, and the broad stretching band corresponding to -OH appeared at 3361.00 cm−1. The intensity of the peaks corresponding to -NH and -OH bending decreased, indicating the involvement of amino and hydroxyl groups in the adsorption process. The -SO3 stretching band shifted to 1377.26 cm−1, and the peaks corresponding to the C-O and C=O bonds shifted to 1647.23 cm−1 (AL Samman and Sánchez 2022). MO and Cr (VI) compete for adsorption sites in the binary adsorption system, as -NH and -OH are involved in the adsorption of both MO and Cr (VI). The intensity and nature of the peak corresponding to C-OH in the profile recorded for the binary adsorption system were similar to those of the hydrogel + Cr system, indicating that most of the secondary -OH sites are occupied by Cr, resulting in a decrease in the extent of MO adsorption (Mahmoud et al. 2017).

Figure 1h presents the XRD patterns recorded for pristine MM-EBC-HD, MO-adsorbed MM-EBC-HD, and Cr (VI)-adsorbed MM-EBC-HD. A crystalline peak appears at 37.05° in the profile recorded for pristine MM-EBC-HD. This indicates that some of the molecular chains in MM-EBC-HD are regularly arranged and gain crystalline properties. The MM-EBC-HD is coated with magnetic antiparticles (Fe3O4), resulting in the appearance of new diffraction peaks in the corresponding spectral profiles. The diffraction peaks at 30.09°, 37.05°, 43.05°, 56.94°, and 62.51° correspond to (220), (222), (400), (511), and (440) crystal planes, respectively, and the peak positions match the peak positions corresponding to the Fe+2Fe2 + 3O4 system. Additionally, peaks corresponding to impurities were absent in the XRD patterns of the pristine and used hydrogels. The 2θ value decreased from 35.559° to 35.492°, and d (crystal spacing) increased from 2.5226 to 2.5272 nm after the adsorption of MO by MM-EBC-HD. This indicated that the interaction of MM-EBC-HD with the adsorbed MO produced a more disordered structure of MM-EBC-HD (Kiprono et al. 2018). Moreover, the absence of specific peaks in the XRD profiles recorded before and after MO adsorption suggests that the MM-EBC-HD was amorphous, and the amorphous nature was retained after MO adsorption. The results also indicated the presence of covalent bonds (Lian et al. 2020). The appearance of the characteristic peak of Cr2FeO4 following the adsorption of Cr (VI) can be attributed to the pore structure of the MM-EBC-HD. The results reveal that Cr (VI) was successfully adsorbed onto Fe and reduced to Cr (III) (Liu et al. 2021). The results agreed well with the results obtained by analyzing the XPS profiles.

Zeta potential is a measure of the strength of mutual repulsion or attraction between particles. The absolute value of zeta potential represents the magnitude of the stability of the particles, and the positive and negative signs represent the particle-carried charge. The Zeta potential plots generated for pristine MM-EBC-HD, MO-adsorbed MM-EBC-HD, and Cr (VI)-adsorbed MM-EBC-HD are presented in Fig. 1i. As presented in the figure, the electric potentials were negative, and the zeta potential was − 12.5 mV before the adsorption process. The Zeta potential was recorded to be − 1.64 mV after the adsorption of MO and − 6.81 mV after the adsorption of Cr (VI). The absolute value of the potential decreased when MO and Cr (VI) were adsorbed, and this could be attributed to the presence of the amino and hydroxyl groups on the surface of the MM-EBC-HD, indicating the involvement of functional groups in the reaction. The absolute value of the zeta potential of the MM-EBC-HD recorded after the adsorption of MO was lower than that recorded after the adsorption of Cr (VI), indicating that the oxygen-containing functional groups reacted with the anionic dye. H-bonding interactions may be present between the MM-EBC-HD and the MO and Cr (VI) units. MO and Cr (VI) primarily exist in the anionic form, and adsorption can potentially occur by exploiting electrostatic interactions. The maximum absolute value was recorded for the pristine system, indicating the high stability of MM-EBC-HD (Teng et al. 2009).

3.3 Analysis of XPS profiles

Figure 2 shows the detailed XPS spectra of MM-EBC-HD (a), MM-EBC-HD after adsorption of MO (b), MM-EBC-HD after adsorption of Cr (VI) (c), and MM-EBC-HD after adsorption of MO&Cr (VI) (d). The characteristic peaks of Na 1 s (1071.99 eV), Fe 2p (711.48), O 1 s (532.17 eV), N 1 s (399.75 eV), C 1 s (286.05 eV), and S 2 s (232.69 eV) appear on Fig. 2a MM-EBC-HD. And the contents of S, C, N, O, Fe, and Na are determined to be 0.16, 39.25, 5.08, 36.02, 6.76, and 2.73 at%, respectively. Figure 2b MM-EBC-HD after adsorption of MO and Fig. 2c MM-EBC-HD after adsorption of Cr (VI), Fe content decreased from 6.76 at% before adsorption to 5.11, 4.48 at%, respectively. According to the observations, the Fe elemental content decreased after the adsorption of MO and Cr (VI), indicating the involvement of Fe in the adsorption reaction. Cr exists as Cr2O7− in an aqueous solution, and the disappearance of the peak corresponding to Na1s after the adsorption of Cr indicates that ion-exchange interactions occur between Na+ and Cr2O7−. Meanwhile, after MO adsorption, the peak corresponding to Na1s also disappears, indicating that the -SO3 group in MO has electrostatic attraction and ion exchange interactions with Na+. The characteristic peak of Cr 2p appeared at 585.61 eV after the adsorption of Cr (Fig. 2c) or the Cr–MO composite (Fig. 2d) system. The results revealed the successful adsorption of Cr on MM-EBC-HD.

XPS profiles recorded for (a) MM-EBC-HD, (b) MO-adsorbed MM-EBC-HD, Cr (VI)-adsorbed MM-EBC-HD, and (d) MO- and Cr (VI)-adsorbed MM-EBC-HD. XPS profiles recorded for (e) C 1 s, (f) N 1 s, (g) O 1 s, (h) Fe 2p, (i) S 2p and (j) Cr 2p corresponding to pristine MM-EBC-HD, MO-adsorbed MM-EBC-HD, Cr (VI)-adsorbed MM-EBC-HD, and MO-& Cr (VI)-adsorbed MM-EBC-HD

Figure 2e shows the high-resolution XPS spectra of C 1 s. The three main C species appearing in the spectrum are C=O/C=N (287.9 eV), C-N (286.3 eV), and C-C (284.8 eV) (Wang et al. 2020). A significant difference in the peak positions was not observed before and after the degradation of MO and Cr (VI). It was also observed that the degradation of MO and Cr (VI) did not result in the appearance of new peaks. However, the peak intensity changed, indicating that the C-containing functional groups present in the system before degradation differed from those present after degradation. This also confirmed the chemical stability of the MM-EBC-HD (Wang et al. 2022). The high-resolution XPS N 1 s spectrum in Fig. 2f indicates the presence of three forms of N, namely -N = (399.7 eV), -NH (399 eV), and -N+- (401.8 eV) (Chen et al. 2022). The adsorption of MO and Cr (VI) did not result in a significant change in the peak positions, and the peak intensity of the peak corresponding to N 1 s increased after the adsorption of MO. This indicated the successful adsorption of MO on MM-EBC-HD, suggesting that cation exchange played an important role in the removal of MO (Kang et al. 2020). The intensity of the -NH peak changed following the adsorption of Cr (VI), indicating that electron transfer occurred between Cr (VI) and -NH. The high-resolution O 1 s profiles are shown in Fig. 2g. The peaks at 529.9, 531.2, and 532.8 eV corresponded to O2−, OH−, and physically or chemically adsorbed water, respectively. The origin of the peaks corresponding to the OH− species can be traced back to the large number of -OH groups in the MM-EBC-HD (Godiya et al. 2020). The intensity of each peak in the O 1 s profile changed following adsorption, suggesting that the O donors (− OH, − COOH) in the MM-EBC-HD participate in the reaction, and the primary functional groups and products obtained by FeCr coprecipitation are changed through redox (Zhou et al. 2019). The high-resolution XPS profiles recorded for Fe 2p reveal the presence of peaks at 711.5 and 724.82 eV (Fig. 2h), and these peaks correspond to Fe 2p3/2 and Fe 2p1/2, respectively. In addition, a peak at 719.0 eV indicates the presence of γ-Fe2O3. Peaks corresponding to Fe (II) (710.8 eV) and Fe (III) (713.8 eV) were also observed in the profile recorded for the MM-EBC-HD sample. The presence of this peak indicated the formation of the Fe (III) tetroxide antiparticle (Anila and Mathew 2021). After adsorbing MO and Cr (VI), the positions and peaks of Fe (II) and Fe (III) peaks shift, because the redox properties of Fe promote the adsorption of contaminants. Fe (III) can oxidize the -SO3 group in MO, while Fe (III) can also reduce Cr (VI) to Cr (III). The high-resolution XPS S 2p spectrum in Fig. 2i shows the presence of two forms of S, namely -SH (162.7 eV), C=S (168.1 eV). As can be seen from the figure, the peak representing sulfur oxide material before adsorption is much weaker than the peak after adsorption, and the peak area increases after adsorption of MO and Cr (VI), which may be the result of chemisorption effect, the prevalence of unbounded S atoms in -SH in MM-EBC-HD. In addition, the binding energy of sulfur electrons in the MM-EBC-HD is reduced due to the binding with Cr (VI) and Cr (III), and the presence of more surface and more electronegative S atoms, which indicates the ion-exchange effect between -SH and contaminants (Hua and Li 2014). Figure 2j presents the high-resolution XPS profiles of Cr 2p. The peaks at the binding energies of 576.9 eV and 586.35 eV correspond to 2p3/2 and 2p1/2 of Cr (III), respectively, and the peaks at the binding energies of 579 eV and 590.7 eV can be attributed to the 2p3/2 and 2p1/2 Cr (VI), respectively. The results indicate that Cr (VI) is reduced to Cr (III) during the reaction with ferric tetroxide.

In summary, when the MM-EBC-HD adsorbs MO, amino and hydroxyl groups on the surface of the MM-EBC-HD form hydrogen bonds, suggesting that the adsorption mechanism involves the participation of electrostatic attraction forces, hydrogen bonds, and van der Waals forces. Ion exchange and electrostatic attraction forces play crucial roles in the adsorption of Cr (VI) on MM-EBC-HD. Additionally, the Fe3O4 antiparticle in the MM-EBC-HD promotes the reduction of Cr (VI) while enhancing the adsorption of Cr (III), and resulting in a synergistic effect that enhances the total Cr adsorption.

3.4 Adsorption properties

The effect of adsorption kinetics on the adsorption capacity of MM-EBC-HD was investigated, as presented in Fig. 3. The MM-EBC-HD dosage used was 1 g L−1. Regarding the MO solution, the concentration was 50 mg L−1, and the sampling time was 5–240 min. For the Cr (VI) solution, the concentration was 25 mg L−1, and the sampling time was 30 s–20 min. Table 1 shows the adsorption kinetic fitting parameters.

Adsorption of (a) MO and (b) Cr (VI) on MM-EBC-HD studied based on the proposed primary kinetic model. Adsorption of (c) MO and (d) Cr (VI) studied based on the proposed secondary kinetic model. Adsorption of the composite MO–Cr (VI) system studied by analyzing the proposed (e) primary and (f) secondary kinetic curves

Figure 3a and c present the proposed first-order kinetic curve and the proposed second-order kinetic curve for the adsorption of MO by MM-EBC-HD, respectively. As presented in Table 1, the the linear fitting correlation coefficient R2 obtained from the proposed second-order kinetic model used to analyze MO adsorption on MM-EBC-HD was 0.99699, which was close to 1, and the value of the theoretical maximum equilibrium adsorption capacity (qmax) was calculated to be 45.11 mg g−1, which was close to the actual adsorption amount at equilibrium. It was observed that the correlation coefficient obtained based on the proposed second-order kinetic linear fit for the case of MO adsorption was better than that obtained for the case of Cr (VI) adsorption. The results indicated that the proposed second-order adsorption kinetic model could explain the process of adsorption of MO on MM-EBC-HD, and the adsorption process was dominated by the chemisorption process and supplemented by the physical adsorption process.

Figure 3b and d present the proposed first-order and second-order kinetic curves, respectively, for the Cr (VI) adsorption process. As presented in Table 1, the value of the linear fit determination coefficient (R2) obtained from the proposed second-order kinetic model was 0.99655 for Cr (VI) adsorption on MM-EBC-HD, and the value of qmax calculated based on the proposed second-order kinetic fit was 22.89 mg g−1. This value was closer to the actual adsorption amount achieved at adsorption equilibrium. The results indicated that the chemisorption process dominated the adsorption process and was supplemented by the physical adsorption process.

Figure 3e and f present the primary and secondary kinetic curves proposed for the adsorption of the MO–Cr (VI) composite system on MM-EBC-HD, respectively. Table 1 shows the kinetic fitting parameters. The R2 values calculated from the proposed secondary kinetic curves were 0.99693 and 0.98606, which were close to 1 and consistent with the proposed secondary kinetic adsorption model. This suggests that chemical interaction primarily controls the adsorption kinetics of the composite system. The R2 values recorded for the adsorption of the composite system were lower than the values recorded for the individual adsorption of MO and Cr (VI), indicating that the fitted data deviate from the results obtained from the kinetic model.

The impact of adsorption isotherms on the adsorption capacity of MM-EBC-HD was investigated, and the findings are presented in Fig. 4. The MM-EBC-HD dosage used was 1 g L−1, and the concentration of MO solution was raised from 50 mg L−1 to 150 mg L−1, while that of Cr (VI) solution was increased from 25 mg L−1 to 150 mg L−1. The Langmuir and Freundlich isotherm models were used to study the adsorption processes, and Table 2 presents details of the parameters fitted by these two equations. Figure 4a illustrates the Langmuir and Freundlich adsorption isotherm curves for MO adsorption. The data in the table revealed that at room temperature, the Langmuir adsorption isotherm yielded a significantly higher linear correlation coefficient (0.98884) than the Freundlich adsorption isotherm (0.85423), and the simulated maximum saturation adsorption of MO on MM-EBC-HD was 71.18 mg g−1. Hence, the Langmuir model better describes the MO adsorption process on the hydrogel than the Freundlich model, indicating that the adsorption of MO on MM-EBC-HD proceeds following the monolayer adsorption process. Most of the MO units were adsorbed on the active sites of the surface of MM-EBC-HD.

Figure 4b displays the Langmuir and Freundlich adsorption isotherms recorded for the MM-EBC-HD during Cr (VI) adsorption. The fitted correlation coefficients (R2) obtained from the Langmuir and Freundlich adsorption isotherms for Cr (VI) were 0.96735 and 0.87283, respectively, indicating a good fit to the Langmuir adsorption isotherm model. The fitted and simulated maximum saturation adsorption for Cr (VI) was calculated to be 115.41 mg g−1, which indicated that the adsorption of Cr (VI) proceeded following a monolayer adsorption process.

3.5 Factors influencing the process of adsorption

Figure 5a presents the two curves illustrating the impact of different pH levels on the removal rate of 50 mg L−1 of MO and 100 mg L−1 of Cr (VI). Curve analysis reveals that the adsorption efficiency of MM-EBC-HD for MO adsorption initially increases and then decreases as pH rises from 1 to 11. The maximum adsorption efficiency of 86% was achieved when the pH of the medium was 3. Therefore, the optimal adsorption efficiency for MO was realized at a pH value of 3. It was observed that the removal efficiency decreased when the pH was lower or higher than this value. The adsorption capacity of the adsorbent decreased below pH 3 as the high concentration of H+ in the solution promotes the reaction between the -SO3− units in the MO molecule with H+, resulting in the formation of -SO3H. This weakens the electrostatic gravitational force between MM-EBC-HD and the MO molecules. The alkalinity of the solution increases as pH increases, resulting in an increase in the OH−− content, which competes with the anionic MO molecules for adsorption. Consequently, the electrostatic adsorption capacity of the MM-EBC-HD for MO decreases, indicating a decrease in the removal rate (Mohamed and Mahmoud 2020). Similar results were reported by Rontgen B (Gapusan and Balela 2020) and co-workers. As the pH increased, the protonated amine groups gradually neutralized, and the degree of electrostatic repulsion between the sulfonate groups in MO and the negatively charged surface of PANI-kapok (PANI-KpF) nanocomposite increased. Furthermore, the competition-induced repulsive forces between a large number of OH− ions and MO anions in solution hinder the adsorption extent of MO on PANI-KpF.

Figure 5a also presents the effect of pH on the adsorption of Cr (VI). As pH increased from 1 to 11, the adsorption efficiency of the magnetically-modified Enteromorpha prolifera-based biochar hydrogel gradually increased till pH 3 and then decreased. The best adsorption efficiency of 72.7% was recorded when the pH was 3. Therefore, the optimal adsorption efficiency of MM-EBC-HD for Cr (VI) was recorded at pH 3. The removal efficiency decreased when the pH was lower or higher than this value. This phenomenon is explained as follows: there are typically three types of Cr (VI) present in solution, and the proportion of each form is related to the pH. When pH < 2.0, Cr (VI) primarily exists as Cr2O72−. Cr (VI) primarily exists as HCrO4− and Cr2O72− when pH is in the range of 3.0–4.0. Cr (VI) exists in two forms, HCrO4− and CrO42−, when pH is in the range of 5.0–6.0. At pH > 7.0, Cr (VI) primarily exists as CrO42−. Lower pH levels lead to higher H+ concentrations and more adsorption sites on the hydrogel surface, allowing the MM-EBC-HD to adsorb large amounts of Cr (VI) as anionic groups such as HCrO4−, CrO42−, and Cr2O72− (Wei et al. 2023). The lower the pH, the higher the H+ concentration, the more the number of adsorption sites on the hydrogel surface, and the greater the amount of Cr (VI) adsorbed as anionic groups (in the form of HCrO4−, CrO42−, and Cr2O72−). However, when pH is 3, Cr (VI) primarily exists as Cr2O72−, which contains twice the amount of Cr (VI) compared to other forms. Thus, the adsorption efficiency for Cr2O72− is higher under the influence of the same electrostatic adsorption force. As pH increases, the concentration of OH− in solution increases, the number of protonated adsorption sites on the adsorbent surface decreases, and the amount of negative charge on the MM-EBC-HD surface increases. The OH− in solution competes with the anionic groups, leading to a decrease in the adsorption capacity of the material (Babu et al. 2005). Meanwhile, due to the presence of Fe2+ in MM-EBC-HD, it can used as an electron donor to reduce Cr (VI) to Cr (III). which is the main adsorption form of Cr in iron-containing media, so the adsorption kinetics of Cr (III) is rapid. The adsorption process is indirectly used for the adsorption of Cr (VI), and Cr (VI) is reduced to Cr (III), which can be precipitated or adsorbed on the adsorption medium (Hlihor et al. 2009).

The effects of different temperatures on the removal rates of MO (50 mg L−1) and Cr (VI) (100 mg L−1) are presented in Fig. 5b. The MO adsorption efficiency of MM-EBC-HD initially increased and then decreased as the temperature increased from 30 to 50 °C. The adsorption rates exceeded 90%, and the maximum adsorption rate of 93.7% was recorded at 40 °C. The increase in the adsorption rate with an increase in temperature can be attributed to the fact that the temperature accelerates the rate of diffusion of MO molecules from the solution into the layer at the boundary between surfaces and the pores on the MM-EBC-HD. The strength of the bonds between the MM-EBC-HD surface and the sulfonic acid groups in the MO molecules decreases, resulting in a decrease in the extent of adsorption of the dye molecules (Anah and Astrini 2017). The adsorption of MO on the surface of MM-EBC-HD is a result of two aspects working synergistically. As the temperature increases, the dye diffusion rate increases while the physical binding ability of the dye molecules with the adsorbent decreases. This increases the MO adsorption capacity of MM-EBC-HD, which reaches a maximum at 40 °C, before decreasing again. The effect of temperature on the removal rate of Cr (VI) (100 mg L−1) was also studied. It was observed that the rate of adsorption of Cr (VI) on MM-EBC-HD decreased when the temperature was increased from 30 °C to 50 °C (Fig. 5b). The optimal adsorption rate of 75% was recorded at 30 °C. Chemisorption dominates the adsorption process, which, according to the equilibrium shift principle, results in a gradual decrease in the adsorption rate with an increase in temperature. This can be attributed to the shift in equilibrium toward desorption for exothermic reactions (Huang et al. 2017).

Figure 5c illustrates the effect of different concentrations of MO on the adsorption capacity of MM-EBC-HD. The adsorption rate decreased from 92.3% to 43.6% as the initial concentration of MO increased from 50 to 150 mg L−1 (adsorbent dosage: 1 g L−1). When the MO adsorption sites of the MM-EBC-HD are saturated, the initial concentration of MO no longer has an effect on the adsorption process. However, the mass transfer resistance between the aqueous and solid phases can be surmounted under conditions of a high initial concentration of MO. A high MO adsorption capacity can be realized under these conditions. This can be attributed to the increase in the strength of the driving force for mass transfer due to the MO concentration gradient between the solution and the surface of the MM-EBC-HD, thereby promoting the binding of MO molecules to the active adsorption sites on the modified peel material (Tanhaei et al. 2020).

The effect of different concentrations of Cr (VI) on the adsorption capacity of MM-EBC-HD is shown in Fig. 5d. The adsorption rate decreased from 85.6% to 46% as the initial concentration increased from 25 to 150 mg L−1 when the adsorbent dosage was 1 g L−1. The limited number of active sites may not be sufficient to saturate the solution with excess Cr (VI) when the initial Cr (VI) concentration is increased without increasing the amount of the adsorbent. This can result in a decrease in the Cr (VI) removal efficiency of the MM-EBC-HD. However, at high initial concentrations, the concentration gradient between solute and adsorbent increases, thereby increasing the strength of the driving force and the adsorption capacity (Sadaf et al. 2015).

3.6 Analysis of the competitive adsorption process associated with the adsorption of the MO–Cr (VI) composite system

The SEM images of MM-EBC-HD adsorbed composite MO and Cr (VI) are shown in Fig. 6a. Because of the adsorption of pollutants, many large protrusions were found on the surface of the hydrogel with a lumpy agglomeration phenomenon. Figure 6b presents the EDS mapping plots corresponding to the elemental distribution characteristics for MM-EBC-HD used for the adsorption of the composite consisting of MO and Cr (VI). Figure 6 presents the elemental distribution of C (Fig. 6c), O (Fig. 6d), Fe (Fig. 6e), N (Fig. 6f), S (Fig. 6g), and Cr (Fig. 6h). Analysis of Fig. 6b reveals the uniform distribution of the elements on MM-EBC-HD and the high content and dense distribution of C and O. The surface of MM-EBC-HD appeared to be rich in S (Fig. 6g) and Cr (Fig. 6 h) following the adsorption of MO and Cr (VI). Additionally, amino and hydroxyl groups were successfully functionalized on the surface of MM-EBC-HD, which promoted the production of abundant active sites on the MM-EBC-HD surface for heavy metals adsorption in the presence of cationic dyes.

As presented in Fig. 7a, the adsorption rates of MM-EBC-HD for MO and Cr (VI) were 74.88% and 62.33%, respectively, when the pollutants did not co-exist in the adsorption system. However, when both contaminants coexisted, as shown in Fig. 7b, the MO and Cr (VI) adsorption performance of MM-EBC-HD decreased significantly, with the adsorption rate for MO dropping to 47.65% and the adsorption rate for Cr (VI) decreasing to 42.5%. The phenomenon can be explained by the analysis of the FTIR profiles in Fig. 1g. As the -NH and -OH groups are involved in the adsorption of both MO and Cr (VI), MO and Cr (VI) compete for the adsorption sites in the binary adsorption system. The intensity of the peak corresponding to C-OH stretching in the binary adsorption system is similar to the intensity of the peak in the hydrogel + Cr system, indicating that most of the secondary -OH sites are occupied by Cr, resulting in a decrease in MO adsorption extent.

Figure 7c presents the saturation adsorption conditions for MO. The MM-EBC-HD was filtered and dried before the adsorption of Cr (VI). Figure 7d presents the saturation adsorption conditions for Cr (VI), and the MM-EBC-HD was filtered and dried before being used for the adsorption of MO. The effect of MO on the Cr (VI) adsorption efficiency of MM-EBC-HD was compared with the effect of Cr (VI) on the MO adsorption efficiency of MM-EBC-HD by analyzing the magnitude of the adsorption rate. It was observed that the Cr (VI) adsorption rate was 23% when the saturation conditions for the adsorption of MO were attained. The adsorption rate was lower than that combined contaminants by 7.32%. Additionally, the same adsorption rate could be reached within 20 min under these conditions. The adsorption rate for MO was 44.7% when saturation adsorption for Cr (VI) was reached. The rate of adsorption recorded under these conditions was lower than the rate of adsorption recorded for the composite system by 2.19%. The same adsorption rate could be reached within 20 min. MO remains dispersed in the malabsorption system as the negative electrostatic charges repel each other. This facilitates the contact of MO with MM-EBC-HD and promotes effective adsorption. The MO–Cr (VI) dual system is acidic, and chromium is primarily present in the system as Cr (III) and Cr2O7−. These negative electrostatic charges are neutralized in the presence of cations such as Cr (III). MO–Cr composites present a compact structure with few reactive groups exposed to the surface of the MM-EBC-HD. Free Cr (VI) ions in the solution compete with the MO–Cr composite for common active sites such as amino groups (Albadarin et al. 2011). Strong competitive adsorption inhibits the adsorption of individual anions, as MO and Cr (VI) exist as anions in an aqueous solution. Moreover, the adsorption extent of MO was higher than that of Cr (VI) under mono- and competitive adsorption conditions, indicating that MO competed with Cr (VI) for the adsorption sites present on the surface of MM-EBC-HD.

3.7 Recovery performance

The recoverability of the sorbent is a crucial factor that helps determine the economic viability of the treatment process. Magnetic nanocomposites can be effortlessly separated in the presence of an external magnetic field following the completion of the adsorption process, minimizing environmental risks associated with the adsorbent (Abou Taleb 2014). The schematic diagram of the magnetic recovery process is shown in Fig. 8a. In this study, the magnets were used to recover MO and Cr (VI)-loaded adsorbents, which were then washed with deionized water. The recovered MM-EBC-HD were utilized in the cycle experiment. Therefore, the recoverability of the MM-EBC-HD nanocomposites was studied post-adsorption, and the results are presented in Fig. 8b. An excellent recovery rate (98.4%) was recorded after the first recovery cycle. A good degree of recoverability (88%) was recorded even after the fourth cycle. There may be two reasons for the decrease in the recovery rate: first, MM-EBC-HD is accompanied by magnetic particle engagement, adsorption, expansion, rupture, and dislodgement during the cycling experiments, which makes the material less magnetic. Secondly, a small amount of MM-EBC-HD nanocomposites will be lost when the supernatant is discarded.

MO are often used for coloring in many industries such as textile, dyeing, leather, and paper making, and Cr (VI) is also widely used in leather tanning, electroplating, metal processing, pigment synthesis, and textile dyeing. At present, the MO/Cr (VI) compound pollution exists in the production process of textile and leather. Commercial heavy metals and dyes adsorbents, such as activated carbon, zeolite, and chitosan, still have the shortcomings of low adsorption capacity, secondary pollution, and high production cost (Chen et al. 2018). However, the MM-EBC-HD prepared in this study can preferably solve the above problems and had advantages in practical application as an efficient, stable, environmentally friendly, and economical adsorbent. In addition, during the adsorption process, pollutants continue to accumulate on MM-EBC-HD until it is completely saturated. This saturated hydrogel can be burned or disposed of in a landfill, but has a negative impact on the environment (Khan and Lo 2016). The MM-EBC-HD can be completely separated from water by an external magnetic field, and it still has good integrity and magnetism after repeated cycles, effectively solving the problem of completely removing pollutants. If the composite material is put into production, it will be environmentally friendly and can make the whole process more economically sustainable.

3.8 Adsorption mechanism associated with the adsorption of MO, Cr (VI), and the composite MO–Cr (VI) system on MM-EBC-HD

The adsorption kinetics was analyzed, and the adsorption isotherm was fit to study the adsorption process of Cr (VI) and MO on MM-EBC-HD. The results revealed that chemisorption predominated the adsorption process, forming a monolayer of the adsorbates. Two possible mechanisms underlie MO adsorption, as shown in Fig. 9a. First, the negatively charged dye and the positively charged active adsorption sites of the adsorbent interact through electrostatic forces and ligand bonds. These interactions occur on the surface of the hydrogel. The results obtained using the FTIR (Fig. 1g) and XPS (Fig. 2) techniques revealed that ionic composites were formed when the sulfonic acid groups present in the MO dye and the charged functional groups (-NH and -OH) in the hydrogel interacted with each other. The dye molecules could also interact with the hydrogel through π–π, hydrophobic, and hydrogen bonding interactions. Hydrophobic interactions can exist in aqueous systems. Analysis of Zeta potential reveals that hydrogen bonds can be formed between the -OH or -COOH groups and the sulfonamide groups of the MO dyes. These can also be formed between the amino and hydroxyl groups in the 3D network and exert strong chelation effects (Chen et al. 2020).

Nanostructured materials generally adsorb heavy metal ions by exploiting electrostatic and/or ion exchange interactions (Singh and Singhal 2015). In addition, another mechanism for heavy metals adsorption by adsorbents is the complexation of metals with carbon and carboxyl functional groups or FexOx (OH) solid phases in magnetic hydrogels (Fahmi et al. 2022). The mechanism of Cr (VI) adsorption on MM-EBC-HD is shown in Fig. 9b. Cr is adsorbed on MM-EBC-HD in an aqueous solution in the form of Cr (VI), Cr2O7−, and Cr (III). It has been observed that Cr2O7− interacts with Na+ through ion exchange interactions. Electrostatic attraction between negative Cr (VI) and the positive surface of MM-EBC-HD is observed in these systems as Cr (VI) exists in an aqueous solution in the form of anions. The coexistence of Cr (III) and Cr (VI) was revealed using the XPS technique (Fig. 2j). The results indicated that Cr (VI) was oxidatively reduced to Cr (III) during the reaction. The progress of the oxidative reduction process was promoted by the redox characteristics of Fe and the amino and hydroxyl groups on the surface of the MM-EBC-HD.

The interactions between organic compounds and heavy metals can be quite complex (Luo et al. 2021). Figure 9c demonstrates that two forms of Cr (MO/Cr [VI] composites and Cr [VI]) are present in the binary adsorption system. The presence of the MO/Cr (VI) composite may hinder the attachment process of the free Cr (VI) ions that exist in the Cr (VI) form, resulting in a decrease in the Cr (VI) adsorption capacity of the hydrogel. These results and the results obtained using the FTIR technique (Fig. 1g) revealed that -NH and -OH were involved in the adsorption of MO and Cr (VI). Thus, it can be inferred that MO and Cr (VI) compete for the adsorption sites in the binary adsorption system, reducing the extent of MO adsorption.

4 Conclusion

Magnetically modified Enteromorpha prolifera-based biochar hydrogel (MM-EBC-HD) with a three-dimensional network space structure was developed to address the issue of environmental pollution caused by heavy metals and dyes. The processes of conversion of Enteromorpha prolifera into a valuable resource and the preparation of hydrogel were carried out to optimize resource utilization. The composite’s stability and applicability were studied using various characterization techniques such as SEM, EDS, FTIR, XRD, and XPS. Numerous active adsorption sites were present on the surface, and the composite exhibited excellent adsorption characteristics for MO, hexavalent chromium, and their composites. The maximum simulated adsorption capacity for MO was found to be 65.45 mg g−1, and the adsorption equilibrium was reached within 60 min. The simulated maximum adsorption amount of Cr (VI) was found to be 71.3 mg g−1, and the equilibrium was reached within 10 min. The adsorption performance of MM-EBC-HD for MO/Cr (VI) composite pollutants was poorer than that of the individual pollutants, which could be attributed to the compact structure of the MO–Cr composite containing few reactive groups exposed to the surface. The most significant advantage of using MM-EBC-HD is that it can be easily separated from aqueous solutions in the presence of a magnetic field. The results indicate that MM-EBC-HD is a low-cost, efficient, and reusable adsorbent that can be used efficiently for the removal of heavy metals and dyes from aqueous solutions. This study reports a feasible method for the preparation of a biochar-based hydrogel adsorbent with excellent adsorption performance. The method of MM-EBC-HD preparation followed is simple, and the system can be used for removing heavy metals and dye composites from the environment.

Availability of data and materials

No data will be shared.

References

Abou Taleb MF (2014) Adsorption and photocatalytic degradation of 2-CP in wastewater onto CS/CoFe2O4 nanocomposite synthesized using gamma radiation. Carbohydr Polym 19(114):65–72

Akl ZF, Zaki EG, ElSaeed SM (2021) Green hydrogel-biochar composite for enhanced adsorption of uranium. ACS Omega 8(6):34193–34205

AL Samman MT, Sánchez J (2022) Chitosan-and alginate-based hydrogels for the adsorption of anionic and cationic dyes from water. Polymers. 14:1498

Albadarin AB, Ala’a H, Al-Laqtah NA, Walker GM, Allen SJ, Ahmad MN (2011) Biosorption of toxic chromium from aqueous phase by lignin: mechanism, effect of other metal ions and salts. Chem Eng J 1(169):20–30

Anah L, Astrini N (2017) Influence of pH on Cr (VI) ions removal from aqueous solutions using carboxymethyl cellulose-based hydrogel as adsorbent. IOP Conference Series: Earth and Environmental Science 60:012010

Anila I, Mathew MJ (2021) Study on the physico-chemical properties magnetic phase resolution and cytotoxicity behavior of chitosan-coated cobalt ferrite nanocubes. Appl Surf Sci 556:149791

Babu NC, Asma K, Raghupathi A, Venba R, Ramesh R, Sadulla S (2005) Screening of leather auxiliaries for their role in toxic hexavalent chromium formation in leather—posing potential health hazards to the users. J Clean Prod 13:1189–1195

Chen S, Huang Y, Han X, Wu Z, Lai C, Wang J, Deng S (2018) Simultaneous and efficient removal of Cr (VI) and methyl orange on LDHs decorated porous carbons. Chem Eng J 352:306–315

Chen B, Long F, Chen S, Cao Y, Pan X (2020) Magnetic chitosan biopolymer as a versatile adsorbent for simultaneous and synergistic removal of different sorts of dyestuffs from simulated wastewater. Chem Eng J 385:123926

Chen T, Zhu Z, Shen X, Zhang H, Qiu Y, Yin D (2022) Boosting peroxymonosulfate activation by porous single-atom catalysts with FeN4O1 configuration for efficient organic pollutants degradation. Chem Eng J 450:138469

Deng H, Tu Y, Wang H, Wang Z, Li Y, Chai L, Lin Z (2022) Environmental behavior, human health effect and pollution control of heavy metal (loid) s towards full life cycle processes. Eco-Environment & Health 1:229–243

Ding J, Pan Y, Li L, Liu H, Zhang Q, Gao G, Pan B (2020) Synergetic adsorption and electrochemical classified recycling of Cr (VI) and dyes in synthetic dyeing wastewater. Chem Eng J 384:123232

Dong C, Lu J, Qiu B, Shen B, Xing M, Zhang J (2018) Developing stretchable and graphene-oxide-based hydrogel for the removal of organic pollutants and metal ions. Appl Catal B Environ 222:146–156

Fahmi AH, Samsuri AW, Singh D (2022) Magnetization improved fine particle biochar adsorption of Lead. Soil Sediment Contam Int J 31:633–654

Fan C, Li K, Li J, Ying D, Wang Y, Jia J (2017) Comparative and competitive adsorption of Pb (II) and cu (II) using tetraethylenepentamine modified chitosan/CoFe2O4 particles. J Hazard Mater 326:211–220

Gan L, Shang S, Hu E, Yuen CWM, Jiang SX (2015) Konjac glucomannan/graphene oxide hydrogel with enhanced dyes adsorption capability for methyl blue and methyl orange. Appl Surf Sci 357:866–872

Gao J, Zhang L, Liu S, Liu X (2022) Enhanced adsorption of copper ions from aqueous solution by two-step DTPA-modified magnetic cellulose hydrogel beads. Int J Biol Macromol 211:689–699

Gapusan RB, Balela MDL (2020) Adsorption of anionic methyl orange dye and lead (II) heavy metal ion by polyaniline-kapok fiber nanocomposite. Mater Chem Phys 243:122682

Godiya CB, Xiao Y, Lu X (2020) Amine functionalized sodium alginate hydrogel for efficient and rapid removal of methyl blue in water. Int J Biol Macromol 144:671–681

Hlihor RM, Apostol LC, Vasile LP, Smaranda C, Robu BM, Caliman FA, Gavrilescu MA (2009) Overview on chromium ocurrence in the environment and its remediation. Buletinul Institutului Politehnic din Iasi, Chimie si Inginerie Chimicá 60:67–83

Hua R, Li Z (2014) Sulfhydryl functionalized hydrogel with magnetism: synthesis, characterization, and adsorption behavior study for heavy metal removal. Chem Eng J 249:189–200

Huang R, Liu Q, Huo J, Yang B (2017) Adsorption of methyl orange onto protonated cross-linked chitosan. Arab J Chem 10:24–32

Ji K, Gao Y, Zhang L, Wang S, Yue Q, Xu X, Chen Y (2021) A tunable amphiphilic Enteromorpha-modified graphene aerogel for oil/water separation. Sci Total Environ 763:142958

Ju XJ, Zhang SB, Zhou MY, Xie R, Yang L, Chu LY (2009) Novel heavy-metal adsorption material: ion-recognition P (NIPAM-co-BCAm) hydrogels for removal of lead (II) ions. J Hazard Mater 167:114–118

Kang S, Qin L, Zhao Y, Wang W, Zhang T, Yang L, Song S (2020) Enhanced removal of methyl orange on exfoliated montmorillonite/chitosan gel in presence of methylene blue. Chemosphere. 238:124693

Khan M, Lo IM (2016) A holistic review of hydrogel applications in the adsorptive removal of aqueous pollutants: recent progress, challenges, and perspectives. Water Res 106:259–271

Kiprono SJ, Ullah MW, Yang G (2018) Encapsulation of E. Coli in biomimetic and Fe3O4-doped hydrogel: structural and viability analyses. Appl Microbiol Biotechnol 102:933–944

Kismir Y, Aroguz AZ (2011) Adsorption characteristics of the hazardous dye brilliant green on Saklıkent mud. Chem Eng J 172:199–206

Li Y, Huang G, Zhang X, Li B, Chen Y, Lu T, Xu F (2013) Magnetic hydrogels and their potential biomedical applications. Adv Funct Mater 23:660–672

Lian F, Zheng M, Chen M, Zhu Y, Zhang L, Zheng B (2020) Modified xanthan gum for methyl orange uptake: kinetic, isotherm, and thermodynamic behaviors. Int J Biol Macromol 165:2442–2450

Liu N, Jin X, Feng C, Wang Z, Wu F, Johnson AC, Giesy JP (2020) Ecological risk assessment of fifty pharmaceuticals and personal care products (PPCPs) in Chinese surface waters: a proposed multiple-level system. Environ Int 136:105454

Liu Q, Xia N, Wan W, Gao Y, Zhu S (2021) Selective capture of toxic anionic dyes of a novel prepared DMDAAC-grafted chitosan/genipin/cellulose hydrogel beads with antibacterial activity. Int J Biol Macromol 189:722–733

Luo Q, Huang X, Luo Y, Yuan H, Ren T, Li X, Wu Y (2021) Fluorescent chitosan-based hydrogel incorporating titanate and cellulose nanofibers modified with carbon dots for adsorption and detection of Cr (VI). Chem Eng J 407:127050

Mahmoud GA, Abdel-Aal SE, Badway NA, Elbayaa AA, Ahmed D (2017) A novel hydrogel based on agricultural waste for removal of hazardous dyes from aqueous solution and reuse process in a secondary adsorption. Polym Bull 74:337–358

Mohamed AK, Mahmoud ME (2020) Nanoscale Pisum sativum pods biochar encapsulated starch hydrogel: a novel nanosorbent for efficient chromium (VI) ions and naproxen drug removal. Bioresour Technol 308:123263

Pawar V, Dhanka M, Srivastava R (2019) Cefuroxime conjugated chitosan hydrogel for treatment of wound infections. Colloids Surf B: Biointerfaces 173:776–787

Sadaf S, Bhatti HN, Nausheen S, Amin M (2015) Application of a novel lignocellulosic biomaterial for the removal of direct yellow 50 dye from aqueous solution: batch and column study. J Taiwan Inst Chem Eng 47:160–170

Sahraei R, Pour ZS, Ghaemy M (2017) Novel magnetic bio-sorbent hydrogel beads based on modified gum tragacanth/graphene oxide: removal of heavy metals and dyes from water. J Clean Prod 142:2973–2984

Singh T, Singhal R (2015) Methyl Orange adsorption by reuse of a waste adsorbent poly (AAc/AM/SH)-MB superabsorbent hydrogel: matrix effects, adsorption thermodynamic and kinetics studies. Desalin Water Treat 53:1942–1956

Tan X, Liu Y, Zeng G, Wang X, Hu X, Gu Y, Yang Z (2015) Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere. 125:70–85

Tang SC, Wang P, Yin K, Lo IM (2010) Synthesis and application of magnetic hydrogel for Cr (VI) removal from contaminated water. Environ Eng Sci 28(27):947–954

Tang H, Zhou W, Lu A, Zhang L (2014) Characterization of new sorbent constructed from Fe3O4/chitin magnetic beads for the dynamic adsorption of Cd2+ ions. J Mater Sci 31(49):123–133

Tang Y, Yang R, Ma D, Zhou B, Zhu L, Yang J (2018) Removal of methyl orange from aqueous solution by adsorption onto a hydrogel composite. Polym Polym Compos 26:161–168

Tanhaei B, Ayati A, Iakovleva E, Sillanpää M (2020) Efficient carbon interlayed magnetic chitosan adsorbent for anionic dye removal: synthesis, characterization and adsorption study. Int J Biol Macromol 164:3621–3631

Teng SX, Wang SG, Liu XW, Gong WX, Sun XF, Cui JJ, Gao BY (2009) Interaction between Congo red and copper in a binary adsorption system: spectroscopic and kinetic studies. Colloids Surf A Physicochem Eng Asp 340:86–92

Wang B, Gao B, Fang J (2017) Recent advances in engineered biochar productions and applications. Crit Rev Environ Sci Technol 47:2158–2207

Wang W, Zhang H, Shen J, Ye M (2018) Facile preparation of magnetic chitosan/poly (vinyl alcohol) hydrogel beads with excellent adsorption ability via freezing-thawing method. Colloids Surf A Physicochem Eng Asp 553:672–680

Wang W, Cao Y, Hu X, Zhou S, Zhu D, Qi D, Deng S (2020) Granular reduced graphene oxide/Fe3O4 hydrogel for efficient adsorption and catalytic oxidation of p-perfluorous nonenoxybenzene sulfonate. J Hazard Mater 386:121662

Wang Z, Berbille A, Feng Y, Li S, Zhu L, Tang W, Wang ZL (2022) Contact-electro-catalysis for the degradation of organic pollutants using pristine dielectric powders. Nat Commun 13:1–9

Wei S, Chen W, Li Z, Liu Z, Xu A (2023) Synthesis of cationic biomass lignosulfonate hydrogel for the efficient adsorption of Cr (VI) in wastewater with low pH. Environ Technol 44:2134–2147

Yu Z, Zhang X, Huang Y (2013) Magnetic chitosan–iron (III) hydrogel as a fast and reusable adsorbent for chromium (VI) removal. Ind Eng Chem Res 52:11956–11966

Zhang H, Yuan X, Xiong T, Wang H, Jiang L (2020) Bioremediation of co-contaminated soil with heavy metals and pesticides: influence factors, mechanisms and evaluation methods. Chem Eng J 398:125657

Zhou M, Wang Z, Sun Q, Wang J, Zhang C, Chen D, Li X (2019) High-performance ag–cu nanoalloy catalyst for the selective catalytic oxidation of ammonia. ACS Appl Mater Interfaces 25(11):46875–46885

Zhu HY, Fu YQ, Jiang R, Yao J, Xiao L, Zeng GM (2012) Novel magnetic chitosan/poly (vinyl alcohol) hydrogel beads: preparation, characterization and application for adsorption of dye from aqueous solution. Bioresour Technol 105:24–30

Zhu L, Zhang L, Tang Y, Kou X (2014) Synthesis of sodium alginate graft poly (acrylic acid-co-2-acrylamido-2-methyl-1-propane sulfonic acid)/attapulgite hydrogel composite and the study of its adsorption. Polym-Plast Technol Eng 53:74–79

Funding

This work was supported by the National Natural Science Foundation of China (42207019), the China Postdoctoral Science Foundation (2022 M721761), and the Postdoctoral Innovation Project Special Foundation of Shandong Province (SDCX-ZG-202203024).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Zihan Song, Yonglin Liu, Lin Liu, Chuanxi Yang, Wei Tian, Baorong Duan, Xu Fang, Yunke Ren, Mingkun Zhang, Si Xiong, Yuzhuo Gong, Haofen Sun and Weiliang Wang. The first draft of the manuscript was written by Zihan Song and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handing Editor: Baoshan Xing.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Song, Z., Liu, Y., Liu, L. et al. Reusable magnetically-modified Enteromorpha prolifera-based biochar hydrogels: competitive removal mechanism for metal-organic dye composite contaminants. Carbon Res. 3, 18 (2024). https://doi.org/10.1007/s44246-023-00098-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-023-00098-6