Abstract

The electrode played an essential role in the operation of CW-MFC system due to its synergistic effect, and the development of electrode strategy has promoted the application of CW-MFC since 2012. In this paper, according to the material and the quantity, the electrode types in CW-MFC were distinctly divided into unified model, composited model, modified model, and multi-electrodes model combined with non-conductive or conductive particle. Different electrode strategies were provided to improve the performance of CW-MFC towards electricity generation, removal of pollutants, and control of greenhouse gas emission, and the coordination mechanism was further reviewed. Furthermore, the development process of the electrode strategy was summarized, and the low-cost, sustainable, and innovated electrode materials were emphatically recommended. For the scale-up application, multi-electrode model was systematically reviewed based on the optimizing of the material, shape, spacing distance, and connection type of electrode. This review may provide guidance to maximize the advantages of CW-MFC applications.

Graphical Abstract

Highlights

• Electronic receiver and non-conductive or conductive particle was firstly classified.

• The electrode application on electricity generation and pollutant removal was reviewed.

• The application of emerging electrode materials in CW-MFC was summarized.

• The multi-anode and multi-cathode strategy may facilitate the scaling-up of CW-MFC.

• The development of electrode material was prospected to extend the function of CW-MFC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

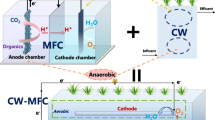

Currently, to face the issues on depletion of water resource and energy, techniques were employed to simultaneously treat wastewater and recover energy from it. Constructed wetland (CW) established based on the natural wetland ecosystem became an emerging wastewater treatment system, which was characterized by limited economical investment, low energy consumption, and significant ecological benefits (Wu et al. 2018). Moreover, the plant uptake, substrate adsorption, and microbial degradation contribute primarily to the contaminant removal in CW, however, the drawbacks (such as long-term operation, clogging, and secondary pollution) limited its further application (Negi et al. 2022; Sharma and Malaviya 2022). Recently, embedding microbial fuel cell (MFC) into CW provided a strategy to overcome the drawbacks due to the redox gradient between the anode and the cathode (Doherty et al. 2015; Gupta et al. 2023; Huang et al. 2023; Ji et al. 2021). Meanwhile, as a significant bioelectrochemical system (BESs), MFC can recover electricity energy from the wastewater treatment via electrochemically active bacteria (EAB), which expanded and enhanced the function of CW (Dwivedi et al. 2022; Kamali et al. 2022).

In 2012, constructed wetland-microbial fuel cell (CW-MFC) system was firstly proposed (Yadav et al. 2012), exhibiting an excellent application prospect in wastewater treatment. Whereafter, CW-MFC was applied to remove a variety of pollutants including nitrogen, phosphorus, heavy metals, dyes, antibiotics, etc. (Ji et al. 2020; Ebrahimi et al. 2021b; Sharma and Malaviya 2022). Furthermore, CW-MFC can effectively reduce CH4 emission from CW (Zhang et al. 2023). Currently, most of the studies on CW-MFC were constructed on lab- or pilot-scale, and it is essential to optimize the electrode strategy to facilitate the scale-up application of CW-MFC (Gupta et al. 2021; Kataki et al. 2021). The electrode material is the key factor to improve the performance of CW-MFC which may affect the microorganism adhesion, the electrons transport, and the pollutants adsorption (Huang et al. 2021; Mier et al. 2021; Ebrahimi et al. 2021a), and nearly 60% of the literature on CW-MFC focused on the electrode strategy (Fig. S1a).

In this paper, the electrode was assembled with electronic receiver and non-conductive or conductive particle. Based on the material and the quantity of the electrode, the electronic receivers were distinctly divided into unified model, composited model, modified model, and multi-electrode model (Fig. S1c), and the corresponding advantage and coordination mechanism were further reviewed. The studies on the electrode strategy and development process in CW-MFC were summarized (Fig. 1, and S1b, c), in which matching scheme and outstanding material were recommended, which may provide support and guidance for future research and the development of CW-MFC.

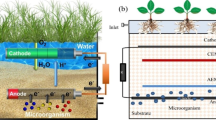

2 Metal− or carbon-based electronic receiver combined with non-conductive particle

Due to the high conductivity, a serial of metal-based (stainless steel meshes, foamed nickel, aluminum, magnesium) and carbon-based (carbon felt, carbon cloth, graphite rod, graphite plate) materials were introduced into CW-MFC as electronic receiver, and initially combined with non-conductive particle to assemble the electrode. Non-conductive particle, such as gravel, sand, zeolite, and volcanic cinder played a critical role in the wastewater filtration and provided a habitat matrix for the microorganisms and plants. The electronic receiver was further classified as unified model, composited model, and modified model (Fig. 2).

2.1 Unified model

The unified model referred to the anode and the cathode in CW-MFC shared the same material of electronic receiver (Table S1 in the supplementary materials). The relatively simple configuration made it easy to compare the performance of the electrode with each other, which was proposed in the early stage of CW-MFC development. Compared with stainless steel meshes (SSM) (41 mV), foamed nickel (FN) (148 mV), and graphite rod (GR) (52 mV), carbon felt (CF) embraced in quartz sand showed the highest voltage (177 mV) in CW-MFC, since it provided a suitable substrate for the attachment and growth of electrogenic bacteria, i.e., Proteobacteria (Wang et al. 2016); for the pollutant removal capacity, CF embraced in quartz sand also peaked in the removal efficiency of COD (> 80%), TN (> 70%) and NO3−-N (> 85%) (Wang et al. 2017a; Wang et al. 2017b); for the decolorization, CF embraced in the gravel showed the best decolorization towards azo dye Acid Red (96%), followed by Acid Orange 7 (67%) and Congo Red (60%) at the anaerobic anodic region, leading to the formation and accumulation of bio-refractory aromatic amine in the middle region, which was further mineralized at the aerobic cathodic region (Oon et al. 2020).

Compared with SSM and carbon cloth (CC), CW-MFC constructed by the electrode of CF combined with the gravel showed the minimum emission flux of greenhouse gases (CH4: 0.77 mg·m−2·h−1; N2O: 130.78 μg·m−2·h−1; CO2: 4.24 mg·m−2·h−1) and the maximum power density of 2.99 W·m−3, which was attributed to the large specific surface area, excellent catalytic activity, and proliferated aerobic bacteria of CF. The addition of Ni and high pH value inhibited the emission of greenhouse gases; low C/N ratio and high C/N ratio reduced emission of CH4 and N2O, respectively (Fig. S2) (Liu et al. 2022a).

Alternatively, when the graphite plate (GP) characterized by the outstanding electrical conductivity was placed in the sand, pebble, or gravel, the electrical performance of CW-MFC was enhanced, and a comparably high voltage (860 mV) and power density (112 mW·m−2) were attained accompanied by an efficient removal of TN (> 60%), NO3−-N (> 90%), and NH4+-N (> 70%). The mechanism of nitrogen removal in CW-MFC commonly included the denitrification (NO3−-N → N2) and the nitrification (NH4+-N → NO2−-N → NO3−-N). The denitrification occurred in anoxic anode area with low redox potential, which was enhanced through EAB via converting the electron from the organics to NO3−-N; whereas the nitrification occurred in high redox potential aerobic cathode area depended on the enriched Nitrospirae (Fig. S3) (Tao et al. 2022a, 2022b, 2022c).

To sum up, the carbon-based material with an excellent specific surface area, strong chemical stability, and biocompatibility for the attachment of functional bacteria showed a superior property compared with the metal-based material. Whereas the metal-based material could improve the performance by the building a three-dimensional configuration, such as foamed nickel (Wang et al. 2017c).

2.2 Composited model

The composited model referred to the electronic receiver of the anode and the cathode assembled by the metal- and/or carbon-based materials in CW-MFC (Table S2). In addition to SSM (Hartl et al. 2019; Hartl et al. 2021), expressly alkaline-earth metal was also used as the cathodic electronic receiver in the composited model. Magnesium with the gravel layer and GP with the mixture layer of organic based peat and sand were designed as the cathode and the anode, respectively. The maximum power reached 78 mW·m−2 and 63% of boron was removed (Türker and Yakar 2017). Compared with the sand and volcanic cinder, the maximum average output voltage and the power density achieved 1008 mV and 15 mW·m−2, respectively. 92% of COD, 93% of NH4+-N, 81% of NO3−-N, and 96% of TP were removed in CW-MFC with the cathodic magnesium and anodic GP insert into the zeolite. The large specific surface area and hydroxyls (Si-OH) groups of zeolites facilitated enzymatic production, which enhanced the bioelectric generation and biodegradation of pollutants in CW-MFC (Yakar et al. 2018).

The sandwiched electrode combined with two layers of CF and one layer of SSM was embedded into the pebble to construct CW-MFC; the maximum power density was 38 mW·m−2 (the cathode area was 75 cm2) and the Cr(VI) removal efficiency peaked at 99% (the cathode area was 100 cm2) (Liu et al. 2022b). In addition, the performance of GF-SSM electrode exceeded CF-SSM, with the maximum power density reaching 64 mW·m−2 and a removal rate of 99% towards Cr(VI) (Wang et al. 2023a). The combination of carbon- and metal-based material as the electronic receiver exhibited an excellent performance, especially in the maximum power density and Cr(VI) removal.

2.3 Modified model

To further improve the performance of CW-MFC, a variety of catalytical materials have been applied to modify the carbon-based electronic receiver (Table S3). As a representative noble metal, Pt was coated on CC as the cathode and GF as the anode, and the electrodes were inserted into the gravel lay in CW-MFC; the maximum power density achieved 31 mW·m−3 and 79% of COD was removed due to the efficient cathode reaction via radial oxygen loss (Srivastava et al. 2017). Moreover, an outstanding removal efficiency towards E.coli (nearly 100%) and COD (99%) together with a maximum power density of 4 mW·m−3 were attained when Pt was coated on carbon paper as the cathode in CW-MFC (Bolton and Randall 2019). However, the high cost and potential ecotoxicity of Pt hindered its further application.

CF was firstly modified by the nano zero valent iron (nZVI) as the anode in CW-MFC in 2019, the maximum voltage output and power density was 425 mV and 26 mW·m−2, respectively, which were higher than those of three-dimensional FN-nZVI due to the relative abundance of EAB; nZVI also exhibited a positive effect on biodegradation of polycyclic aromatic hydrocarbons (PAHs) such as phenanthrene (95%) and anthracene (97%) (Wang et al. 2019a). However, the catalytic mechanism on degradation of the refractory pollutants was not sufficiently revealed.

In 2021, titanium dioxide (TiO2)/graphene loaded on CF as the cathode was firstly introduced into CW-MFC, the maximum voltage and power density reached 490 mV and 99 mW·m−2, respectively, when placed into sterile tezontle volcanic rock, and the results were higher than that of Pt/C cathode under the same condition due to the increase in the active site for the oxygen reduction reaction (ORR) by TiO2. Furthermore, the graphene characterized by high electronic conductivity, large surface area, and excellent bio-adhesive property made it a promising material in CW-MFC (Estrada-Arriaga et al. 2021).

3 Metal− or carbon-based electronic receiver combined with conductive particle

To improve the power generation and pollutant removal, different conductive particles were assembled around the metal− or carbon-based electronic receiver to establish the electrode in CW-MFC (Fig. 3), in which the conductive particle functioned as either an electron acceptor in the anaerobic environment or an electron donor to reduce the pollutants.

3.1 Activated carbon

Activated carbon (AC) is widely used as the conductive particle in CW-MFC due to its unique physiochemical property and bio-compatibility. AC combined with SSM was firstly applied in CW-MFC in 2013, an excellent decolorization rate (91% for reactive brilliant red X-3B) was attained, and likewise the bioelectricity generation (voltage output: 610 mV; power density: 0.3 W·m−3) (Fang et al. 2013). In 2016, CM-MFC with AC + SSM as the anode and the cathode can efficiently decolorize MO by 88% via hydrogenation and demethylation, and the degradation rate reached 96%. The abundant surface oxygen-containing groups on AC may promote the degradation performance of CW-MFC (Fang et al. 2016). Subsequently, AC + SSM became the most widely applied electrode strategy in CW-MFC. The three-dimensional ring-shape SSM combined with granular AC (GAC) as the electrode showed a maximum voltage of 458 mV and power density of 14 mW·m−2, and COD removal rate was over 90%, however, sandwich shaped SSM + GAC or SSM + columnar AC (CAC) electrode did not exhibit a comparable performance.

CW-MFC was firstly recommended to remove polyfluoroalkyl substances (PFASs) in 2020 (Ji et al. 2020), and the removal mechanism was demonstrated in Fig. S4. C-F bond in PFASs was broken by the defluorinated microorganisms, and further mineralized by other functional microorganisms. GAC may be an excellent choice as an anode material to remove PFASs, due to its considerable adsorption capacity and electrical conductivity. In 2023, CW-MFC with GAC + SSM as the electrode removed over 95% of PFOA and PFOS, and the dominant bacterial genus included Lactobacillus, Fusobacterium, Frateuria, Vibrio, Thiobacillus, Helicobacter, and Bacteroides. However, due to the negative impacts of PFOA and PFOS, the voltage (555 mV) decreased by 7.32% in comparison with the control group (Ji et al. 2023).

Combination of GAC with titanium mesh or CF as the electrode also well performed in CW-MFC, with the maximum voltage reaching approximately 1000 mV. Significant removal capacity towards COD (> 80%), NH4+-N (> 85%), NO3−-N (> 85%), TN (> 80%), and sulfamethoxazole (> 90%) may be attributed to the extra enrichment of the functional bacteria on GAC layer (Xu et al. 2018a; Yang et al. 2022). However, TP removal efficiency (60%) in CW-MFC with GAC + CF was lower than that in CW-MFC with GAC + SSM (95%) or GAC + titanium mesh (97%).

In CW-MFC with SSM combined with GAC/volcanic rock and GAC/zeolite, the removal efficiency of Cr(VI) achieved 99% and 96%, respectively, which were higher than that of bio-ceramic (72%) and calcite (90%). The output voltage and power density followed the order as volcanic rock (675 mV, 490 mW·m−3) > zeolite (595 mV, 460 mW·m−3) > calcite (561 mV, 440 mW·m−3) > bio-ceramic (554 mV, 300 mW·m−3). Moreover, high content of extracellular polymeric substances (EPS) in CW-MFC with volcanic rock and zeolite contributed primarily to Cr(VI) removal, and the relevant mechanism included reduction, electrostatic interaction, and complexation (Fig. S5a) (Mu et al. 2021). In 2020, Pb(II) was firstly treated by CW-MFC system with titanium mesh+GAC. Likewise, Pb(II) was complexed by COO- and -NH2 on EPS to achieve a removal rate of 85% (Fig. S5b) (Zhao et al. 2020).

Based on the existing literature (Table S4), the following conclusions can be drawn: (1) the application of AC as the electrode layer may significantly promote the electricity generation; (2) in comparison with CAC, GAC may be more appropriate in CW-MFC; (3) the application of SSM combined with AC attained an excellent performance, especially three-dimensional structured SSM; (4) the application of AC enhanced the removal efficiency towards dye, antibiotic, COD, TN, TP, NH4+-N, NO3−-N, heavy metals, and PFAS; (6) AC facilitates the enrichment of functional bacteria.

Graphite granule was commonly used as conductive particle to combine with carbon-based electronic receiver (GR, CF, GF, GP) in CW-MFC, resulting in a significant promotion of electricity generation and pollution treatment efficiency (Table S5). In addition, certain extra function of CW-MFC was developed based on graphite granule+SSM (Xu et al. 2018b).

Graphite granule was firstly combined with GR as the anode in CW-MFC in 2015 and Pt/C as the cathode; a maximum power density of 321 mW·m−3 was attained, which was much higher than that of AC (92 mW·m−3) under the same conditions (Srivastava et al. 2015). Graphite granule was combined with GR-titanium wire as the anode and the cathode in CW-MFC; an increase in maximum power density (720 ± 68 mW·m−3) was attained, and the removal efficiency of COD and NO3−-N achieved 92% and 87%, respectively, whereas the removal rate of PO43−-P (56%) and total suspended solid (78%) were comparably low (Araneda et al. 2018). In addition, CW-MFC with graphite granule and GR exhibited a better performance for the removal of Congo red dye, NH4+-N, and power recovery (Saket et al. 2022; Mittal et al. 2023).

Interrelation between SO42− and conductive materials and its impact on ammonium and organic pollutants removal was firstly evaluated in CW-MFC with the electrode of CF + graphite granule; the removal efficiency reached 82% for COD, 66% for TN, and 65% for NH4+-N, since graphite granule may reduce the adverse impacts of sulfide on the microbial diversity (Srivastava et al. 2021a). CW-MFC equipped with GF + graphite granule (as the anode) and GP + graphite granule (as the cathode) showed an excellent output voltage (394 mV) and removal efficiency of TN (78%), NH4+-N (80%), and COD (91%) (Srivastava et al. 2021b), in which air pump was firstly introduced into the cathode area to improve the electron flow via increasing DO content together with the pollutant removal efficiency. When GP + graphite granule was used as the electrode in CW-MFC, 90% of TN and 94% of NH4+-N were removed, and the anode reaction mechanism was dominated by the bacterial electroanammox process and the ammonium oxidation pathway using the electrode as the electron acceptor (Fig. S6) (Srivastava et al. 2020).

CW-MFC with the electrode of graphite granule plus SSM was firstly utilized to monitor COD in 2017; a significant linear correlation (R2 > 0.90) was obtained between COD and the output voltage according to Gibbs energy; acetate was the favorable substrate to anodic bacteria compared to glucose and citric acid (Xu et al. 2017). Moreover, a better linear correlation between COD concentration and Ecell was achieved in CW-MFC with an anode of graphite granule plus SSM, indicating that CW-MFC may have a potential application in monitoring COD (Corbella et al. 2019). The association of metal-based anodic electronic receiver and air biocathode may provide an efficient strategy of biosensor in CW-MFC due to its stable electrical signal and rapid response (Xu et al. 2021b). In addition, the sandwich-shape anode was firstly constructed in 2018 in CW-MFC established by a piece of SSM buried in a layer of graphite gravel and AC to harvest energy via a capacitator engaged duty cycling strategy, and multi-electrode system was recommended due to the limited energy lost (Xu et al. 2018b).

3.2 Biochar

Due to the advantages including low cost, high porosity, excellent conductivity, and biocompatibility, biochar (BC) became one of the most concerned emerging materials in optimizing the performance of CW-MFC (Table S6) (Pahunang et al. 2021), especially in the enhancement of attaching the microbes. Furthermore, BC has unique properties, such as sustainability and carbon sequestration, and outdoes other conductive particles (Prado et al. 2020).

BC was firstly introduced into CW-MFC in 2018 to combine with iron plate, providing an effective strategy to remove N and P simultaneously, since iron can promote the removal of PO43−-P by chemical sedimentation and physical adsorption and NO3−-N by electrochemical denitrification. Moreover, the pore structure of BC not only provided a habitat for functional bacteria community but also enhanced the adsorption capacity of the pollutants. Another superiority of BC lied in the discoloration of the effluent water (Gao et al. 2018). The mixture of BC and activated sludge combined with titanium cylinder was used as the anode in CW-MFC and the titanium mesh as the cathode to treat saline wastewater (the salinity reached 5 g·L−1), the output voltage stabilized at 390 mV, the highest power density was 16 mW·m−2, and the removal rates of COD, TP, TN, and NH4+-N were 86%, 65%, 71%, and 80%, respectively (Xu et al. 2019).

The flat TiO2/BC air-photocathode, reversed U shape air-cathode, W shape CF anode combined with BC layer wrapped with SSM were used in CW-MFC to inhibit the bio-clogging, in which reed was used as a raw material of BC. The photocatalyst was successfully introduced into CW-MFC via modifying the photocathode by TiO2/BC, which promoted the electric energy (91 mW·m−3) and restored 63% porosity of CW, together with a removal rate of 32% for NH4+-N and 86% for COD (Wang et al. 2023b). In CW-MFC, the directional migration and dispersion of negatively charged particle were accelerated, and EPS that caused the clogging was degraded into low-molecular-weight organics by micro-electric filed (Fig. S7). The application of BC in CW-MFC may provide an economic and sustainable strategy for pollutant removal, energy recovery, vegetal waste management, and ecological protection.

3.3 Manganese ore

Manganese ore (MO) is a strong natural oxidant, which not only showed an excellent performance on the enrichment of the functional bacteria, but also significantly contributed to the reduction of the methane emission in CW-MFC (Table S7) (Dessie et al. 2020).

In CW-MFC that MO and carbon brushes (CB) were combined as the electrode, the voltage and power density achieved 302 mV and 79 mW·m−3, respectively, COD removal rate reached over 99%, and the methane emission (54 mg·m−2·h−1) was 56% lower than that of CW (121 mg·m−2·h−1), which was attributed to the enrichment of EAB and inhibition of hydrogenotrophic methanogens Methanobacterium (Zhang et al. 2021). Likewise, the combination of MO and SSM can reduce the methane emission by 58%, and remove 95% of COD; 96% of NH4+-N, and 46% of SO42−. SO42−, NO3−-N, and MO acted as the electron acceptor to drive anaerobic oxidation of methane (AOM), providing a novel strategy to control complex pollution in a mutual benefit way. Meanwhile, the voltage and the power density were 402 mV and 161 mW·m−3, respectively, and limited Mn(II) was determined in the effluent (Zhang et al. 2022a).

MO and graphite were combined with CF-SSM as the electrode in CW-MFC, exhibiting a high electricity generation (output voltage: above 500 mV; maximum power density: above 9 mW·m−2), antibiotic removal efficiency (e.g., sulfadiazine, ciprofloxacin > 95%), and antibiotic resistant genes (ARGs). MO enriched the functional genes related to extracellular electron transfer (EET), while the graphite enhanced the adsorption of filter towards antibiotics and ARGs. Furthermore, the cost of MO (12 RMB per milliwatt) was much lower than that of graphite (758 RMB per milliwatt) (Li et al. 2019; Xu et al. 2021a).

CW-MFC filled by MO and AC was further combined with CF as the electrode; MO acted as the electron acceptor; the introduction of MO and AC increased the key nitrogen and carbon metabolism genes, which promoted the removal of NH4+-N (56%), TN (66%), and organics (Wang et al. 2022a). Moreover, MO and AC were combined with CF in CW-MFC to propose a successful strategy for the bioelectric generation (891 mV) and NH4+-N removal (6 gN·m−2·d−1), and the interaction between exoelectrogen and MO as well as the direct interspecies electron transfer was enhanced by conductive AC. The adsorption and oxidation of NH4+-N played a major role at the beginning, while the microbial nitrification was dominant after 4 h, and the nitrogen removal was further accelerated by the cycle of Mn(IV)/Mn(II) (Wang et al. 2022b).

3.4 Iron and its compounds

Iron in CW-MFC may also improve its electricity generation by enhancing the microbial abundance (Wang et al. 2022c), the redox cycle between Fe2+ and Fe3+ promoted the removal of organic matter, N, P, etc. Moreover, iron is also a promising antibacterial material due to its physical destruction and oxidative stress to ARBs (Table S8).

3.4.1 Zero-valent iron

ZVI (Scrap iron) and AC were combined with titanium mesh to improve the power generation of CW-MFC and municipal sewage treatment efficiency by Fe/C micro-electrolysis (formula 1–2):

The active [OH]− and Fe2+ improved the removal rates of COD, TP, TN, and NH4+-N to 79%, 83%, 82%, and 84%, respectively; owing to the acceleration of the electron transfer rate and the enrichment of EAB community, the voltage and maximum power density reached 326 mV and 2 mW·m−2, respectively; additionally, ZVI dissimilated nitrate-oxidizing bacteria (NOB), denitrifying bacteria (DNB), and ammonium bacteria (DNRA) that played an active role during N removal process, and Fe may enhance P removal due to its high binding capacity (Dai et al. 2020).

In CW-MFC system constructed by the electrodes of SSM + AC with the interlayer of biomass modified ceramsite (BMC)/Fe-C, organic matter and phosphorus can be adsorbed by the generated Fe(OH)2+ and Fe(OH)2+, whereas DO depletion by Fe0 and Fe2+ may inhibit nitrification. In Fe-C micro electrolysis process, the produced Fe2+ and [H]+ promoted the denitrification reaction in BMC, and the redox cycle of Fe2+/Fe3+ can participate in the reduction of NO3−-N; as common electrogenic bacteria, Geobacter and Pseudomonas may donate electron to reduce Fe3+ and further mineralize the organics (Li et al. 2022).

3.4.2 Sponge iron

The electrode was composed of sponge iron (s-Fe0 comprised ZVI and Fe3O4) and SSM improved the elimination of sulfamethoxazole (97%–98%), tetracycline (80%–88%), sul genes (84%–94%), and tet genes (50%–61%) with a voltage of 706 mV and power density of 83 mW·m−3, providing a cost-effective strategy for eliminating antibiotics and ARGs in wastewater (Wen et al. 2022). The antibiotics removal mechanism included physical adsorption, electrostatic interaction, bio-utilization as carbon and/or nitrogen source, and the co-metabolic bio-degradation. In addition, ZVI directly inhibited the horizontal transfer of ARGs and enhanced the removal of organic matter via dissimilatory iron reduction. In CW-MFC with the anode combined with s-Fe0/AC layer and SSM, the bioelectricity generation reached 36 mW·m−3 and NO3−-N removal achieved 100%, but the strong reducibility of s-Fe0 was not beneficial for the oxidation of NH4+-N (89%) (Cheng et al. 2022).

3.4.3 Pyrite

As a natural mineral, pyrite (FeS2) may act as anodic conductive particle in CW-MFC to promote the autotrophic denitrification and phosphorus precipitation. In 2020, CF was firstly applied as the electronic receiver to combine with FeS2; the output voltage was 330 mV; the removal efficiency of COD, NO3−-N, total inorganic nitrogen (TIN), and TP achieved 72%, 70%, 63%, and 91%, respectively (Ge et al. 2020). Phosphorus was eliminated via precipitation and adsorption; SO42−-S was reduced by sulfate-reducing bacteria (SRB); NO3−-N was removed by simultaneous heterotrophic denitrification under sufficient carbon source or autotrophic denitrification (HAD)/mixotrophic denitrification under insufficient carbon source. A dissimilatory nitrate reduction to ammonia (DNRA) process was promoted by the released electrons in the oxidization process of Fe2+ and Thiobacillus drove the process of autotrophic denitrification (Fig. S8).

In CW-MFC that FeS2/quartz sand was combined with CF-SSM as the anode, a high voltage of 416 mV was observed and the removal rate of COD increased to 87%, which were higher than FeS2 or quartz sand. Moreover, the cost can be reduced by 53%–90% in comparison with other conductive particles (such as AC and graphite granular), which provided an economically sustainable strategy (Yan et al. 2021). The coupling of FeS2 and s-Fe0 was further combined with titanium mesh as the electrode in CW-MFC, showing a synergistic effect in the removal of Cr(VI) (98%), total chromium (88%), NH4+-N (65%), and TP (79%), and the electricity production (573 mV, 19 mW·m−2) was higher than FeS2 as the conductive particle, since Fe2+ released from iron scraps can reduce Cr(VI) into Cr(III), and EPS regulated by s-Fe0 further accelerated the reduction of Cr(VI), while FeS2 also enriched EAB, iron-, and chromium-reducing bacteria (Kong et al. 2021).

3.4.4 Ferriccarbide

In 2022, ferriccarbide (Fe3C) and AC were firstly combined with the titanium mesh and copper wire as the anode in CW-MFC; AC was combined with the titanium sheet as the cathode; the voltage of 352 mV and power density of 4 mW·m−2 were attained due to the mediation of microbe metabolism by Fe3C, accompanied by a removal efficiency of 92% towards bisphenol A (BPA) and 76% towards COD. Fe3C that simultaneously contains iron and carbon may be promising in practical application, since it can overcome the drawbacks associated with other iron-based materials, such as the released sulfate from the FeS2 caused by acidification (Zhu et al. 2022).

4 Multi-electrode in CW-MFC

CW-MFC with multi-electrode can enhance COD removal efficiency and decrease energy consumption, which may take full advantages to provide a promising strategy for scaling-up of CW-MFC.

4.1 Multi-anode and mono-cathode

4.1.1 Multi metal− or carbon-based anodic receiver combined with non-conductive particle

Double-anode

In CW-MFC constructed by double-anode and mono-cathode (SSM-CF) embedded in solid waste, 83% of TN and 89% of TP were removed from wastewater with a low C/N ratio; the process was enhanced by siphon aeration via tidal flow; the power density peaked at 98 mW·m−3 and voltage reached 350 mV (Zhang et al. 2022b).

Triple-anode

A triple-anode CW-MFC was firstly established by triple CF and single CF placed in the gravel; the anaerobic and aerobic regions were well-developed by upflowed mode; the removal efficiency of COD and NH4+-N achieved 100% and 91%, respectively, with the maximum power density of 6 mW·m−2 (Oon et al. 2015).

Quadruple-anode

A pilot-scale CW-MFC was established with quadruple-SSM anode by parallel connection and single U shape CF-SSM cathode embedded in the gravel in 2019, and 92% of COD and 97% of NH4+-N were removed. The highest voltage of 640 mV and power density of 8 mW·m−2 were superior to those with combined connection. The U shape cathode setting position, aeration, and local effluent circulation may enhance the diffusion of oxygen to the cathode, and the wet degree of cathode facilitated the proton transfer (Tang et al. 2019). Moreover, as the most commonly-used anionic surfactant, the environmental risk of sodium dodecyl benzene sulfonate (SDBS) was effectively reduced by CW-MFC with triple (GR-titanium wire) + lava anode and single (GR-titanium wire) + sand cathode (Wang et al. 2023c). The biodegradation processes of SDBS included alkyl chain degradation, desulfonation, benzene ring cleavage in sequence via ω, β and/or α-oxidations, and radical attack by coenzyme and oxygen.

Therefore, in CW-MFC assembled by the multi-anode with non-conductive particle (Table S9) (Fig. 4), the electron generated from multi-anode either reduced the organic pollutant or transferred to the cathode, and consequently, to enhance the electron accepting capacity. It is essential to increase the contact surface between the cathode and water/air, and optimize the flow mode and the connection type between the anode and the cathode.

4.1.2 Multi metal− or carbon-based anodic receiver combined with conductive particle

Double-anode

CW-MFC assembled with double anode and single cathode (SSM + graphite gravel) exhibited a high removal efficiency towards COD (47%–52%), NO3−-N (95%–97%), NH4+-N (43%–72%), and PO43−-P (96%–98%); the maximum voltage and power density achieved 282 mV and 25 mW·m−2, respectively (Yang et al. 2020).

Double anode and single cathode (stainless steel wire+AC) were embedded in CW-MFC, which firstly used a siphon to create the “tidal flow” to realize significant aerobic condition in the cathode with zero energy cost. Different operation modes, including full siphon recirculation (FSR), semi-siphon recirculation (SSR), low level recirculation (LLR), and high-level recirculation (HLR), created different redox conditions to accelerate the removal rate towards organic matter and nitrogen. The highest removal efficiency of TN was 96% in the 1st FSR, and nitrogen was removed by the following mechanisms: (1) NH4+-N was oxidized to NO3−-N or NO2−-N in both the anoxic and aerobic zones; (2) NO3−-N and/or NO2−-N were digested through the conventional denitrification process in anoxic, aerobic, and anaerobic zone and assimilated by microbes in the aerobic zone. The highest COD removal efficiency was 92% in the 2nd FSR, and the organics were: (1) oxidized by EAB in anaerobic zone and assimilated by microbes in anaerobic zone; (2) degraded by MFC and metabolized by microorganisms in anoxic zone; (3) assimilated and mineralized in aerobic zone (Fig. S9) (Cheng et al. 2021).

As an electro-conductive material with a low resistivity (1 × 10−3 Ω·cm−1–1 × 10−1 Ω·cm−1), pyrrhotite was firstly combined with SSM as the cathode and graphite gravel was combined with SSM as the double-anode in CW-MFC; a maximum power density achieved 15 mW·m−2 and NH4+-N and NO3−-N removal rates reached 89% and 95%, respectively. SSM + pyrrhotite cathode may facilitate the scale-up of CW-MFC due to the advantages including relatively high potential, favorable pH gradient, high redox activity of Fe3+/Fe2+, no secondary pollution, no negative effects on plant growth, and low cost (77–25 US dollars·W−1) (Yang et al. 2021). Moreover, the overgrown plant roots in the cathode area exerted a negative influence on the energy production, thus the strategy with separated anode and cathode area can be an efficient configuration for CW-MFC.

Triple-anode

In up-flow CW-MFC equipped with triple anode and single cathode combined by AC, stainless steel, and carbon rod (CR), the maximum voltage output was 546 mV and the power density was 185 mW·m−3, and the removal efficiency of NH4+-N, NO3−-N, and COD was 97%, 98%, and 99%, respectively, under aeration rate of 600 mL·min−1. The normalized energy recovery (NER) reached 204 W·kg−1 COD, and the low aeration rate can further reduce energy consumption (Oon et al. 2017). Similarly, triple anode and single cathode (AC + stainless steel-CR-copper wire) were served in CW-MFC; the maximum voltage and power density were 553 mV and 186 mW·m−3, respectively; 98% of caffeine was removed by demethylation and oxidation regardless of its concentration accompanied by a detoxification rate of 51%, and NER was 24 Wh·kg−1 COD (Teoh et al. 2022).

CW-MFC equipped with CF-copper mesh+AC, the number of the anode and the cathode were three and one, respectively; the volume of the reactor was 167 L; the maximum voltage and the power density reached 358 mV and 214 mW·m−3, respectively; when the electrode interval was 30 cm, the highest removal rate of NO3−-N was 68% (Wang et al. 2020). In multi-anode CW-MFC, AC and graphite were commonly used as conductive particles (Fig. 5 and Table S10), and the performance can be affected by the interval between the electrodes, the root length of cathode plant, and tidal flow pattern. The cost of electrode and NER may be the controlling factors for scale-up of CW-MFC in the future.

4.2 Multi-cathode and mono-anode

4.2.1 Metal− or carbon-based cathode

CW-MFC with multi-cathode and mono-anode was firstly reported in 2016 (Corbella et al. 2016), in which five pieces of GF were inter-connected by stainless steel wire as the cathode and SSM was embedded into the grave as the anode; MFC was further utilized to assess the clogging in CW based on the correlation between the electric charge and the amount of retained sludge (Fig. 6). In CW-MFC with the cathode of four pieces of GF and SSM combined with gravel or graphite as the anode, the maximum voltage was 238 mV and 245 mV, respectively; domestic wastewater influent containing COD (625 mg·L−1) and NH4+-N (50 mg·L−1) were treated to 108 mg·L−1 (graphite) and 112 mg·L−1 (gravel) for COD, and 16 mg·L−1 (graphite) and 16 mg·L−1 (gravel) for NH4+-N (Corbella and Puigagut 2018). Moreover, CW-MFC with the same configuration was applied to monitor COD in the domestic wastewater and the pilot-plant based experiment presented an acceptable bio-indication response between COD and coulombic efficiency (Corbella et al. 2019).

4.2.2 Bio-cathode

Multiple bio-cathode consisting of GF-stainless steel wire was firstly located at the air-water interface in 2018 in CW-MFC with the anode of SSM + graphite granules, providing a promising strategy for the scaling-up application (Table S11). The energy loss was effectively alleviated (maximum power density: 26 mW·m−2) when the cathode number increased from one to three due to the evenness distribution of electrons, a reduction in ohmic resistance by the parallel connection, and increase in the formation of anoxic zone (Fig. 7). The improvement of NH4+-N removal (81%) was attributed to the electrical enhanced nitrification and denitrification processes on bio-cathode (Xu et al. 2018c).

4.3 Multi-anode and multi-cathode

4.3.1 Double-anode and double-cathode

SSM and CF were co-applied as the anode and the cathode, and two pieces of anode and cathode were vertically set up in CW-MFC (Fig. 8a, Table S12); the average voltage achieved 450 mV and the maximum power density was 114 mW·m−3; the best removal effect of COD, NH4+-N, TN, and TP in low C/N ratio wastewater was 98%, 79%, 84%, and 90%, respectively, suggesting that the agricultural residues (the rape straw) may have a great potential in CW-MFC as the cellulose carbon source (Zhang et al. 2022c).

4.3.2 Triple-anode and triple-cathode

A two-stage CW-MFC was firstly developed to treat the swine wastewater in 2021, in which three SSM pads and three SSM arched bridges acted as the anode and the cathode, respectively, to form 2nd stage CW-MFC which assisted 1st stage CW-MFC with SSM box filled with charcoal as the anode and empty SSM cage as cathode (Fig. 8b). COD, NH4+-N, NO3−-N, TN, TP, and PO43−-P were removed by 72%, 59%, 69%, 47%, 85%, and 88%, respectively. An excellent voltage (440 mV; 340 mV) and power density (33 mW·m−3; 9 mW·m−3) were attained in 1st and 2nd stage CW-MFC, respectively; moreover, the average NER reached 1 Wh·kg−1·COD and 3 Wh·kg−1·COD, respectively (Ren et al. 2021).

4.3.3 Quintuple-anode and quadruple-cathode

Five CB were positioned vertically in the four corners and the middle of the reactor, four GP were horizontally placed in cathode area, the granular graphite was added in each layer to increase the conductivity (Fig. 8c), the bioelectricity generation achieved over 400 mV and over 90% of TN was removed (Wang et al. 2019b; Wang et al. 2019c).

5 Conclusion

CW- MFC is a promising technique in wastewater treatment, power generation, carbon emission reduction, and carbon sequestration. The electrode strategy, including its material, type, matching, and configuration determined the overall performance of CW-MFC. Notably, the electrode with carbon-based electronic receiver modified by novel catalysts (such as TiO2 or nZVI) was excellent in the removal of the refractory pollutants due to the increase in ORR, conductivity, and specific surface area. As the conductive particle of the electrode, BC, manganese, or iron mineral provided a more efficient, environmental-friendly, and economical approach for the application of CW-MFC in comparison with AC or graphite granule, due to the additional advantages such as reusability, low-cost, high electron transport capacity, and facilitating the growth of functional bacteria. The three-dimensional ring or U shape electrode based on the structure features and ductility of the materials was another effective way to improve the performance of CW-MFC.

6 Outlook

The following topics should be further explored in the future research of CW-MFC:

-

(1)

The low power output is still the shortcoming of CW-MFC; the super-capacitive electrode and hybrid CW-MFC coupled with external off-the-shelf harvesting system may provide a strategy.

-

(2)

The biofilm formation process on the electrode, the electron transport paths from the electroactive microorganism to the electrode surface, the influencing of plant root exudates on the microbial community on the cathode, and the competition of the electron between the pollutant and electrode should be further revealed.

-

(3)

The recycle and reuse of the used electrodes as well as the nutrients and heavy metals in wastewater from CW-MFC should be further exploited.

-

(4)

The biochemical removal mechanism and pathway of the refractory and emerging contaminants on different electrodes (especially novel catalytic electrode) in anodic and cathodic area should be further revealed, and the bioavailability of the intermediate products should be considered to further improve the power generation performance of CW-MFC.

-

(5)

More research (hardy plants and microorganisms) should be carried out under the low-temperature hydrologic condition to extend the application zone of CW-MFC in the temperate and cold latitudes.

-

(6)

Clogging derived from the retention of organic/inorganic particle, precipitation, biofilm formation, and root-system growth is still one of the major problems of CW-MFC operation. Assembling air-photocathode into CW-MFC may provide a strategy for the mitigation of clogging.

-

(7)

Microplastics as an emerging artificial vector for the microorganism and contaminant may raise various influences on the power generation and pollutant removal in CW-MFC, which deserves further study in the future.

-

(8)

As the core of CW-MFC, the specific interaction mechanism among macrophyte, substrate, and microbe is still unclear. It is necessary to further reveal the relative mechanism regarding different materials.

Availability of data and materials

Not applicable.

Abbreviations

- CW-MFC:

-

Constructed wetland-microbial fuel cell

- CW:

-

Constructed wetland

- MFC:

-

Microbial fuel cell

- BES:

-

Bioelectrochemical system

- SSM:

-

Stainless steel mesh

- FN:

-

Foamed nickel

- GR:

-

Graphite rod

- CF:

-

Carbon felt

- CC:

-

Carbon cloth

- GP:

-

Graphite plate

- GF:

-

Graphite felt

- Cr:

-

Chromium

- nZVI:

-

Nano zero valent iron

- PAHs:

-

Polycyclic aromatic hydrocarbons

- TiO2 :

-

Titanium dioxide

- ORR:

-

Oxygen reduction reaction

- AC:

-

Activated carbon

- GAC:

-

granular activated carbon

- CAC:

-

Columnar activated carbon

- PFASs:

-

Polyfluoroalkyl substances

- EPS:

-

Extracellular polymeric substances

- Pt:

-

Platinum

- BC:

-

Biochar

- MO:

-

Manganese ore

- CB:

-

Carbon brush

- AOM:

-

Anaerobic oxidation of methane

- ARGs:

-

Antibiotic resistant genes

- EET:

-

Extracellular electron transfer

- ARBs:

-

Angiotonin receptor blocker

- ZVI:

-

Zero-valent iron

- NOB:

-

Nitrate-oxidizing bacteria

- DNB:

-

Denitrifying bacteria

- DNRA:

-

Ammonium bacteria

- BMC:

-

Biomass modified ceramsite

- FeS2 :

-

Pyrite

- TIN:

-

Total inorganic nitrogen

- SRB:

-

Sulfate-reducing bacteria

- Fe3C:

-

Ferriccarbide

- BPA:

-

Bisphenol A

- SDBS:

-

Sodium dodecyl benzene sulfonate

- FSR:

-

Full siphon recirculation

- SSR:

-

Semi-siphon recirculation

- LLR:

-

Low level recirculation

- HLR:

-

High-level recirculation

- CR:

-

Carbon rod

- NER:

-

Normalized energy recovery

References

Araneda I, Tapia NF, Allende KL, Vargas IT (2018) Constructed wetland-microbial fuel cells for sustainable greywater treatment. Water 10:940. https://doi.org/10.3390/w10070940

Bolton CR, Randall DG (2019) Development of an integrated wetland microbial fuel cell and sand filtration system for greywater treatment. J Environ Chem Eng 7:103249. https://doi.org/10.1016/j.jece.2019.103249

Cheng R, Zhu H, Wang JF, Hou SN, Shutes B, Yan BX (2022) Removal of microcystin (MC-LR) in constructed wetlands integrated with microbial fuel cells: efficiency, bioelectricity generation and microbial response. J Environ Manag 309:114669. https://doi.org/10.1016/j.jenvman.2022.114669

Cheng T, Zhao YQ, Kang C, He JT, Yang Y, Morgan D (2021) Creating tidal flow via siphon for better pollutants removal in a microbial fuel cell-constructed wetland. J Environ Manag 290:112592. https://doi.org/10.1016/j.jenvman.2021.112592

Corbella C, García J, Puigagut J (2016) Microbial fuel cells for clogging assessment in constructed wetlands. Sci Total Environ 569–570:1060–1063. https://doi.org/10.1016/j.scitotenv.2016.06.163

Corbella C, Hartl M, Fernandez-Gatell M, Duigagut J (2019) MFC-based biosensor for domestic wastewater COD assessment in constructed wetlands. Sci Total Environ 660:218–226. https://doi.org/10.1016/j.scitotenv.2018.12.347

Corbella C, Puigagut J (2018) Improving domestic wastewater treatment efficiency with constructed wetland microbial fuel cells: influence of anode material and external resistance. Sci Total Environ 631–632:1406–1414. https://doi.org/10.1016/j.scitotenv.2018.03.084

Dai MX, Li YX, Li PF, Guo WH, Qi XY, Zhang YJ, Kong Q (2020) Constructed wetland-microbial fuel cells enhanced with zero-valent iron for wastewater treatment and power generation. Int Biodeterior Biodegradation 153:105048. https://doi.org/10.1016/j.ibiod.2020.105048

Dessie Y, Tadesse S, Eswaramoorthy R (2020) Review on manganese oxide based biocatalyst in microbial fuel cell: nanocomposite approach. Mater Sci Technol 3:136–149. https://doi.org/10.1016/j.mset.2019.11.001

Doherty L, Zhao YQ, Zhao XH, Hu YS, Hao XD, Xu L, Liu RB (2015) A review of a recently emerged technology: constructed wetland-microbial fuel cells. Water Res 85:38–45. https://doi.org/10.1016/j.watres.2015.08.016

Dwivedi AK, Huang SJ, Wang CT, Kumar S (2022) Fundamental understanding of microbial fuel cell technology: recent development and challenges. Chemosphere. 288:132446. https://doi.org/10.1016/j.chemosphere.2021.132446

Ebrahimi A, Sivakumar M, Mclauchlan C (2021a) A taxonomy of design factors in constructed wetland-microbial fuel cell performance: a review. J Environ Manag 291:112723. https://doi.org/10.1016/j.jenvman.2021.112723

Ebrahimi A, Sivakumar M, Mclauchlan C, Ansari A, Vishwanathan AS (2021b) A critical review of the symbiotic relationship between constructed wetland and microbial fuel cell for enhancing pollutant removal and energy generation. J Environ Chem Eng 9:105011. https://doi.org/10.1016/j.jece.2020.105011

Estrada-Arriaga EB, Guadarrama-Pérez O, Silva-Martínez S, Cuevas-Arteaga C, Guadarrama-Pérez VH (2021) Oxygen reduction reaction (ORR) electrocatalysts in constructed wetland-microbial fuel cells: effect of different carbon-based catalyst biocathode during bioelectricity production. Electrochim Acta 370:137745. https://doi.org/10.1016/j.electacta.2021.137745

Fang Z, Song HL, Cang N, Li XN (2013) Performance of microbial fuel cell coupled constructed wetland system for decolorization of azo dye and bioelectricity generation. Bioresour Technol 144:165–171. https://doi.org/10.1016/j.biortech.2013.06.073

Fang Z, Song HL, Yu R, Li XN (2016) A microbial fuel cell-coupled constructed wetland promotes degradation of azo dye decolorization products. Ecol Eng 94:455–463. https://doi.org/10.1016/j.ecoleng.2016.06.020

Gao Y, Zhang W, Gao B, Jia W, Miao A, Xiao L, Yang LY (2018) Highly efficient removal of nitrogen and phosphorus in an electrolysis integrated horizontal subsurface-flow constructed wetland amended with biochar. Water Res 139:301–310. https://doi.org/10.1016/j.watres.2018.04.007

Ge XY, Cao X, Song XS, Wang YH, Si ZH, Zhao YF, Wang WT, Tesfahunegen AA (2020) Bioenergy generation and simultaneous nitrate and phosphorus removal in a pyrite-based constructed wetland-microbial fuel cell. Bioresour Technol 296:122350. https://doi.org/10.1016/j.biortech.2019.122350

Gupta S, Patro A, Mittal Y, Dwivedi S, Saket P, Panja R, Saeed T, Martínez F, Yadav AK (2023) The race between classical microbial fuel cells, sediment-microbial fuel cells, plant-microbial fuel cells, and constructed wetlands-microbial fuel cells: applications and technology readiness level. Sci Total Environ 879:162757. https://doi.org/10.1016/j.scitotenv.2023.162757

Gupta S, Srivastava P, Patil SA, Yadav AK (2021) A comprehensive review on emerging constructed wetland coupled microbial fuel cell technology: potential applications and challenges. Bioresour Technol 320:124376. https://doi.org/10.1016/j.biortech.2020.124376

Hartl M, Bedoya-Rios DF, Fernandez-Gatell M, Rousseau D, Laing GD, Garfí M, Puigagut J (2019) Contaminants removal and bacterial activity enhancement along the flow path of constructed wetland microbial fuel cells. Sci Total Environ 652:1195–1208. https://doi.org/10.1016/j.scitotenv.2018.10.234

Hartl M, García-Galan MJ, Matamoros V, Fernandez-Gatell M, Kousseau DPC, Laing DG, Garfí M, Puigagut J (2021) Constructed wetlands operated as bioelectrochemical systems for the removal of organic micropollutants. Chemosphere 271:129593. https://doi.org/10.1016/j.chemosphere.2021.129593

Huang L, He JK, Jiang CL, Weng SJ, Zhao F, Zhong H, Chen YC (2023) Strategies to alleviate clogging in constructed wetlands: what can be learned from the microbial fuel cell coupled membrane bioreactor? J Clean Prod 405:136973. https://doi.org/10.1016/j.jclepro.2023.136973

Huang X, Duan CS, Duan WY, Sun FY, Cui HW, Zhang S, Chen X (2021) Role of electrode materials on performance and microbial characteristics in the constructed wetland coupled microbial fuel cell (CW-MFC): a review. J Clean Prod 301:126951. https://doi.org/10.1016/j.jclepro.2021.126951

Ji B, Kang PY, Wei T, Zhao YQ (2020) Challenges of aqueous per- and polyfluoroalkyl substances (PFASs) and their foreseeable removal strategies. Chemosphere 250:126316. https://doi.org/10.1016/j.chemosphere.2020.126316

Ji B, Zhao YQ, Vymazal J, Mander U, Lust R, Tang C (2021) Mapping the field of constructed wetland-microbial fuel cell: a review and bibliometric analysis. Chemosphere 262:128366. https://doi.org/10.1016/j.chemosphere.2020.128366

Ji B, Zhao YQ, Yang Y, Li QM, Man Y, Dai YN, Fu JM, Wei T, Tai YP, Zhang XM (2023) Curbing per- and polyfluoroalkyl substances (PFASs): first investigation in a constructed wetland-microbial fuel cell system. Water Res 230:119530. https://doi.org/10.1016/j.watres.2022.119530

Kamali M, Aminabhavi TM, Abbassi R, Dewil R, Appels L (2022) Engineered nanomaterials in microbial fuel cells-recent developments, sustainability aspects, and future outlook. Fuel 310:122347. https://doi.org/10.1016/j.fuel.2

Kataki S, Chatterjee S, Vairale MG, Sharma S, Dwivedi SK, Gupta DK (2021) Constructed wetland, an eco-technology for wastewater treatment: a review on various aspects of microbial fuel cell integration, low temperature strategies and life cycle impact of the technology. Renew Sust Energ Rev 148:111261. https://doi.org/10.1016/j.rser.2021.111261

Kong Q, Guo WH, Sun RP, Qin Y, Zhao CC, Wang XY, Zhang RT, Zhang XY (2021) Enhancement of chromium removal and energy production simultaneously using iron scrap as anodic filling material with pyrite-based constructed wetland-microbial fuel cell. J Environ Chem Eng 9:106630. https://doi.org/10.1016/j.jece.2021.106630

Li C, Hao LS, Cao JS, Zhou K, Fang F, Feng Q, Luo JY (2022) Mechanism of Fe–C micro-electrolysis substrate to improve the performance of CW-MFC with different factors: insights of microbes and metabolic function. Chemosphere 304:135410. https://doi.org/10.1016/j.chemosphere.2022.135410

Li H, Xu H, Yang YL, Wu Y, Zhang S, Song HL (2019) Effects of graphite and Mn ore media on electro-active bacteria enrichment and fate of antibiotic and corresponding resistance gene in up flow microbial fuel cell constructed wetland. Water Res 165:114988. https://doi.org/10.1016/j.watres.2019.114988

Liu S, Lu YX, Chen H, Zhang S, Chen B, Song HL (2022a) Variation in the microbial community in bioelectrochemical systems treating sulfamethoxazole wastewater—Identifying key operating parameters and revealing sul gene-harboring host bacteria. J. Water Process Eng 46:102572. https://doi.org/10.1016/j.jwpe.2022.102572

Liu ST, Qiu DF, Lu FF, Wang Y, Wang Z, Feng XJ, Pyo SH (2022b) Acorus calamus L. constructed wetland-microbial fuel cell for Cr(VI)-containing wastewater treatment and bioelectricity production. J Environ Chem Eng 10:107801. https://doi.org/10.1016/j.jece.2022.107801

Mier AA, Olvera-Vargas H, Mejía-L’opez M, Longoria A, Vereal L, Sebastian PJ, Arias DM (2021) A review of recent advances in electrode materials for emerging bioelectrochemical systems: from biofilm-bearing anodes to specialized cathodes. Chemosphere 283:131138. https://doi.org/10.1016/j.chemosphere.2021.131138

Mittal Y, Noori T, Saeed T, Yadav AK (2023) Influence of evapotranspiration on wastewater treatment and electricity generation performance of constructed wetland integrated microbial fuel cell. J Water Process Eng 53:103580. https://doi.org/10.1016/j.jwpe.2023.103580

Mu CX, Wang L, Wang L (2021) Removal of Cr(VI) and electricity production by constructed wetland combined with microbial fuel cell (CW-MFC): influence of filler media. J Clean Prod 320:128860. https://doi.org/10.1016/j.jclepro.2021.128860

Negi D, Verma S, Singh S, Daverry A (2022) Nitrogen removal via anammox process in constructed wetland – a comprehensive review. Chem Eng J 437:135434. https://doi.org/10.1016/j.cej.2022.135434

Oon YL, Ong SA, Ho LN, Wong YS, Dahalan FA, Oon YS, Lehl HK, Thung WT, Nordin N (2017) Role of macrophyte and effect of supplementary aeration in up-flow constructed wetland-microbial fuel cell for simultaneous wastewater treatment and energy recovery. Bioresour Technol 224:265–275. https://doi.org/10.1016/j.biortech.2016.10.079

Oon YL, Ong SA, Ho LN, Wong YS, Dahalan FA, Oon YS, Teoh TP, Lehl HK, Thung WE (2020) Constructed wetland–microbial fuel cell for azo dyes degradation and energy recovery: influence of molecular structure, kinetics, mechanisms and degradation pathways. Sci Total Environ 720:137370. https://doi.org/10.1016/j.scitotenv.2020.137370

Oon YL, Ong SA, Ho LN, Wong YS, Oon YS, Lehl HK, Thung WE (2015) Hybrid system up-flow constructed wetland integrated with microbial fuel cell for simultaneous wastewater treatment and electricity generation. Bioresour Technol 186:270–275. https://doi.org/10.1016/j.biortech.2015.03.014

Pahunang RR, Buonerba A, Senatore V, Oliva G, Ouda M, Zarra T, Muñoz R, Puig S, Florencio C, Li CW, Hasan SW, Belgiorno V, Naddeo V (2021) Advances in technological control of greenhouse gas emissions from wastewater in the context of circular economy. Sci Total Environ 792:148479. https://doi.org/10.1016/j.scitotenv.2021.148479

Prado A, Ramírez-Vargas CA, Arias CA, Esteve-Núñez A (2020) Novel bioelectrochemical strategies for domesticating the electron flow in constructed wetlands. Sci Total Environ 735:139522. https://doi.org/10.1016/j.scitotenv.2020.139522

Ren BM, Wang TY, Zhao YQ (2021) Two-stage hybrid constructed wetland-microbial fuel cells for swine wastewater treatment and bioenergy generation. Chemosphere 268:128803. https://doi.org/10.1016/j.chemosphere.2020.128803

Saket P, Mittal Y, Bala K, Joshi A, Yadav AK (2022) Innovative constructed wetland coupled with microbial fuel cell for enhancing diazo dye degradation with simultaneous electricity generation. Bioresour Technol 345:126490. https://doi.org/10.1016/j.biortech.2021.126490

Sharma R, Malaviya P (2022) Constructed wetlands for textile wastewater remediation: a review on concept, pollutant removal mechanisms, and integrated technologies for efficiency enhancement. Chemosphere 290:133358. https://doi.org/10.1016/j.chemosphere.2021.133358

Srivastava P, Abbassi R, Yadav AK, Garaniya V, Levis T, Zhao YQ, Aminabhavi T (2021a) Interrelation between Sulphur and conductive materials and its impact on ammonium and organic pollutants removal in constructed wetlands-microbial fuel cells. J Hazard Mater 419:126417. https://doi.org/10.1016/j.jhazmat.2021.126417

Srivastava P, Belford A, Abbassi R, Asadnia M, Garaniva V, Yadav AK (2021b) Low-power energy harvester from constructed wetland-microbial fuel cells for initiating a self-sustainable treatment process. Sustain Energy Technol Assess 46:101282. https://doi.org/10.1016/j.seta.2021.101282

Srivastava P, Dwivedi S, Kumar N, Abbassi R, Garaniya V, Yadav AK (2017) Performance assessment of aeration and radial oxygen loss assisted cathode based integrated constructed wetland-microbial fuel cell systems. Bioresour Technol 244:1178–1182. https://doi.org/10.1016/j.biortech.2017.08.026

Srivastava P, Yadav AK, Garaniya V, Lewis T, Abbassi R, Khan SJ (2020) Electrode dependent anaerobic ammonium oxidation in microbial fuel cell integrated hybrid constructed wetlands: a new process. Sci Total Environ 698:134248. https://doi.org/10.1016/j.scitotenv.2019.134248

Srivastava P, Yadav AK, Mishra BK (2015) The effects of microbial fuel cell integration into constructed wetland on the performance of constructed wetland. Bioresour Technol 195:223–230. https://doi.org/10.1016/j.biortech.2015.05.072

Tang C, Zhao YQ, Kang C, Yang Y, Morgan D, Xu L (2019) Towards concurrent pollutants removal and high energy harvesting in a pilot-scale CW-MFC: insight into the cathode conditions and electrodes connection. Chem Eng J 373:150–160. https://doi.org/10.1016/j.cej.2019.05.035

Tao MN, Jing ZQ, Tao ZK, Luo H, Zuo SM, Li YY (2022a) Efficient nitrogen removal in microbial fuel cell–constructed wetland with corncobs addition for secondary effluent treatment. J Clean Prod 332:130108. https://doi.org/10.1016/j.jclepro.2021.130108

Tao MN, Kong Y, Jing ZQ, Jia QS, Tao ZK, Li YY (2022b) Denitrification performance, bioelectricity generation and microbial response in microbial fuel cell - constructed wetland treating carbon constraint wastewater. Bioresour Technol 363:127902. https://doi.org/10.1016/j.biortech.2022.127902

Tao ZK, Jing ZQ, Tao MN, Chen RJ (2022c) Recycled utilization of ryegrass litter in constructed wetland coupled microbial fuel cell for carbon-limited wastewater treatment. Chemosphere 302:134882. https://doi.org/10.1016/j.chemosphere.2022.134882

Teoh TP, Ong SA, Ho LN, Wong YS, Lutpi NA, Oon YL, Tan SM, Ong YP, Yap KL (2022) Caffeine-containing wastewater treatment and bioelectricity generation in up-flow constructed wetland-microbial fuel cell: influence of caffeine concentration, operating conditions, toxicity assessment, and degradation pathway. J Water Process Eng 46:102623. https://doi.org/10.1016/j.jwpe.2022.102623

Türker OC, Yakar A (2017) A hybrid constructed wetland combined with microbial fuel cell for boron (B) removal and bioelectric production. Ecol Eng 102:411–421. https://doi.org/10.1016/j.ecoleng.2017.02.034

Wang HX, Wang XO, Wang MY, Zhang CP, Li JY, Xue M, Xia WY, Xie HJ (2023c) Degradation and transformation of linear alkyl-benzene sulfonates (LAS) in integrated constructed wetland–microbial fuel cell systems. Chemosphere 321:138135. https://doi.org/10.1016/j.chemosphere.2023.138135

Wang J, Song X, Li QS, Bai H, Zhu CY, Weng BS, Yan DH, Bai JH (2019a) Bioenergy generation and degradation pathway of phenanthrene and anthracene in a constructed wetland-microbial fuel cell with an anode amended with nZVI. Water Res 150:340–348. https://doi.org/10.1016/j.watres.2018.11.075

Wang J, Song X, Wang Y, Bai JH, Bai H, Yan DM, Cao Y, Li YH, Yu ZL, Dong GQ (2017a) Bioelectricity generation, contaminant removal and bacterial community distribution as affected by substrate material size and aquatic macrophyte in constructed wetland-microbial fuel cell. Bioresour Technol 245:372–378. https://doi.org/10.1016/j.biortech.2017.08.191

Wang J, Song X, Wang Y, Bai JH, Li MJ, Dong GQ, Lin FD, Lv YF, Yan DH (2017b) Bioenergy generation and rhizodegradation as affected by microbial community distribution in a coupled constructed wetland-microbial fuel cell system associated with three macrophytes. Sci Total Environ 607–608:53–62. https://doi.org/10.1016/j.scitotenv.2017.06.243

Wang JF, Song XS, Wang YH, Abayneh B, Ding Y, Yan DH, Bai JH (2016) Microbial community structure of different electrode materials in constructed wetland incorporating microbial fuel cell. Bioresour Technol 221:697–702. https://doi.org/10.1016/j.biortech.2016.09.116

Wang JF, Zhu CY, Li QS, Yan DM, Wang LL, He T, Cai ZX, Zhou HZ, Song XS (2022c) Anaerobic granular sludge coupled with artificial aeration or Fe-based substrate enhanced nitrogen conversion dynamic based on CW-MFCs. J Water Process Eng 45:102483. https://doi.org/10.1016/j.jwpe.2021.102483

Wang L, Song XS, Wang YH, Zhao YH, Zhao ZM, Wang BD, Yan DH (2017c) Effects of electrode material and substrate concentration on the bioenergy output and wastewater treatment in air-cathode microbial fuel cell integrating with constructed wetland. Ecol Eng 99:191–198. https://doi.org/10.1016/j.ecoleng.2016.11.015

Wang LM, Pang QQ, Zhou Y, Peng FQ, He F, Li WX, Xu B, Cui YB, Zhu X (2020) Robust nitrate removal and bioenergy generation with elucidating functional microorganisms under carbon constraint in a novel multianode tidal constructed wetland coupled with microbial fuel cell. Bioresour Technol 314:123744. https://doi.org/10.1016/j.biortech.2020.123744

Wang WY, Dong L, Zhai TY, Wang WP, Wu HZ, Kong FL, Cui YQ, Wang S (2023b) Bio-clogging mitigation in constructed wetland using microbial fuel cells with novel hybrid air-photocathode. Sci Total Environ 881:163423. https://doi.org/10.1016/j.scitotenv.2023.163423

Wang XO, Tian YM, Liu H, Zhao XH, Peng S (2019c) Optimizing the performance of organics and nutrient removal in constructed wetland–microbial fuel cell systems. Sci Total Environ 653:860–871. https://doi.org/10.1016/j.scitotenv.2018.11.005

Wang XO, Tian YM, Liu H, Zhao XH, Wu Q (2019b) Effects of influent COD/TN ratio on nitrogen removal in integrated constructed wetland–microbial fuel cell systems. Bioresour Technol 271:492–495. https://doi.org/10.1016/j.biortech.2018.09.039

Wang Y, Zhang XH, Yu G, Yao Y, Lin H (2023a) Effects of flow pattern, Leersia hexandra, and circuit mode on the Cr(VI) removal capacity, electricity generation performance, and microbial community of constructed wetland-microbial fuel cells. Fuel 338:127326. https://doi.org/10.1016/j.fuel.2022.127326

Wang YF, Li DP, Song XS, Cao X, Xu ZS, Huang W, Wang YH, Wang ZW, Sand W (2022a) Intensifying anoxic ammonium removal by manganese ores and granular active carbon fillings in constructed wetland-microbial fuel cells: metagenomics reveals functional genes and microbial mechanisms. Bioresour Technol 352:127114. https://doi.org/10.1016/j.biortech.2022.127114

Wang YF, Song XS, Cao X, Xu ZS, Huang W, Wang YH, Ge XY (2022b) Integration of manganese ores with activated carbon granules into CW-MFC to trigger anoxic electron transfer and removal of ammonia nitrogen. J Clean Prod 334:130202. https://doi.org/10.1016/j.jclepro.2021.130202

Wen HY, Zhu H, Yan BX, Bañuelos B, Wang XY, Cao SJ, Cheng R, Tian LP (2022) High removal efficiencies of antibiotics and low accumulation of antibiotic resistant genes obtained in microbial fuel cell-constructed wetlands intensified by sponge iron. Sci Total Environ 806:150220. https://doi.org/10.1016/j.scitotenv.2021.150220

Wu SB, Lyu T, Zhao YQ, Vymazal J, Arias AC, Brix H (2018) Rethinking intensification of constructed wetlands as a green eco-Technology for Wastewater Treatment. Environ Sci Technol 52:1693–1694. https://doi.org/10.1021/acs.est.8b00010

Xu F, Cao FQ, Kong Q, Zhou LL, Yuan Q, Zhu YJ, Wang Q, Du YD, Wang ZD (2018a) Electricity production and evolution of microbial community in the constructed wetland-microbial fuel cell. Chem Eng J 339:479–486. https://doi.org/10.1016/j.cej.2018.02.003

Xu F, Quyang DL, Rene ER, Ng HY, Guo LL, Zhu YJ, Zhou LL, Yuan Q, Miao MS, Wang Q, Kong Q (2019) Electricity production enhancement in a constructed wetland-microbial fuel cell system for treating saline wastewater. Bioresour Technol 288:121462. https://doi.org/10.1016/j.biortech.2019.121462

Xu H, Song HL, Singh RP, Yang YL, Xu JY, Yang XL (2021a) Simultaneous reduction of antibiotics leakage and methane emission from constructed wetland by integrating microbial fuel cell. Bioresour Technol 320:124285. https://doi.org/10.1016/j.biortech.2020.124285

Xu L, Wang BD, Liu XH, Yu WZ, Zhao YQ (2018b) Maximizing the energy harvest from a microbial fuel cell embedded in a constructed wetland. Appl Energy 214:83–91. https://doi.org/10.1016/j.apenergy.2018.01.071

Xu L, Yu WZ, Graham N, Zhao YQ (2021b) Revisiting the bioelectrochemical system based biosensor for organic sensing and the prospect on constructed wetland-microbial fuel cell-ScienceDirect. Chemosphere 264:128532. https://doi.org/10.1016/j.chemosphere.2020.128532

Xu L, Zhao YQ, Fan C, Fan ZR, Zhao FC (2017) First study to explore the feasibility of applying microbial fuel cells into constructed wetlands for COD monitoring. Bioresour Technol 243:846–854. https://doi.org/10.1016/j.biortech.2017.06.179

Xu L, Zhao YQ, Wang XD, Yu WZ (2018c) Applying multiple bio-cathodes in constructed wetland-microbial fuel cell for promoting energy production and bioelectrical derived nitrification-denitrification process. Chem Eng J 344:105–113. https://doi.org/10.1016/j.cej.2018.03.065

Yadav AK, Dash P, Abbassi MR, Mishra BK (2012) Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal. Ecol Eng 47:126131. http://dx.doi.org/10.1016/j.ecoleng.2012.06.029

Yakar A, Türe C, Türker OC, Vymazal J, Saz C (2018) Impacts of various filtration media on wastewater treatment and bioelectric production in up-flow constructed wetland combined with microbial fuel cell (UCW-MFC). Ecol Eng 117:120–132. https://doi.org/10.1016/j.ecoleng.2018.03.016

Yan J, Hu XB, He Q, Qin H, Yi D, Lv DZ, Cheng C, Zhao YQ, Chen Y (2021) Simultaneous enhancement of treatment performance and energy recovery using pyrite as anodic filling material in constructed wetland coupled with microbial fuel cells. Water Res 201:117333. https://doi.org/10.1016/j.watres.2021.117333

Yang HY, Chen J, Yu L, Li WH, Huang XH, Qin Q, Zhu SG (2022) Performance optimization and microbial community evaluation for domestic wastewater treatment in a constructed wetland-microbial fuel cell. Environ Res 212:113249. https://doi.org/10.1016/j.envres.2022.113249

Yang Y, Zhao Y, Tang C, Liu RB, Chen TH (2021) Dual role of macrophytes in constructed wetland-microbial fuel cells using pyrrhotite as cathode material: a comparative assessment. Chemosphere 263:128354. https://doi.org/10.1016/j.chemosphere.2020.128354

Yang Y, Zhao Y, Tang C, Xu L, Morgan D, Liu RB (2020) Role of macrophyte species in constructed wetland-microbial fuel cell for simultaneous wastewater treatment and bioenergy generation. Chem Eng J 392:123708. https://doi.org/10.1016/j.cej.2019.123708

Zhang K, Wu X, Chen J, Wang W, Luo H, Chen W, Ma D, An X, Wei Z (2021) The role and related microbial processes of Mn-dependent anaerobic methane oxidation in reducing methane emissions from constructed wetland-microbial fuel cell. J Environ Manag 294:112935. https://doi.org/10.1016/j.jenvman.2021.112935

Zhang K, Wu XL, Wang W, Chen J, Luo HB, Chen W, Ma DD, An XC, Chen FH, Cheng L, Mo Y, Wei ZL, Zhang XX (2022a) Anaerobic oxidation of methane (AOM) driven by multiple electron acceptors in constructed wetland and the related mechanisms of carbon, nitrogen, sulfur cycles. Chem Eng J 433:133663. https://doi.org/10.1016/j.cej.2021.133663

Zhang K, Yang SQ, Luo HB, Chen J, An XC, Chen W, Zhang XX (2022b) Enhancement of nitrogen removal and energy recovery from low C/N ratio sewage by multi-electrode electrochemical technology and tidal flow via siphon aeration. Chemosphere 299:134376. https://doi.org/10.1016/j.chemosphere.2022.134376

Zhang K, Yang SQ, Wang W, Luo HB, Chen W, Zhang XX, Ma DD, An XC, Chen FH, Cheng L, Chen J, Mo Y, Fan LQ, Xiao WM (2022c) Bioelectrochemical processes and cellulosic carbon source enhance the autotrophic and heterotrophic denitrification of low C/N ratio wastewater in tidal flow constructed wetland - microbial fuel cells. J Clean Prod 363:132368. https://doi.org/10.1016/j.jclepro.2022.132368

Zhang LJ, Liu YL, Lv SC, Wang R, Wang Y, Lin KX, Hu XK, Liu YC, Dong ZJ, Liu LS (2023) An overview on constructed wetland-microbial fuel cell: greenhouse gases emissions and extracellular electron transfer. J Environ Chem Eng 11:109551. https://doi.org/10.1016/j.jece.2023.109551

Zhao CC, Shang DW, Zou YL, Du YD, Wang Q, Xu F, Ren L, Kong Q (2020) Changes in electricity production and microbial community evolution in constructed wetland-microbial fuel cell exposed to wastewater containing Pb(II). Sci Total Environ 732:139127. https://doi.org/10.1016/j.scitotenv.2020.139127

Zhu YJ, Gai XX, Xue YY, Zhou Y, Leng SG, Li HL, Zhao Z, Huang J, Kong Q (2022) Electroactive constructed wetland using Fe3C as an anodic exogenous electron donor: performance and mechanisms. J Water Process Eng 50:103223. https://doi.org/10.1016/j.jwpe.2022.103223

Funding

This work was financially supported by National Natural Science Foundation of China [41702370, 51408109, 42130705], the Experimental Technology Research Project of Northeast Normal University [135132027].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Writing-original draft, conceptualization and data curation were performed by Rongdi An. Writing-review & editing and methodology were performed by Jiunian Guan and Nan Lu. Visualization and data curation were performed by Gaoxiang Li and Zhuoyu Li. Funding acquisition and project administration were performed by Jiunian Guan, Hongfeng Bian and Lianxi Sheng. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Fengchang Wu

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Fig. S1.

The electrode researches and electrode strategies in CW-MFC. Fig. S2. Greenhouse gas emission from CW-MFC with SSM/CC/CF+grave. Fig. S3. Nitrogen removal mechanism in CW-MFC with GP+gravel. Fig. S4. Schematics of CW-MFC system removal of PFASs (a) Adsorption, (b) Uptake, (c) MFC, (d) CW (Ji et al. 2020). Fig. S5. Removal of Cr(VI) (a) (Mu et al. 2021) and Pb(II) (b) (Zhao et al. 2020) by CW-MFC. Fig. S6. Anaerobic ammonium oxidation in CW-MFC (Srivastava et al. 2020). Fig. S7. Bio-clogging mitigation in CW-MFC with the photocathode by TiO2/BC. Fig. S8. Simultaneous removal of nitrate and phosphorus in CW-MFC with FeS2 (Ge et al. 2020). Fig. S9. The pollutant removal in CW-MFC with double anode and single cathode by tidal flow (Cheng et al. 2021). Table S1. Unified model electronic receiver combined with non-conductive particle in CW-MFC. Table S2. Composited model of the electronic receiver combined with non-conductive particle in CW-MFC. Table S3. Modified model electronic receiver combined with non-conductive particle in CW-MFC. Table S4. Metal-/carbon-based electronic receivers combined with AC in CW-MFC. Table S5. Metal-/carbon-based electronic receiver combined with graphite granule in CW-MFC. Table S6. Metal-/carbon-based electronic receiver combined with BC in CW-MFC. Table S7. Metal-/carbon-based electronic receiver combined with MO in CW-MFC. Table S8. Metal-/carbon-based electronic receiver combined with iron and its compound in CW-MFC. Table S9. Multi metal-/carbon-based anodic receiver combined with non-conductive particle. Table S10. Multi metal-/carbon-based anodic receiver combined with conductive particle. Table S10. Multi metal-/carbon-based anodic receiver combined with conductive particle. Table S11. Multi metal-/carbon-based cathodic receiver combined with non- or conductive particle. Table S12. Multi metal-/carbon-based anodic and cathodic receiver combined with non- or conductive particle.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

An, R., Guan, J., Li, G. et al. The electrode strategy and its coordination mechanism in constructed wetland-microbial fuel cell (CW-MFC): a review. Carbon Res. 3, 17 (2024). https://doi.org/10.1007/s44246-023-00092-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-023-00092-y