Abstract

It is a green route to prepare H2O2 through electrochemical oxygen reduction at normal temperature and pressure using only oxygen and water as feedstock. This method is suitable for the distributed production of H2O2, avoiding the safety problems caused by long-term storage and long-distance transportation. We propose a mild strategy modulating carbon materials i.e., the carbon black is treated by a low-concentration H2O2, where the oxidation reactions occur by hydroxyl radicals. The oxygenated groups and carbon defects were regulated by adjusting the concentration H2O2 used. The modified carbon black showed excellent selectivity and stability in the electrosynthesis of H2O2 under neutral conditions. The optimal catalyst had a selectivity of 99% for H2O2 at a potential of 0.25 V vs. reversible hydrogen electrode and remained above 90% in a wide potential window. The activity of optimal catalyst was increased by 19% compared to the pristine carbon black. It was found that the improvement of catalytic activity and selectivity was mainly ascribed to carbon defect. The concentration of H2O2 produced was 0.33 mol L−1 with 80% Faradaic efficiency at 4.5 V in the flow cell. The productivity of H2O2 could reach 2.23 mol g−1 h−1 during a continuous operation of 10 h.

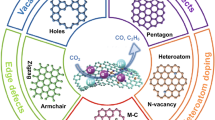

Graphical Abstract

Highlights

• Modifying carbon materials by a mild treatment of H2O2.

• Regulating oxygenated groups and carbon defects for selective H2O2 production.

• Faradaic efficiency of 80% and productivity of 2.23 mol g−1 h−1 in a flow cell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

H2O2, a kind of green chemical, has been extensively utilized in versatile fields such as fabric and pulp bleaching, chemical synthesis, disinfection and sterilization, electronic etching and rocket fuel (Campos-Martin et al. 2006). At present, anthraquinone process is an industrial method to produce H2O2 in large scale, which requires complex infrastructure, high energy cost and generates substantial organic byproducts (Yang et al. 2018). H2O2 can also be directly synthesized from the reaction of H2 and O2 over noble-metal-based e.g., Pd catalysts at elevated temperature and pressure. The main problem is the inevitable explosion risk from the mixture of gaseous H2 and O2. Dilution of the solution with inert gases reduces the reaction activity (Mumma et al. 2009; Freakley et al. 2016).

In the last decades, the electrochemical synthesis of H2O2 via two-electron oxygen reduction reaction (2e-ORR) has aroused tremendous attention because of mild conditions, easily accessible feedstocks and versatile catalytic systems (Wang et al. 2021c; Jiang et al. 2018; Jung et al. 2020a, 2020b). The renewable electricity generated from solar or wind energy is used as energy input, which paves a carbon-neutral pathway for H2O2 synthesis. The key to electrochemical synthesize of H2O2 is the pursuit of high-efficiency catalysts. Precious metal-based electrocatalysts, such as Au (Lu et al. 2014), Pt-Hg (Siahrostami et al. 2013), and Pt/C (Choi et al. 2014) exhibit superior ORR activity and selectivity. However, the inherent scarce of precious metals limits their mass applications (Rao et al. 2022).

Carbon materials have the characteristics of versatile structures, abundant sources and adjustable electronic properties, which are ideal candidates as 2e-ORR catalysts (Bu et al. 2021; Hu et al. 2020; Guo et al. 2022). Nevertheless, the weak interaction between carbon structure itself and oxygenated intermediates impairs its catalytic capability (Wang et al. 2023). Consequently, the carbon structure needs to be regulated by modification strategy. One strategy is the doping of Co (Chen et al. 2022; Gong et al. 2022b), Zn (Jia et al. 2022; Zhang et al. 2022) metal atoms or B (Xia et al. 2021), N (Li et al. 2020; Rawah et al. 2022) and F (Zhao et al. 2018) heteroatoms. Another is the modification by grafting oxygen-containing groups onto the parent carbon structures using oxidation reactions (Lu et al. 2018). The oxidants available include concentrated nitric acid (Zhang et al. 2021a; Xia et al. 2019), potassium permanganate (Kim et al. 2018; Lee et al. 2022), and sodium persulfate (Wang et al. 2021a), which are severely corrosive and irritating. The oxidation involves tedious steps and is less environmentally friendly.

Furthermore, the recognition of the active sites in oxygen-doped carbon materials is controversial. Cui and co-workers agreed that the activity and selectivity of catalysts is closely related to the oxygen content (Lu et al. 2018). Wang suggested that surface functional groups such as C-O-C and HO-C=O activated adjacent carbon atom sites (Xia et al. 2019). Eigler and colleagues consented to the point that the catalytic capability towards 2e-ORR is associated with the combined effect of defect structures and oxygen-containing groups on carbon materials (Wang et al. 2021b). Lu and co-workers focused on the M-O-C sites, where the M-O bond could optimize the *OOH adsorption/desorption intensity of adjacent carbon sites (Zhang et al. 2022; Yang et al. 2020). As a consequence, the disclosure of active sites in carbon-based catalysts remains a challenge. It is desirable to identify the active sites for enhancing the electrochemical synthesis of H2O2.

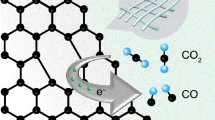

Here, we propose an environmentally friendly and mild method to derive carbon-based oxygen reduction catalysts by treating nanosized carbon black with a low-concentration H2O2 solution (0.5 ~ 2 wt%). The amount of carbon defects and oxygen-containing groups can be easily adjusted by changing the H2O2 concentration. The electronic structure of carbon framework in carbon black was tuned by carbon defects and oxygen-containing groups, which affected the activity and selectivity of 2e-ORR to H2O2. The roles of carbon defects and oxygen-containing groups were decoupled by removing the C=O groups in treated carbon black under a flowing H2 atmosphere. The findings indicate that the activity and selectivity of 2e-ORR to H2O2 displayed correlation with the amount of carbon defects in carbon black, with a high Faradaic efficiency beyond 95% on the optimal catalyst. The H2O2 solution of low-concentration was produced stably and continuously in a flow cell reactor, which can be utilized directly in treating carbon black.

2 Materials and methods

2.1 Materials and method

Commercial carbon black (Vulcan XC-72), isopropanol, sulfuric acid (H2SO4), Nafion 117 solution (5 wt%), and Nafion115 proton exchange membrane were purchased from Aladdin Industries (Shanghai). IrO2/Ti mesh was purchased from Shultai Industrial Co., Ltd. (Suzhou), and Teflon-treated hydrophobic carbon paper HCP120 (with microporous layer) was provided by Hesen Electric Co., Ltd. (Shanghai). All drugs were not further processed.

The commercial 30 wt% H2O2 solution was diluted to 0.5, 1, 2 and 4 wt%. Next, 100 mg of commercial carbon black (XC-72) is dispersed into 100 mL of diluted solution. The bottles were heated to 90 °C and maintained for 2 h. After natural cooling to room temperature, treated carbon black was washed with a continuous flow of deionized water, and then dried at 50 °C in an oven for 12 h. The obtained catalysts were named CB-0.5, CB-1, CB-2 and CB-4, respectively.

The catalyst ink was prepared by dispersing catalysts (10 mg) in the mixed solvent consisting of 490 μL of H2O, 490 μL of isopropanol and 20 μL of Nafion 117(5 wt%) followed by an hour sonication. In the rotating ring-disk electrode (RRDE) test, 8 μ L of catalyst slurry was dripped on the surface of glassy carbon electrode and dried naturally in the air at 200 rpm to obtain uniform catalyst coating. In the electrode preparation of flow electrolytic cell, 0.5 mL of catalyst slurry was sprayed on the surface of hydrophobic carbon paper by air spray gun.

The H2O2 concentration was measured using the cerium sulfate titration method where the yellow Ce4+ solution would be reduced by H2O2 to colorless Ce3+ following the stoichiometry of 2Ce4+ + H2O2 = 2Ce4+ + 2H+ + O2. The measured wavelength was 316 nm.

2.2 Characterizations

X-ray diffraction (XRD) patterns were obtained using a high-power X-ray diffractometer (Shimadzu XRD-6000) with a Cu Kα radiation source operated at 40 kV. The crystal phase structure of the sample was determined in the scanning range of 3–80° at the scanning rate of 10° min−1.

Raman spectra were measured on a Horiba Labram HR800 Raman spectrometer under the 532 nm laser excitation in the wavenumber range of 2500–750 cm−1.

Transmission electron microscope (TEM) and elemental mapping analysis were measured by a JEM-2100 operated at 200 kV.

Fourier transform infrared spectrometry (FTIR) was carried out on a NEXUS 870 spectrograph to analyze the change of the peak position of the oxygen-containing functional group of the prepared catalysts.

X-ray photoelectron spectroscopic (XPS) measurements were performed on a Kratos Axis Supra using Al Kα radiation, and the binding energies were referenced to the C 1 s line at 284.8 eV from adventitious carbon.

UV-Vis spectra were performed on a SHIMADZU UV-3000 configured with a photomultiplier tube from the wavelength of 350 to 550 nm.

2.3 Electrochemical measurements

All the data were obtained with no iR-correction. Wave Driver 20 double potentiostat (Pine, USA) was used for electrochemical test. Before the linear sweep voltammetry (LSV) test with RRDE, nitrogen was injected into the electrolyte solution to remove the gas impurities in the solution. The CV curve test was cycled for 10 times in N2 saturated electrolyte solution to activate the catalyst, and the disk voltage and scanning speed were set to 0.05 V ~ 1.1 V vs. reversible hydrogen electrode (RHE) and 100 mV s−1 respectively. The working electrode did not rotate during this test. In order to reduce the error of measuring H2O2 selectivity, the ring electrode needs to be electrochemically cleaned to remove the oxide on the surface. During the LSV test, the ring electrode voltage was fixed at 1.2 V vs. RHE to oxidize H2O2 generated on the disk electrode. We measured the ORR performances of catalysts by conducting LSV measurements at 10 mV s−1 in the disk potential range of 0.2 ~ 1.0 V vs. RHE under deoxygenated 0.1 M phosphate buffer electrolyte. During the test, it is necessary to continue to inject oxygen above the solution to ensure the saturation of oxygen in the electrolyte and reduce the escape of dissolved oxygen. Before each subsequent test, oxygen shall be injected to supplement the oxygen consumption of the previous test.

The selectivity of H2O2 and the number of transferred electrons was calculated according to the measured disk current (ID, mA) and ring current (IR, mA). N is current collection efficiency of the Pt ring, which was determined as 0.37.

The electrochemical active surface area was measured by the double-layer capacitance method (Cdl), and the intrinsic activity of the catalyst was determined by normalizing the current density. The double-layer capacitance is calculated according to the slope between the current density and the scanning rate in the non-Faradaic region of the potential range, A Pt foil and Ag/AgCl (saturated KCl aqueous solution) serves as the counter electrode and the reference electrode, respectively. Phosphate buffer (0.1 M) solution saturated with nitrogen is the electrolyte.

Where Cs represents the specific capacitance of the standard electrode with a surface area of 1 cm2.The value of Cs was determined to be 40 μF cm−2. Cdl represents the double layer capacitance (μF cmelectrode−2), ECSA indicates electrochemically active surface area (cm2 cmelectrode−2), J refers to current density (mA cmelectrode−2).

Electrochemical impedance spectroscopy (EIS) was performed using CHI660E electrochemical workstation (Chenhua Instrument Co., Ltd., Shanghai). The frequency range is set to 0.01 Hz−10 kHz with 5 mV disturbance amplitude in the N2-saturated phosphate buffer electrolyte.

2.4 Bulk electrolysis

Bulk electrolysis was carried out in a flowing electrolytic cell with two electrodes. Gas diffusion electrode (GDE) loaded with CB-1 catalyst (0.5 mg cm−2) was used as the cathode of oxygen reduction, while commercial IrO2-Ti mesh (0.5 mg cm−2 IrO2) was used as the anode of water oxidation reaction. A Nafion 115 film was sandwiched by the two PTFE sheets to separate the chambers. The anode electrolyte was circulated with 0.5 M sodium sulfate at a flow rate of 2 mL min−1, while 0.1 M phosphate buffer was used as the single-channel flow cathode electrolyte with 13 mL h−1 flow rate. The flow cell was operated at constant current of 100, 200 and 300 mA, respectively. H2O2 concentration was measured using the cerium sulfate titration method where the yellow Ce4+ solution would be reduced by H2O2 to colorless Ce3+ following the stoichiometry of 2Ce4+ + H2O2 = 2Ce3+ + 2H+ + O2. The measured wavelength was 316 nm.

Where C1 and V1 indicate the concentration (mol L−1) and volume (L) of Ce4+ before reaction, C2 is the concentration (mol L−1) of remaining Ce4+after reaction, V2 represents the measured volume (L) of the H2O2.Faraday efficiency (FE) of H2O2 production in flow cell can be calculated according to the concentration of H2O2 obtained by titration.

where Q is the amount of charge (C) accumulated during electrolysis time (s), I represents the set current (A), F indicates the Faraday constant (96,485 C mol−1), C(H2O2) is the concentration (mol L−1) of H2O2, V(H2O2) refers to the volume (L) of cathode electrolyte.

3 Results and discussion

3.1 Structural characterization

The carbon-based catalysts were prepared by modifying commercial carbon black (CB) using low-concentration H2O2 solution (Fig. 1). H2O2 is unstable at elevated temperatures and can be decomposed into hydroxyl radicals. The hydroxyl radicals in aqueous solution act as an aggressive oxidant, which oxidizes carbon materials to introduce carbon defects and oxygen-containing groups (Wang et al. 2019; Han et al. 2019). H2O2 solutions of various concentrations (0.5 ~ 2 wt%) were used to modify pristine CB. Terephthalic acid was used as the indicator of hydroxyl radicals (Ai et al. 2014). The fluorescence measurements indicated the amount of hydroxyl radicals was correlated with the concentration of H2O2 (Fig. S1). The higher H2O2 concentration was, the larger amount of hydroxyl radicals was. The microstructure of carbon-based catalysts e.g., carbon defects or oxygen-containing groups could be different from each other at the presence of hydroxyl radicals of varied amount. In our method, the treatment of carbon black only requires low-concentration H2O2. Consequently, the H2O2 synthesized via 2e-ORR in a flow-cell reactor could be directly utilized in modifying carbon black, which achieves an ideal recycling.

The phase structure of modified carbon catalysts was confirmed by XRD. The pristine carbon black exhibited two peaks at 2 theta of 25 and 44 degrees, which correspond to graphite carbon (002) and (100) plane, respectively (Fig. 2a). The large intensity of characteristic diffraction of (002) indicates the ordered graphite structure (Lu et al. 2018; Wu et al. 2020) in carbon black. The treated carbon catalysts CB-X (X = 0.5, 1, 2, 4) showed obviously reduced intensity of the two diffractions. The higher H2O2 concentration used, the lower the peak intensity. This result reflects the structure of carbon becomes more disordered after modified by H2O2 oxidation, which could be ascribed to the introduction of defects or oxygen-containing groups.

Raman spectroscopy could be an indicative technique to differentiate the defective structure of carbon materials (Fig. 2b). One can observe two distinct bands in the range of 750–2500 cm−1. The peak centered at around 1345 cm−1 is assigned to the vibration of disordered structure e.g., sp3 carbon atoms within graphitic layer, which is recognized as D band. Another peak at 1585 cm−1 corresponds to the in-plane stretching vibration of sp2-hybridized carbon atoms (Chakthranont et al. 2021). It is known that the intensity ratio of D band and G band is usually used as a describer to reveal the defect density in carbon material. The larger the ratio of ID/IG, the higher the defect density. The ID/IG value presents a volcano-type trend and reaches the highest value of 1.08 in CB-1 catalyst. It indicates that the modification of carbon black by H2O2 of an appropriate concentration leads to the transformation of sp2-hybrizidation to sp3-hybrizidation carbon, which locally breaks the atomic symmetry and order of the graphite lattice. It is in agreement with the XRD results (Fig. 2a), where the characteristic diffractions of graphite phase are weakened in the modified carbon black catalysts.

The FTIR absorption spectra were shown to analyze the functional groups grafted onto the surface of the catalysts. The intensive band peaked at 3440 cm−1 is assigned to the stretching vibration of -OH in H2O or C-OH (Jung et al. 2020b). The peaks at 2925 and 2855 cm−1 originate from the C-H vibrations in carbon framework (Fig. 2c) (Zhang et al. 2020a). In the range of 2000–1000 cm−1, one can see a weak peak at 1740 cm−1 neighboring the bending vibration of C-OH at 1630 cm−1 (Fig. 2d), which is due to the stretching vibration of C=O (Lu et al. 2018; Lim et al. 2021). The absorption peak at 1117 cm−1 is ascribed to the stretching vibration of C-O (Zhang et al. 2021b), and the peak at 1250 cm−1 is caused by the stretching vibration of C-O-C group (Zhang et al. 2021a, 2021b). The two peaks show a gradually increased intensity from CB to CB-4 catalysts. It suggests that C-O-C/C-O groups are incorporated to carbon framework by the ·OH radicals-modifying method. It is reported that the electrophilic hydroxyl radicals could attack double bonds with π electrons on the surface of carbon nanotubes, forming C-OH or carbonyl groups (Wang et al. 2019) (Fig. S2b).

The characteristic absorption at 1460 cm−1 and 1385 cm−1 is assigned to asymmetric and symmetric stretching vibration of C-H, respectively. With the increase of H2O2, the treated catalyst showed a peak of C=O at 1740 cm−1, indicating that the oxygen-containing groups are oxidized to C=O during the treatment process. It is known that the stretching vibration of O-H in -COOH group show an absorption band at 3000 cm−1, accompanied by a couple of weak peaks at 2700–2500 cm−1. The absorption peaks are ascribed to the frequency doubling and combination of stretching and deformation vibrations in -COOH group (Han et al. 2020). Nevertheless, the corresponding absorption was not observed in these catalysts. It is an indication that the present modification method little introduces –COOH group onto the surface of carbon black. HRTEM observations show that CB-1 catalyst has more disordered structure than CB and both of them have close particle size of 50–80 nm (Fig. 2e-f and Fig. S3). The treatment of carbon black could break carbon layer arrangement in atomic scale and results in a defective structure.

XPS technique was used to analyze the surface oxygen and carbon species of the catalysts. According to the semi-quantitative analysis of XPS survey spectra (Fig. S4), the oxygen content in CB, CB-0.5, CB-1, CB-2 and CB-4 catalysts was 3.48%, 2.24%, 2.27%, 3.32% and 4.01%, respectively. As the carbon black was modified with an increasing concentration of H2O2, the overall oxygen content elevated. When the concentration of H2O2 increased from 0.5% to 1%, there was no significant increase in the oxygen content of the catalyst, which may be due to competition between different reaction pathways when the concentration of H2O2 is low. On the one hand, H2O2 increases lattice defects in the plane through etching; on the other hand, it is easy to dissociate into strong electrophilic addition and oxidizing hydroxyl radical (Fig. S2). When the free radical contacts with carbon, hydroxyl radical will attack the unsaturated C=C double bond with π electron on the carbon surface, and hydroxylation addition reaction will occur to form C-OH group. In addition, under the further action of hydroxyl radical, a part of hydroxyl will continue to be oxidized to C=O (Han et al. 2019). Therefore, as the concentration of H2O2 continues to increase to 2% and 4%, its overall oxygen content shows a gradually increasing trend. H2O2 of low concentrations plays a critical role in etching carbon black. Limited oxygen-containing groups are generated when the hydroxyl radical content is low. The oxygen-containing groups in pristine carbon black are reduced by the etching effect.

The O 1 s spectra of the pristine carbon black exhibit two deconvoluted peaks at 532.6 eV and 533.7 eV, which is assigned to C-O-C and C-O-H species, respectively (Lee et al. 2022; Wu et al. 2020). An additional peak at 531.7 eV corresponding to C=O species appears in O 1 s spectra of modified carbon black catalysts (Han et al. 2019). The distinct feature indicates that the modification appends C=O to the surface of catalysts.

The C 1 s spectra can be deconvoluted to four peaks at 284.1 eV, 285.4 eV, 286.5 eV and 288.4 eV (Fig. 3b), which corresponds to C=C, sp3-C, C-O, and C=O, respectively (Xia et al. 2019; Wang et al. 2021b). The exception is the absence of C=O in C 1 s spectra of carbon black itself. It agrees with the result shown in O 1 s spectra. The content of varied oxygen and carbon species was quantitatively analyzed by the ratio of peak areas (Table S1 and S2). The comparisons of oxygen species percentages in these catalysts are displayed in Fig. 3c.

The contents of C=O and C-O-C groups in carbon black increase with the increasing H2O2 concentration. The content of C-O shows a downward tendency first. It is due to the fact that carbon black itself contains a certain amount of C-OH, and some of C-OH bonds are cut off during H2O2 treatment (Yan et al. 2022), resulting in a decrease in the content. However, with the increase of H2O2 treatment concentration, its content is basically stable with little change. According to Fig. 3d, the content of sp3-C in CB, CB-0.5, CB-1, CB-2 and CB-4 catalysts was 7.41%, 9.20%, 11.19%, 10.58% and 9.33% respectively. This trend is consistent with the change of defect carbon content in Raman spectra. The etching effect of H2O2 leads to an increase in carbon defects. As the concentration of H2O2 increases, more hydroxyl radicals are generated and attack the carbon defects, making the sp3-C content lower.

3.2 Electrochemical performance

The RRDE device is usually used to quickly and quantitatively detect the formation of H2O2 on the electrocatalyst (Jung et al. 2020a). According to voltametric curves (Fig. 4a and Fig. S5), the reduction current of saturated O2 solution is significantly higher than that of saturated N2, which indicates that there is indeed an oxygen reduction reaction. A typical irreversible reduction peak appeared at about 0.3 V vs RHE, which was caused by the shift of Nernst potential due to the low concentration of H2O2 in the electrolyte. As shown in Fig. 4b, the ring current densities of CB, CB-0.5, CB-1, CB-2 and CB-4 were 1.48 mA cm−2, 2.04 mA cm−2, 2.86 mA cm−2, 2.45 mA cm−2 and 2.04 mA cm−2 at 0.15 V vs. RHE potential, respectively. It shows that the catalytic activity and selectivity of carbon black treated with H2O2 were higher than those of untreated carbon black. According to Fig. 4c, it is noteworthy that at 0.25 V vs. RHE potential, the selectivity of CB-1 catalyst to H2O2 was close to 100%, which is the highest reported efficiency. Compared with the original carbon black, the electron transfer number of the oxidized catalyst was closer to 2 (Fig. 4d), which indicates that the catalyst was more inclined to 2e-ORR than the original carbon black.

a Cyclic voltammograms of CB-1 in N2- and O2-saturated 0.1 M phosphate buffer at a scan rate of 10 mV s−1. b Disk currents (solid line) and ring currents (dash line) on the catalysts via RRDE 1600 rpm rotation speed in 0.1 M phosphate buffer (pH = 7.4). c H2O2 selectivity and (d) electron transfer number during the potential sweep on different catalysts

The electron transfer number calculated according to Koutecky−Levich equation (Guo et al. 2022; Liu et al. 2021). As shown in Fig. S6, the electron transfer number was 2.04 at a potential of 0.15 V vs. RHE, and as the potential became increasingly negative, the electron transfer number also gradually increased. At a potential of 0.05 V vs. RHE, the electron transfer number increased to 2.44, which is consistent with the calculated results based on the polarization curve of the rotating ring disk electrode test. This change in selectivity may be related to the oxygen-containing functional groups and defects increasing the treatment of H2O2 solution (Gong et al. 2022b; Wang et al. 2019).

Electrochemical impedance spectroscopy (EIS) was conducted on the catalyst to evaluate the electron transfer rate. If the voltage is too low and the catalytic reaction has not yet occurred, the test results will not reflect the electron transfer characteristics during the catalytic process. If the voltage is too high, it will lead to intense catalytic reactions, and disordered test values will increase the error of data processing (Gao et al. 2018; Zhang et al. 2016). Therefore, as shown in Fig. 5a and b, the constant voltage was set to 0.3 V, 0.4 V, 0.5 V, 0.6 V, and 0.7 V based on the catalytic characteristics of the catalyst during the testing process. The radius of the Nyquist plots is equal at all applied potentials, showing the stability and low ohmic resistance of the system. The reaction kinetics are dominated by the charge transfer between the interface of the electrolyte and the electrode, corresponding to the diffusion control region. Based on this, a set of data at 0.5 V vs. RHE potential was selected to fit the equivalent circuit diagram. As shown in Fig. S7, the components of the equivalent circuit diagram include interfacial charge transfer resistance, electric double layer capacitance at the electrode-electrolyte interface, solution resistance, and Warburg impedance caused by diffusion (Gong et al. 2022a). The fitted curve and results are shown in Fig. 5c and Table S3. Compared with the original CB, the CB-1 catalyst had a smaller interfacial charge transfer resistance (6.57 Ω is less than 14.36 Ω), which is more conducive to the electron transfer and the diffusion of reactants.

The specific activity is a reliable indicator for studying the intrinsic activity of catalysts (Ni et al. 2022). The electrochemical active area was calculated by linear fitting and the specific activity was obtained by normalizing the current density. As shown in Fig. 6a and b, the current densities in the CV curves of the CB and CB-1 catalysts gradually increased with the increase of the scan rate. The CV curves and results of other catalysts are shown in Fig. S8 and Table S4. According to the result of Fig. 6c and d, the specific activity of the original CB was 33.63 μA cm−2, while the specific activity of CB-1 catalyst was up to 40.00 μA cm−2, its intrinsic activity increased by 19%.

Because the RRDE requires a certain rotational speed when analyzing the catalyst, the test results often ignore the limitation of mass transfer, and cannot characterize the long-term stability of the catalyst (Zhang et al. 2020b). RRDE is good at rapid performance evaluation, but it cannot accumulate H2O2. In addition, the dissolved concentration of oxygen in water is 0.9 mmol at 298 K and 1 atm pressure (Cao et al. 2021). In order to promote the diffusion of O2 in the cathode, many studies have turned to gas diffusion electrode (GDE), which is composed of porous hydrophobic gas diffusion layer (GDL) and catalyst layer (Jung et al. 2020a, 2020b; Gao and Liu 2020). Electrocatalyst is deposited on the catalyst layer to form a solid-liquid-gas three-phase interface. In addition, a static electrolyte may lead to a higher local concentration of H2O2 near the catalyst surface, increasing the possibility of further reduction of the product. Therefore, the mobile electrolytic cell with gas diffusion electrode is more suitable for preparing H2O2. The device is shown in Fig. 7a.

a Schematic illustration of the flow-cell electrolyzer. b H2O2 concentrations and faradaic efficiencies of CB-1 catalysts at varied currents. c solution output per hour from the flow cell at 200 mA current. d Stability test of CB-1 at continuous operations at 200 mA current in 0.1 M phosphate buffer solution (pH = 7.4). O2 flow rate: 30 sccm, electrode area: 4 cm2, catalyst mass: 0.5 mg cm−2

There is a reference electrode in the three-electrode system, and the measured voltage represents the potential difference between the cathode electrode and the reference electrode, which is not suitable for practical application. Therefore, the two-electrode system is assembled for the preparation of H2O2. The concentration of H2O2 can be determined by measuring the UV-visible absorbance using the Ce(SO4)2 titration method (Fig. S9). The flow cell was operated at different currents and the curve of voltage over time was recorded using chronopotentiometry (Fig. S10). The test results are shown in Fig. 7b. When the flow rate of the fixed cathode electrolyte was 13.5 mL h−1 and the current was 100 mA, and the concentration of H2O2 in the product solution was 130 mmol L−1. When the current continued to increase to 300 mA, the product concentration could reach 330 mmol L−1, and it could reach 1.12 wt%. The productivity of H2O2 could reach 2.23 mol g−1 h−1. The H2O2 of around 1 wt% obtained from electrochemical production could be recycled as a feedstock solution for modifying CB, eliminating the need of diluting a high concentration of H2O2. According to Fig. 7c, the output of cathode solution was relatively stable, and its average flow rate was 13 mL h−1. In addition to catalytic activity and selectivity, long-term stability is also an important indicator for evaluating catalysts. Therefore, this work tested the operation of the catalyst assembly in a flow cell at a current of 200 mA (Fig. 7d). During operation, the voltage between the two electrodes was always stable at about 4.5 V and there was no obvious attenuation phenomenon. After 10 h catalytic reaction, the catalysts on the surface of the two electrodes remained stable and did not fall off (Fig. S11). The concentration of H2O2 in the solution was 240 mmol L−1 measured by redox titration. The Faradaic efficiency remained above 80% at different currents, which indicates that the catalyst has excellent catalytic performance in producing H2O2 at neutral conditions and can be used to produce H2O2 solution in practice.

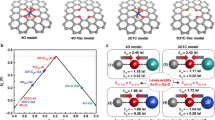

In order to decouple the role of oxygen-containing groups and carbon defect structures on the catalytic activity and selectivity, CB and CB-1 catalysts were annealed in a H2 flow atmosphere at high temperature to eliminate the oxygenated groups. The samples CB-H2 and CB-1-H2 were obtained. The performance evaluation of the two catalysts were carried out by rotating the ring disk electrode tests. According to the ring current in LSV curves (Fig. 8a), the overall oxygen reduction activities of CB-H2 and CB-1-H2 catalysts were close to each other. The H2O2 selectivity of CB-H2 and CB-1-H2 catalysts is shown in Fig. 8b. The CB-1-H2 had an around 10% higher selectivity towards H2O2 than CB-H2 within the potential range applied. Based on the analyses of oxygen species from XPS O1s spectra (Fig. 8c), the CB-H2 and CB-1-H2 catalysts contained C-O-C and C-OH groups. The content of each oxygen-containing group was comparatively close to each other (Fig. 8e). The oxygen content in CB-1-H2 and CB-H2 was substantially reduced compared to the CB-1 and CB because of the reducing effect of H2 atmosphere. The defect in carbon structure was analyzed by Raman spectra (Fig. 8d). The ratio of ID/IG for CB-1-H2 and CB-H2 was 1.04 and 1.00, respectively (Fig. 8f). It suggests that CB-1-H2 preserved more defect structure e.g., sp3-carbon than CB-H2 after H2 treatment. It is documented that the defect of sp3-carboncould act as active sites for adsorption and transformation of the intermediates in oxygen reduction reaction to H2O2 formation. (Liu et al. 2015) Consequently, the decoupling of oxygen-containing groups and carbon defect discloses that the defect in the carbon framework play a dominant role in regulating the oxygen reduction selectivity towards H2O2. This is consistent with the comparisons of CB-1 and CB before H2 treatment. We also examined the effect of H2O2 on carbon black at room temperature. The carbon black was treated in 1 wt% H2O2 without heating. The structure of the catalyst had no change compared to the pristine carbon black (Fig. S12). The defective carbon structure of the CB-1 catalyst had little change after the operation of 2 h at room temperature in the flow cell (Fig. S13). It indicates that the structure of catalyst was stable during the H2O2-generating reactions.

a Polarization curves and b H2O2 selectivity via RRDE during the potential sweep for CB-H2 and CB-1-H2 catalysts in 0.1 M phosphate buffer (pH = 7.4). c XPS O 1 s and (d) Raman spectra of CB-H2 and CB-1-H2 catalysts. e The content of oxygen species and (f) ID/IG ratios of CB-H2 and CB-1-H2 catalysts

4 Conclusions

We develop a mild and self-recycled modification strategy to derive high-efficiency carbon-based catalysts for electrochemical oxygen reduction to H2O2. This method was not involved in any concentrated acids or bases and unfriendly reagents. The oxygenated groups and carbon defect within the pristine carbon black were modulated by a facile treatment of low-concentration H2O2 solution. The optimal CB-1 catalyst exhibited a high H2O2 selectivity close to 100% at a potential of 0.25 V vs. RHE and kept the selectivity above 90% within a wide potential window. The assembled device using CB-1 catalyst showed a continuous production of H2O2 at a potential of 4.5 V for 10 h in a flow cell. The concentration of H2O2 reached 0.33 mol L−1 with a Faraday efficiency of 80%. The production rate was as high as 2.23 mol g−1 h−1. The produced H2O2 solution from the flow cell was directly applied to modify the carbon black and to obtain carbon-based catalysts without concentrating the solution, which indicates a self-recycled strategy. The decoupling of oxygenated groups and carbon defect reveals that the defective carbon in the carbon framework is a dominant factor in regulating the oxygen reduction selectivity towards H2O2. The larger amount the carbon defect, the higher H2O2 selectivity. The mechanism of H2O2 electrosynthesis at neutral electrolytes is understood with respect to carbon-based catalyst. This work paves a promising avenue for preparing carbon-based catalysts towards highly selective H2O2 electrosynthesis in an environment-benign and recyclable way.

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- 2e-ORR:

-

Two-electron oxygen reduction reaction

- RRDE:

-

Rotating ring-disk electrode

- XRD:

-

X-ray diffraction

- TEM:

-

Transmission electron microscope

- FTIR:

-

Fourier transform infrared spectrometry

- XPS:

-

X-ray photoelectron spectroscopic

- LSV:

-

Linear sweep voltammetry

- RHE:

-

Reversible hydrogen electrode

- EIS:

-

Electrochemical impedance spectroscopy

- GDE:

-

Gas diffusion electrode

- FE:

-

Faraday efficiency

- CB:

-

Carbon black

- GDL:

-

Gas diffusion layer

References

Ai LH, Zhang CH, Li LL, Jiang J (2014) Iron terephthalate metal–organic framework: revealing the effective activation of hydrogen peroxide for the degradation of organic dye under visible light irradiation. Appl Catal B Environ 148-149:191–200. https://doi.org/10.1016/j.apcatb.2013.10.056

Bu YF, Wang YB, Han GF, Zhao YX, Ge XL, Li F, Zhang ZH, Zhong Q, Baek JB (2021) Carbon-based electrocatalysts for efficient hydrogen peroxide production. Adv Mater:2103266. https://doi.org/10.1002/adma.202103266

Campos-Martin JM, Blanco-Brieva G, Fierro JLG (2006) Hydrogen peroxide synthesis: an outlook beyond the anthraquinone process. Angew Chem Int Ed 45(42):6962–6984. https://doi.org/10.1002/anie.200503779

Cao PK, Quan X, Zhao K, Zhao XY, Chen S, Yu HT (2021) Durable and selective electrochemical H2O2 synthesis under a large current enabled by the cathode with highly hydrophobic three-phase architecture. ACS Catal 11:13797–13808. https://doi.org/10.1021/acscatal.1c03236

Chakthranont P, Nitrathorn S, Thongratkaew S, Khemthong P, Nakajima H, Supruangnet R, Butburee T, Sano N, Faungnawakij K (2021) Rational design of metal-free doped carbon nanohorn catalysts form efficient electrosynthesis of H2O2 from O2 reduction. ACS Appl Energy Mater 4:12436–12447. https://doi.org/10.1021/acsaem.1c02260

Chen SY, Luo T, Li XQ, Chen KJ, Fu JW, Liu K, Cai C, Wang QY, Li HM, Chen Y, Ma C, Zhu L, Lu YR, Chan TS, Zhu MS, Cortés E, Liu M (2022) Identification of the highly active co−N4 coordination motif for selective oxygen reduction to hydrogen peroxide. J Am Chem Soc 144:14505–14516. https://doi.org/10.1021/jacs.2c01194

Choi CH, Kwon HC, Yook S, Shin H, Kim H, Choi M (2014) Hydrogen peroxide synthesis via enhanced two-electron oxygen reduction pathway on carbon-coated Pt surface. J Phys Chem C 118:30063–30070. https://doi.org/10.1021/jp5113894

Freakley SJ, He Q, Harrhy JH, Lu L, Crole DA, Morgan DJ, Ntainjua EN, Edwards JK, Carley AF, Borisevich AY, Kiely CJ, Hutchings GJ (2016) Palladium-tin catalysts for the direct synthesis of H2O2 with high selectivity. Science 351:965–968. https://doi.org/10.1126/science.aad5705

Gao JJ, Liu B (2020) Progress of electrochemical hydrogen peroxide synthesis over single atom catalysts. ACS Materials Lett 2:1008–1024. https://doi.org/10.1021/acsmaterialslett.0c00189

Gao TT, Zhou CX, Zhang YJ, Jin ZY, Yuan HY, Xiao D (2018) Ultra-fast pyrolysis of ferrocene to form Fe/C heterostructures as robust oxygen evolution electrocatalysts. J Mater Chem A 6:21577–21584. https://doi.org/10.1039/C8TA05733H

Gong HS, Wei ZX, Gong ZC, Liu JJ, Ye GL, Yan MM et al (2022b) Low-coordinated Co-N-C on oxygenated graphene for efficient electrocatalytic H2O2 production. Adv Funct Mater 32:2106886. https://doi.org/10.1002/adfm.202106886

Gong SH, Wang WB, Zhang CN, Zhu MH, Lu RQ, Ye JJ et al (2022a) Tuning the metal electronic structure of anchored cobalt phthalocyanine via dual-regulator for efficient CO2 electroreduction and Zn–CO2 batteries. Adv Funct Mater 32:2110649. https://doi.org/10.1002/adfm.202110649

Guo Y, Zhang R, Zhang SC, Hong H, Zhao YW, Huang ZD, Han CP, Li HF, Zhi CY (2022) Ultrahigh oxygen-doped carbon quantum dots for highly efficient H2O2 production via two-electron electrochemical oxygen reduction. Energy Environ Sci 15:4167–4174. https://doi.org/10.1039/D2EE01797K

Han GF, Li F, Zou W, Karamad M, Jeon JP, Kim SW, Kim SJ, Bu YF, Fu ZP, Lu YL, Siahrostami S, Baek JB (2020) Building and identifying highly active oxygenated groups in carbon materials for oxygen reduction to H2O2. Nat Commun 11:2209–2217. https://doi.org/10.1038/s41467-020-15782-z

Han L, Sun YY, Li S, Cheng C, Halbig CE, Feicht P, Hübner JL, Strasser P, Eigler S (2019) In-plane carbon lattice-defect regulating electrochemical oxygen reduction to hydrogen peroxide production over nitrogen-doped graphene. ACS Catal 9:1283–1288. https://doi.org/10.1021/acscatal.8b03734

Hu XY, Zeng XK, Liu Y, Lu J, Zhang XW (2020) Carbon-based materials for photo- and electrocatalytic synthesis of hydrogen peroxide. Nanoscale 12(30):16008–16027. https://doi.org/10.1039/D0NR03178J

Jia YL, Xue ZQ, Yang J, Liu QL, Xian JH, Zhong YC, Sun YM, Zhang XX, Liu QH, Yao DX, Li GQ (2022) Tailoring the electronic structure of an atomically dispersed zinc electrocatalyst: coordination environment regulation for high selectivity oxygen reduction. Angew Chem Int Ed 61:e202110838. https://doi.org/10.1002/anie.202110838

Jiang YY, Ni PJ, Chen CX, Lu YZ, Yang P, Kong B, Fisher A, Wang X (2018) Selective electrochemical H2O2 production through two-electron oxygen electrochemistry. Adv Energy Mater 8:1801909. https://doi.org/10.1002/aenm.201801909

Jung EY, Shin HJ, Lee B, Efremov V, Lee S, Lee HS, Kim J, Antink WH, Park S, Lee KS, Cho SP, Yoo JS, Sung YE, Hyeon T (2020b) Atomic-level tuning of co–N–C catalyst for high-performance electrochemical H2O2 production. Nat Mater 19:436–442. https://doi.org/10.1038/s41563-019-0571-5

Jung E, Shin H, Antink WH, Sung Y-E, Hyeon T (2020a) Recent advances in electrochemical oxygen reduction to H2O2: catalyst and cell design. ACS Energy Lett 5:1881–1892. https://doi.org/10.1021/acsenergylett.0c00812

Kim HW, Ross MB, Kornienko N, Zhang L, Guo JH, Yang PD, McCloskey BD (2018) Efficient hydrogen peroxide generation using reduced graphene oxide-based oxygen reduction electrocatalysts. Nat Catal 1:282–290. https://doi.org/10.1038/s41929-018-0044-2

Lee K, Lim J, Lee MJ, Ryu K, Lee H, Kim JY, Ju H, Cho HS, Kim BH, Hatzell MC, Kang J, Lee SW (2022) Structure-controlled graphene electrocatalysts for high-performance H2O2 production. Energy Environ Sci 15:2858. https://doi.org/10.1039/D2EE00548D

Li LQ, Tang C, Zheng Y, Xia BQ, Zhou XL, Xu HL, Qiao SZ (2020) Tailoring selectivity of electrochemical hydrogen peroxide generation by tunable pyrrolic-nitrogen-carbon. Adv Energy Mater 10:2000789. https://doi.org/10.1002/aenm.202000789

Lim JS, Kim JH, Woo J, Baek DS, Ihm K, Shin TJ, Sa YJ, Joo SH (2021) Designing highly active nanoporous carbon H2O2 production electrocatalysts through active site identification. Chem 7:3114–3130. https://doi.org/10.1016/j.chempr.2021.08.007

Liu MH, Li YL, Qi ZM, Su H, Cheng WR, Zhou WL, Zhang H, Sun X, Zhang XX, Xu YZ, Jiang Y, Liu QH, Wei SQ (2021) Self-nanocavity-confined halogen anions boosting the high selectivity of the two-electron oxygen reduction pathway over Ni-based MOFs. J Phys Chem Lett 12:8706–8712. https://doi.org/10.1021/acs.jpclett.1c01981

Liu YM, Quan X, Fan XF, Wang H, Chen S (2015) High-yield Electrosynthesis of hydrogen peroxide from oxygen reduction by hierarchically porous carbon. Angew Chem Int Ed 54:6837–6841. https://doi.org/10.1002/anie.201502396

Lu YZ, Jiang YY, Gao XH, Chen W (2014) Charge state-dependent catalytic activity of [Au25(SC12H25)18] nanoclusters for the two-electron reduction of dioxygen to hydrogen peroxide. Chem Commun 50:8464–8467. https://doi.org/10.1039/C4CC01841A

Lu ZY, Chen GX, Siahrostami S, Chen ZH, Liu K, Xie J, Liao L, Wu T, Lin DC, Liu YY, Jaramillo TF, Nørskov JK, Cui Y (2018) High-efficiency oxygen reduction to hydrogen peroxide catalysed by oxidized carbon materials. Nat Catal 1:156–162. https://doi.org/10.1038/s41929-017-0017-x

Mumma MJ, Geronimo L, Villanueva GL, Novak RE, Hewagama T, Bonev BP, DiSanti MA, Mandell AM, Smith MD (2009) Switching off hydrogen peroxide hydrogenation in the direct synthesis process. Science 323:1037–1041. https://doi.org/10.1126/science.1168980

Ni WY, Wang T, Héroguel F, Krammer A, Lee S, Yao L, Schüler A, Luterbacher JS, Yushan Yan YS, Hu XL (2022) An efficient nickel hydrogen oxidation catalyst for hydroxide exchange membrane fuel cells. Nat Mater 21(7):804–810. https://doi.org/10.1038/s41563-022-01221-5

Rao P, Wu DX, Wang TJ, Li J, Deng PL, Chen Q, Shen YJ, Chen Y, Tian XL (2022) Single atomic cobalt electrocatalyst for efficient oxygen reduction reaction. eScience. 2:399–404. https://doi.org/10.1016/j.esci.2022.05.004

Rawah BS, Albloushi M, Li WZ (2022) Highly efficient electrochemical synthesis of hydrogen peroxide(H2O2) enabled by amino acid glycine-derived metal-free nitrogen doped ordered mesoporous carbon. ACS Sustain Chem Eng 10:5453–5462. https://doi.org/10.1021/acssuschemeng.1c08285

Siahrostami S, Verdaguer-Casadevall A, Karamad M, Deiana D, Malacrida P, Wickman B, Escudero-Escribano M, Paoli EA, Frydendal R, Hansen TW, Chorkendorff I, Stephens IEL, Rossmeisl J (2013) Enabling direct H2O2 production through rational electrocatalyst design. Nat Mater 12:1137–1143. https://doi.org/10.1038/nmat3871

Wang N, Ma SB, Zuo PJ, Duan JZ, Hou BR (2021c) Recent progress of electrochemical production of hydrogen peroxide by two-electron oxygen reduction reaction. Adv Sci 8:2100076. https://doi.org/10.1002/advs.202100076

Wang X, Yu MH, Feng XL (2023) Electronic structure regulation of noble metal-free materials toward alkaline oxygen electrocatalysis. eScience 3:100141. https://doi.org/10.1016/j.esci.2023.100141

Wang Y, Zhou W, Gao JH, Ding YN, Kou KK (2019) Oxidative modification of graphite felts for efficient H2O2 electrogeneration: enhancement mechanism and long-term stability. J Electroanal Chem 833:258–268. https://doi.org/10.1016/j.jelechem.2018.11.051

Wang YQ, Grote F, Cao Q, Eigler S (2021a) Regiochemically oxo-functionalized graphene, guided by defect sites, as catalyst for oxygen reduction to hydrogen peroxide. J Phys Chem Lett 12:10009. https://doi.org/10.1021/acs.jpclett.1c02957

Wang Z, Li QK, Zhang CH, Cheng ZH, Chen WY, McHugh EA, Carter RA, Yakobson BI, Tour JM (2021b) Hydrogen peroxide generation with 100% faradaic efficiency on metal-free carbon black. ACS Catal 11:2454–2459. https://doi.org/10.1021/acscatal.0c04735

Wu KH, Wang D, Lu XY, Su DS, Qi W, Guo SJ (2020) Highly selective hydrogen peroxide electrosynthesis on carbon: in situ interface engineering with surfactants. Chem 6:1443–1458. https://doi.org/10.1016/j.chempr.2020.04.002

Xia C, Xia Y, Zhu P, Fan L, Wang HT (2019) Direct electrosynthesis of pure aqueous H2O2 solutions up to 20% by weight using a solid electrolyte. Science 366:226–231. https://doi.org/10.1126/science.aay1844

Xia Y, Zhao XH, Xia C, Wu ZY, Zhu P, Kim JY, Bai XW, Gao GH, Hu YF, Zhong J, Liu YY, Wang HT (2021) Highly active and selective oxygen reduction to H2O2 on boron-doped carbon for high production rates. Nat Commun 12(1):4225–4236. https://doi.org/10.1038/s41467-021-24329-9

Yan B, Feng L, Zheng JJ, Zhang Q, Jiang SH, Zhang CM, Ding YC, Han JQ, Chen W, He SJ (2022) High performance supercapacitors based on wood-derived thick carbon electrodes synthesized via green activation process. Inorg Chem Front 9:6108–6123. https://doi.org/10.1039/D2QI01914K

Yang QH, Xu WW, Gong S, Zheng GY, Tian ZQ, Wen YJ, Peng LM, Zhang LJ, Lu ZY, Chen L (2020) Atomically dispersed Lewis acid sites boost 2-electron oxygen reduction activity of carbon-based catalysts. Nat Commun 11:5478–5487. https://doi.org/10.1038/s41467-020-19309-4

Yang S, Verdaguer-Casadevall A, Arnarson L, Silvioli L, Čolić V, Frydendal R, Rossmeisl J, Chorkendorff I, Stephens IEL (2018) Toward the decentralized electrochemical production of H2O2: a focus on the catalysis. ACS Catal 8(5):4064–4081. https://doi.org/10.1021/acscatal.8b00217

Zhang D, Tsounis C, Ma ZP, Djaidiguna D, Bedford NM, Thomsen L, Lu XY, Chu DW, Amal R, Han ZJ (2021b) Highly selective metal-free electrochemical production of hydrogen peroxide on functionalized vertical graphene edges. Small:2105082. https://doi.org/10.1002/smll.202105082

Zhang HC, Zhao YS, Li YJ, Li GH, Li J, Zhang F (2020b) Janus electrode of asymmetric wettability for H2O2 production with highly efficient O2 utilization. ACS Appl Energy Mater 3:705–714. https://doi.org/10.1021/acsaem.9b01908

Zhang QR, Tan X, Bedford NM, Han ZJ, Thomsen L, Smith S, Amal R, Lu XY (2020a) Direct insights into the role of epoxy groups on cobalt sites for acidic H2O2 production. Nat Commun 11:4181–4191. https://doi.org/10.1038/s41467-020-17782-5

Zhang SX, Xu WW, He PL, Chen X, Su LF, Ma TF, Lu ZY (2022) Tafel analysis guided optimization of ZnNP-O-C catalysts for the selective 2-electron oxygen reduction reaction in neutral media. Phys Chem Lett 13:3409–3416. https://doi.org/10.1021/acs.jpclett.2c00526

Zhang Y, Melchionn M, Medved M, Błoński P, Steklý T, Bakandritsos A, Kment S, Zbořil R, Otyepka M, Fornaserio P, Naldoni A (2021a) Enhanced on-site hydrogen peroxide electrosynthesis by a selectively carboxylated N-doped graphene catalyst. ChemCatChem 13:4372–4383. https://doi.org/10.1002/cctc.202100805

Zhang YJ, Gao TT, Jin ZY, Chen XJ, Xiao D (2016) A robust water oxidation electrocatalyst from amorphous cobalt–iron bimetallic phytate nanostructures. J Mater Chem A 4:15888–15895. https://doi.org/10.1039/C6TA05322J

Zhao K, Su Y, Quan X, Liu YM, Chen S, Yu HT (2018) Enhanced H2O2 production by selective electrochemical reduction of O2 on fluorine-doped hierarchically porous carbon. J Catal 357:118–126. https://doi.org/10.1016/j.jcat.2017.11.008

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grants 21978021, 22288102), the Fundamental Research Funds for the Central Universities (XK1803) and the Innovation Fund of SINOPEC Catalyst Co. Ltd-State Key Laboratory of Chemical Resource Engineering (No. 36100000-22-ZC0607-0041).

Author information

Authors and Affiliations

Contributions

Xu Xiang contributed to the conception and design. Material preparation, data collection and analysis were performed by Chong Ma and Qing Hao. The first draft of the manuscript was written by Xu Xiang, Chong Ma and Qing Hao, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Handling editor: Wenli Zhang

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, C., Hao, Q., Hou, J. et al. Regulating oxygenated groups and carbon defects of carbon-based catalysts for electrochemical oxygen reduction to H2O2 by a mild and self-recycled modification strategy. Carbon Res. 3, 5 (2024). https://doi.org/10.1007/s44246-023-00090-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-023-00090-0