Abstract

Biochar application in agricultural and metal mines has been studied widely; however, very few studies have been conducted on its application as an amendment for the restoration of coal mine degraded land. Thus, for the application of biochar for coal mine spoil restoration, the best pyrolysis temperature profile needs to be established. Biochar produced at different pyrolysis temperatures has distinct physio-chemical and nutritive properties, which impact its performance when applied as an amendment. The objective of the current study is to conduct a meta-analysis on the pyrolysis temperature and summarize the results using forest plots. The current study quantifies the effect of pyrolysis temperature on biochar production and its optimum nutritional properties. Based on pyrolysis temperature, biochar has to be categorized into low (< 450 °C), moderate (450–550 °C) and high-temperature biochar (> 550 °C). The pH range of biochar was 6.6–12.3 for high pyrolysis temperature and 5.8–11.1 for medium pyrolysis temperature. However, cation exchange capacity was in the range of 3.18–187 m mol kg− 1 for high pyrolysis temperature. For medium and low, the range was 4.63-210 m mol kg− 1 and 23.6–228 m mol kg− 1, respectively. Similarly, at low pyrolysis temperature, the organic content was 14.3–88%, while it was 4.7–60% and 11.2–86.2% for high and medium. Also, the nutrient contents such as Ca, Fe, Mg, and K were high at moderate temperature conditions. The study concluded that low to moderate pyrolysis temperature was best suited for coal mine spoil restoration.

Graphical Abstract

Highlights

• Meta-analysis on the effect of pyrolysis temperature on biochar physio-chemical and nutritive properties was stated.

• Common effect size metric and response ratio used for meta-analysis was clarified.

• Biochar prepared at ~ 450–550 °C best suited for coal mine spoil restoration was proved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pyrolysis is a multi-step complex process which disintegrates organic matter thermally in the absence of oxygen (Lehmann 2007; Ippolito et al. 2012; Ghosh and Maiti 2020). Biochar is pyrolytic end product of biomass; and temperature plays a role in determining its properties. The pyrolysis of biomass can be broadly divided into primary and secondary mechanisms. In the primary step, breakdown of chemical bonds of the feedstock takes place and releases volatile compounds. This undergoes further reactions as part of the secondary mechanism (Al-Rumaihi et al. 2022). The decomposition of organic feedstock comprising of long polymeric chains results in depolymerisation which releases water, gas, oils and tars, and other volatile compounds at ~ 250–300 °C (Lanzetta and Di Blasi 1998). The initial phase of thermal decomposition results in the creation of benzene rings that combine to form the solid char residue with organic matter continuing to decompose up to 800 °C (Al-Rumaihi et al. 2022). In the secondary mechanism, unstable compounds either crack or recombine to restructure. In addition, secondary mechanisms can also result in the formation of char in some cases. Pyrolysis at slow heating rates and temperatures less than 450 °C yields higher quantities of biochar; intermediate temperature ranges with slightly higher heating rates yield higher quantities of bio-oil; and high heating rates at temperatures greater than 800 °C yield greater quantities of gas and ash (Shakya et al. 2022). Thus, pyrolysis temperature and residence time have a pronounced influence on biochar properties, such as carbon content, mineral compositions, chemical functionalities and micro-structure (Tan and Yuan 2019). Biochar produced by varying pyrolysis temperature has different properties and influences soil physio-chemical and microbiological properties distinctively.

Optimising the production conditions (like, pyrolysis temperature and residence time) is essential for the production of biochar which can be effectively used for soil reclamation (Liao et al. 2022; Pap et al. 2022). Some examples of effect of feedstock type and pyrolysis temperature on biochar properties are given in Table 1. Studies reported that with an increase in pyrolysis temperature, the surface area, pH, and total nutrients increased as shown in Table 1. Also, with increase in temperature, elements such as C, Ca, K, and Mg increase, while easily decomposable matter, volatile matter, and elements such as H, O, S, and N are often lost (Table 1). Pecan shell biochar produced at 700 °C has a specific surface area of 222 m2 g− 1, pH of 7.2, and organic carbon content of 91.2%. When the same pecan shell is pyrolyzed at 350 °C, it has a surface area of 1.01 m2 g− 1, pH of 3.5, and organic carbon of 65% (Novak et al. 2019). Similarly, chicken manure biochar at low pyrolysis temperature increases essential elements, K (13%), Mg (18%), Ca (20%), S (10%), and P (24%), and an increase in pyrolysis temperature decreases the availability of nutrients (Hass et al. 2012). P content was found to be stable at temperature < 750 °C and nitrogen content was found to be high at a temperature range of 300–400 °C (Cantrell et al. 2012; Ippolito et al. 2012). Thus, the knowledge of pyrolysis temperature at which maximum nutrients retention takes place is essential for standardising the biochar production temperature for soil amelioration.

The increase in temperature decreases the acid functional group and makes the biochar alkaline in nature (Wang et al. 2015). Aromatic carbon is found in high-temperature biochar, while alkyl, alkoxy, and carboxylic carbon are usually found in low-temperature biochar (Wang et al. 2019). An increase in cation exchange capacity and surface negative charge was observed in canola biochar pyrolyzed at 500 °C compared to that produced in 750 °C (Qadeer et al. 2017). A review conducted on 10 different feedstocks shows that with increase in pyrolysis temperature, the cation exchange capacity of biochar decreases (Yu et al. 2019). Biochar which is produced at 450 °C has been reported to improve the soil microbial and biochemical activity of the mine degraded land (Jain et al. 2016; Ali et al. 2017). Polar or inorganic pollutants can be minimized by lower temperature biochar while high-temperature biochar is effective in the sorption of organic contamination (Tan and Yuan 2019). Hence, temperature is a critical parameter by which the property of biochar can be optimised according to the needs of a degraded land.

Surface mining causes complete land destruction, stripping it off the vegetation, soil structure, and biodiversity. This causes changed topography and drainage, ecosystem pollution and unsightly aesthetics. These mine spoil dumps have rock fragments, impoverished soil conditions, extremely low water holding capacity, absence of organic carbon and nutrient, acidic pH and low cation exchange capacity which causes difficulties in biological reclamation (Maiti 2013). An array of studies have been focused on the sustainable use of biochar for restoration of degraded agricultural soil by improving the soil physicochemical, nutritional, and biological properties. However, only a few studies focus on its specialised application in coal mine spoils (Ghosh et al. 2020; Ghosh and Maiti 2021a, b, 2022). Due to the limited number of studies, optimization of its properties for coal mine spoil restoration has not been done widely. Thus, a meta-analysis study is important for determining the temperature of biochar production which will retain nutrients and hold all the necessary properties for mine spoil amelioration.

The current meta-analysis study systematically examines the effect of pyrolysis temperature on the biochar properties. A number of meta-analysis studies have been conducted on the impact of temperature and other production conditions on biochar properties (Majumder et al. 2019; Ippolito et al. 2020; Chagas et al. 2022). However, a study which focuses on the impact of pyrolysis temperature on biochar properties with the objective of coal mine spoil restoration is currently missing. The current study was carried out using the published data between the years 2000–2021. Variables considered for this study were biochar physico- chemical properties such as pH, electrical conductivity, cation exchange capacity, organic content, ash content, volatile matter, total carbon, hydrogen, nitrogen and oxygen, and nutritive properties like Ca, Fe, Mg, and K. The forest plot was used to determine the degree to which biochar properties at varying temperature overlap with one another in different studies. The hypothesis of this study is weather pyrolysis temperature influences physio-chemical and nutritive properties of biochar so that it can be effectively used as an ameliorating agent for coal mine spoil restoration. This meta-analysis will be instrumental in providing optimum pyrolysis temperature for pre-determined biochar properties. Thus, the objectives of this study were to (i) determine which pyrolysis temperature gives best nutritional properties to the biochar; (ii) develop forest plots to obtain conclusive data from a large data set; and (iii) provide the best pyrolysis temperature for biochar production for coal mine spoil restoration.

2 Materials and methods

2.1 Literature search

The meta-analysis was based on dataset collected from peer-reviewed articles on the effects of pyrolysis on the physicochemical properties of biochar. Web of Science (WoS), Google Scholar and Science Direct were used for searching keywords like “biochar”, “biochar application”, and “biochar application in coal mines”. A total of 80 research papers (2000–2021) were used and the data related to pyrolysis temperature of biochar vis-a-vis physio-chemical and nutritive properties were extracted. Relevant data from the biochar database UC Davis library was also used for the study (UC Davis Biochar Database, http://biochar.ucdavis.edu/download/). After compiling all the data on an Excel sheet, about 1400 observations were obtained with respect to pyrolysis temperature and biochar physico-chemical and nutritional properties. The steps involved in the meta-analysis study are given in Fig. 1. The details of the meta-analysis and the equations used are given in Supplementary 1.

3 Results and discussions

3.1 Effect of temperature on biochar physico-chemical properties

3.1.1 pH

Figure 2a shows the effect of pyrolysis temperature on the pH of the biochar. The analysis comprises of k (Number of temperature range used for study) were including 3 studies. Fisher r-to-z converted correlation coefficient was in the range of − 0.1598 to 0.4380, with the majority of estimates being positive (67%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.1079 (95% CI (confidence interval): − 0.2338 to 0.4496). Therefore, the average outcome did not differ significantly from zero (z = 0.6190, p = 0.5359). The genuine outcomes were heterogeneous, according to the Q-test (Q = 43.4282, p < 0.0001, tau2 = 0.0870, I2 = 95.3947%). The actual occurrences were projected with a 95% confidence interval as − 0.5635 to 0.7794. Hence, despite the fact that the average outcome is positive, the true outcome in some research could be negative. Thus, it can be concluded that 37.35% of the studies reported a pH range of 5.1–10.6 at low temperature (< 450 °C). On contrary, 29.92% of the studies reported a pH range to be 6.6–12.3 for high pyrolysis temperature (> 550 °C), and 5.8–11.1 for the medium pyrolysis temperature (450–550 °C). Thus, for remediating an acidic coal mine spoil, biochar should be produced at medium or low temperature. A number of studies reported that when the pyrolysis temperature increases, pH of the biochar also increases (Kim et al. 2012; Al-Wabel et al. 2013; El-Naggar et al. 2019). Increasing biochar pH generally correlates with an increase in ash content (Lehmann 2007). This correlation could be useful for practitioners designing pyrolysis systems for creating biochar needed for soil liming purposes, e.g., in acidic mine drainage in coal mine spoils. Increasing pyrolysis temperature caused biochar pH to increase (Fig. 2a), likely due to the loss of acidic functional groups and the formation of Ca-, Mg-, Na-, and K-bearing oxide, hydroxide, and carbonate mineral phases (Jin-Hua et al. 2011; Ding et al. 2014) that can raise the pH to ranges extending from 9.9 to 13.

3.1.2 Electrical conductivity

Fisher r-to-z converted correlation coefficient was calculated to be in the range of − 0.1607 to 0.0330, with the majority of estimates being negative (67%) (k = 3). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0790 (95% CI: − 0.2043 to 0.0462) as shown in Fig. 2b. Therefore, the average outcome did not differ significantly from zero (z = − 1.2372, p = 0.2160). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 1.9577, p = 0.3757, tau2 = 0, I2 = 0) Some studies reported that the electrical conductivity (EC) was 85–137 mS cm− 1 in oak wood biochar, 52–95 mS cm− 1 for pine, 220–609 mS cm− 1 for sugarcane and 415–569 mS cm− 1 for peanut shell biochar produced at pyrolysis temperature of 350 and 990 °C (Zhang et al. 2017). The change in EC for white pine and sugar maple was found from 1 to 350 Sm− 1 and 1 to 1000 Sm− 1 respectively for change in pyrolysis temperature from 600 °C to 1000 °C. This increase in electrical conductivity is linked to a rise in the degree of carbonization, as measured by carbon content (Gabhi et al. 2020; Rehrah et al. 2014). Thus, from the above meta-analysis data, it can be concluded that EC increases as the pyrolysis temperature increases.

3.1.3 Cation exchange capacity

Fisher r-to-z converted correlation coefficient was calculated to be in the range of − 0.2215 to 0.2825, for cation exchange capacity (CEC) which was examined/used/mentioned in three studies, with the majority of estimates being positive (67%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0698 (95% CI: − 0.2251 to 0.3647). Therefore, the average outcome did not differ significantly from zero (z = 0.4638, p = 0.6428). The genuine outcomes appeared to be heterogeneous, according to the Q-test (Q = 9.6967, p = 0.0078, tau2 = 0.0538, I2 = 79.3744%). The actual occurrences were projected with a 95% confidence interval and given by − 0.4722 to 0.6118 as shown in Fig. 2c. Hence, despite the fact that the average outcome is positive, the true outcome in some research could be negative. Thus, it can be concluded that the CEC was in the range of 3.18–187 m mol kg− 1 for high pyrolysis temperatures (28.88% of the studies). While for medium and low temperature biochar, the range was found to be 4.63- 210 m mol kg− 1 and 23.6–228 m mol kg− 1, respectively. Kloss et al. (2012) reported that the CEC of biochar decreased with its production temperature. The study reported that biochar at 525 °C had a CEC of 82.9 mmol kg− 1 while at 400 °C it was 92 mmol kg− 1. Lower temperature biochar has high CEC because of carboxylate and -OH functional groups, while at higher temperature, biochar has positive surface charge due to oxygen containing functional groups which reduce the CEC of biochar. Also at > 250 °C mass reduction takes place due to the evaporation of moisture and volatile gases. At this temperature range, internal structures are re-ordered due to the moisture release, bond re-organisation and formation of -COOH and -CO groups (Anawar et al. 2015). This also leads to a decrease in CEC at higher production temperatures. Thus, lower temperature biochar (~ 450 °C) will be best suited for improving the CEC of an impoverished coal mine spoil which is essential for nutrient retention and exchange in the substrate.

3.1.4 Organic content

Figure 2d shows the effect of pyrolysis temperature on the organic contents of the biochar from three studies. Fisher r-to-z converted correlation coefficient was calculated to be in the range of 0.0298 to 0.2823, with the majority of estimates being positive (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.1824 (95% CI: 0.0099 to 0.3550). Therefore, the average outcome differed significantly from zero (z = 2.0721, p = 0.0383). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 0.9823, p = 0.6119, tau2 = 0, I2 = 0). The formation of biochar with a highly developed specific surface area, high porosity, pH, ash and carbon content. But low CEC and volatile matter content is facilitated by a high pyrolysis temperature. This is most likely related to a high level of decomposition of organic matter (Tomczyk et al. 2020). At low pyrolysis temperature, the organic content in the range of 14.3–88% (38.84% of the studies), 4.7–60% for high pyrolysis temperature (19.42% of the studies) and for medium pyrolysis temperature, and the range is 11.2–86.2% (41.72% of the studies). We can conclude that biochar prepared at 550 °C would have the best effect on the reclamation of mine soil. The organic content in the biochar can be either labile or recalcitrant in nature. When biochar is pyrolysed at higher temperature, the labile fraction is often lost and the most stable carbon is formed. A meta-analysis on the biochar carbon content reported that biochar produced at low temperature has higher organic carbon content (Chagas et al. 2022). Thus, biochar pyrolyzed at low temperatures has a greater potential to increase the organic carbon content of degraded coal mine spoils which are totally devoid of soil organic matter.

3.1.5 Surface area of biochar

For the analysis of surface area (SA) of biochar, the study comprised of a total of three ranges of pyrolysis temperature, for which correlation coefficient was calculated to be in the range of 0.0230 to 0.2572, with all of the estimates being positive (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.1508 (95% CI: 0.0097 to 0.2918). Therefore, the average outcome differed significantly from zero (z = 2.0951, p = 0.0362). Although the Q-test for heterogeneity found no significant differences, some heterogeneity may still remain in the true results (Q = 5.2903, p = 0.0710, tau2 = 0.0097, I2 = 62.1952%). The actual occurrences are projected with a 95% confidence interval and given by − 0.0880 to 0.3895 as shown in Fig. 2e. Hence, despite the fact that the average outcome is positive, the true outcome in some research could be negative. At low pyrolysis temperature, surface area was found in the range of 0.02 to 422 m2g− 1 (34.03% of the studies), for high pyrolysis temperature, SA was in the range of 1–907.4 m2g− 1 (38.09% of the studies). For medium pyrolysis temperature the value was 1–500.9 m2g− 1 (27.80% of the studies). The surface area and porosity of biochar have been found to alter as the pyrolysis temperature increases (Bonelli et al. 2007). Specific surface area of biochar produced at 800 °C is significantly higher than that of the biochar produced at 400 °C (Tan and Yuan 2019). This is most likely related to organic matter breakdown and the production of micropores (Katyal et al. 2003). Furthermore, higher pyrolysis temperatures may result in increased surface area due to the degradation of aliphatic alkyls and ester groups, as well as the exposure of the aromatic lignin core (Chen and Chen 2009). Due to the large SA of the biochar, it helps retain water in coarse coal mine spoils which improves the plant available water. Also, these pores provide abode for microbial activities and enzyme exchange (Ghosh and Maiti 2020).

3.2 Proximate analysis

3.2.1 Ash content

Ash content was calculated on the basis of three ranges of pyrolysis temperatures had a Fisher r-to-z converted correlation coefficient of − 0.1813 to 0.2206, with the majority of estimates being positive (67%) as shown in Fig. 3a. Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0515 (95% CI: − 0.1751 to 0.2781). Therefore, the average outcome did not differ significantly from zero (z = 0.4456, p = 0.6559). The genuine outcomes appeared to be heterogeneous, according to the Q-test (Q = 22.7260, p < 0.0001, tau2 = 0.0366, I2 = 91.1995%). The true outcomes were projected with a 95% confidence interval and given by − 0.3864 to 0.4894. Hence, despite the fact that the average outcome was positive, the true outcome in some research could be negative. For pyrolysis temperature less than 450 °C, 39.86% of considered studies reported ash content between of 0.3 to 74.95%, 58% of study reported ash content between 2.1 to 88% for pyrolysis temperature greater than 550 °C and for medium pyrolysis temperature 30.3% study reported ash content in between 0.7–76.9%. The ash content of biochar increased significantly as the pyrolysis temperature increased, but the residence time had little effect on the ash content. This is expected because more burn off over time at this high temperature leads to yield loss mostly because of the organic matter loss (Rehrah et al. 2014; Noor et al. 2019). Thus, for low to medium temperature biochar would be best suited for coal mine restoration as the higher ash content can affect its pH.

3.2.2 Volatile matter

Figure 3b shows the effect of pyrolysis temperature on the volatile matter of the biochar at three different ranges of pyrolysis temperature. Fisher r-to-z converted correlation coefficient was calculated to be in the range of − 0.8160 to − 0.0719, with all of estimates being negative (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.3407 (95% CI: − 0.8293 to 0.1479). Therefore, the average outcome did not differ significantly from zero (z = − 1.3667, p = 0.1717). The genuine outcomes appeared to be heterogeneous, according to the Q-test (Q = 58.4738, p < 0.0001, tau2 = 0.1800, I2 = 96.5797%). The actual occurrences were projected with a 95% confidence interval and given by − 1.3052 to 0.6238. As a result, while the average outcome was projected to be negative, the true outcome in some studies might be positive. For the low pyrolysis temperature, volatile matter was 7.6–78%, for high pyrolysis temperature, it was 1.3–58.3%, and for medium pyrolysis temperature, it was 5.72–70%. Pyrolysis temperature causes the release of volatiles and creation and volatilization of intermediate melts, which affect the structure of the biochar (Crombie et al. 2013; Shaaban et al. 2014; Tag et al. 2016). A 60.8% to 14.9% decrease in volatile matter was also reported by Zhao et al. (2017) with increase in temperature. Thus, from the above meta-analysis data it can be concluded that as the temperature increases, the amount of volatile matter decreases.

3.3 Ultimate analysis

3.3.1 Total carbon in biochar

Fisher r-to-z converted correlation coefficient was in the range of − 0.0530 to 0.1149, with the maximum of estimates being positive (67%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0356 (95% CI: − 0.0557 to 0.1269). Therefore, the average outcome did not differ significantly from zero (z = 0.7649, p = 0.4443). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 4.3543, p = 0.1134, tau2 = 0.0035, I2 = 54.0689%). The actual occurrences were projected with a 95% confidence interval and given by − 0.1122 to 0.1835. Hence, despite the fact that the average outcome was positive, the true outcome in some research could be negative as shown in Fig. 4a. For low pyrolysis temperature, reported carbon content was in the range of 14.11–85.2% (30.20% of the studies), while for high pyrolysis temperature, 30.8% of the studies reported high carbon content in the range of 24.6–97.3% and for medium pyrolysis temperature the carbon content was also high (20.3–93%). The carbon content of biochar increases as the pyrolysis temperature increases (Chen et al. 2008; Fuertes et al. 2010). Other meta-analyses, evaluating up to 56 articles, found overall increases of 39% (Bai et al. 2019) and 52% (Liu et al. 2016) in organic C for soils with biochar. C increments promoted by biochar in the present study were greater than those observed in the above mentioned studies. Another study conducted by Ahmad et al. (2014) reported the C content to be 26.62–90.10% in low pyrolysis temperature while 20.19–94.20% in high pyrolysis temperature. Increased carbon content at higher temperature might be due to high degree of polymerization with increase in pyrolysis temperature (Domingues et al. 2017). There is a decrease in the acidic functional group due to increase in temperature making the biochar alkaline in nature (Wang et al. 2015). Alkyl (C≡), alkoxy (CH3O-), and carboxylic carbon (−COOH) are usually found in the lower temperature biochar while aromatic carbon is mostly found in the high temperature biochar (Wang et al. 2019). Thus, for the restoration of coal mine spoils, biochar can be produced at low or medium temperature for labile carbon for microbial activity enhancement. At higher pyrolysis temperature, it will help enhance the carbon stock of the coal mine spoils.

3.3.2 Total hydrogen in biochar

Fisher r-to-z converted correlation coefficient was calculated to be in the range of − 0.5702 to 0.1428 for total hydrogen in biochar. The analysis comprised a total of three studies with the majority of estimates being negative (67%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was − 0.1583 (95% CI: − 0.5906 to 0.2739) as shown Fig. 4b. Therefore, the average outcome did not differ significantly from zero (z = − 0.7180, p = 0.4727). The genuine outcomes appeared to be heterogeneous, according to the Q-test (Q = 71.8883, p < 0.0001, tau2 = 0.1418, I2 = 97.2179%). The actual occurrences were projected with a 95% confidence interval and given by − 1.0136 to 0.6969. Hence, as a result, while the average outcome was projected to be negative, the true outcome in some studies might be positive. As the temperature increases, the elemental hydrogen is usually lost (Kim et al. 2012). Low pyrolysis temperature had a H content of 0.5–15.1%, 0.21-8% for high pyrolysis temperature and 0.8-8.5% for medium pyrolysis temperature. Similarly, Fernandes et al. (2020) reported that the H content decreased from 3.76 to 0.9% as the pyrolysis temperature increased (R = 0.72). A greater release rate of hydrogen and oxygen in the form of water vapour caused the progressive increase in C content of the biochar as the temperature goes up (dehydration). The ratios of H and C play a very important role in determining the aromaticty of the produced biochar.

3.3.3 Total nitrogen in biochar

Figure 4c shows the effect of pyrolysis temperature on the total nitrogen of the biochar. Fisher correlation coefficient was calculated to be in the range of − 0.0983 to − 0.0470, with the majority of estimates being negative (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0623 (95% CI: − 0.1260 to 0.0015). Therefore, the average outcome did not differ significantly from zero (z = − 1.9146, p = 0.0555). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 0.5192, p = 0.7714, tau2 = 0, I2 = 0). The N content was unaffected by the pyrolysis temperature, indicating a non-significant correlation (R = 0.08). In general, the amount of nitrogen in biochar is determined by the type of feedstock material utilised and not by the pyrolysis conditions. Furthermore, N-containing structures in woody matrices are more resistant to destruction as the temperature increases (Fernandes et al. 2020). N is highly preserved in raw material wood-derived biochar, which is likely due to the production of heterocyclic N such as pyridines and pyrroles (Huang et al. 2020).

3.3.4 Total oxygen in biochar

The variation in the total oxygen in biochar with three ranges of pyrolysis temperature is shown in Fig. 4d. Fisher r-to-z converted correlation coefficient was calculated to be in the range of − 0.7218 to − 0.0651, with all of the estimates being negative (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was − 0.2855 (95% CI: − 0.7233 to 0.1523). Therefore, the average outcome did not differ significantly from zero (z = − 1.2783, p = 0.2012). The genuine outcomes appeared to be heterogeneous, according to the Q-test (Q = 75.0820, p < 0.0001, tau2 = 0.1457, I2 = 97.3362%). The actual occurrences were projected with a 95% confidence interval and given by − 1.1522 to 0.5812. Hence, as a result, while the average outcome was projected to be negative, the true outcome in some studies might be positive. 40.9% of considered studies reported total oxygen in the range of 4.1 to 50.1% for low pyrolysis temperature, 32.05% of the studies reported oxygen content in the range of 0.15–26.8% for high pyrolysis temperature and for medium pyrolysis temperature, 27.03% of the studies found total oxygen in the range of 0.52 to 40.6. The increase in pyrolysis temperature was negatively correlated with the increase in O content (R = 0.84), with a decrease of 19.41% to 10.75%), A greater release rate of hydrogen and oxygen in the form of water vapour caused the progressive decrease in O content (Gonzaga et al. 2017; Fernandes et al. 2020). The pyrolysis process favours the removal of H and O from the organic phase over C, and increasing the pyrolysis temperature accelerates the removal of H and O (Joseph et al. 2010).

3.4 Effect of pyrolysis temperature on biochar nutrient content

3.4.1 Total calcium content of biochar

Fisher r-to-z converted correlation coefficient was found to be in the range of 0.0112 to 0.0871, with all the estimates being positive (100%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0586 (95% CI: − 0.0528 to 0.1699). Therefore, the average outcome did not differ significantly from zero (z = 1.0309, p = 0.3026). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 0.2946, p = 0.8630, tau2 = 0, I2 = 0). Ca content was 100 to 267,804 mg kg− 1 for low pyrolysis biochar, 92 to 311,232 mg kg− 1 for high and 392 to 300,000 mg kg− 1 for biochar produced at ~ 450–500 °C. Thus, from the above meta-analysis data it can be concluded that with increase in temperature, the Ca content also increases in the biochar (Fig. 5a). Thus, as high calcium content in coal mine spoils can affect plant growth negatively, low temperature biochar (~ 450 °C) should be best suited for biochar production. Ghosh et al. (2020) studied the biochar properties at 250–450 °C and reported that Lantana biochar produced at 450 °C was best suited for coal mine spoil restoration.

3.4.2 Total iron content in biochar

Figure 5b shows the effect of pyrolysis temperature on the Fe content of the biochar. The analysis was comprised with a total of three studies. Fisher r-to-z converted correlation coefficient was in the range of − 0.1273 to 0.3245, with the majority of estimates being negative (67%). Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0395 (95% CI: − 0.1989 to 0.2779). Therefore, the average outcome did not differ significantly from zero (z = 0.3248, p = 0.7453). Although the Q-test for heterogeneity found no significant differences, some heterogeneity might still remain in the true results (Q = 5.5629, p = 0.0619, tau2 = 0.0282, I2 = 64.0478%). The actual occurrences were projected with a 95% confidence interval and given by − 0.3671 to 0.4461. Hence, despite the fact that the average outcome was positive, the true outcome in some research could be negative. For low pyrolysis temperature 39% of the studies found Fe content in the range of 5 to 18,000 mg kg− 1; for high pyrolysis temperature, 21.50% of the studies reported the Fe content in the range of 51 to 37,202 mg kg− 1 and for medium pyrolysis temperature, 39.50% of the studies found the Fe content between 16 to 31,123 mg kg− 1.

3.4.3 Total magnesium content in biochar

The analysis comprised a total of three studies. Fisher r-to-z converted correlation coefficient found to be in the range of 0.0633 to 0.0946, with all of the estimates being positive. Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0847 (95% CI: − 0.0273 to 0.1968). Therefore, the average outcome did not differ significantly from zero (z = 1.4820, p = 0.1383). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 0.0531, p = 0.9738, tau2 = 0, I2 = 0) as shown in Fig. 5c. For low pyrolysis, 32.70% reported the Mg content in the range of 25–165,000 mg kg− 1; for high pyrolysis temperature, 27.30% reported the Mg content in the range of 57 to 211,000 mg kg− 1. For the medium pyrolysis temperature 40% of the studies found Mg content between 21.8 to 128,000 mg kg− 1. According to Enders et al. (2012), biochar prepared at pyrolysis temperature of 600 °C has a concentration of calcium (31%) and magnesium (0.29%) (Cantrell et al. 2012). Thus, from the above meta-analysis data, it can be concluded that as temperature increases Mg content increases in the biochar.

3.4.4 Total potassium content of biochar

K content analysis included a total of three ranges of pyrolysis temperatures. Fisher r-to-z converted correlation coefficient was calculated to be in the range of 0.0002 to 0.0271, with all of the estimates being positive (100%) as shown in Fig. 5d. Based on the random-effects model, the calculated Fisher r-to-z transformed coefficient of correlation was 0.0162 (95% CI: − 0.0885 to 0.1208). Therefore, the average outcome did not differ significantly from zero (z = 0.3027, p = 0.7621). The Q-test indicated that the genuine outcomes seemed to have no significant heterogeneity (Q = 0.0579, p = 0.9715, tau2 = 0, I2 = 0). Out of considered studies 35.83% reported K content in the range of 264 to 172,000 mg kg− 1 for low pyrolysis temperature, 25% study reported the K content in the range of 682 to 257,000 mg kg− 1 for high pyrolysis temperature and 39.17% study reported K content in range of 525 to 255,000 mg kg− 1 for medium pyrolysis temperature. According to the research of Hossain et al. (2020), to retain plant nutrient such as N, P and K, the temperature for biochar production should be low temperature < 400 °C. Major et al. (2010) reported an incerase in the nutrient uptake by 5–100 kg K ha− 1 in maize by biochar at 20 t ha− 1. As temperature increases, K content increases in the biochar. The amount of K increases as the pyrolysis temperature increases; hence, it can be concluded that K is mostly found in the inorganic part of the plant biomass (Hossain et al. 2011; Anawar et al. 2015). Thus, maximum K availability by biochar application can be obtained by pyrolysing the biomass at ~ 450 °C.

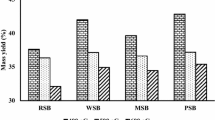

Summary of the biochar characteristics obtained in low, medium, and high pyrolysis temperatures and the percentages of the data from the meta-analysis study are given in Table 2. Percentage of studies for each parameter indicates the proportion of the total studies that reported the mentioned range of value in each temperature range. For example, in low pyrolysis temperature the percentage of studies for pH is 37.35%, which indicates that 37.5% of the total study reported a pH range of 5.1–10.6, 32.74% reported pH range of 5.8–11.1 and 29.91% reported pH value to be 6.6–12.3. Thus, the higher the percentage of the studies reported, higher is the higher data homogenous and reliability are.

4 Conclusions

Understanding the impact of pyrolysis temperature on biochar can help researchers and practitioners optimise its production conditions to meet the mining industry's coal mine spoil restoration needs. This meta-analysis summarised the effect of pyrolysis temperature on biochar physio-chemical and nutrient properties. The pH varied significantly with pyrolysis temperature. Biochar produced at a high temperature (pH = 6.6–12.3) was more alkaline compared to that at a low temperature (pH = 5.8–11.1). Similarly, specific surface area and the contents of ash and carbon also increased by ascending temperature. However, CEC showed an opposite trend where the value was maximum at low temperature, followed by those at medium and low temperatures. Similarly, at low pyrolysis temperature, the organic content was 14.3–88%, while it was 4.7–60% and 11.2–86.2% for high and medium. Biochar produced at high pyrolysis temperatures had high Ca, Mg, Na, and K content. Although the meta-analysis shows that biochar is produced at different temperatures, it is advisable that neither low nor high temperature is best suited for nutrient retention properties of biochar which are required for plant growth. Thus, from this meta-analysis, it can be concluded that moderate pyrolysis temperature (450–550 °C) is best suited for producing high-quality biochar with respect to nutritional parameter for mine spoil reclamation.

5 Future recommendations

Predictive relationships between biochar production, properties and performance are particularly important for discussing the economic viability of biochar for mine spoil reclamation and sustainability. However, more accurate predictions using the present approaches are limited by a shortage of effective data despite the large number of biochar-related publications. In order to fill the data and research gaps, additional biochar studies are encouraged to be conducted systematically in the following directions:

-

(1)

Current literature mostly reports pot / greenhouse experiments. Thus, biochar produced at varying pyrolysis temperature ranges should be applied for long-term experiment which are correlated with nutrient availability. The vis-a-vis plant growth should be done to popularise biochar based mine spoil reclamation.

-

(2)

For the in-situ biochar production, three aspects need to be considered, i.e., cost, available feedstock and mass scale in-situ production. To minimise the cost of biochar production and application, feedstock such as invasive weeds growing abundantly in mining areas should be utilized. This will help reduce transportation cost and also help eradicate invasive weeds which cause allellopathy during plantation stages of coal mine reclamation. Mass scale production on-site by Sub-Saharan Africa can also help reduce the cost of production as the method does not require any machinery or fuel for its pyrolysis.

Availability of data and materials

The datasets generated are available from the corresponding author on reasonable request.

References

Abdelhafez AA, Li J, Abbas MHH (2014) Feasibility of biochar manufactured from organic wastes on the stabilization of heavy metals in a metal smelter contaminated soil. Chemosphere 117:66–71. https://doi.org/10.1016/j.chemosphere.2014.05.086

Ahmad M, Rajapaksha AU, Lim JE et al (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere 99:19–33. https://doi.org/10.1016/j.chemosphere.2013.10.071

Ali A, Guo D, Zhang Y et al (2017) Using bamboo biochar with compost for the stabilization and phytotoxicity reduction of heavy metals in mine-contaminated soils of China. Sci Rep 7:1–12. https://doi.org/10.1038/s41598-017-03045-9

Al-Rumaihi A, Shahbaz M, Mckay G et al (2022) A review of pyrolysis technologies and feedstock: a blending approach for plastic and biomass towards optimum biochar yield. Renew Sust Energ Rev 167:112715. https://doi.org/10.1016/j.rser.2022.112715

Al-Wabel MI, Al-Omran A, El-Naggar AH et al (2013) Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour Technol 131:374–379. https://doi.org/10.1016/j.biortech.2012.12.165

Anawar HM, Akter F, Solaiman ZM, Strezov V (2015) Biochar: an emerging panacea for remediation of soil contaminants from mining, industry and sewage wastes. Pedosphere 25:654–665. https://doi.org/10.1016/S1002-0160(15)30046-1

Bai S, Li R, Su G, Duan X, Wang S, Ren NQ, Ho SH (2019) Magnetic biochar catalysts from anaerobic digested sludge: Production, application and environment impact. Environment international 126:302-308. https://doi.org/10.1016/j.envint.2019.02.032

Bernardino CAR, Mahler CF, Veloso MCC, Romeiro GA (2017) Preparation of biochar from sugarcane by-product filter mud by slow pyrolysis and its use like adsorbent. Waste Biomass Valorization 8:2511–2521. https://doi.org/10.1007/s12649-016-9728-5

Bonelli PR, Buonomo EL, Cukierman AL (2007) Pyrolysis of sugarcane bagasse and co-pyrolysis with an Argentinean subbituminous coal. Energy Sour Part A Recover Util Environ Eff 29:731–740. https://doi.org/10.1080/00908310500281247

Cantrell KB, Hunt PG, Uchimiya M et al (2012) Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour Technol 107:419–428. https://doi.org/10.1016/j.biortech.2011.11.084

Chagas JKM, de Figueiredo CC, Ramos MLG (2022) Biochar increases soil carbon pools: evidence from a global meta-analysis. J Environ Manag 305. https://doi.org/10.1016/j.jenvman.2021.114403

Chen B, Chen Z (2009) Sorption of naphthalene and 1-naphthol by biochars of orange peels with different pyrolytic temperatures. Chemosphere 76:127–133. https://doi.org/10.1016/j.chemosphere.2009.02.004

Chen B, Zhou D, Zhu L (2008) Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ Sci Technol 42:5137–5143. https://doi.org/10.1021/es8002684

Crombie K, Mašek O, Sohi SP et al (2013) The effect of pyrolysis conditions on biochar stability as determined by three methods. GCB Bioenergy 5:122–131. https://doi.org/10.1111/gcbb.12030

Devi P, Saroha AK (2015) Effect of pyrolysis temperature on polycyclic aromatic hydrocarbons toxicity and sorption behaviour of biochars prepared by pyrolysis of paper mill effluent treatment plant sludge. Bioresour Technol 192:312–320. https://doi.org/10.1016/j.biortech.2015.05.084

Ding W, Dong X, Ime IM et al (2014) Pyrolytic temperatures impact lead sorption mechanisms by bagasse biochars. Chemosphere 105:68–74. https://doi.org/10.1016/j.chemosphere.2013.12.042

Domingues RR, Trugilho PF, Silva CA et al (2017) Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS One 12. https://doi.org/10.1371/journal.pone.0176884

El-Naggar A, Lee SS, Rinklebe J et al (2019) Biochar application to low fertility soils: a review of current status, and future prospects. Geoderma 337:536–554

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour Technol. 114: 644–653. https://urldefense.com/v3/__https://doi.org/10.1016/j.biortech.2012.03.022__;!!NLFGqXoFfo8MMQ!txepJePqt94teMRtjdiYxz9sZ-4Ochs7RMyJQ3pGDMojg-nHW2REzlNHaTao7WN8eFGg61QwhGi4flxFMbZ9MD4sP_w$; https://doi.org/10.1016/j.biortech.2012.03.022

Fernandes BCC, Mendes KF, Júnior AFD et al (2020) Impact of pyrolysis temperature on the properties of eucalyptus wood-derived biochar. Materials (Basel) 13:1–13. https://doi.org/10.3390/ma13245841

Fuertes AB, Arbestain MC, Sevilla M, Maciá-Agulló JA, Fiol S, López R, Smernik RJ, Aitkenhead WP, Arce F, Macìas F (2010) Chemical and structural properties of carbonaceous products obtained by pyrolysis and hydrothermal carbonisation of corn stover. Soil Res 48(7):618-626. https://doi.org/10.1071/SR10010

Gabhi R, Basile L, Kirk DW, Giorcelli M, Tagliaferro A, Jia CQ (2020) Electrical conductivity of wood biochar monoliths and its dependence on pyrolysis temperature. Biochar 2(3):369-378

Ghosh D, Maiti SK (2020) Can biochar reclaim coal mine spoil ? J Environ Manag 272:111097. https://doi.org/10.1016/j.jenvman.2020.111097

Ghosh D, Maiti SK (2021a) Effect of invasive weed biochar amendment on soil enzymatic activity and respiration of coal mine spoil: a laboratory experiment study. Biochar 3:519–533. https://doi.org/10.1007/s42773-021-00109-y

Ghosh D, Maiti SK (2021b) Eco-restoration of coal mine spoil: biochar application and carbon sequestration for achieving un sustainable development goals 13 and 15. Land 10. https://doi.org/10.3390/land10111112

Ghosh D, Maiti SK (2022) Invasive weed-based biochar facilitated the restoration of coal mine degraded land by modulating the enzyme activity and carbon sequestration. Restor Ecol:1–11. https://doi.org/10.1111/rec.13744

Ghosh D, Masto RE, Maiti SK (2020) Ameliorative effect of Lantana camara biochar on coal mine spoil and growth of maize (Zea mays). Soil Use Manag:1–14. https://doi.org/10.1111/sum.12626

Gonzaga MIS, Mackowiak CL, Comerford NB et al (2017) Pyrolysis methods impact biosolids-derived biochar composition, maize growth and nutrition. Soil Tillage Res 165:59–65. https://doi.org/10.1016/j.still.2016.07.009

Hass A, Gonzalez JM, Lima IM et al (2012) Chicken manure biochar as liming and nutrient source for acid Appalachian soil. J Environ Qual 41:1096–1106. https://doi.org/10.2134/jeq2011.0124

Hossain MK, Strezov Vladimir V, Chan KY et al (2011) Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J Environ Manag 92:223–228. https://doi.org/10.1016/j.jenvman.2010.09.008

Hossain MZ, Bahar MM, Sarkar B, Donne SW, Ok YS, Palansooriya KN, Kirkham MB, Chowdhury S, Bolan N (2020) Biochar and its importance on nutrient dynamics in soil and plant. Biochar 2(4):379-420. https://doi.org/10.1080/01904167.2016.1267746

Houben D, Evrard L, Sonnet P (2013) Mobility, bioavailability and pH-dependent leaching of cadmium, zinc and lead in a contaminated soil amended with biochar. Chemosphere 92:1450–1457. https://doi.org/10.1016/j.chemosphere.2013.03.055

Huang H, Liu J, Liu H et al (2020) Pyrolysis of water hyacinth biomass parts: bioenergy, gas emissions, and by-products using TG-FTIR and Py-GC/MS analyses. Energy Convers Manag 207. https://doi.org/10.1016/j.enconman.2020.112552

Ippolito JA, Laird DA, Busscher WJ (2012) Environmental benefits of biochar. J Environ Qual 41:967–972. https://doi.org/10.2134/jeq2012.0151

Ippolito JA, Cui L, Kammann C et al (2020) Feedstock choice, pyrolysis temperature and type influence biochar characteristics: a comprehensive meta-data analysis review. Biochar 2:421–438. https://doi.org/10.1007/s42773-020-00067-x

Jain S, Mishra D, Khare P et al (2016) Impact of biochar amendment on enzymatic resilience properties of mine spoils. Sci Total Environ 544:410–421. https://doi.org/10.1016/j.scitotenv.2015.11.011

Jin-Hua Y, Ren-Kou X, Ning W, Jiu-Yu L (2011) Amendment of acid soils with crop residues and biochars * 1

Joseph SD, Camps-Arbestain M, Lin Y et al (2010) An investigation into the reactions of biochar in soil. Aust J Soil Res:501–515

Karaosmanoǧlu F (2000) Biobriquetting of rapeseed cake. Energy Sources 22:257–267. https://doi.org/10.1080/00908310050014045

Katyal S, Thambimuthu K, Valix M (2003) Carbonisation of bagasse in a fixed bed reactor: influence of process variables on char yield and characteristics

Kim KH, Kim JY, Cho TS, Choi JW (2012) Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresour Technol 118:158–162. https://doi.org/10.1016/j.biortech.2012.04.094

Kloss S, Zehetner F, Dellantonio A, Hamid R, Ottner F, Liedtke V, Schwanninger M, Gerzabek MH, Soja G (2012) Characterization of slow pyrolysis biochars: effects of feedstocks and pyrolysis temperature on biochar properties. Journal of environmental quality 41(4):990-1000

Lanzetta M, Di Blasi C (1998) Pyrolysis kinetics of wheat and corn straw. Journal of Analytical and Applied Pyrolysis 44(2):181-192

Lehmann J (2007) A handful of carbon. Nature 447:143–144. https://doi.org/10.1038/447143a

Li B, Zhang Y, Xu J et al (2022) Facile preparation of magnetic porous biochars from tea waste for the removal of tetracycline from aqueous solutions: effect of pyrolysis temperature. Chemosphere 291. https://doi.org/10.1016/j.chemosphere.2021.132713

Liao W, Zhang X, Ke S et al (2022) Effect of different biomass species and pyrolysis temperatures on heavy metal adsorption, stability and economy of biochar. Ind Crop Prod 186:115238. https://doi.org/10.1016/j.indcrop.2022.115238

Liu S, Zhang Y, Zong Y et al (2016) Response of soil carbon dioxide fluxes, soil organic carbon and microbial biomass carbon to biochar amendment: a meta-analysis. GCB Bioenergy 8:392–406. https://doi.org/10.1111/gcbb.12265

Maiti SK (2013) Ecorestoration of coal mine degraded lands. Springer, New Delhi

Major J, Rondon M, Molina D, Riha SJ, Lehmann J (2010) Maize yield and nutrition during 4 years after biochar application to a Colombian savanna oxisol. Plant and soil 333(1):117-128. https://doi.org/10.1007/s11104-010-0327-0

Majumder S, Neogi S, Dutta T et al (2019) The impact of biochar on soil carbon sequestration: meta-analytical approach to evaluating environmental and economic advantages. J Environ Manag 250:109466. https://doi.org/10.1016/j.jenvman.2019.109466

Noor NM, Shariff A, Abdullah N, et al (2019) Temperature effect on biochar properties from slow pyrolysis of coconut flesh waste

Novak JM, Ippolito JA, Watts DW et al (2019) Biochar compost blends facilitate switchgrass growth in mine soils by reducing Cd and Zn bioavailability. Biochar 1:97–114. https://doi.org/10.1007/s42773-019-00004-7

Pap S, Gaffney PPJ, Zhao Q et al (2022) Optimising production of a biochar made from conifer brash and investigation of its potential for phosphate and ammonia removal. Ind Crop Prod 185:115165. https://doi.org/10.1016/j.indcrop.2022.115165

Qadeer S, Anjum M, Khalid A et al (2017) A dialogue on perspectives of biochar applications and its environmental risks. Water Air Soil Pollut 228. https://doi.org/10.1007/s11270-017-3428-z

Rafiq MK, Bachmann RT, Rafiq MT et al (2016) Influence of pyrolysis temperature on physico-chemical properties of corn stover (zea mays l.) biochar and feasibility for carbon capture and energy balance. PLoS One 11. https://doi.org/10.1371/journal.pone.0156894

Rajabi H, Mosleh MH, Mandal P et al (2021) Sorption behaviour of xylene isomers on biochar from a range of feedstock. Chemosphere 268. https://doi.org/10.1016/j.chemosphere.2020.129310

Rehrah D, Reddy MR, Novak JM et al (2014) Production and characterization of biochars from agricultural by-products for use in soil quality enhancement. J Anal Appl Pyrolysis 108:301–309. https://doi.org/10.1016/j.jaap.2014.03.008

Ren X, Zhang P, Zhao L, Sun H (2016) Sorption and degradation of carbaryl in soils amended with biochars: influence of biochar type and content. Environ Sci Pollut Res 23:2724–2734. https://doi.org/10.1007/s11356-015-5518-z

Rinklebe J, Shaheen SM, Frohne T (2016) Amendment of biochar reduces the release of toxic elements under dynamic redox conditions in a contaminated floodplain soil. Chemosphere 142:41–47. https://doi.org/10.1016/j.chemosphere.2015.03.067

Shaaban A, Se SM, Dimin MF et al (2014) Influence of heating temperature and holding time on biochars derived from rubber wood sawdust via slow pyrolysis. J Anal Appl Pyrolysis 107:31–39. https://doi.org/10.1016/j.jaap.2014.01.021

Shakya A, Vithanage M, Agarwal T (2022) Influence of pyrolysis temperature on biochar properties and Cr(VI) adsorption from water with groundnut shell biochars: mechanistic approach. Environ Res 215:114243. https://doi.org/10.1016/j.envres.2022.114243

Shan J, Wang Y, Gu J et al (2014) Effects of biochar and the geophagous earthworm Metaphire guillelmi on fate of 14C-catechol in an agricultural soil. Chemosphere 107:109–114. https://doi.org/10.1016/j.chemosphere.2014.03.030

Song XD, Xue XY, Chen DZ et al (2014) Application of biochar from sewage sludge to plant cultivation: influence of pyrolysis temperature and biochar-to-soil ratio on yield and heavy metal accumulation. Chemosphere 109:213–220. https://doi.org/10.1016/j.chemosphere.2014.01.070

Suliman W, Harsh JB, Abu-Lail NI et al (2016) Influence of feedstock source and pyrolysis temperature on biochar bulk and surface properties. Biomass Bioenergy 84:37–48. https://doi.org/10.1016/j.biombioe.2015.11.010

Tag AT, Duman G, Ucar S, Yanik J (2016) Effects of feedstock type and pyrolysis temperature on potential applications of biochar. J Anal Appl Pyrolysis 120:200–206. https://doi.org/10.1016/j.jaap.2016.05.006

Tahervand S, Jalali M, Buss W (2022) Pyrolysis treatment enables safe application of sewage sludge in horticulture: tracking potentially toxic elements through the biochar-soil–plant system in tomato. Waste Biomass Valorization 13:1277–1292. https://doi.org/10.1007/s12649-021-01558-z

Takaya CA, Fletcher LA, Singh S et al (2016) Phosphate and ammonium sorption capacity of biochar and hydrochar from different wastes. Chemosphere 145:518–527. https://doi.org/10.1016/j.chemosphere.2015.11.052

Tan Z, Yuan S (2019) The effect of preparing temperature and atmosphere on biochar’s quality for soil improving. Waste Biomass Valorization 10:1395–1405. https://doi.org/10.1007/s12649-017-0145-1

Tomczyk A, Sokołowska Z, Boguta P (2020) Biochar physicochemical properties: pyrolysis temperature and feedstock kind effects. Rev Environ Sci Biotechnol 19:191–215. https://doi.org/10.1007/s11157-020-09523-3

Tsai WT, Liu SC, Chen HR et al (2012) Textural and chemical properties of swine-manure-derived biochar pertinent to its potential use as a soil amendment. Chemosphere 89:198–203. https://doi.org/10.1016/j.chemosphere.2012.05.085

Wang X, Song D, Liang G et al (2015) Maize biochar addition rate influences soil enzyme activity and microbial community composition in a fluvo-aquic soil. Appl Soil Ecol 96:265–272. https://doi.org/10.1016/j.apsoil.2015.08.018

Wang Y, Villamil MB, Davidson PC, Akdeniz N (2019) A quantitative understanding of the role of co-composted biochar in plant growth using meta-analysis. Sci Total Environ 685:741–752. https://doi.org/10.1016/j.scitotenv.2019.06.244

Wang K, Peng N, Lu G, Dang Z (2020) Effects of pyrolysis temperature and holding time on physicochemical properties of swine-manure-derived biochar. Waste Biomass Valorization 11:613–624. https://doi.org/10.1007/s12649-018-0435-2

Yu H, Zou W, Chen J et al (2019) Biochar amendment improves crop production in problem soils: a review. J Environ Manag 232:8–21. https://doi.org/10.1016/j.jenvman.2018.10.117

Zhang H, Chen C, Gray EM, Boyd SE (2017) Effect of feedstock and pyrolysis temperature on properties of biochar governing end use efficacy. Biomass and Bioenergy 105:136-146. https://doi.org/10.1016/j.biombioe.2017.06.024

Zhao SX, Ta N, Wang XD (2017) Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 10. https://doi.org/10.3390/en10091293

Acknowledgements

The authors would like to express their gratitude to the Indian Institute of Technology (Indian School of Mines) Dhanbad and the Ministry of Human Resource Development of India for supporting the first author with a stipend (20MT0032).

Funding

The authors would like to acknowledge IIT (ISM), Dhanbad and MHRD, Government of India for giving contingency funds for research and scholarship to the first author and second authors.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Akash Roshan and Dipita Ghosh. Prof. Subodh Kumar Maiti was the overall supervisor of the work. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Meta-analysis.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Roshan, A., Ghosh, D. & Maiti, S.K. How temperature affects biochar properties for application in coal mine spoils? A meta-analysis. Carbon Res. 2, 3 (2023). https://doi.org/10.1007/s44246-022-00033-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-022-00033-1