Abstract

One of the biggest problems responsible of the nonrenewable resources depletion and environmental issues is the construction industries, which generates large amounts of mineral waste and harmful emitted gases. Therefore, these problems generated the necessity to search for alternative natural building materials based on renewable resources. To study the mechanical characteristics and microstructural behavior of the concrete reinforced by raw wheat straw basalt fiber composite (RWSBFc), and treated rice straw basalt fiber composite (TRSBFc), a number of experimental tests were carried out with different composites ratios. Concrete compressive strength, splitting tensile strength, and flexural strength tests were considered as main parameters. The results showed that the RWSBFC has a positive effect on concrete flexural strength by increasing of 12.58%, compared with control samples. Also, it showed good enhancement in concrete flexibility and ductility. In contrast, both RWSBFc and TRSBFc showed uneven deterioration in concrete compressive strength and splitting tensile strength. To avoid the deterioration in compressive strengths of the various composites types, some improvement methods such as processors for the used straw, and adding some additives were recommended.

摘要

建筑业是造成不可再生资源枯竭和环境问题的主要行业之一, 该行业会产生大量的废弃物和有害气体。为解决上述问题, 有必要研究使用可再生资源用以替代天然建筑材料。本文通过一系列试验研究了未经处理的小麦秸秆-玄武岩纤维混杂复合材料 (RWSBFc) 与经处理后的稻草-玄武岩纤维混杂复合材料 (TRSBFc) 在不同掺量比例对混凝土力学特性和微观结构的影响, 包括混凝土的抗压强度、劈裂抗拉强度和抗弯强度等主要指标。结果表明, 相较于对照组, RWSBFc使混凝土的抗弯强度提高了12.58%。同时, RWSBFc可以显著提高混凝土的变形性能。然而, RWSBFc和TRSBFc也会不同程度地降低混凝土的抗压强度和劈裂抗拉强度。为减小各类复合材料混凝土抗压强度的弱化, 建议对秸秆进行处理并使用添加剂等方法。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently there was an increased interest in research and studies on natural fibers and renewable sources materials as an alternative to conventional reinforcement in composite materials [1]. Moreover, the ecological and environmental issues have encouraged wide research on environmentally friendly green materials considering the wide use of natural and renewable sources fibers in a broad and multiple areas fields as composite materials [2,3,4,5]. Fiber cements products and plant biomass were accepted and used widely in many application areas for developing energy efficient and low-cost construction materials in an emerging field, building construction, and civil engineering. In spite of the multi pros of the biomass-based cement and concrete composite materials such as low densities, low amount of CO2 gas emission, good thermal insulation, earthquake resistance, fire resistance, and noise insulation [6,7,8]. Furthermore, there are also some disadvantages of biomass-based cement and concrete composite materials like weak resistance to the cement alkalinity, high water absorption, and lack of the cement-biomass compatibility [9,10,11]. Moreover, natural fiber and biomass-based cement and concrete composites have limited durability in the long term due to their highest permeability and poor resistance to the growth of the crack [12, 13].

Recently, agricultural by-product rice straw fiber utilization is used to replace the convention of artificial fibers in production of concrete and present an eco-friendly prospective contender to enhance the static and dynamic performance [14].

The plant-based fibers have a significant effect on the enhancement of the cementitious materials properties. The great benefits from the large using of natural fibers as a renewable material for cement based and concrete composites are great in terms of the environment, and energy sources [15,16,17].

A new concrete block filling with compacted straw blocks was studied by Fusheng Liu [18], while the lightweight cement based straw fiber foamed wall material that has a low density, low bibulous rate, and good intensity was developed by Lijiu Wang [19]. Mud reinforced with short straw has widely utilization in building and construction applications. In addition, natural fibers have many other utilizations as reinforcement material in cement, concrete, and polymer composites, as a discrete with non-uniformed and randomly distributed fibers. The performance of this type of fibers was investigated in wall panels, cement board applications, and asbestos cement fiberboard [20,21,22]. Natural fibers also have become a successful alternative to conventional building materials and elements. However, there are limited and shortages in information for the wheat straw reinforced cement and concrete composites structures [23, 24].

Concrete is a material which characterized by high resistance to the compressive stresses compared with the other building materials, but on the other side, it has low tensile strength. Recently there has been an increase in studies and thoughts for the use of natural fibers to reinforce the matrix (paste, mortar, and concrete) [25, 26]. Therefore, the strength properties of the fiber, matrix and fiber matrix interface should be well understood to predict the behavior of the resulting composite, particularly after cracking. The natural fibers are environmentally friendly as compared to the steel and synthetic fibers [27, 28]. Natural fibers-material was evolved in a clear and tangible way through extensive research to identify its characteristics as a new alternative and renewable sources material. It has low density and with lightweight, and it exhibits a high tensile strength and stable elastic modulus, as shown in previous studies to some types of natural fibers such as hemp, ramie, and jute [2, 29,30,31].

Natural fibers reinforced polymeric and cementitious materials become one of the significances and favored materials that can be used in the construction of structural components. They also have excellent results in improving and increasing the ductility and the absorption of energy in the produced elements. Moreover, they have exquisite and promising results increase tensile strength and ductility when used in reinforced concrete elements [32,33,34,35,36,37]. In spite of The very scarce and limited data and research available on natural fiber reinforced concrete composites, the researcher's all over the world working hard to develop and improve the utilization of the natural fibers in various structural applications to offset replace artificial fibers [38]. In the last decades, microstructural characterization of 3D printed concrete for concrete was carried out by many researchers. The morphology and particle size distribution of admixtures indicate influence the printability of mortar, the yield stress of the paste affected positively the vitreous surface of GGBS, in contrast, the porous surface of CBP [39, 40].

The main objective of this research is focused on mechanical properties of the concrete reinforced with RWSBFc and TRSBFc. To achieve the goal of the study, a number of the tests were conducted with considering compressive strength, splitting tensile strength (SpTS), and flexural strength tests.

2 Experimental

For the experimental tests, 24 cylindrical samples (300-mm depth and 150-mm diameter), and 12 beam samples (10×10×40 cm) with different proportions of RWSBFc, were fabricated and tested. Same numbers of the above-mentioned samples were used in TRSBFc type. Each composites type of RWSBFc and TRSBFc considered 12 samples for cylindrical and compressive strength. Details of the experimental program were provided in the following sections. The beam samples were tested for flexural strength.

2.1 Materials and specimen preparation

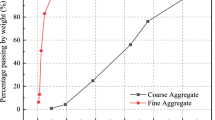

The samples (cylindrical and beams) were divided into 4 groups (M1, M2, M3, and M4) with various RWSBFc and TRSBFc ratios of 0.0%, 0.3%, 0.5%, and 0.7%, respectively. In this study, two different stages of preparation and testing of concrete composite (RWSBFc and TRSBFc) were carried out. The concrete mix proportions were prepared according to the variation of RWSBFc, and TRSBFc ratios. Table 1 shows the mix proportions for one cubic meter of RWSBFc and TRSBFc (control samples).

Portland cement (Type 1) was used as a binder with sand and crushed limestone as aggregates. In addition, fly ash type C was added to the concrete mix (by replacing cement by 67%, and sand by 33% of fly ash amount) to improve the compressive strength of the composite which expected to decrease due to the presence of the straw in the concrete. Fly ash was added in a ratio of 15%, 25%, and 35% of cement amount to the samples contains 0.3%, 0.5%, and 0.7% of TRSBFc respectively. All specimens were prepared in accordance with the ASTM [41] specification and cured under same conditions for 28 days at a temperature ranged from 20 to 25°C, and relative humidity 100%. Then, the samples were placed in natural conditions to obtain the maximum concrete strength prior to exposure to different natural conditions.

For RWSBFc concrete, the raw wheat straw was collected from Lianyungang - Jiangsu province, and basalt fibers were supplied by Zhejiang Gold Stone Basalt Fiber Co., Ltd (GBF). The samples were prepared by mixing raw wheat straw fiber (50 -120-mm length and 2.65 - 3.38 mm diameter) with basalt fiber (9 mm length and 13μm diameter), where the basalt fiber percentage was 20% of the total weight of the composite (straw + basalt fiber). For TRSBFc, the basalt fibers were supplied by Zhejiang GBF Basalt Fiber Co., Ltd. The TRSBFc was prepared by mixing the treated rice straw (10 - 30- mm length, with tensile strength of 20.25MPa) with basalt fiber (20-mm length, 1~2mm width), where the basalt fiber content was 25% of the composite (straw + basalt fiber) total weight.

Basalt fiber type used with raw wheat straw has low resistant to the cement alkalinity compared to that with treated rice straw which has a good resistant to the cement alkalinity. Rice straw was immersed in sodium hydroxide solution (NaOH, 5% concentration) for 12 hours to remove the sugar in the straw stalks so as not to inhibit cement reactions, while the wheat straw was used as its. After the pretreatment process, the straw was washed and dried before use. The total amounts of WSBFc and TRSBFc for different ratios are shown in Table 2.

2.2 Test setup

The concrete surface was prepared and cleaned, and the samples were labeled before the tests. For cylindrical samples (compressive test), two linear variable differential transducers (LVDTs) were used to measure displacement, and two electrical-resistance strain gauges (horizontal and vertical) with the length of 100 mm to measure vertical and horizontal trains. For beam samples (flexural strength test), an electrical-resistance strain gauge with lengths of 10 mm on the bottom of the beam were used to measure vertical displacement. All beam samples was tested under three-point loading in accordance with ASTM specifications. Flexural and compressive strength tests were implemented by Servo-hydraulic Dynamic Fatigue Testing machine and compression test machine as shown in Fig. 1a and b, respectively (test set- up).

After sample preparation, microscope images were taken by using a scanning electron microscope (SEM Quanta 200 FEI) to study the topography and composition of RWSBFc samples.

3 Results and discussion

3.1 Compressive test result

The compressive strength test was performed using Hydraulic Pressure Testing Machine (HPTM) type YY-200A-2000 K. The obtained test results showed that the compressive strength of the samples reinforced with both RWSBFc and TRSBFc decreased proportionally with the increase of the composite content. Comparing with the control for each type of composite, the compressive strength values and the decreasing percentage were shown in Fig. 2a. Moreover, the weight of the concrete samples has decreased with the increase of the composite content, where the percentages of weight reduction are shown in Fig. 2b.

Adding natural fiber composites (RWSBFc, and TRSBFc) with a random distribution manner to the concrete leads fiber to occupy small voids in the concrete mass. Existing of these fibers in the concrete mass affects the concrete compressive strength due to the significant difference in the properties of the two materials, where the natural fibers have a weak compressive strength. Moreover, the effect on the concrete strength depends on the voids size caused by the fibers in the concrete mass. In the case of RWSBFc, the decrease in compressive strength was bigger compared to that in the case of TRSBFc, because the wheat straw was used in its raw conditions with dimension bigger than the treated rice straw which increases the probability of irregular distribution and random orientation of the straw fibers through the concrete mix comparing with TRSBFc.

The failure modes of the tested samples are shown in Fig. 3. RWSBFc samples (Fig. 3a-d top row) showed splitting tension, crushing, and wedge splitting failure, in addition to that the compression failure for these samples involves internal buckling, vertical cracks, and horizontal strain, while TRSBFc samples (Fig. 3a-d bottom row) showed splitting tension and shear crushing failure.

Although, adding natural fiber composites (RWSBFc and TRSBFc) to the concrete mix has an adverse effect on the compressive strength, but it makes the concrete show more cohesive and flexible during the loading process. In addition, during loading and after reaches peak point in plasticity stage, the mechanical behavior of the samples reinforced with RWSBFc is quite different from those of TRSBFc and control samples (Fig. 4a). RWSBFc and TRSBFc enhanced the first crack initiation of the sample earlier, and its failure process is gradual, this reveals the change in concrete performance. According to the above statement, using of RWSBFc in reinforcing concrete members can’t prevent the collapse caused by compressive strength, but it can enhance the concrete performance with more flexibility, which can act as an indicator for safety, and provide people with a certain amount of time to avoid or reduce the serious consequences of sudden collapse of concrete.

From stress-strain curves for different types of samples (Fig. 4), it was observed that the curve M1 which resulted from the sample contain 0.0% of the composite has highest stress value for both composites types, while the curve M4 which resulted from the sample containing 0.7% of the composite shows lowest stress value. Moreover, curve M2 showed a little decrease in stress value compared with M1 (control) and highest value in the other curves, but simultaneously it showed stability or very slight change in the stress value while the strain increasing from 0.015 to 0.025 before the stress landing directly to zero. This behavior becomes clearer in the curves M3 and M4 in which the stress value is lower than in M2 due to increasing of composite content (Fig. 4a). Regardless the decreasing in stress values that fit with the increase in straw content in samples, the constancy of maximum stress value for each type of samples indicates that there is an improvement in the concrete flexibility. In addition, the samples reinforced with TRSBFc shows the same behavior, but it is somewhat less than it in case of samples reinforced with RWSBFc (Fig. 4b).

3.2 Splitting tensile test result

Splitting tensile test was performed using (Hydraulic Pressure Testing Machine (HPTM) type YY-200A-2000K), and the obtained results were presented (Fig. 5a). Through the results, and by comparing with the control samples, a clear deterioration in splitting tensile strength of the samples reinforced with RWSBFc and TRSBFc was observed. This decrease is proportional to the composite content in the sample. Moreover, the samples reinforced with TRSBFc showed slight percentages of decrease in splitting tensile strength when compared with both control samples and RWSBFc samples contains the same percentage of the composite. The splitting tensile strength values for the different samples in addition to the decreasing percentage are shown in Fig. 5a. As this test gives an indicator to concrete shear strength, it could be argued that the utilization of straw composites in reinforcing the concrete may lead to decrease in concrete shear strength.

3.3 Flexural strength test results

Flexural strength test is usually done using three or four loading point bending test technique. In this test, the specimens were loaded until the fracture or rupture point. In the other side, the flexural strength test was considered to measure the concrete tensile strength, where it expressed as Modulus of Rupture (MOR). Three-point bending test was carried out using Servo-hydraulic Dynamic Fatigue Testing System (Series LFV- 1000 kN), and the values of the load, stain, and displacement were recorded.

From the test results, it was revealed that the flexural strength of the samples reinforced with RWSBFc increased proportionally with increasing of the RWSBFc content ratios 0.3%, 0.5% and 0.7%, while it showed lower values for the same content ratios from TRSBFc compared with the control. Therefore, we can report that the use of RWSBFc improve the concrete flexural strength by approximately 12.58%, and showed 38.35% decreasing in case of TRSBFc. Figure 5b shows the changes in flexural strength values for different mix types of RWSBFc and TRSBFc. While, the load displacement plots for flexural strength of different ratios of RWSBFc and TRSBFc fibres were showed in Fig. 6a and b, respectively.

From the various tests results, it was observed that there was a variation in the obtained values and the drawn curves even for the samples with the same ratio of RWSBFc. This can be attributed to the heterogeneous distribution of RWSBFc and the direction of the straw basal fibers in the concrete samples; thereby could results in varying tensile strength of some samples compared with the others contains the same ratio of RWSBFc. Moreover, the load-displacement curves of the control samples steeper when compared with some of the others obtained from the samples reinforced with RWSBFc which indicates that reinforcing the concrete with RWSBFc improve the flexibility and the ductility of the concrete.

Generally, the decreasing percentages in justification the differences between the values of compressive strength and splitting tensile strength for the RWSBFc and TRSBFc attributed to several factors as shown in Table 3.

3.4 Microstructure of RWSBFc and TRSBFc concrete samples

The microstructure was examined for both RWSBFc and TRSBFc by taking a small specimen from each type of samples, prepared, dried, and coated with palladium layer (thickness≈30 nm) to avoid sample charging under the electron beam. The sample scanned using scanning electronic microscope (SEM) Quanta 200 FEI, to study the surface topography and composition of the various samples.

From scanning results, the images obtained from both RWSBFc and TRSBFc samples showed some voids resulting from the natural cavity of straw, as well as the voids that originated from the nesting of fiber when mixed with the concrete components. Although the volume of voids increase by the increase of straw content in the sample, TRSBFc illustrated voids volume less than that in RWSBFc because the short length of TRSBFc ensures a fairly good distribution compared with RWSBFc, as well as the treatment process of TRSBFc has a significant impact in terms of the physical properties of the straw, which helps in well blend and adhesion with other concrete components unlike RWSBFC (Fig. 7). Moreover, some cracks were observed through the scanned samples, in addition to the irregular random distribution and orientation of the straw fibers which may affect the tensile strength (Fig. 8). Furthermore, the basalt fiber used with TRSBFc was observed clearly (Fig. 9b) because it has a good resistant to the alkalinity of cement, unlike the basalt fibe type which was used with RWSBFc (Fig. 9a). In addition, what it looks like rot and decomposition of some straw fibers were observed (Fig. 10), this may attribute to its presence of straw in the wet or saturated environment and soluble alkali content of cement, which may lead to bad effect in terms of the mechanical properties and the durability properties of the concrete samples. The rot and decomposition in TRSBFc samples was bigger than it in RWSBFc, because the wheat straw has a wax layer covered its surface which reduce the water absorption, while the wax layer on rice straw was removed due to the treatment process. Finally, the results showed that there are some factors significantly effect on the mechanical properties of the RWSBFc and TRSBFc concrete, such as fiber content, fibers orientation and distribution, bonding, humidity absorption, water, and cement alkalinity resistance.

4 Conclusion

This paper presented a study on concrete behavior reinforced with RWSBFc and TRSBFc, and their effect on the concrete mechanical properties. Several tests were conducted include compressive strength, splitting tensile strength, and flexural strength. In addition, microstructure was examined to study the surface topography and composition of the various specimens for RWSBFc and TRSBFc. From the test results, the following points can be concluded.

There are some positive signs can observables in the concrete reinforced with RWSBFc and TRSBFc indicates the possibility of benefiting of this study through attention to the results and address the shortcomings and weaknesses, in order to improve the flexibility, ductility, and the impact resistance of the concrete.

-

1- The moisture content has a significant effect on the mechanical strength and durability properties of natural fiber reinforced concrete composites, and the possibility of rot and decomposition of the straw due to its presence in wet or saturated environment and soluble alkali content of cement, the natural fibers should be treated and protected from the alkalinity of cement, so as to reduce or prevent the water absorption of the fiber, which reduce the fibers rotting and decomposition.

-

2- To improve the concrete compressive strength and splitting tensile strengths, as well as tensile strength for the samples reinforced with RWSBFc, some concrete additives must add to the composite with the using of treated and coated wheat straw, to decrease the produced concrete voids and reduce the rot and decomposition. Moreover, a method for homogeneous distribution of the composite should be searched to minimize the voids volume and to avoid the large deviation in results.

-

3- Reinforcing of concrete composites with natural fibers is an emerging and promising technique. However, it needs more effort and research to contribute and solving the construction problems such as the shortage of construction renewable materials sources. In addition, the concrete reinforced with natural fiber composites (RWSBFc) can be used in producing of precast concrete elements by casting it in the part subjected to tensile stress from the concrete section, so as to improve the concrete tensile strength and reduce tensile reinforcement.

-

4- the mechanical properties for the samples reinforced with RWSBFc and TRSBFc depend on certain factors; the fiber content (0.3%- 0.7%), the orientation of the straw fibers and its balanced distribution in the concrete mix, the bonding between cement matrix and straw fibers, the resistance of cement alkalinity, and the absorption of humidity and water.

References

Ardanuy, M., Claramunt, J., & Toledo Filho, R. D. (2015). Cellulosic fiber reinforced cement-based composites: A review of recent research. Construction and building materials, 79, 115–128.

Bledzki, A., & Gassan, J. (1999). Composites reinforced with cellulose based fibres. Progress in polymer science, 24(2), 221–274.

Biagiotti, J., Puglia, D., & Kenny, J. M. (2004). A review on natural fibre-based composites-part I: Structure, processing and properties of vegetable fibres. Journal of Natural Fibers, 1(2), 37–68.

John, M. J., & Thomas, S. (2008). Biofibres and biocomposites. Carbohydrate polymers, 71(3), 343–364.

Faruk, O., Bledzki, A. K., Fink, H. P., & Sain, M. (2012). Biocomposites reinforced with natural fibers: 2000–2010. Progress in polymer science, 37(11), 1552–1596.

Sampathrajan, A., Vijayaraghavan, N., & Swaminathan, K. (1992). Mechanical and thermal properties of particle boards made from farm residues. Bioresource Technology, 40(3), 249–251.

Zhang, Y., Lu, X., Pizzi, A., & Delmotte, L. (2003). Wheat straw particleboard bonding improvements by enzyme pretreatment. Holz als Roh-und Werkstoff, 61, 49–54.

Ren, Y. Z., Gu, Y. Y., Yang, X. Y., & Chen, J. X. (2016). Characteristics development bottle necks and counter measures of straw- based building materials. Journal of Functional Materials, 47(6), 6056-6062,6070.

Kuroki, Y., Nagadomi, W., Kaneko, S., Tachi, M., Kawai, S., & Sasaki, H. (1998). Transition of markets for cement exterior sidings and development of new technology in Japan. Inorganic-bonded wood and fiber composite materials, 6, 61–98.

Soroushian, P., Aouadi, F., Chowdhury, H., Nossoni, A., & Sarwar, G. (2004). Cement-bonded straw board subjected to accelerated processing. Cement and Concrete Composites, 26(7), 797–802.

Vo, L. T. T., & Navard, P. (2016). Treatments of plant biomass for cementitious building materials–A review. Construction and Building Materials, 121(5), 161–176.

SWAMY, R. (1988). Natural fibre reinforced cement and concrete. Blackie Academic & Professional.

Agopyan, V., & Savastano Jr., H., John, V. M., & Cincotto, M. (2005). Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Cement and Concrete Composites, 27(5), 527–536.

Mahdy, M. M., Mahfouz, S. Y., Tawfic, A. F., & Ali, M. A. E. M. (2023). Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation. Fibers, 11(5), 42.

Betterman, L. R., Ouyang, C., & Shah, S. P. (1995). Fiber-matrix interaction in microfiber-reinforced mortar. Advanced Cement Based Materials, 2(2), 53–61.

Banthia, N., Moncef, A., Chokri, K., & Sheng, J. (1994). Micro-fiber reinforced cement composites. I. Uniaxial tensile response. Canadian Journal of Civil Engineering, 21(6), 999–1011.

Melchert, L. (2007). The Dutch sustainable building policy: A model for developing countries. Building and Environment, 42(2), 893–901.

Liu, F. S., Zhang, Y. W., Lu, Z. G., Fan, J., & Liu, J. (2009). Hollow fiber concrete sandwich of compressed straw brick block. (China Patent No. 200910020713. 3). IP China.

Wang, L., & JIANG, H. (2008). Study on lightweight cement based straw fiber foamed wall material [J]. New Building Materials, 7, 1–3.

Ghavami, K., Toledo Filho, R. D., & Barbosa, N. P. (1999). Behaviour of composite soil reinforced with natural fibres. Cement and Concrete Composites, 21(1), 39–48.

Selçuk, S., & Lamanna, A. J. (2007). Feasibility investigation of oriented straw cable cement composites. Composites Part A: Applied Science and Manufacturing, 38(9), 1965–1974.

Thakur, V. K., Thakur, M. K., & Gupta, R. K. (2014). Raw natural fiber–based polymer composites. International Journal of Polymer Analysis and Characterization, 19, 256–271.

Selcuk, S. (2007). A study on mechanical behavior of structural composites reinforced with wheat straw fibers and their use as building materials. [Doctoral dissertation, Tulane University]. ProQuest Dissertations and Theses database.

Elbashiry, E. M., Chen, J. X., Tuo, W. Y., Ren, Y. Z. & Guo, Z. S. (2018). Review of the pretreatment methods for wheat straw building materials. Journal of Reinforced Plastics and Composites, 37(1), 35–48

Ali, M., & LI, X. Y. & Chouw, N. (2013). Experimental investigations on bond strength between coconut fibre and concrete. Materials & Design, 44, 596–605.

Cunha, V. M. C. F., Barros, J. A., & Sena-cruz, J. M. (2010). Pullout behavior of steel fibres in self-compacting concrete. Journal of Materials in Civil Engineering, 22(1), 1–9.

Paramasivam, P., Nathan, G. K., & Gupta, N. C. D. (1984). Coconut fibre reinforced corrugated slabs. International Journal of Cement Composites and Lightweight Concrete, 6(1), 19–27.

John, V. M., Cincotto, M. A., Sjöström, C., Agopyan, V., & Oliveira, C. T. A. (2005). Durability of slag mortar reinforced with coconut fibre. Cement and Concrete Composites, 27(5), 565–574.

Sedan, D., Pagnoux, C., Smith, A., & Chotard, T. (2008). Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. Journal of the European Ceramic Society, 28(1), 183–192.

Gassan, J. (2002). A study of fibre and interface parameters affecting the fatigue behaviour of natural fibre composites. Composites part A: Applied science and manufacturing, 33(3), 369–374.

Mishra, S., Tripathy, S. S., Misra, M., Mohanty, A. K., & Nayak, S. K. (2002). Novel eco-friendly biocomposites: Biofiber reinforced biodegradable polyester amide composites—fabrication and properties evaluation. Journal of Reinforced Plastics and Composites, 21(1), 55–70.

O’donnell, A., Dweib, M. A., & Wool, R. P. (2004). Natural fiber composites with plant oil-based resin. Composites science and technology, 64(9), 1135–1145.

Pessiki, S., Harries, K. A., Kestner, J. T., Sause, R., & Ricles, J. M. (2001). Axial behavior of reinforced concrete columns confined with FRP jackets. Journal of Composites for Construction, 5(4), 237–245.

Elsanadedy, H. M., Al-salloum, Y. A., Alsayed, S. H., & Iqbal, R. A. (2012). Experimental and numerical investigation of size effects in FRP-wrapped concrete columns. Construction and Building Materials, 29, 56–72.

Micelli, F., & Modarelli, R. (2013). Experimental and analytical study on properties affecting the behaviour of FRP- confined concrete. Composites Part B: Engineering, 45(1), 1420–1431.

Vincent, T., & Ozbakkaloglu, T. (2013). Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Construction and Building materials, 47, 814–826.

Xiao, Y., & Wu, H. (2000). Compressive behavior of concrete confined by carbon fiber composite jackets. Journal of materials in civil engineering, 12(2), 139–146.

Sen, T., & Paul, A. (2015). Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. International Journal of Sustainable Built Environment, 4(2), 248–264.

Zhao, Y. S., Gao, Y. Y. Z., Chen, G. F., Li, S. J., Singh, A., Luo, X., Liu, C., Gao, J. M., & Du, H. J. (2023). Development of low-carbon materials from GGBS and clay brick powder for 3D concrete printing. Construction and Building Materials, 383, 131232.

Van Der Putten, J., Deprez, M., Cnudde, V., De Schutter, G., & Van Tittelboom, K. (2019). Microstructural Characterization of 3D Printed Cementitious Materials. Materials, 12(18), 2993.

ASTM. (2016). Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory (ASTM C192/C192M-16). ASTM International.

Acknowledgements

The authors would like to acknowledge all authors whose works have been cited in this study.

Funding

This work was supported in part by the Priority Academic Program Development of Jiangsu Higher Education Institutions under Grant 1105007002.

Author information

Authors and Affiliations

Contributions

EMAE performed research, did the experiments, analyzed the results, and wrote the manuscript. BHO selected the title name, contributed to the preparation of the manuscript, revised and overall supervision of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Competing interests

All authors declare that there are no other competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elbashiry, E.M.A., Osman, B.H. Mechanical properties of straw basalt fiber reinforced concrete composites. Low-carbon Mater. Green Constr. 1, 30 (2023). https://doi.org/10.1007/s44242-023-00028-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44242-023-00028-0