Abstract

Here we review scanning tunneling microscopy research on the surface determination for various types of kagome materials, including 11-type (CoSn, FeSn, FeGe), 32-type (Fe3Sn2), 13-type (Mn3Sn), 135-type (AV3Sb5, A = K, Rb, Cs), 166-type (TbMn6Sn6, YMn6Sn6 and ScV6Sn6), and 322-type (Co3Sn2S2 and Ni3In2Se2). We first demonstrate that the measured step height between different surfaces typically deviates from the expected value of ±0.4 ∼0.8Å, which is owing to the tunneling convolution effect with electronic states and becomes a serious issue for Co3Sn2S2 where the expected Sn-S interlayer distance is 0.6Å. Hence, we put forward a general methodology for surface determination as atomic step geometry imaging, which is fundamental but also experimentally challenging to locate the step and to image with atomic precision. We discuss how this method can be used to resolve the surface termination puzzle in Co3Sn2S2. This method provides a natural explanation for the existence of adatoms and vacancies, and beyond using unknown impurity states, we propose and use designer layer-selective substitutional chemical markers to confirm the validity of this method. Finally, we apply this method to determine the surface of a new kagome material Ni3In2Se2, as a cousin of Co3Sn2S2, and we image the underlying kagome geometry on the determined Se surface above the kagome layer, which directly visualizes the p-d hybridization physics. We emphasize that this general method does not rely on theory, but the determined surface identity can provide guidelines for first-principles calculations with adjustable parameters on the surface-dependent local density of states and quasi-particle interference patterns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Layered quantum materials are commonly cleaved into a variety of surface terminations. Determining these cleavage surfaces is fundamental because each surface carries its exclusive intrinsic properties to exhibit novel physical manifestations. The kagome material contains a kagome atomic layer with shared triangular lattices and harbors many novel physical phenomena, such as Dirac points, van Hove singularities, and flat bands [1–5]. In recent years, exotic phenomena such as superconductivity, spin density waves, and chiral electronic states emerging in kagome materials have attracted widespread attention in the condensed matter physics community [6–21]. Most intricate physical phenomena originate from the kagome layer [22, 23]. Therefore, determining the atomic surface is crucial for analyzing the electronic states and their coupling [24]. Scanning tunneling microscopy/spectroscopy (STM/S) can obtain local morphological structure and electronic state at the atomic level [25–27], which have played essential roles in exploring novel materials through their cleavage surfaces, such as AEFe2As2 (A\(E = K\), Ca, Ba, La) [28–31], (Ba, Sr) Ni2As2 [32], URu2Si2 [33, 34], GdRu2Si2 [35], YbRh2Si2 [36–38], and CeCoIn5 [39–41]. STM/STS is also one of the most effective research methods in studying kagome materials, especially, in determining their cleavage surfaces.

In most single-crystal STM research, a chunk is usually cryogenically cleaved in an ultra-high vacuum to obtain clean sample surfaces. To identify the surfaces, the straightforward methods include measuring the height difference at atomic steps [42] or atomically identifying the symmetry and lattice constants, and then comparing them with the lattice structure, which proves the fundamental evidence for the determination of the cleavage surfaces and provides an essential prerequisite for many experimental analyses, such as quasi-particle interference [23, 43]. However, the complex tunneling matrix element affects the distance between the tip and surface [44], making it difficult to determine the interlayer distance precisely (details see below). Furthermore, the surface reconstruction may change the lattice constant as well as the symmetry of the surface structure, making it inappropriate to correspond with the bulk lattice structure. These reasons make the determination of cleavage surfaces in some kagome materials challenging [23, 24, 30, 33, 34, 45–55]. Therefore, the academic community urgently needs an experimental method with high versatility and accuracy to determine the cleavage surfaces of kagome materials through STM/STS.

2 Imaging atomic step geometry

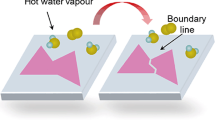

Here, we put forward a plain vanilla and general method to determine the cleavage surfaces by comprehensively imaging kagome materials’ atomic step geometry. The recently studied kagome materials are mostly layered structures, and we classify their atomic layers into three types: kagome layers (K), neighboring layers (N), and isolated layers (I) (Fig. 1a). Atomic kagome (K) layers usually comprise smaller atoms, with dense atomic arrangement, high state density, and tight chemical bonds. Neighboring layers (N) are next to kagome layers in the crystal and are bonded to kagome layers or have strong interlayer interactions. Isolated layers (I) are relatively far from the kagome layers in the crystal and have weak interlayer interactions with adjacent atomic layers. Their intervals indicate the interlayer bonding strength. Since K layers have tight bonds, and the stronger bonding of the N-K-N trilayered block, the cleavage almost occurs between the neighboring layers N and isolated layer I by breaking the interlayer and intralayer bonds of I, which yields an atomic step with vacancy defects and adatom defects on both sides simultaneously and symmetrically (Fig. 1b).

Schematics and identifications of atomic step cleavage. a A typical kagome model is perioded with a trilayered strong-bonding N-K-N block further sandwiched by the isolated weak-bonding I layers. b Schematic diagram illustrating a typical cleavage process of a kagome bulk. Cleavage occurs between the N layers and I layer, yielding vacancy defects on the I layer and adatom defects on the N layer at both cleaving sides simultaneously and symmetrically. c, d Unreliable height determination method. The measured h might be lower than the expected layer distance d, since the lower layer has a higher density of state than that of the upper layer c; or reverse d. e, f Identification of cleavage surfaces by different types of defects. The upper broken I layer produces vacancy defect e, and remains adatom defect on the lower N layer f. g Identification of cleavage surfaces by layer selective chemical marker. The atoms of the selective layer are substituted by the dopants from the same group element

Based on the simple cleavage scheme of kagome materials (Fig. 1a-1b), the atomic step edge offers abundant facts to explore, such as step height, defects, interlayer relationship, edge state, and so on. The step height usually cannot give a precise reference, since the discrepancy of electronic states between two adjacent layers in kagome materials always exists, and the tunneling measurement convolutes the local density of states. As shown in Fig. 1c (and d), since the electronic state of the lower N layer is higher (lower) than the upper I layer, the measured h is lower (higher) than the expected layer distance d. Surprisingly, we discover that the defect types are always helpful in determining the cleavage surfaces due to the interlayer relationship. From the cleavage scheme, vacancy defects always appear on the bonds broken layer (I) (Fig. 1e), meanwhile, the adatom defect always remains on the neighboring layer (N) (Fig. 1f). In fact, the defect types provide evidence to determine cleavage surfaces to some extent. Another independent piece of evidence is from the designer layer selective substitutional chemical maker. As shown in Fig. 1g, the atoms of the selected layer can be replaced equivalently by the same group of element atoms, thus, identifying the cleavage surfaces. This paper put forward a universal atomic step geometry imaging methods to determine the cleavage surfaces by reviewing previous reports, including 11-type (CoSn), 32-type (Fe3Sn2), 13-type (Mn3Sn) [56–58], 135-type (KV3Sb5), 166-type (TbMn6Sn6), and 322-type (Co3Sn2S2) [22, 30, 47, 49, 52–54, 59–62], and the latest STM research results on 166-type (ScV6Sn6), and 322-type (Ni3In2Se2). We also note that the atomic step geometry imaging method sounds fundamental but it is also challenging to implement, requiring patience for scanning large areas and even several samples to locate the atomic step (that can take several weeks) and exceptional experimental skills for precise imaging with atomic resolution and without muti-tip effects. It is our experience that with many adjustable parameters, first principles can be consistent with both cases when the experiment results on surface terminations are controversial. Therefore, it is crucial to first determine the surface identity in a self-consistent experimental way without referring to theory, after which, the determined surface identity can be used as a guideline for further first-principles calculations (or other model analysis) on surface-dependent density of states and quasi-particle interferences.

3 Surface determination of multiple layered kagome materials

3.1 11-type

The 11-type including CoSn [50, 60, 63–65], FeSn [53, 54, 66, 67], and FeGe [19, 59, 62, 68–71], only contains one kagome layer and one honeycomb layer. We start from the simplest bilayer kagome lattice CoSn (space group P6/mmm). It consists of a Co3Sn kagome layer (Fig. 2a left panel, K layer) and a Sn2 honeycomb layer (Fig. 2a right panel, I layer) with alternating stacking and no N layer in between. Consequently, cryogenically cleaving a CoSn single crystal just yields Co3Sn kagome or Sn2 honeycomb surfaces. Utilizing atomic-level ultra-high resolution STM imaging, the Co3Sn surface with kagome feature (Fig. 2b left panel) and the Sn2 surface with honeycomb feature (Fig. 2b right panel) have been observed unambiguously [50, 60], respectively. It is also a rare case that all the Co kagome atoms and central Sn atoms are resolved individually. In most cases, the imaging of TM3Sn (TM is the transition metal) layer yields a hexagonal symmetry lattice with Sn atomic position as a dark spot. In fact, if one performs a direct first-principles simulation for the TM3Sn topographic image, one will often find that the highest spot should be the Sn atom position as the Sn atom is larger. This discrepancy highlights the correlated nature of these kagome materials that often go beyond the simple first-principles simulation, and warns us of the importance of experimentally determining the atomic details before seeking help from first-principles. If the conclusion cannot be drawn from the experimental data independently, then it can often lead to systematic errors with combined scanning tunneling microscopy experiments and first-principles calculations, which is at least true in our research experience.

Atomic-scale surface identification of CoSn and Fe3Sn2. a Kagome lattice structure of the Co3Sn layer (left panel) and the adjacent honeycomb Sn2 layer (right panel). b Atomically resolved topographic image with the corresponding atomic lattice structures of the Co3Sn surface (left panel) and Sn2 surface (right panel) (5 × 7.5 nm2, \(V=-10\) mV, \(I=8\) nA). c Side view of the crystal structure and illustration of the two possible terminating surfaces. The curve illustrates the surface profile. d Topographic image of a single atomic step between two surfaces (30 × 15 nm2, \(V=100\) mV, \(I=0.3\) nA). e The topological profile cutting the step along the line marked in d shows a step height of ∼1.6 Å, while the expected step height is 2.09 Å. Adapted from [60]. f Kagome lattice structure of the Fe3Sn layer (left panel) and the adjacent honeycomb Sn2 layers (right panel). g Atomically resolved Fe3Sn (left panel) and Sn2(right panel) surfaces. The insets show the corresponding atomic lattice structures (5 × 7.5 nm2, \(V=50\) mV, \(I=0.8\) nA). h Side view of the crystal structure and illustration of the two possible terminating surfaces. The curve illustrates the surface profile. i Lattice alignment between the Sn2 surface and the Fe3Sn surface from an edge of a Sn surface step (15 × 7.5 nm2, \(V=50\) mV, \(I=0.8\) nA). j Comparison of the line-cut profiles taken along the red and blue lines marked in i. Adapted from [52]

As shown in Fig. 2c, a step schematic is generated by breaking the bonds between the Co3Sn and the Sn2 layers as well as the bonds in the Sn2 intralayer, where the expected step height is half of the c-axis lattice constant. Figure 2d presents a representative single atomic step between the lower Co3Sn kagome layer and the upper Sn2 honeycomb layer. The step height is measured as 1.6 Å smaller than the expected height of 2.09 Å [63] in Fig. 2e. The discrepancy comes from the higher integrated density of states of the Co3Sn kagome layer than the Sn2 honeycomb layer at the bias voltage of 100 mV [60].

3.2 32-type

Correspondingly, Fe3Sn2 (space group \(R\overline{3} m\)) is another kind of trilayer kagome lattice structure without N layer, which only consists of a Fe3Sn kagome bilayer (Fig. 2f left panel, K layer) and a Sn2 honeycomb layer (Fig. 2f right panel, I layer) in a unit cell. In our high-resolution STM images, we can distinguish the Fe3Sn kagome surface (Fig. 2g left panel) from the Sn2 honeycomb surface (Fig. 2g right panel). Similar to CoSn, a dilemma of step height appears in the Fe3Sn2 system. Due to the density of states of the Sn2 honeycomb layer being higher than that of the Fe3Sn kagome layer at a bias voltage of 50 mV [52], the step height of the Sn2 layer on the Fe3Sn layer measured as 3.0 Å, which is larger than the expected value of 2.15Å. The constant current topographic image convolutes the spatial variation of the integrated local density of states (LDOS) and the geometrical corrugations, the step height measured by the STM tip cannot become conclusive evidence for surface determinations [30].

In the crystal structure, the Sn2 honeycomb layer has perfect C6 symmetry, while the Fe3Sn kagome bilayer is C3 symmetry. It seems that the two surfaces can also be distinguished by lattice symmetry. However, due to electronic perturbation of the underneath breath kagome bilayer, the perfect C6 symmetry of the Sn2 honeycomb lattice is also reduced into the C3 symmetry in the STM image. Therefore, in STM images with low resolution, the Sn2 honeycomb lattice may be misidentified with Fe3Sn kagome bilayer. While in our high-resolution STM image, the atoms in the Sn2 honeycomb termination are all resolved, with alternative brightness and dimness feature points (Fig. 2g right panel). The ultra-high-resolution STM image of the atomic step further determines lattice alignment (Figs. 2i and j), showing that the dark position of the Fe3Sn layer aligns with the dark position of the Sn2 layer. This allows us to assign the Fe and Sn atoms for the topographic image of Fe3Sn layer in the left panel of Fig. 2g. Again, here the dark position in the Fe3Sn layer corresponds to the Sn atom, and the first-principles calculation can often assign the Sn atom to the highest position in the topographic image of Fe3Sn layer, opposite to the experimentally determined case.

3.3 135-type

For the above two simple cases, high-resolution imaging of atomic step provides a feasible method to identify cleavage surfaces, rather than step height. The same approach applies to the well-known 135-type [72], for instance, CsV3Sb5 [17, 73–75], KV3Sb5 [7, 18, 61, 76, 77], RbV3Sb5 [8, 78–80], Cs(V, Ta)3Sb5 [21, 81]. As Fig. 3a shows, a typical crystal structure of KV3Sb5 consists of a vanadium-based kagome layer (K layer) and two sandwiched antimonene (Sb) honeycomb lattices (N layer). The I layers are hexagonal alkali metal lattices with the largest intralayer bond length, making them fragile for cleavage. According to the crystalline symmetry, the cleavage between the alkali metal layer and the Sb2 layer yields a step with the upper alkali layer and the lower Sb layer (Fig. 3b). Figure 3c shows a typical gradient atomic step edge, where the Sb surface is transiting to the K surface from left to right. Atomically resolved topographies exhibit a close-knit honeycomb lattice of lower Sb surface (Fig. 3d) and hexagonal lattice of upper K surface [78, 82] (Fig. 3e), respectively, in which a 2 × 2 charge order wave modulates both layers and breaks the translational symmetry. We also note that the weakly bonded alkali islands or adatoms in 135-type of materials can be swept away by the STM tip when the tip is very close to the surface, which can help to create a large area of Sb surface for further spectroscopic research [73].

Surface identification of KV3Sb5 at the atomic scale. a Crystal structure of KV3Sb5. b Cleavage surfaces of KV3Sb5 illustrated from the side view of the crystal structure. c Topographic image of a surface step edge, containing both K (right region) and Sb (left region) surfaces (54 × 27 nm2, \(V=100\) mV, \(I=0.05\) nA). d Atomically resolved topographic images of the Sb honeycomb surface (2.8 × 2.8 nm2, \(V=100\) mV, \(I=0.5\) nA). e Atomically resolved topographic images of the K hexagonal surface (2.8 × 2.8 nm2, \(V=100\) mV, \(I=0.5\) nA). The black lines marked in d and e denote the underlying kagome lattice. Adapted from [61]

3.4 166-type

Another kagome lattice worth discussing in detail is the 166-type for its different interlayer structure [83–87]. Figure 4a shows a unit lattice structure of ScV6Sn6, a typical 166-kagome lattice, in which the blue kagome layers are made of vanadium (V) atoms. Three contiguous Sn layers form triangular (Sn2 surface), honeycomb (Sn1 surface), and triangular (Sn2 surface) structures, respectively. Between V layers, a sharing Sc-Sn mix-layer has large interlayer distances with these two kagome layers symmetrically, thus, a cleave can occur between them in this case. Considering our previous points, in this system, cleavage can occur between any layers, forming all four terminations. Here, we found three consecutive atomic steps of ScV6Sn6 [83]. From low to high in Fig. 4c, they are honeycomb, triangle, and tripped structures, corresponding to the Sn1 layers, Sn2 layers, and V layers respectively. Their magnifying images are shown in Fig. 4d-f. Due to the small size of V atoms, the resolution of the kagome lattice in this system is insufficient to display, so we have presented the Mn kagome lattice layer of TbMn6Sn6 with a larger atomic size, and its high-resolution kagome lattice is shown in the Fig. 4g [22]. Additionally, our previously published article showed a possible Tb-Sn layer of TbMn6Sn6 that corresponds to the Sc-Sn layer in ScV6Sn6 not present here [22].

Surface identification of RT6Sn6 (R = Sc, Tb; T = V, Mn) at the atomic scale. a Crystal structure of ScV6Sn6. b Cleavage surfaces of ScV6Sn6 illustrated from the side view of the crystal structure. c Topographic image of three consecutive steps, containing V, Sn2, and Sn1 surfaces from left to right (10 × 20 nm2, \(V=100\) mV, \(I=0.1\) nA). d STM topography for V kagome surface (2.8 × 2.8 nm2, \(V=-200\) mV, \(I=0.5\) nA). e Atomically resolved topographic images of the Sn1 honeycomb surface (2.8 × 2.8 nm2, \(V=100\) mV, \(I=1\) nA). f Atomically resolved topographic images of the Sn2 hexagonal surface (2.8 × 2.8 nm2, \(V=100\) mV, \(I=0.1\) nA). g Atomically resolved topographic images of the Mn kagome surface in TbMn6Sn6 (2.8 × 2.8 nm2, \(V=100\) mV, \(I=0.1\) nA). The yellow line in d, e, f, and the red line in g denote their kagome lattices, respectively. Adapted from [83]

3.5 322-type

We have discussed the cleavage surfaces of different stacking kagome lattices from honeycomb-kagome-honeycomb (11-type), honeycomb-kagome-kagome-honeycomb (32-type), hexagon-honeycomb-kagome-honeycomb-hexagon (135-type) to super-complex-interlayer (166-type). There is a consensus in these systems, making them a good starting point for the atomic step geometry imaging method. Now we take a step forward to identify the controversial cleavage surface of another layered kagome lattice Co3Sn2S2 (Fig. 5a) [23, 24, 45–49]. Co3Sn2S2 (space group \(R\overline{3} m\)) has similar stacking behavior to 135-type, except for hexagon-hexagon-kagome-hexagon-hexagon, which manifests Sn- and S- terminated non-kagome surfaces with the identical lattice constant and hexagonal symmetry. In this case, a single atomic step is indispensable for identifying these surfaces.

Atomic-scale visualization of the cleavage surface of Co3Sn2S2. a Crystal structure of Co3Sn2S2. b Cleavage surfaces of Co3Sn2S2 illustrated from the side view of the crystal structure. c Atomically resolved topographic image of the boundary between the S surface and Sn surface (54 × 27 nm2). The S surface smoothly evolves into the Sn surface with increasing coverage of the Sn adatom. d The common defect on the S surface is Sn adatom (4 × 4 nm2). e The common defect on the Sn surface is Sn vacancy (4 × 4 nm2). (all images recorded at \(V=-50\) mV, \(I=0.2\) nA). Adapted from [47]

By summarizing the three above cases, the cleavage always occurs at the interval between the N (or K) layer and I layer, due to the weaker chemical bonding of the N (or K)-I interlayer and I intralayer. Hence, in the step edge, the I layer forms vacancy defects, such as Sn2 and alkali metal surfaces, while the N (or K) layer forms adatom defects, such as Co3Sn kagome, Fe3Sn kagome, and Sb2 honeycomb surfaces. Applying this experience to Co3Sn2S2, it will be brief to determine the cleavage surfaces when encountering a promising atomic step. As illustrated in Fig. 5b, the bonds between the Sn neighboring layer and the S isolated layer are broken. Similar to the three previous cleavage cases, the upper I layer forms vacancies, and the lower N layer forms adatoms. The high-resolution STM image of an ideal step edge of Co3Sn2S2 shown in Fig. 5c demonstrates the upper Sn isolated surface with vacancy defects and the lower S neighboring surface with adatom defects. Moreover, Sn has smaller corrugation than the S surface, due to the atomic radius of Sn being larger than S, which further proves the surface identification from the high-resolution images of the S surface and the Sn surface in Figs. 5d-5e, respectively. We have also been aware that Ref. [23] mainly uses the step height argument for the surface identification, and it is clear from Fig. 2e, g and the basic principle of STM that the topographic height convolutes the LDOS and the geometrical corrugations that the step height argument is not decisive for termination assignment.

To further confirm the assignation, a chemical-marker experiment is designed such that 1% In impurities are doped into Co3Sn2S2 bulk [39], where In dopants equivalently substituted Sn preferentially [88, 89]. Figure 6a demonstrates a high-resolution topographic image showing that the layer selective In-dopants with consistent concentration are distributed sparsely on the Sn-terminated surface. Moreover, from the high-resolution image of the typical defect (Fig. 6b), the substituted site is consistent with the topmost Sn site without lattice mismatch, which proves this surface with vacancy defects is the Sn surface. Following Ref. [23], the imaged impurity states shape with substantial multi-tip effects from unknown underlying (not at the surface) defects are used to provide hints for surface terminations [43]. The chemical identity, atomic position, and tunneling matrix element of the underlying defects are all unknown. Even for known underlying impurities such as Zn in cuprates [90], it is well known that the simple model would not produce the correct symmetry of the impurity states and the tunneling matrix element has to be considered. Therefore, its accuracy in identifying surface terminations with unknown underlying defects is not at the same level as the chemical marker experiment [30, 39]. We further propose using 1% Se to replace S in Co3Sn2S2 to mark the S layer as a complementary layer-selective chemical marker experiment.

Atomic impurity state on Sn layer of In doped Co3Sn2S2. a Atomically-resolved topographic image of Sn layer of 1% In doped Co3Sn2S2 (30 × 17 nm2, \(V=-500\) mV, \(I=0.1\) nA). b Topographic image of an isolated impurity (4 × 4 nm2, \(V=-300\) mV, \(I=0.1\) nA). c Correlation between the atomic structure and the pattern in the Topographic image. Adapted from [49]

Recently, the qPlus non-contact atomic force microscopy [24] has also revealed differences between the two terminations. However, the experimental data would probably not be capable of assigning the surface identifications directly and independently. Unlike the step edge imaging method, it has not been put as a general for determining surfaces in other kagome materials and other quantum materials. The first-principles calculations are then used for guiding the surface identification by matching with the atomic force microscopy data. It was our experience in 122 iron-based superconductors [30] that depending on the adjusting parameters, first principles can assign the surface terminations quite differently and oppositely. Its reliability in identifying the surfaces 122 iron-based superconductors is in doubt in the community. Even in the case of Co3Sn2S2, first-principles calculated LDOS can always match with the experimentally observed ones with both scenarios depending on the choice of shifting the Fermi energy within ±500 meV, substantially reducing its credibility. It is our understanding that in the electronic structure community including angle-resolved photoemission and scanning tunneling microscopy, researchers including ourselves often seek help from first principles when the experimental data alone is inconclusive and our subjective interpretation of the data can guide the parameter tuning directions of the first-principles. Therefore, a first-principles independent methodology as demonstrated here is very crucial to firstly set up the correct and objective directions for the adjustable parameter tuning in the first-principles. Although STM cannot directly resolve the surface atomic element, it can detect the electronic structure beneath the surface through tunneling, which provides a chance to extract the information from the underlying kagome layer. Therefore, we chose another 322-type analogue, nominating Ni3In2Se2 [91], which has the same lattice structure as Co3Sn2S2. Figure 7a shows the side view of the step schematic model of Ni3In2Se2, where the cleavage occurs between the In isolated layer and the Se neighboring layer. Figure 7b shows the typical step of the In and Se surface. Similar to Co3Sn2S2, the left upper isolated layer is defined as In surface with typical vacancy defect, meanwhile, the right lower neighboring layer is defined as Se surface with In adatom defects. Although they have identical lattice symmetry, their electronic states affected by the underlying kagome layer are different. In surface is far away from the Ni3In kagome layer, so its STM topographic images show a stubborn triangular lattice for both positive and negative bias voltage (Fig. 7c), whereas, the lower Se surface directly bonding to the Ni3In kagome layer manifests a kagome lattice feature (Fig. 7d). Hence, we observed an apparent kagome symmetry on the Se surface at the bias voltage of −100 mV and −200 mV (Fig. 7d), whereas, an affected triangular lattice is shown in the atomic resolution image at a bias voltage of +100 mV and +200 mV (Fig. 7d). Similar to Si(111)-7 × 7, lower negative bias voltage imaging facilitates the visualization of the underlying kagome layer, because their electronic states act on tunneling at this time [92, 93]. Our observation of kagome geometry on the Se surface also directly visualized the p-d orbital hybridization physics as discussed in the atomic force microscopy work [24]. In short, this experimental approach and evidence provide another theory-independent way for surface identification in the 322 family.

Cleavage surface identification of Ni3In2Se2. a Cleavage surface illustration of Ni3In2Se2. b Atomically resolved topographic image of the boundary between the In surface and the Se surface (28 × 23 nm2, \(V=100\) mV, \(I=0.1\) nA). c Topographic image of In surface obtained at a bias voltage of +200 mV, +100 mV, −100 mV and −200 mV and tunneling current of 1 nA. The yellow lines illustrate the underlying kagome lattice. d Topographic image of the Se surface obtained at a bias voltage of +200 mV, +100 mV, −100 mV and −200 mV and tunneling current of 1 nA. The yellow lines illustrate the underlying kagome lattice. The data at −100 mV and −200 mV shows kagome geometry, highlighting the p-d orbital hybridization between Ni d-orbital and Se p-orbital

3.6 31-type

We discuss the surface termination of kagome antiferromagnet Mn3Sn [56–58], which is well known for its giant room temperature anomalous Hall effect and potential in antiferromagnetic spintronics application. The atomic Mn3Sn kagome layers (K) directly stack with each other with AB stacking order (Figs. 8 a and b). Because the interlayer bond distance is similar to the in-plane bond distance, the cryogenic cleavage of the Mn3Sn crystals would not yield a flat surface with atomic lattice resolution, but disordered surfaces. To prepare a large atomic flat surface, we can either anneal the surface in-situ with a high temperature (1100 K) for hours or apply a large pulse voltage (10 V) to bomb out a fresh surface [56, 58]. The topographic image of the Mn3Sn layer (Fig. 8c) is very similar to the Fe3Sn layer in Fe3Sn2. For each kagome pattern, it can be seen from the topographic image that the symmetry is reduced to C3 from bulk C6. This is likely due to the impact of the AB stacking, and the existence of the underlying Sn atom could play a role (lower panel of Fig. 8b) which can be studied by imaging atomic step geometry.

Atomic identification of Mn3Sn. a Crystal structure of the Mn3Sn kagome lattice. b c-axis AB stacking of the kagome lattice from side view and top view, respectively. c STM topographic images of Mn3Sn showing the lattice with hexagonal symmetry. d STM topographic image across multiple steps of single layers, whose line profile is shown on the right. e Left panel shows the stacking alignment of two layers across a step, with the black and blue dots denoting Sn atoms of the upper and lower layers, respectively. Right panel shows their atomically resolved topographic images with the corresponding atomic lattices. All topographic data were taken at T = 4.6 K, V = −50 mV, I = 50 pA. Adapted from [56]

Figure 8d shows a series of atomic steps. Because every step is of the Mn3Sn layer, the convolution effect of the local density of states cancels out and the step height in this case matches the expected value. Then we focus on one atomic step in Fig. 8e. We first mark the position of the Sn atom for both layers corresponding to the periodic dark spots. It can be seen that the positions of the Sn atoms from the two layers do not overlap, supporting the AB stacking structure. Then we zoom into both layers to observe the C3 kagome pattern and mark the position of the Sn atom from the sublayer. This geometry analysis based on experimental data demonstrates that the coupling with the underlying Sn atom makes the kagome pattern C3 symmetric.

4 Conclusions

We have summarized the theory-independent atomic step geometry imaging methods to identify cleavage surfaces in various kagome lattices. High-resolution imaging of atomic steps on different terminations provides a straightforward judgment to determine the cleavage surfaces. Terminations with the same lattice symmetry and lattice constant are not so obvious to distinguish. Just like the atomic step height between two vicinal terraces convoluted with disparate electronic properties does not provide a precise value corresponding to the crystal structure. Both criteria are ambiguous in determining the cleavage surfaces of kagome materials. To settle this problem, we did a time-consuming scouring of the atomic steps of various kagome lattices. First, we have obtained the lattice alignments through the across-step profiles of height. Secondly, we have simultaneously recorded the topographies of the upper and the lower surfaces at different bias voltages. Thirdly, the continuous step shows the formation and evolution of defects on the upper and the lower surfaces. From CoSn, Fe3Sn2, KV3Sb5 ScV6Sn6 and TbMn6Sn6, to Co3Sn2S2 and Ni3In2Se2, all results show that the surfaces with vacancy defects are the In surface or Sn surface, and the surfaces with adatom defects are the S surface or Se surface in 322-type. The methodology provided here is general and consistent for different kagome cleavages and will be beneficial to the rapid development of new kagome materials and other layered quantum materials.

Availability of data and materials

All data are available from the authors.

References

Yin JX, Lian B, Hasan MZ (2022) Topological kagome magnets and superconductors. Nature 612(7941):647–657

Jiang K, et al. (2022) Kagome superconductors AV3Sb5 (A = K, Rb, Cs). Nat Sci Rev 10(2):nwac199

Wang Y, et al. (2023) Quantum states and intertwining phases in kagome materials. Nat Rev Phys 5:635–658

Jia-Xin Y (2023) Exploring hitherto unknown quantum phases in kagome crystals. Physics 52(3):157

Neupert T, et al. (2022) Charge order and superconductivity in kagome materials. Nat Phys 18(2):137–143

Ortiz BR, et al. (2020) CsV3Sb5: A Z2 topological kagome metal with a superconducting ground state. Phys Rev Lett 125(24):247002

Ortiz BR, et al. (2021) Superconductivity in the Z2 kagome metal KV3Sb5. Phys Rev Mater 5(3):034801

Yin Q, et al. (2021) Superconductivity and normal-state properties of kagome metal RbV3Sb5 single crystals. Chin Phys Lett 38(3):037403

Ohgushi K, Murakami S, Nagaosa N (2000) Spin anisotropy and quantum Hall effect in the kagome lattice: chiral spin state based on a ferromagnet. Phys Rev B 62(10):R6065–R6068

Yu S-L, Li J-X (2012) Chiral superconducting phase and chiral spin-density-wave phase in a Hubbard model on the kagome lattice. Phys Rev B 85(14):144402

Sethi G, Cuma M, Liu F (2023) Excitonic condensate in flat valence and conduction bands of opposite chirality. Phys Rev Lett 130(18):186401

Yang H, et al. (2017) Topological Weyl semimetals in the chiral antiferromagnetic materials Mn3Ge and Mn3Sn. New J Phys 19(1):015008

Muechler L, et al. (2020) Emerging chiral edge states from the confinement of a magnetic Weyl semimetal in Co3Sn2S2. Phys Rev B 101(11):115106

Feng X, et al. (2021) Chiral flux phase in the kagome superconductor AV3Sb5. Sci Bull 66(14):1384–1388

Guo C, et al. (2022) Switchable chiral transport in charge-ordered kagome metal CsV3Sb5. Nature 611(7936):461–466

Scammell HD, et al. (2023) Chiral excitonic order from twofold van Hove singularities in kagome metals. Nat Commun 14(1):605

Zhao H, et al. (2021) Cascade of correlated electron states in the kagome superconductor CsV3Sb5. Nature 599(7884):216–221

Mielke C 3rd, et al. (2022) Time-reversal symmetry-breaking charge order in a kagome superconductor. Nature 602(7896):245–250

Teng X, et al. (2022) Discovery of charge density wave in a kagome lattice antiferromagnet. Nature 609(7927):490–495

Zheng L, et al. (2022) Emergent charge order in pressurized kagome superconductor CsV3Sb5. Nature 611(7937):682–687

Zhong Y, et al. (2023) Nodeless electron pairing in CsV3Sb5-derived kagome superconductors. Nature 617(7961):488–492

Yin J-X, et al. (2020) Quantum-limit Chern topological magnetism in TbMn6Sn6. Nature 583(7817):533–536

Morali N, et al. (2019) Fermi-arc diversity on surface terminations of the magnetic Weyl semimetal Co3Sn2S2. Science 365(6459):1286–1291

Huang L, et al. (2023) Discovery and construction of surface kagome electronic states induced by p-d electronic hybridization in Co3Sn2S2. Nat Commun 14(1):5230

Piquero-Zulaica I, et al. (2022) Engineering quantum states and electronic landscapes through surface molecular nanoarchitectures. Rev Mod Phys 94(4):045008

Bian K, et al. (2021) Scanning probe microscopy. Nat Rev Methods Primers 1(1):36

Zhou L, et al. (2023) A spectroscopic-imaging scanning tunneling microscope in vector magnetic field. Rev Sci Instrum 94(3):033704

Kim J-J, et al. (2023) Observations of nematicity, dopants, and zero-bias conductance peaks for the Ca0.9La0.1FeAs2 superconductor. Nanomaterials 13(4):622

Nascimento VB, et al. (2009) Surface geometric and electronic structures of BaFe2As2(001). Phys Rev Lett 103(7):076104

Li A, et al. (2019) Surface terminations and layer-resolved tunneling spectroscopy of the 122 iron pnictide superconductors. Phys Rev B 99(13):134520

Yu X, et al. (2021) Surface morphology and electronic structure in stoichiometric superconductor CaKFe4As4 probed by scanning tunneling microscopy/spectroscopy. Sci China, Phys Mech Astron 64(12):127411

Qin T, et al. (2023) Real-space observation of unidirectional charge density wave and complex structural modulation in the pnictide superconductor Ba1−xSrxNi2As2. Nano Lett 23(7):2958–2963

Schmidt AR, et al. (2010) Imaging the Fano lattice to ‘hidden order’ transition in URu2Si2. Nature, 465(7298):570–576

Aynajian P, et al. (2010) Visualizing the formation of the Kondo lattice and the hidden order in URu2Si2. Proc Natl Acad Sci 107(23):10383–10388

Yasui Y, et al. (2020) Imaging the coupling between itinerant electrons and localised moments in the centrosymmetric skyrmion magnet GdRu2Si2. Nat Commun 11(1):5925

Ernst S, et al. (2011) Emerging local Kondo screening and spatial coherence in the heavy-fermion metal YbRh2Si2. Nature 474(7351):362–366

Wirth S, et al. (2012) Structural investigations on YbRh2Si2: from the atomic to the macroscopic length scale. J Phys Condens Matter 24(29):294203

Seiro S, et al. (2018) Evolution of the Kondo lattice and non-Fermi liquid excitations in a heavy-fermion metal. Nat Commun 9(1):3324

Aynajian P, et al. (2012) Visualizing heavy fermions emerging in a quantum critical Kondo lattice. Nature 486(7402):201–206

Chen W, et al. (2023) Interplay of hidden orbital order and superconductivity in CeCoIn5. Nat Commun 14(1):2984

Zhou BB, et al. (2013) Visualizing nodal heavy fermion superconductivity in CeCoIn5. Nat Phys 9(8):474–479

Barth JV, et al. (1990) Scanning tunneling microscopy observations on the reconstructed Au(111) surface: atomic structure, long-range superstructure, rotational domains, and surface defects. Phys Rev B 42(15):9307–9318

Yin J-X, Pan SH, Zahid Hasan M (2021) Probing topological quantum matter with scanning tunnelling microscopy. Nat Rev Phys 3(4):249–263

Chen CJ (1990) Tunneling matrix elements in three-dimensional space: the derivative rule and the sum rule. Phys Rev B 42(14):8841–8857

Howard S, et al. (2021) Evidence for one-dimensional chiral edge states in a magnetic Weyl semimetal Co3Sn2S2. Nat Commun 12(1):4269

Jiao L, et al. (2019) Signatures for half-metallicity and nontrivial surface states in the kagome lattice Weyl semimetal Co3Sn2S2. Phys Rev B 99(24):245158

Yin J-X, et al. (2019) Negative flat band magnetism in a spin–orbit-coupled correlated kagome magnet. Nat Phys 15(5):443–448

Xing Y, et al. (2020) Localized spin-orbit polaron in magnetic Weyl semimetal Co3Sn2S2. Nat Commun 11(1):5613

Yin J-X, et al. (2020) Spin-orbit quantum impurity in a topological magnet. Nat Commun 11(1):4415

Liu Z, et al. (2020) Orbital-selective Dirac fermions and extremely flat bands in frustrated kagome-lattice metal CoSn. Nat Commun 11(1):4002

Lin Z, et al. (2018) Flatbands and emergent ferromagnetic ordering in Fe3Sn2 kagome lattices. Phys Rev Lett 121(9):096401

Yin J-X, et al. (2018) Giant and anisotropic many-body spin–orbit tunability in a strongly correlated kagome magnet. Nature 562(7725):91–95

Multer D, et al. (2023) Imaging real-space flat band localization in kagome magnet FeSn. Commun Mater 4(1):17

Lee S-H, et al. (2022) Spin-polarized and possible pseudospin-polarized scanning tunneling microscopy in kagome metal FeSn. Commun Phys 5(1):235

Chen H, et al. (2024) Atomically precise engineering of spin–orbit polarons in a kagome magnetic Weyl semimetal. Nat Commun 15(1):2301

Zhang SS, et al. (2020) Many-body resonance in a correlated topological kagome antiferromagnet. Phys Rev Lett 125(4):046401

Nakatsuji S, Kiyohara N, Higo T (2015) Large anomalous Hall effect in a non-collinear antiferromagnet at room temperature. Nature 527(7577):212–215

Yang H-H, et al. (2019) Scanning tunneling microscopy on cleaved Mn3Sn(0001) surface. Sci Rep 9(1):9677

Yin J-X, et al. (2022) Discovery of charge order and corresponding edge state in kagome magnet FeGe. Phys Rev Lett 129(16):166401

Yin JX, et al. (2020) Fermion–boson many-body interplay in a frustrated kagome paramagnet. Nat Commun 11(1):4003

Jiang YX, et al. (2021) Unconventional chiral charge order in kagome superconductor KV3Sb5. Nat Mater 20(10):1353–1357

Shao S, et al. (2023) Intertwining of magnetism and charge ordering in kagome FeGe. ACS Nano 17(11):10164–10171

Mats L, et al. (1974) Specific heat measurements of the FeGe, FeSn and CoSn compounds between 0.5 and 9 K. Phys Scr 9(1):51

Kang M, et al. (2020) Topological flat bands in frustrated kagome lattice CoSn. Nat Commun 11(1):4004

Huang H, et al. (2022) Flat-band-induced anomalous anisotropic charge transport and orbital magnetism in kagome metal CoSn. Phys Rev Lett 128(9):096601

Kang M, et al. (2020) Dirac fermions and flat bands in the ideal kagome metal FeSn. Nat Mater 19(2):163–169

Li H, et al. (2022) Spin-polarized imaging of the antiferromagnetic structure and field-tunable bound states in kagome magnet FeSn. Sci Rep 12(1):14525

Teng X, et al (2023) Magnetism and charge density wave order in kagome FeGe. Nat Phys

Ziyuan Chen XW, Yin R, Zhang J, Wang S, Li Y, Li M, Wang A, Wang Y, Yan Y-J, Feng D-L (2023) Charge density wave with strong quantum phase fluctuations in kagome magnet FeGe. arXiv:2302.04490

Chen L, et al. (2024) Competing itinerant and local spin interactions in kagome metal FeGe. Nat Commun 15(1):1918

Chen Z, et al. (2024) Discovery of a long-ranged charge order with 1/4 Ge1-dimerization in an antiferromagnetic kagome metal. Nat Commun 15(1):6262

Wilson SD, Ortiz BR (2024) AV3Sb5 kagome superconductors. Nat Rev Mater 9(6):420–432

Chen H, et al. (2021) Roton pair density wave in a strong-coupling kagome superconductor. Nature 599(7884):222–228

Le T, et al (2024) Superconducting diode effect and interference patterns in kagome CsV3Sb5. Nature

Li H, et al. (2023) Small Fermi pockets intertwined with charge stripes and pair density wave order in a kagome superconductor. Phys Rev X 13(3):031030

Deng H, et al. (2024) Chiral kagome superconductivity modulations with residual Fermi arcs. Nature 632(8026):775–781

Li H, et al. (2022) Rotation symmetry breaking in the normal state of a kagome superconductor KV3Sb5. Nat Phys 18(3):265–270

Yu J, et al. (2022) Evolution of electronic structure in pristine and rb-reconstructed surfaces of kagome metal RbV3Sb5. Nano Lett 22(3):918–925

Xing Y, et al. (2024) Optical manipulation of the charge-density-wave state in RbV3Sb5. Nature 631(8019):60–66

Xiao-Yu Yan HD, Yang T, Liu G, Song W, Miao H, Tu Hechang Lei Z, Wang S, Lin B-C, Qin H, Yin J-X (2024) Chiral pair density waves with residual Fermi arcs in RbV3Sb5. Chin Phys Lett 41(9):097401

Deng H, et al (2024) Evidence for time-reversal symmetry-breaking kagome superconductivity. Nat Mater

Liang Z, et al. (2021) Three-dimensional charge density wave and surface-dependent vortex-core states in a kagome superconductor CsV3Sb5. Phys Rev X 11(3):031026

Jiang Y-X, et al. (2024) Van Hove annihilation and nematic instability on a kagome lattice. Nat Mater 23(9):1214–1221

Li H, et al. (2022) Manipulation of Dirac band curvature and momentum-dependent g factor in a kagome magnet. Nat Phys 18(6):644–649

Li H, et al. (2024) Spin Berry curvature-enhanced orbital Zeeman effect in a kagome metal. Nat Phys 20(7):1103–1109

Cheng S, et al. (2024) Nanoscale visualization and spectral fingerprints of the charge order in ScV6Sn6 distinct from other kagome metals. npj Quantum Mater 9(1):14

Di Sante D, et al (2023) Flat band separation and robust spin Berry curvature in bilayer kagome metals. Nat Phys

Weihrich R, Anusca I (2015) Half antiperovskites. III. Crystallographic and electronic structure effects in Sn2 − xInxCo3S2. Z Anorg Allg Chem 632(8):1531–1537

Corps J, et al. (2015) Interplay of metal-atom ordering, Fermi level tuning, and thermoelectric properties in cobalt shandites Co3M2S2 (M = Sn, In). Chem Mater 27(11):3946–3956

Pan SH, et al. (2000) Imaging the effects of individual zinc impurity atoms on superconductivity in Bi2Sr2CaCu2 O8+δ. Nature 403(6771):746–750

Cao L, et al. (2023) Crystal growth, transport, and magnetic properties of antiferromagnetic semimetal Ni3In2Se2 crystals. Phys Rev Mater 7(8):084203.

Liu G, et al. (2021) Controlled implantation of phosphorous atoms into a silicon surface lattice with a scanning tunneling microscopy tip. ACS Appl Electron Mater 3(8):3338–3345

Wang YL, et al. (2008) Toward a detailed understanding of Si(111)-\(7\times 7\) surface and adsorbed Ge nanostructures: fabrications, structures, and calculations. J Nanomater 2008:1–18

Acknowledgements

We acknowledge that Shuheng Pan and Ang Li for proposing this method in studying surface terminations of iron-based superconductors. This perspective is written to celebrate Shuheng Pan’s 75 birthday.

Funding

J.X.Y. acknowledges the support from the National Key R&D Program of China (No. 2023YFA1407300) and the National Science Foundation of China (No. 12374060). Project funded by China Postdoctoral Science Foundation (No. 2023M741546, No. 2023M731530). The work at Princeton is supported by Gordon and Betty Moore Foundation (GBMF4547 and GBMF9461; M.Z.H.).

Author information

Authors and Affiliations

Contributions

GL, TY and JXY wrote the manuscript with contributions from all authors. GL, TY and HD performed STM measurements on Ni2In2Se2. YJ and MSH performed STM measurements on ScV6Sn6. HD, MZH, and JXY supervised the project. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

All authors declare that there are no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, G., Yang, T., Jiang, YX. et al. Perspective: imaging atomic step geometry to determine surface terminations of kagome materials and beyond. Quantum Front 3, 19 (2024). https://doi.org/10.1007/s44214-024-00066-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44214-024-00066-0